Device and method for enhancing coal seam fracturing effect

A technology of coal seam fracturing, which is applied in the field of devices that increase the effect of coal seam fracturing, can solve the problems of inability to drain coal bed methane, difficult drainage, etc., so as to improve the drainage rate of coal bed methane, increase the degree of fragmentation, and improve the efficiency of coal seam gas. The effect of draw rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

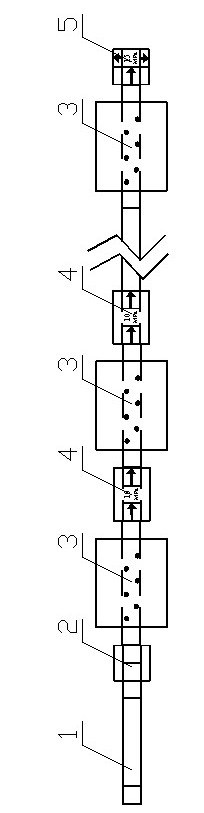

[0020] The device for increasing coal seam cracking effect of the present invention is as figure 1 As shown, the device includes a connecting rod 1, several expandable sleeves 2 and several constant pressure switches, the constant pressure switch is divided into constant pressure switch I4 and constant pressure switch II5, expandable sleeve 2 and constant pressure The switches are arranged at intervals, and the connecting rod 1 and the first expandable sleeve 3 are connected through the connecting sleeve 2 .

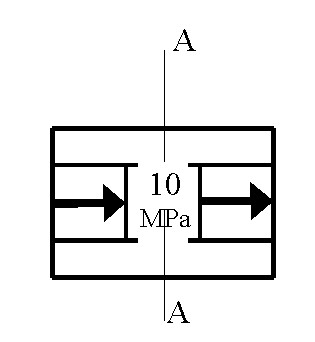

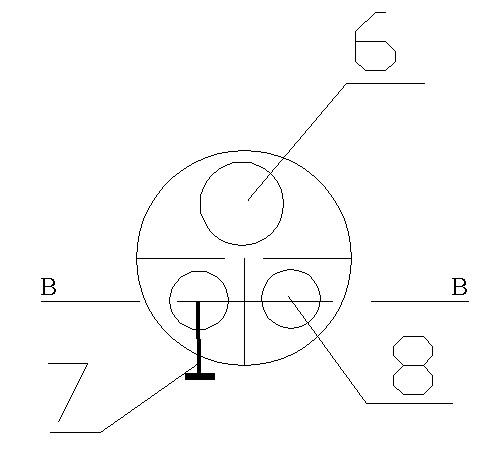

[0021] The constant pressure switch is composed of a switch channel 6 and a switch control device. The switch control device includes a compression chamber 8, and a compression spring 10 is arranged in the compression chamber 8. One end of the compression spring 10 is fixed, and the other end is provided with a soft pressure piece 11 for compression. A switch inner handle 9 is arranged in the cavity 8, and an outer switch handle 7 is arranged outside the constant pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com