Cutting device of a corn harvester

A harvester, corn technology, applied in the direction of harvesters, agricultural machinery and implements, external crop dividers, etc., can solve the problems of corn lodging, tight corn recovery time, reduced harvest quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

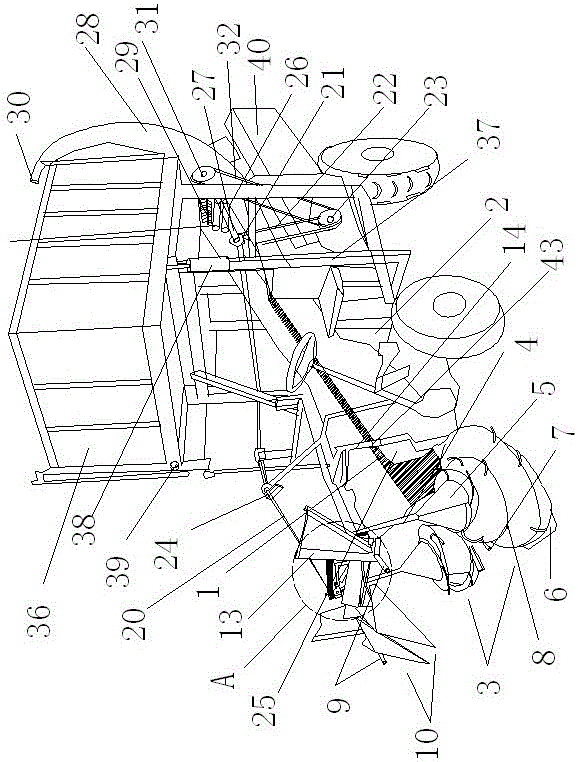

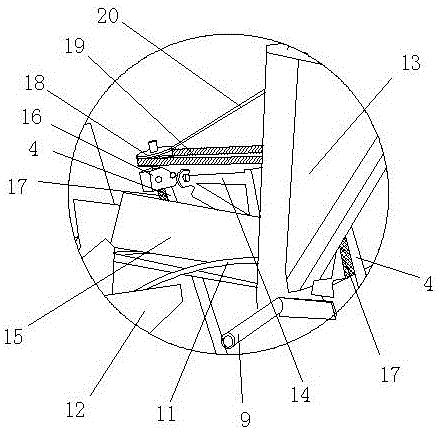

[0024] Example 1. Such as Figure 1 to Figure 3 As shown, a corn harvester using the cutting device of the present invention includes a cutting device, a fruit separating device, a crushing device, a crushing stalk collecting device, a tractor as a power drive device and a corresponding transmission device; the cutting device The device includes a stalk dividing device, a stalk cutting device and a conveying device.

[0025] The conveying device includes a conveyor belt 1, which is installed on the body 2 of the tractor, and the height of the front end of the conveyor belt 1 from the ground is lower than the height of the rear end of the conveyor belt 1 from the ground;

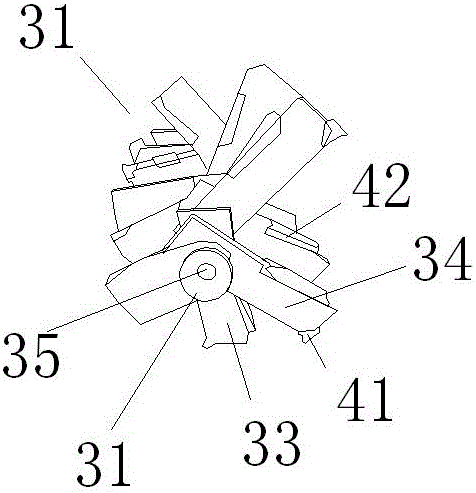

[0026] The stalk cutting device is connected to the front end of the conveyor belt 1, and the stalk cutting device includes a pair of conical spiral cutters 3, and the two conical spiral cutters 3 are arranged symmetrically along the central axis of the conveyor belt 1; The conical spiral cutting device 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com