Rotary stirring and emulsification viscosity reduction flow string under high thick oil pump

A technology of rotary stirring, emulsification and viscosity reduction, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of crude oil viscosity increase, affect emulsification effect, uneconomical, etc., reduce frictional resistance, improve Oil recovery effect, load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

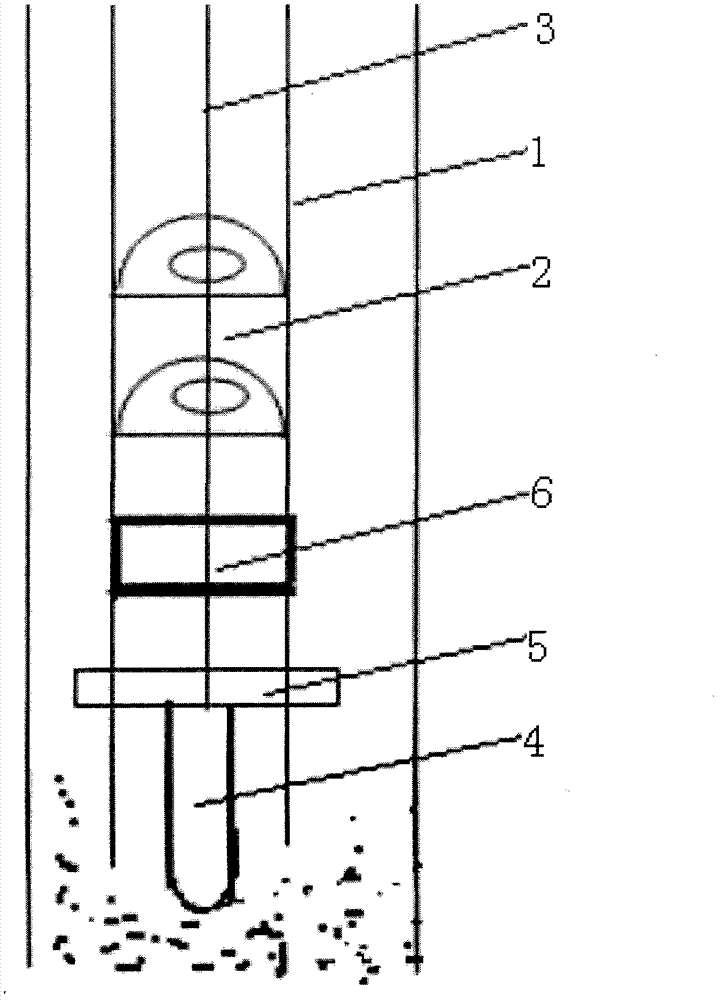

[0021] Such as figure 1 As shown, the rotary stirring emulsification viscosity-reducing oil production string under the high-viscosity oil pump involved in this embodiment is mainly composed of the oil pipe 1 and the oil well pump 2 arranged inside the oil pipe 1. The oil well pump 2 is installed with a sucker rod3.

[0022] A special sucker rod 4 is also installed below the oil well pump 2 .

[0023] A rotary agitator 5 is also arranged between the special sucker rod 4 and the oil pump 2 .

[0024] The rotary agitator 5 and the oil well pump 2 are connected together through an anti-loosening joint 6 .

[0025] The working process of the present invention is as follows: since the rotating agitator can generate vortex action upwards, the filling factor of the pump can be effectively improved. Due to the function of the rotating agitator, the aqueous solution of the viscosity reducer can be fully mixed with the heavy oil to form a stable O / W (oil-in-water) type emulsion, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com