An energy-storage micro-head fluid energy pumping system using solar pressurization

A technology of solar energy and fluid energy, applied in solar heating systems, solar thermal energy, solar thermal power generation, etc., can solve problems such as difficult, slow, and unrealistic pumping, and achieve the effect of solving slow pumping, ensuring full utilization, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples and accompanying drawings, because the following description is only a specific embodiment of the present invention, but the protection of the present invention is not limited thereto, and any changes or substitutions conceived by those skilled in the art are all covered within the protection scope of the present invention.

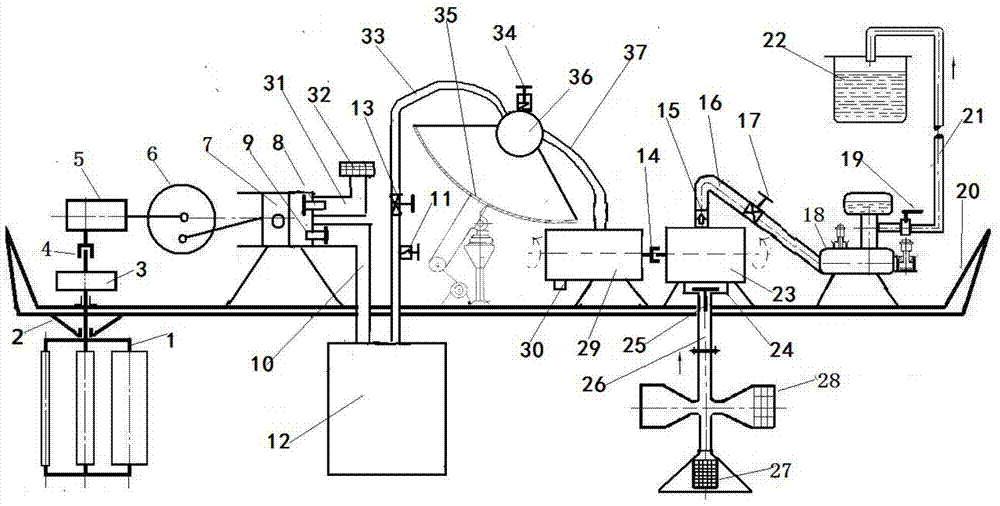

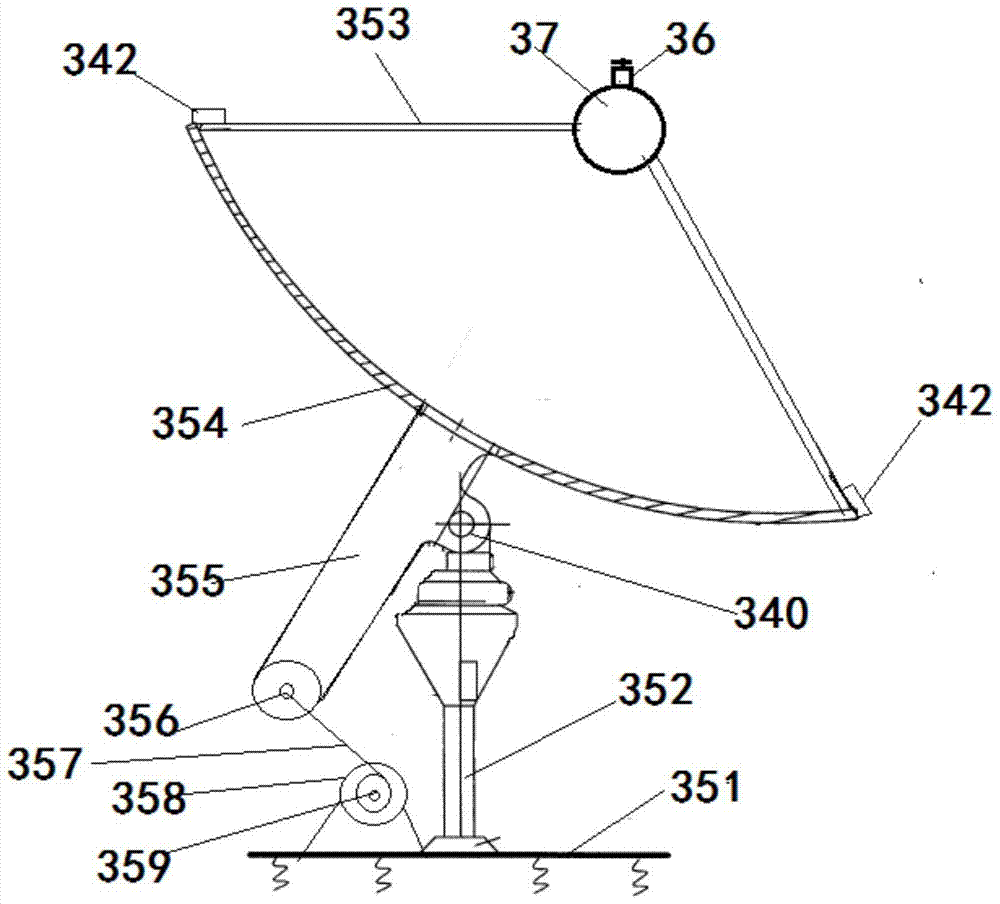

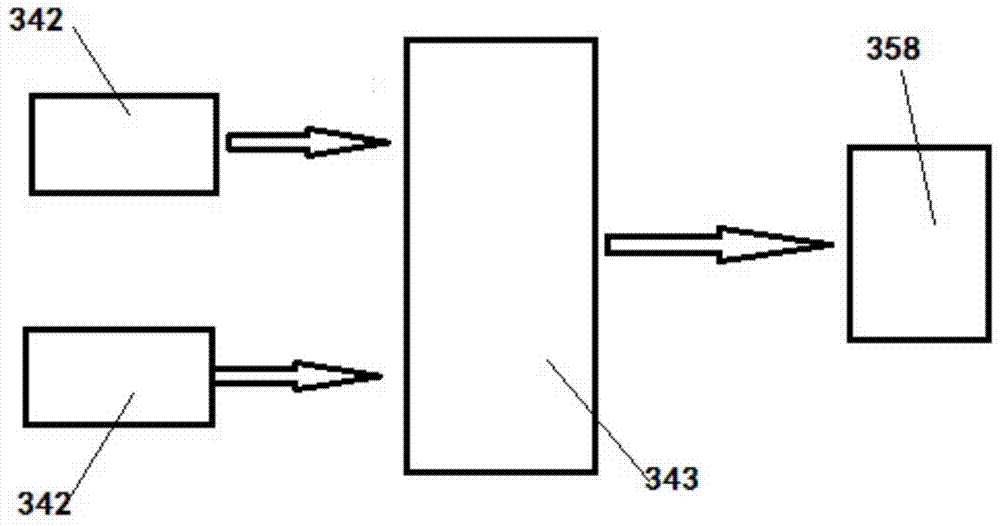

[0035] Such as Figures 1 to 3 As shown, an energy-storage micro-head fluid energy pumping system using solar energy supercharging, the system consists of a fluid energy harvesting mechanism 1, a speed change mechanism 5, a crank linkage mechanism 6, a plunger type air pump 7, an air storage tank 12, and an air pressure motor 30. Rotor type water pump 23, water hammer pump 18, solar tracking system 35, gas heating chamber 36 and pipelines, wherein the fluid energy harvesting mechanism 1 is connected to the speed change mechanism 5, and the speed change mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com