Method for preparing silage through combination of mold for producing cellulase and lactic acid bacteria

A cellulase and combined preparation technology, applied in the preservation method of animal feed raw materials, animal feed, application, etc., can solve the problems of moldy and deteriorated silage, which cannot be fully realized, and affects the quality and economic benefits of silage products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

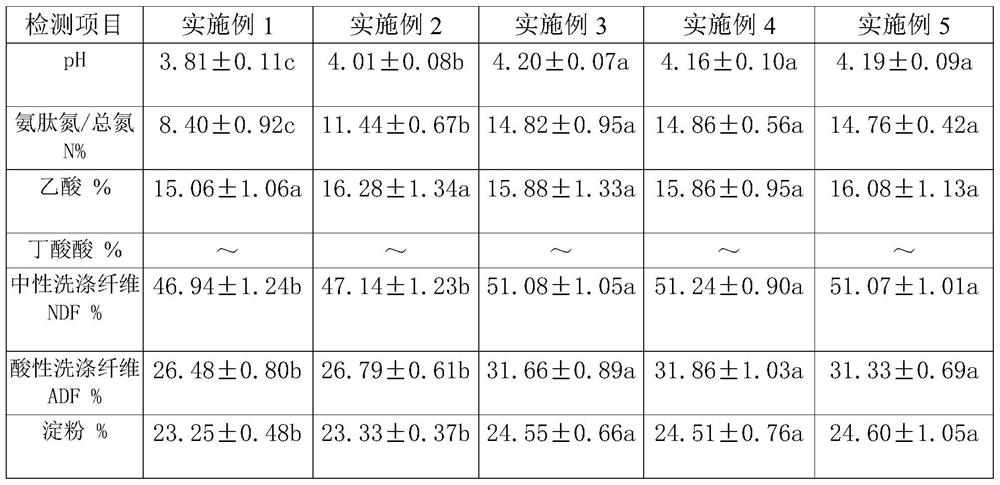

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the method that the mold that produces cellulase in this embodiment and lactic acid bacteria jointly prepares silage, it is characterized in that said method realizes according to the following steps:

[0016] 1. Preparation of lactic acid bacteria liquid and mold spore suspension producing cellulase;

[0017] 2. Preparation of lactic acid bacteria liquid starch liquid: add starch to the lactic acid bacteria liquid to make starch-containing lactic acid bacteria liquid;

[0018] 3. Crushing and filling of straw: After crushing the straw, add lactic acid bacteria starch solution and mold spore suspension that produces cellulase while stirring, and pack and seal after stirring evenly;

[0019] 4. Silage fermentation: the silage bag is naturally fermented in a cool, rain-proof, room temperature environment to a pH below 4.2, that is, the silage feed is obtained;

[0020] Wherein, the mold producing cellulase is Aspergillus usamil 3.2926; the straw ...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the concentration of starch in the starch-containing lactic acid bacteria liquid in Step 2 is 2.0% to 5.0%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: in step one, lactic acid bacteria undergo secondary activation and proliferation in the MRS medium, and the effective number of viable lactic acid bacteria in the bacterial liquid reaches 1×10 8 ~1×10 9 CFU / ml. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0023] The lactic acid bacteria in this embodiment are lactobacillus plantarum (lactobacillus plantarum) 1.11; the culture conditions of plant lactobacillus (lactobacillus plantarum) 1.11 are constant temperature 30 degrees, static culture, culture 18hr to 24hr, the number of effective viable bacteria can reach 1×10 8 ~10 9 CFU / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com