Straw pulverizing mechanism for corn harvester

A corn harvester and straw crushing technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of high stubble, missed cutting of corn straw, and failure to meet the requirements of agronomic planting, and achieve low stubble , the effect of high fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

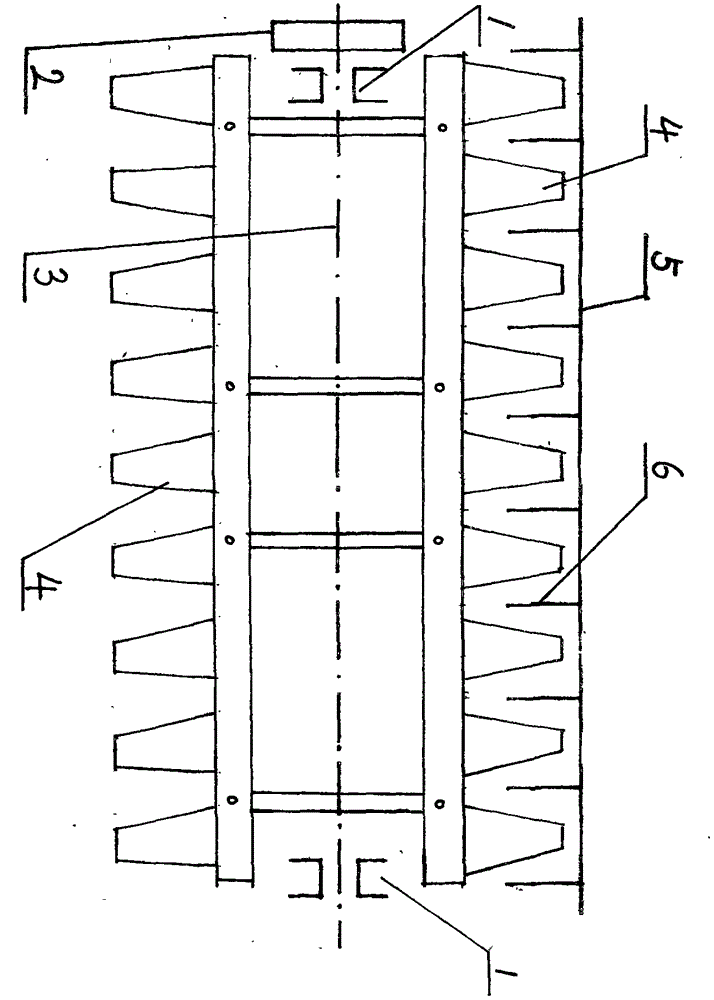

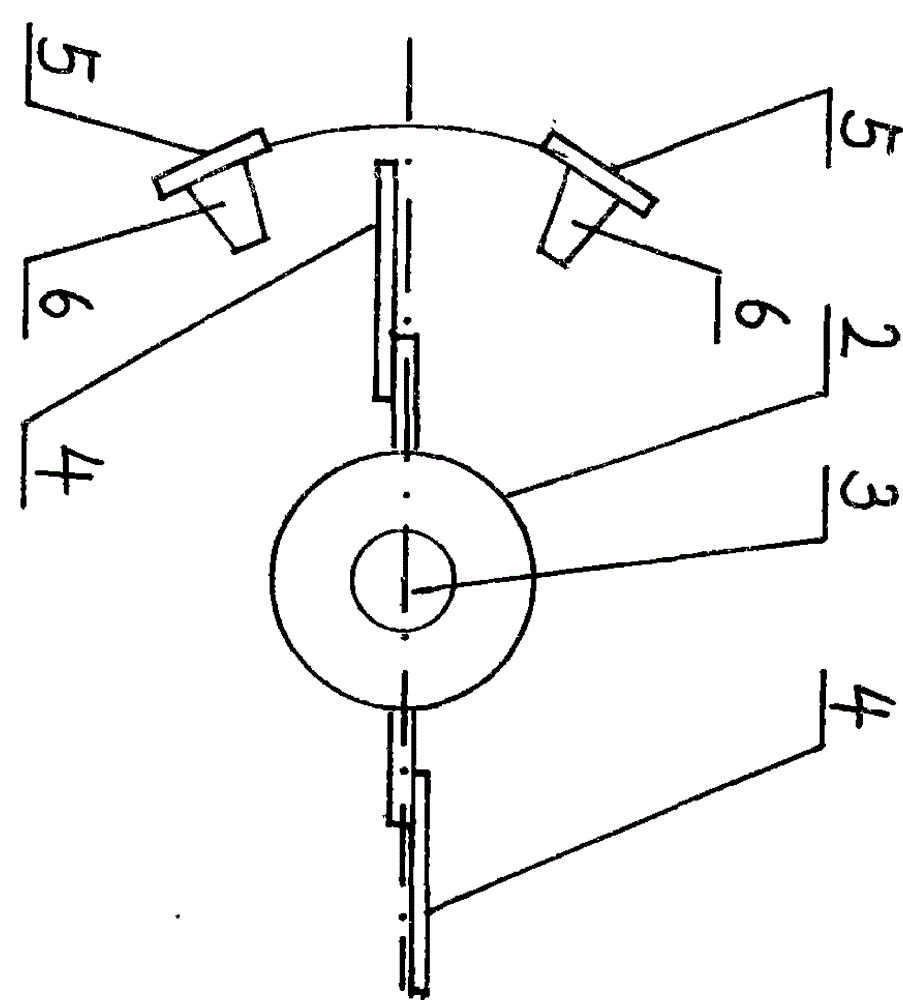

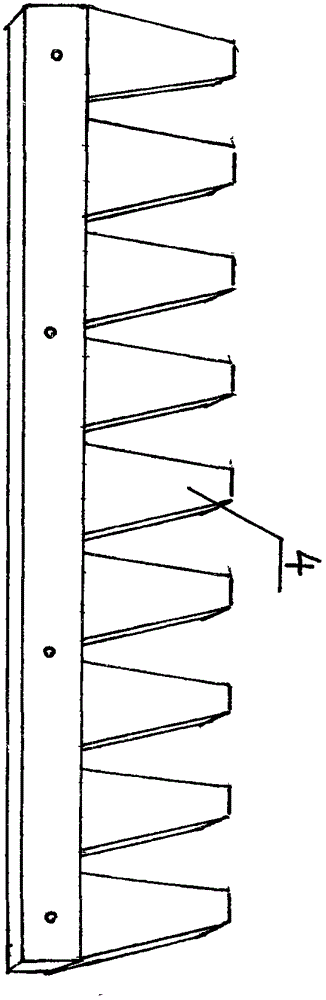

[0014] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the shown embodiment, a straw crushing mechanism of a corn harvester is installed on the bearing seat 1 under the header of the corn harvester, including the driven wheel 2 installed on the main shaft 3, and the tooth cutting knife is installed on the main shaft 3 4. The tooth cutting knife 4 installed on the main shaft 3 is fixed relative to the main shaft 3 as a reference object. A plurality of fixed knife assemblies 5 are installed near the rotation track of the tooth cutting knife 4. When rotating, the fixed knife assembly 5 The fixed knife 6 is inserted in the concave groove of the tooth cutting knife 4.

[0015] The fixed knife composition 5 is arranged and fixed on the same base plate 7 by a plurality of fixed knives 6 .

[0016] Working process: When the corn harvester is working forward, the driven wheel 2 is driven to rotate, and the tooth cutting knife 4 is rotated through the main shaft 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com