Crushing device and crushing method for waste PP materials

A technology of crushing device and crushing cavity, applied in mechanical material recovery, chemical instruments and methods, plastic recycling, etc., can solve the problems of wasting time, jamming, not very careful crushing, etc., achieving high crushing degree, prolonging service life, reducing light The effect of breaking the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

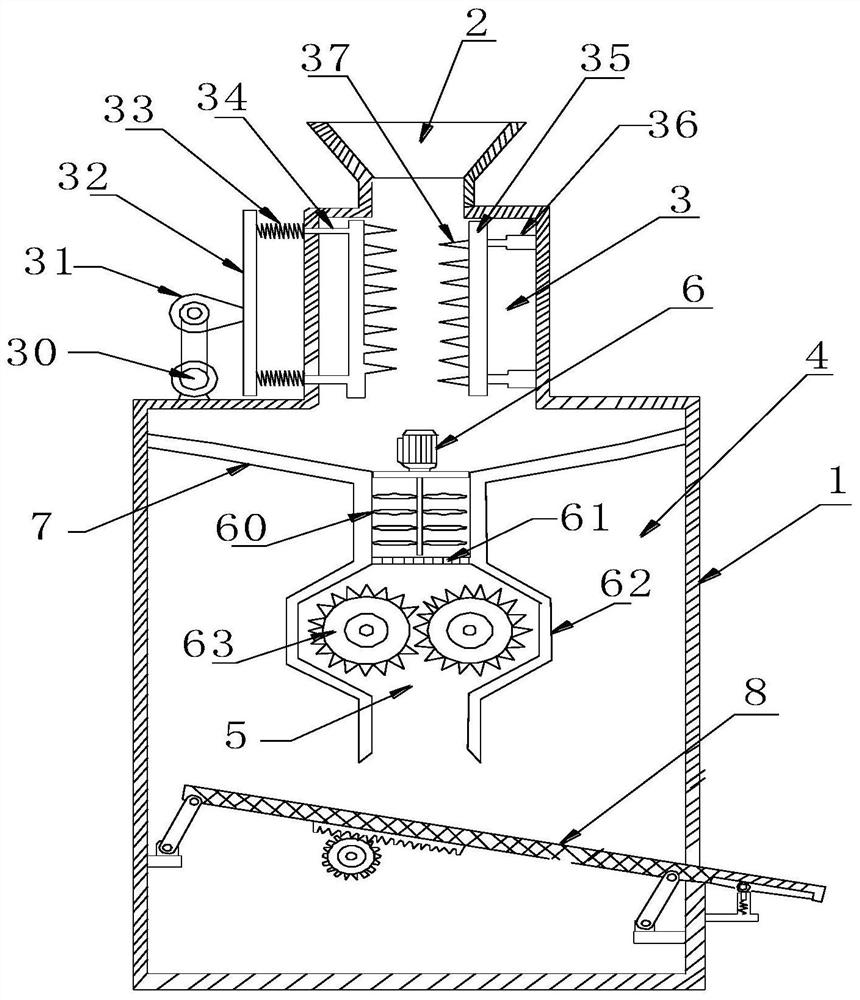

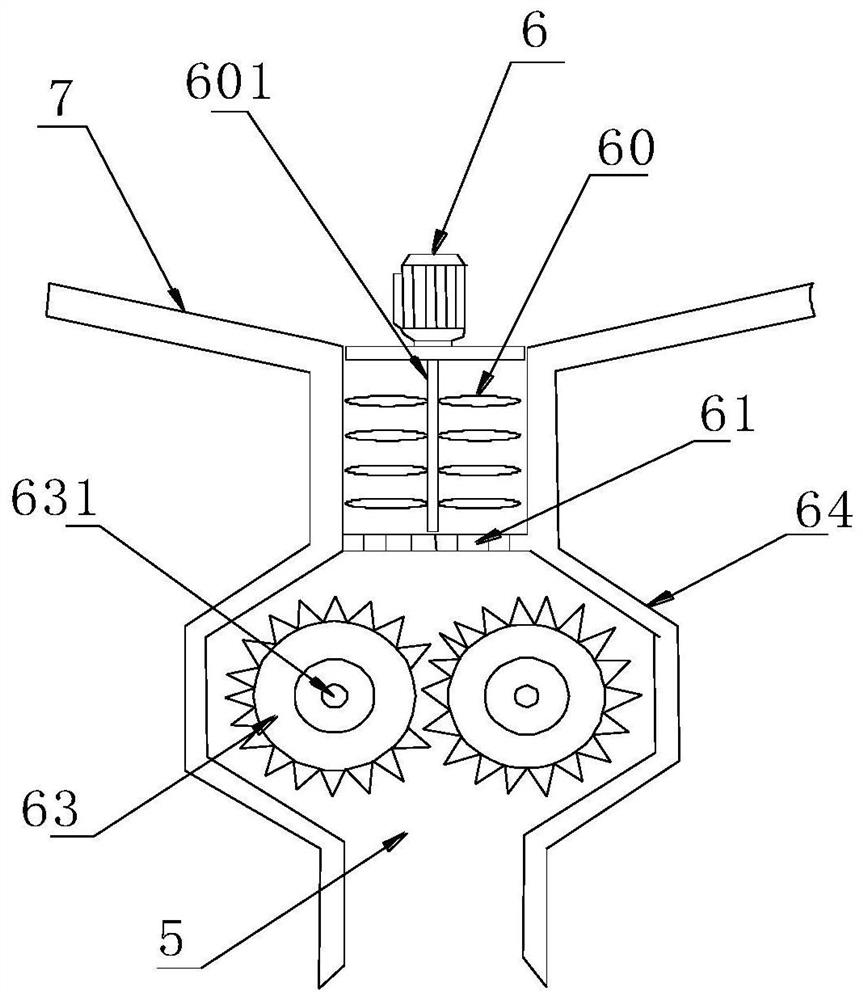

[0034] Such as Figure 1-3 As shown, a crushing device for waste PP materials in this embodiment includes a main body 1, a feed hopper 2, a primary crushing device, a secondary crushing device, a tertiary crushing device, and a screening device.

[0035] The feed hopper 2 is fixed on the main body 1 and communicates with the inside of the main body 1;

[0036] The primary crushing device, which is located below the outlet of the feed hopper 2, includes a primary crushing chamber 3, a connecting rod 34, two crushing plates 35 and crushing teeth 37; the two crushing plates 35 are arranged side by side in the primary crushing chamber 3 On both sides, the connecting rod 34 passes through the outer wall of the primary crushing chamber 3 and is connected to the spring one 33. The other end of the spring one 33 is fixed on the movable plate 32, and the other side of the movable plate 32 opposite to the spring one 33 is fixed on the cam 31. Above, the cam 31 is driven by a second mot...

Embodiment 2

[0043] This embodiment applies the crushing method of the crushing device of the above embodiment, including the following steps:

[0044] First-level cutting, the material is fed into the first-level crushing chamber 3 through the feed hopper 2, and the second motor 30 is used to drive the cam 31 to periodically squeeze the movable plate 32. The crushing plate 35 connected by the connecting rod 34 and the telescopic rod 36 is in the The movable plate 32 is driven to collide periodically, and the crushing teeth 37 on the crushing plate 35 cut the waste for the first time;

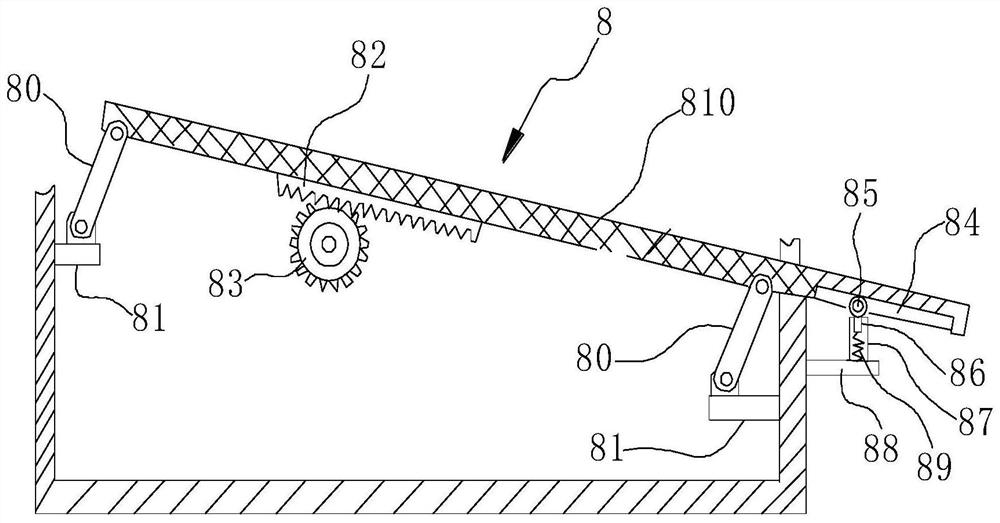

[0045] Secondary crushing, the waste material cut for the first time is guided into the secondary crushing chamber 4 through two sloping plates 7, and the two sloping plates 7 are fixed on the outer wall of the secondary crushing chamber 4 to form a discharge channel; above the discharge channel, use The fixed frame 64 is equipped with the first motor 6, the rotating shaft 601 of the first motor 6 fixes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com