Split riprap buoyancy tank

A floating box, split technology, applied in the direction of the hull, foldable/inflatable hull, ships, etc., can solve the problems of severe shaking of the hull, poor stability, and out-of-sync speed and amplitude of opening, so as to improve stability and stability Strong, close-fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

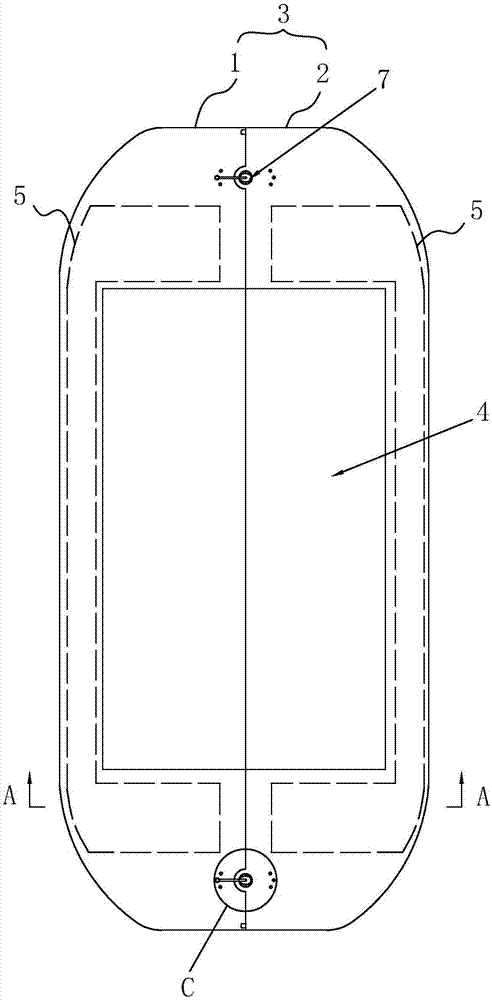

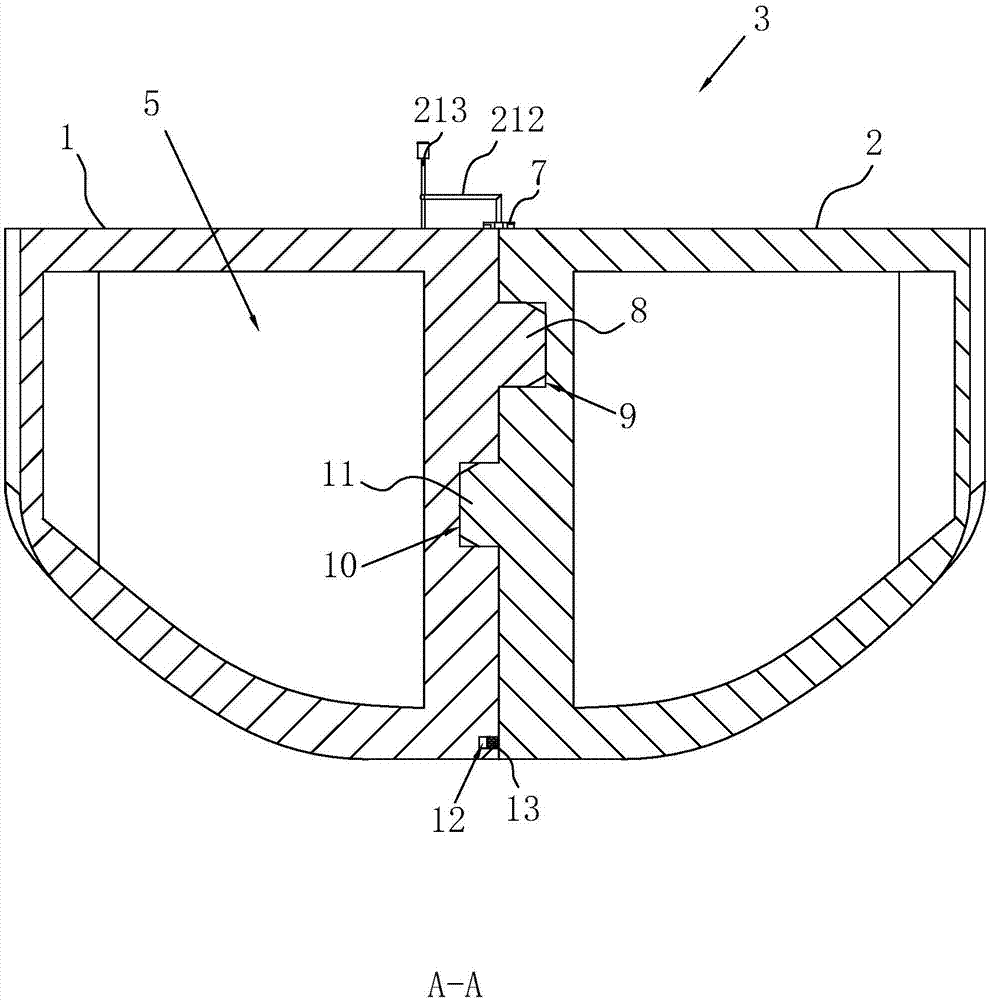

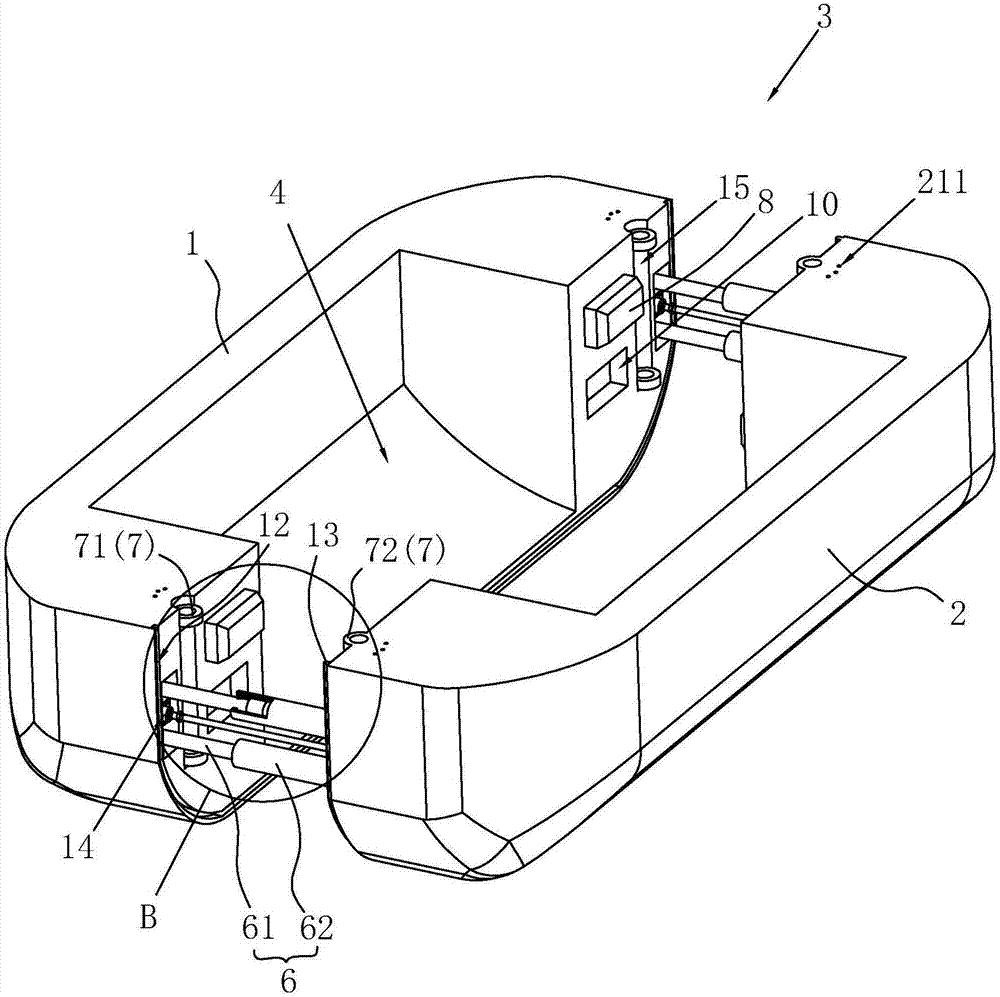

[0038] Embodiment 1, a split riprap floating tank:

[0039] as attached figure 1 with 3As shown, it includes a buoyancy tank 3 spliced by the left half body 1 and the right half body 2, and a mud tank 4 is arranged in the middle of the buoyant tank body 3, and the bottom surface of the mud tank 4 is a concave arc bottom surface, with a certain The downward slope is conducive to the automatic falling of sand, earth and rocks by gravity. The floating tank body 3 is provided with a driving part 14 for pushing the left half body 1 and the right half body 2 to separate from each other. In the present embodiment, the driving part 14 is a hydraulic cylinder, and the hydraulic cylinder is fixed on the head of the floating tank body of the left half body 1 and On the tail of the floating tank. When the floating tank body 3 needs to be loaded with sand, earth and rocks, the left half body 1 and the right half body 2 are closed to form a complete floating tank body 3, and the left h...

Embodiment 2

[0048] Embodiment 2, a split riprap floating tank:

[0049] The difference between the second embodiment and the first embodiment is that a power system is added in the second embodiment.

[0050] as attached Figure 8 As shown, the tail of the floating tank body 3 is provided with a power system 22, and the power system 22 includes a fixed frame 23, a propeller 24, and a drive motor 25 that drives the propeller 24 to rotate, and the drive motor 25 passes through a turntable 26. It is fixed on the fixed frame 23 and can rotate left and right in a small range, and the propeller 24 is located at the seam position of the left half body 1 and the right half body 2 of the floating tank body 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com