Production line for scrap metal treatment

A technology of production line and scrap metal, which is applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc. It can solve the problems of low recovery rate of metal resources, high difficulty of recovery, low production efficiency, etc., and achieve less consumption of human resources , Improve the effective recovery rate and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with specific embodiments.

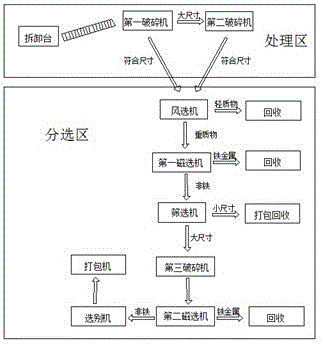

[0013] A scrap metal processing production line proposed by the present invention includes a processing area, a sorting area and a control area. The waste material passes through the processing area and the sorting area in turn, and finally completes the work of the entire production line, and the equipment on the entire production line is started and ended by the control area. computer control; the processing area includes a dismantling table, a conveyor, a first crusher and a second crusher in sequence, and is used to complete the dismantling and crushing operations of scrap metal; the sorting area is the main working area of the entire production line, It is used to recover the valuable metals in the broken waste step by step. The equipment in the sorting area includes the first wind separator, the first magnetic separator, the screening machine, the third crusher, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com