Device for processing circuit board and recycling iron powder

A recycling device and circuit board technology, applied in grain processing, magnetic separation, solid separation, etc., can solve the problems of high transportation cost, large proportion of waste circuit board space, secondary pollution of air and water quality, etc., to reduce secondary pollution. The effect of pollution, high availability and effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

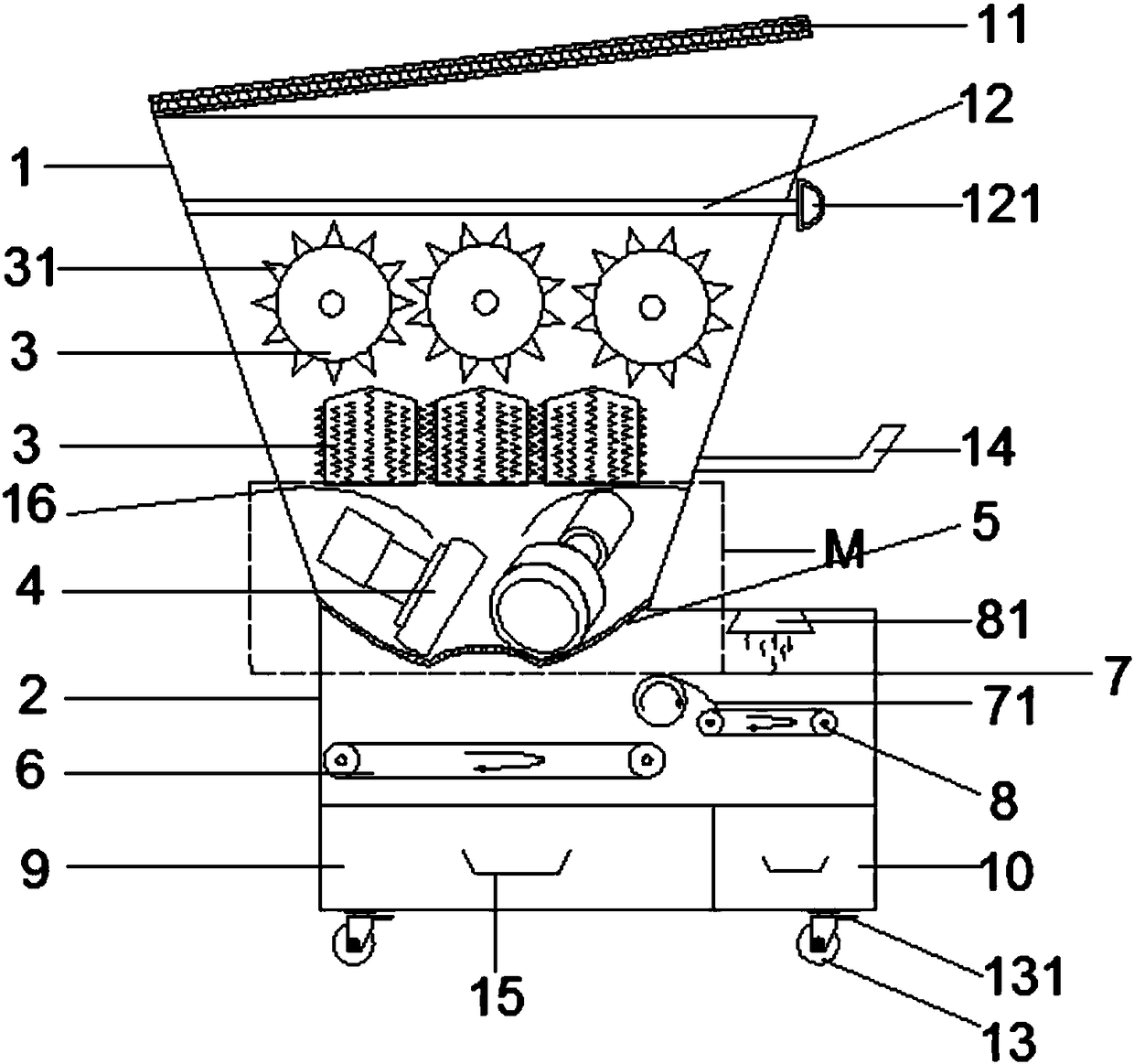

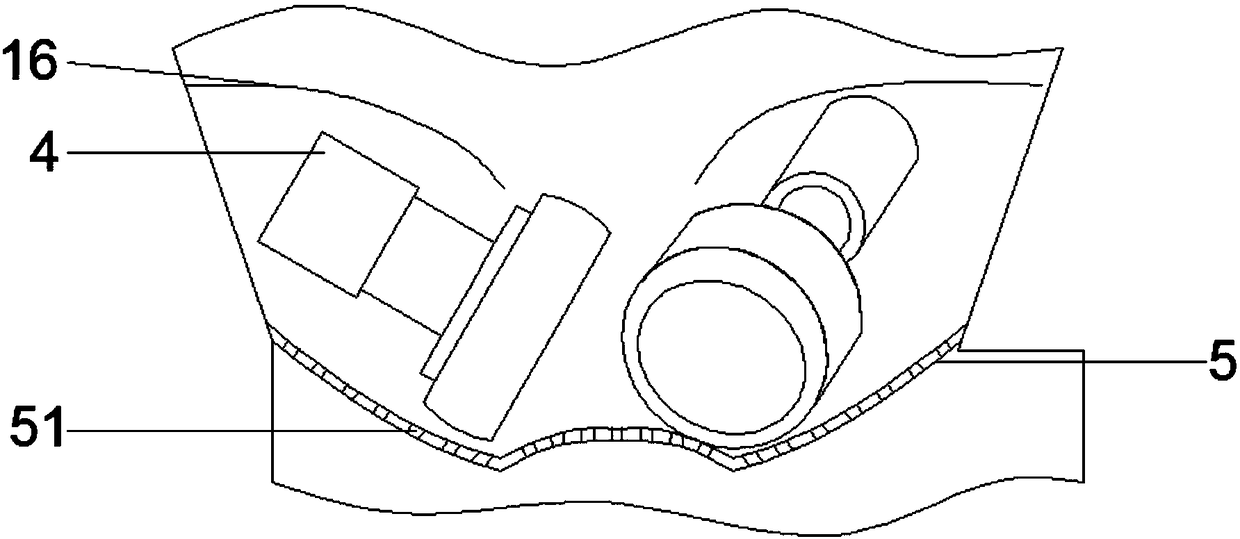

[0022] A circuit board processing and iron powder recovery device, comprising a casing 1 with an inverted cone-shaped opening at the top and a box body 2 connected to the bottom of the casing. The inside of the casing 1 is along the horizontal direction and Three crushing rollers 3 with triangular teeth 31 are respectively arranged in the vertical direction; a pair of grinding hammers 4 are arranged below the crushing rollers 3 in the vertical direction; A filter layer 5 for grinding hammer 4 rolling operations; a first belt conveying mechanism 6 is provided below the filter layer 5; a magnetic separation drum 7 is provided above the feeding end side of the first belt conveying mechanism 6; Described magnetic separation cylinder 7 is provided with second belt conveyance mechanism 8 relative to the first belt conveyance mechanism 6 side, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com