Solid-phase gap gas sampling rod

A gas sampling and sampling rod technology, applied in the field of measuring tools, can solve problems such as clogged sampling rods, and achieve the effects of convenient operation, increased volume, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

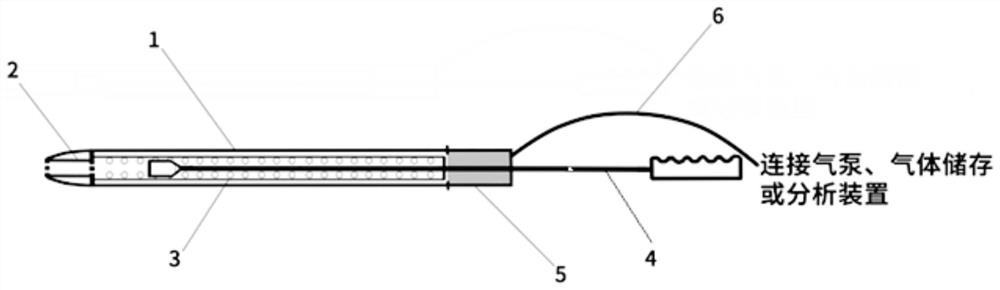

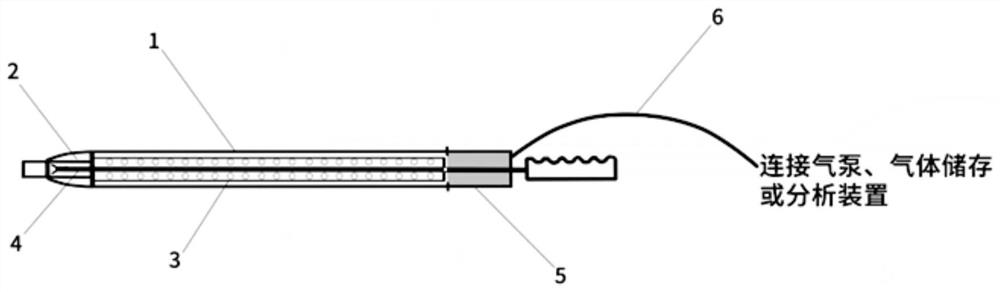

[0037] Application background: During the sludge composting process, the oxygen concentration at different levels in the heap is measured.

[0038] Sampling rod material: the front and rear parts of the push-pull rod 4 are a layer of rubber material (the front end is to make the push-pull rod 4 fit closely with the outer end tube 2, and the rear end is to make the push-pull rod 4 closely fit with the rear-end shell 5) wrapped with stainless steel The rod has an outer diameter of 1 cm, and the material of the two sections of stainless steel rod connectors before and after the push-pull rod 4 is rubber. Airway 6 is made of silica gel. The rest of the material is stainless steel.

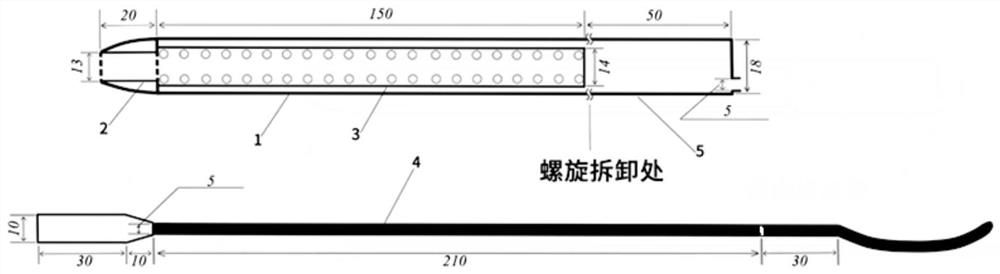

[0039] Such as image 3 As shown in the figure, the unit of dimension in the figure is mm, and the size of the sampling rod is:

[0040] Front shell 1: length 15cm, inner diameter 1.6cm, outer diameter 1.8cm.

[0041]Front end tube 2: length 2cm, inner diameter 1cm, outer diameter 1.2cm.

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com