Straw crushing mechanism under corn harvesting machine header

A corn harvester and straw crushing technology, which is applied to harvesters, agricultural machinery and implements, and cutters. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

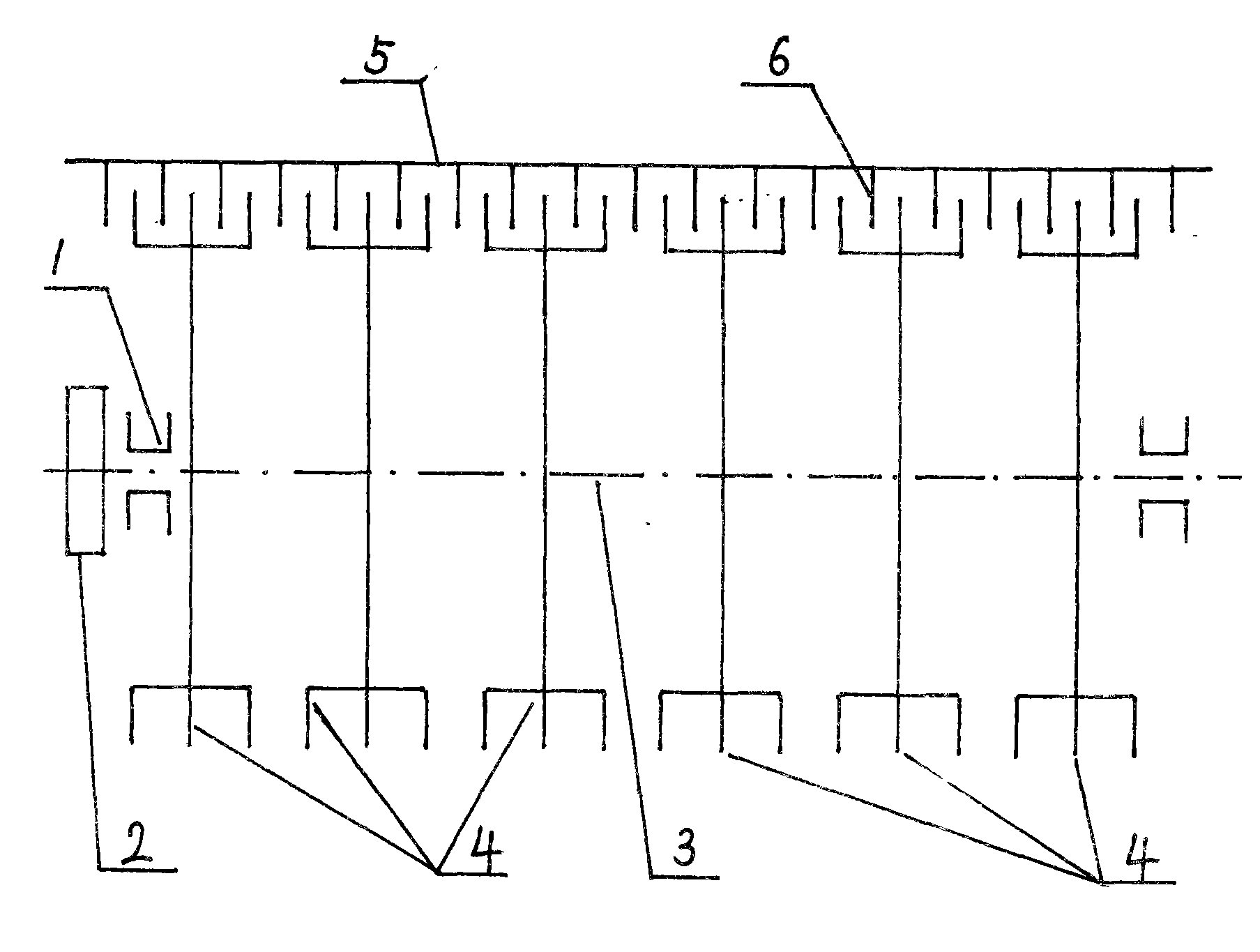

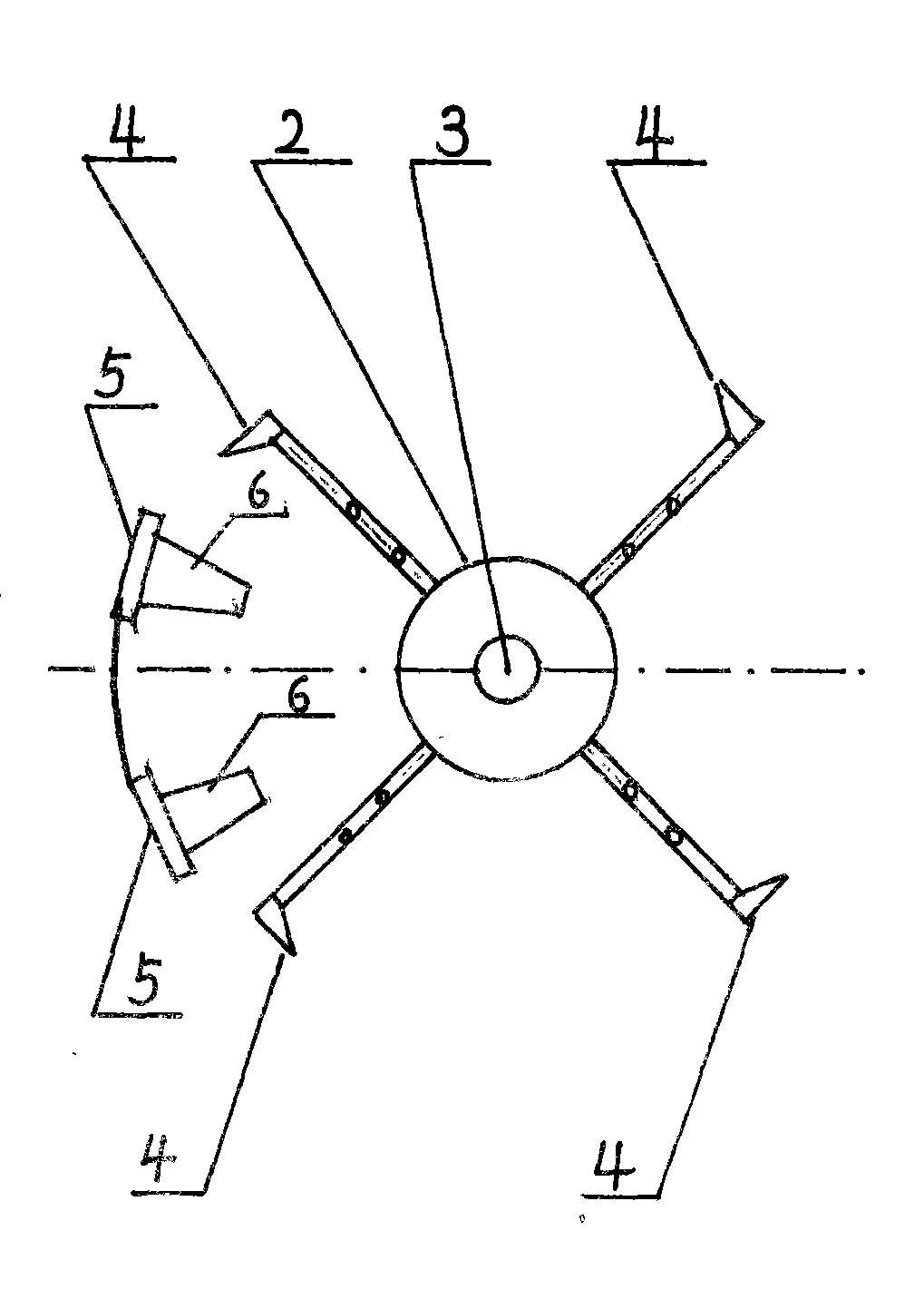

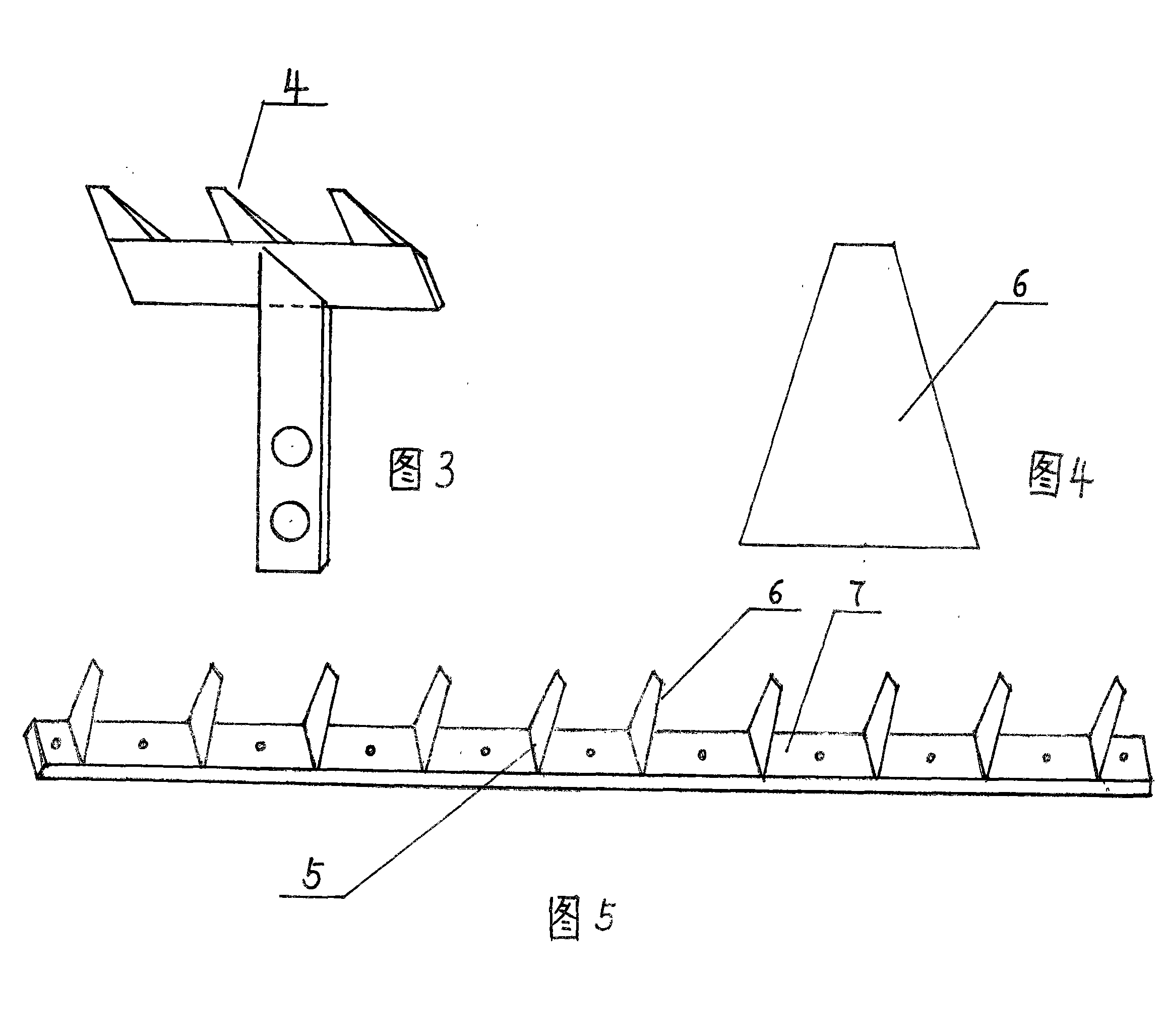

[0015] exist figure 1 , figure 2 , image 3 , Figure 5 In the shown embodiment, a straw crushing mechanism under the header of the corn harvester is installed on the bearing seat 1 under the header of the corn harvester, including the driven wheel 2 installed on the main shaft 3, and the main shaft 3 is installed The claw-shaped cutting and tearing knife 4, the claw-shaped cutting and tearing knife 4 installed on the main shaft 3 is fixed relative to the main shaft 3 as a reference object, and a plurality of fixed knife assemblies 5 are installed near the claw-shaped cutting and tearing knife 4 rotation track , the fixed knife 6 on the fixed knife assembly 5 and the claw type cutting and tearing knife 4 embed each other when rotating.

[0016] The fixed knife assembly 5 is arranged and fixed on the same base plate 7 by a plurality of fixed knives 6 .

[0017] The claw number of claw type cutting and tearing knife 4 is more than 2 claws.

[0018] Working process: When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com