Stripping plate type agricultural film recycling machine

A technology of stripping plate and recycling machine, which is applied in collectors, agricultural machinery and implements, agriculture, etc., can solve the problems of easy winding of nail teeth and attached residual film, time-consuming and laborious separation and cleaning, and low recovery rate of residual film, etc. Achieve the effect of improving the effective recovery rate, prolonging the service life and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0022]In the present invention, for the convenience of description, the forward direction when the present invention is working is taken as the front, and the description of the relative positional relationship of each component is described with reference to the front end of the present invention, such as: front, rear, upper, The positional relationship of down, left, right, etc. is determined according to the direction relative to the front end of the present invention.

[0023] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

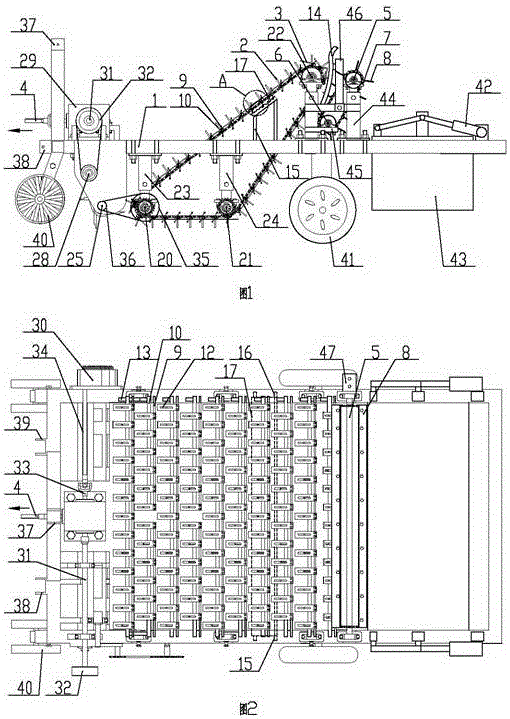

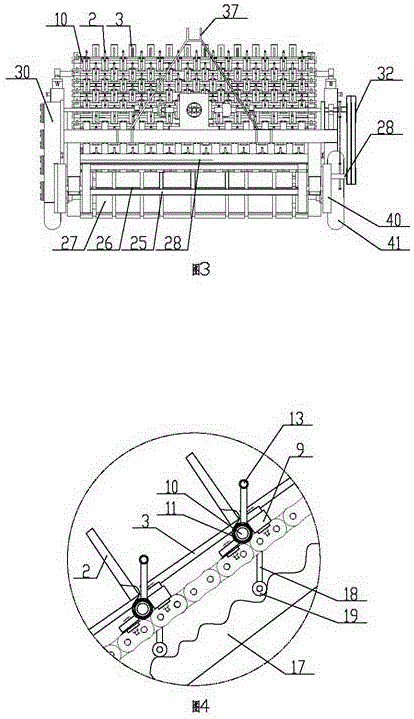

[0024] as attached figure 1 , 2 As shown in , 3, this stripping plate type agricultural film recovery machine comprises frame 1, digging device and stripping plate type nail bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com