Cutting mechanism of soft material product

A cutting mechanism and soft material technology, applied in metal processing and other directions, can solve the problems of increased frictional resistance, loss of kinetic energy of the cutting blade, easy rolling of cutting tools, etc., to reduce frictional resistance, reduce kinetic energy loss, and ensure the effect of cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

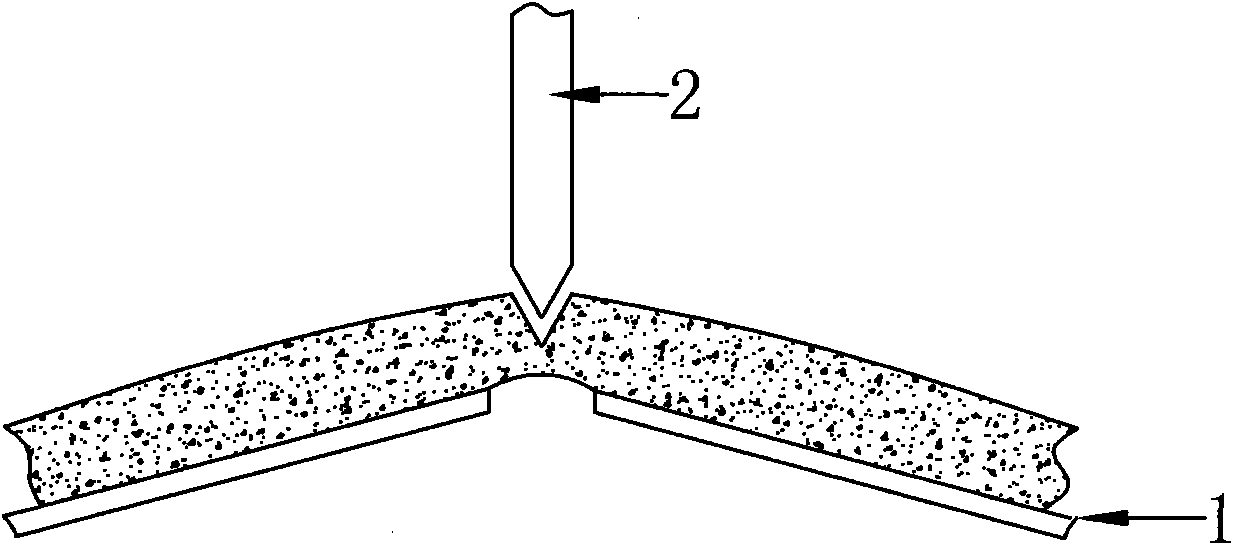

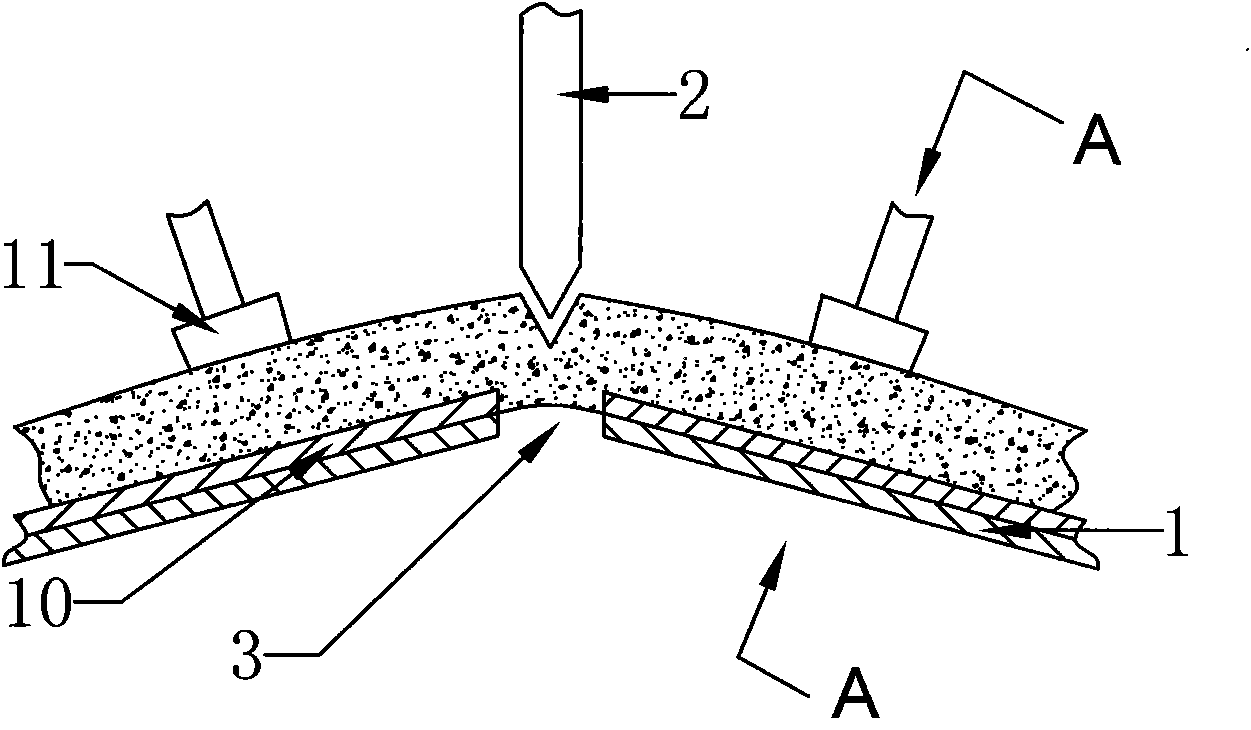

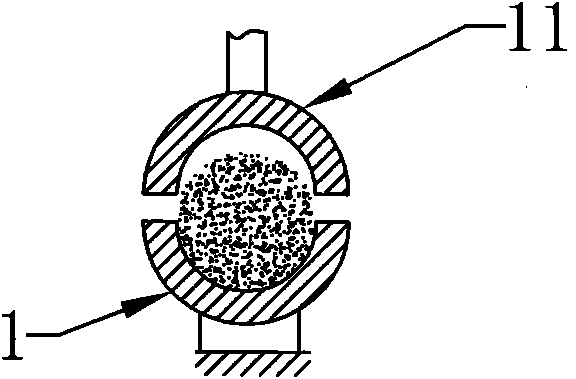

[0030] See attached figure 1 to attach Figure 4 , it includes a holder 1 and a cutting knife 2 described in this embodiment, wherein a cutting groove 3 for matching the cutting knife 2 is provided on the holder 1, and the cutting groove 3 on the holder 1 is formed For the arched structure, the cutting knife 2 is located in the arching direction of the arched structure. The holder 1 is provided with a groove 10 for accommodating the soft material to be cut, and the notch of the groove 10 is provided with a presser 11, and the notch in the presser 11 corresponds to the notch of the groove 10. Cooperate. After adopting the groove 10, the soft material product can be limited in the groove 10 for cutting, so as to ensure the smoothness of the incision after the soft material product is cut, and the phenomenon that the soft material product will not be displaced during the cutting process will affect the cutting process. product quality. The upwardly arched structure at the cut...

Embodiment 2

[0032] See attached Figure 5 The difference between the solution of this embodiment and the first embodiment is that the padding workpiece 4 is a square workpiece.

Embodiment 3

[0034] See attached Figure 6 The difference between the solution of this embodiment and the first embodiment is that the padding workpiece 4 is a circular workpiece, and the circular workpiece can be directly welded on the holder 1 or a concave hole is provided on the holder 1 to Positions circular workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com