Waste gas treatment process and fluidized-bed bioreactor used for same

A bioreactor and exhaust gas treatment technology, which is applied in chemical instruments and methods, air quality improvement, chemical/physical processes, etc., can solve the problems of long reactor start-up time, large reactor footprint, narrow range of pollutant concentration, etc. problems, achieve the effect of overcoming reactor blockage, shortening reaction time, and stabilizing microbial system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

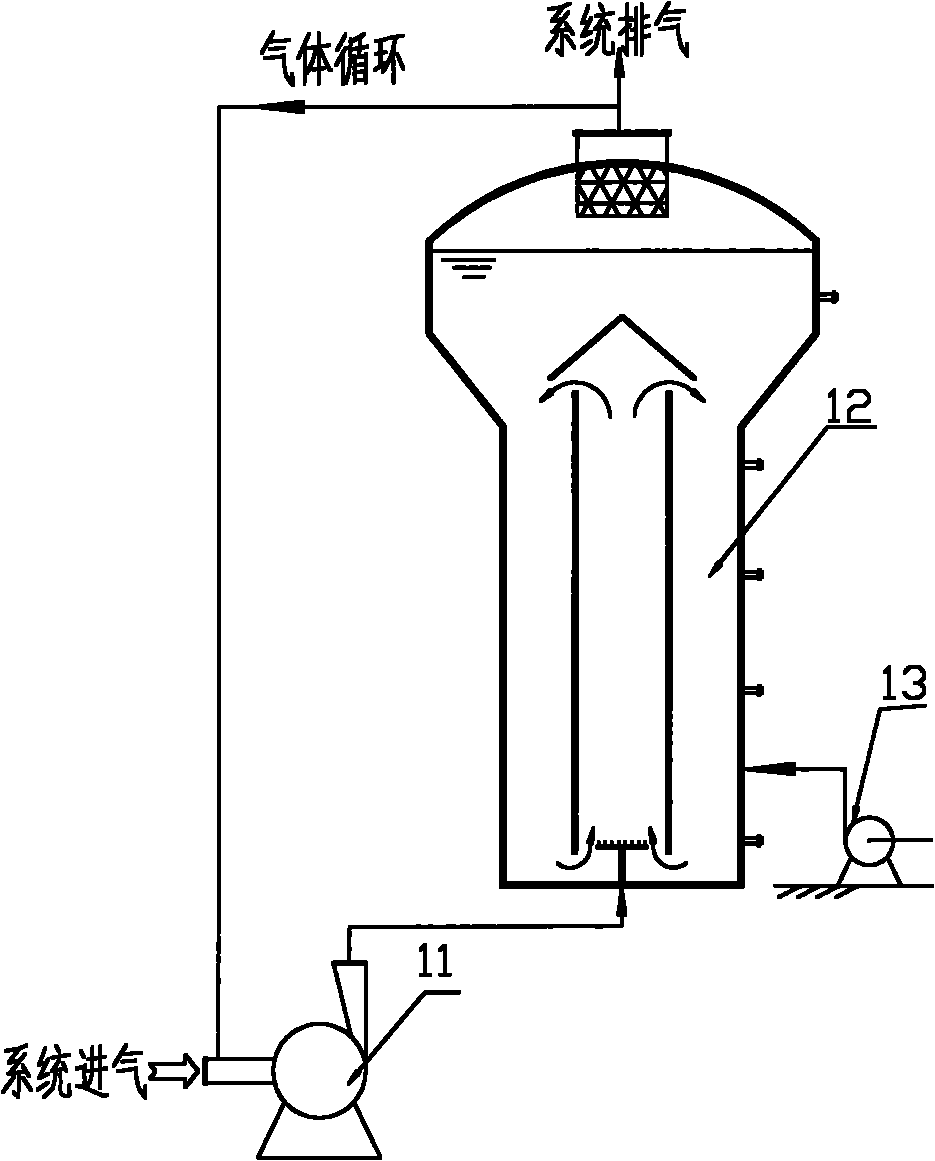

[0027] refer to figure 1 , the waste gas treatment process of the present invention includes processes such as waste gas pressurization, waste gas reaction, circulation treatment and waste gas separation and discharge. First, the waste gas containing pollutants is increased to a certain pressure by the induced draft fan 11 and then enters the fluidized bed bioreactor 12. In the fluidized bed bioreactor 12, the exhaust gas fully reacts with the microorganisms through circulating fluidization and forced mass transfer, and the reaction temperature is kept at 15-40°C. The other part is returned to the induced draft fan and circulated after pressurization. At the beginning of the reactor start-up and during normal operation, the nutrients necessary for bacterial growth and fresh water are supplied to the reactor through the feed pump 13 .

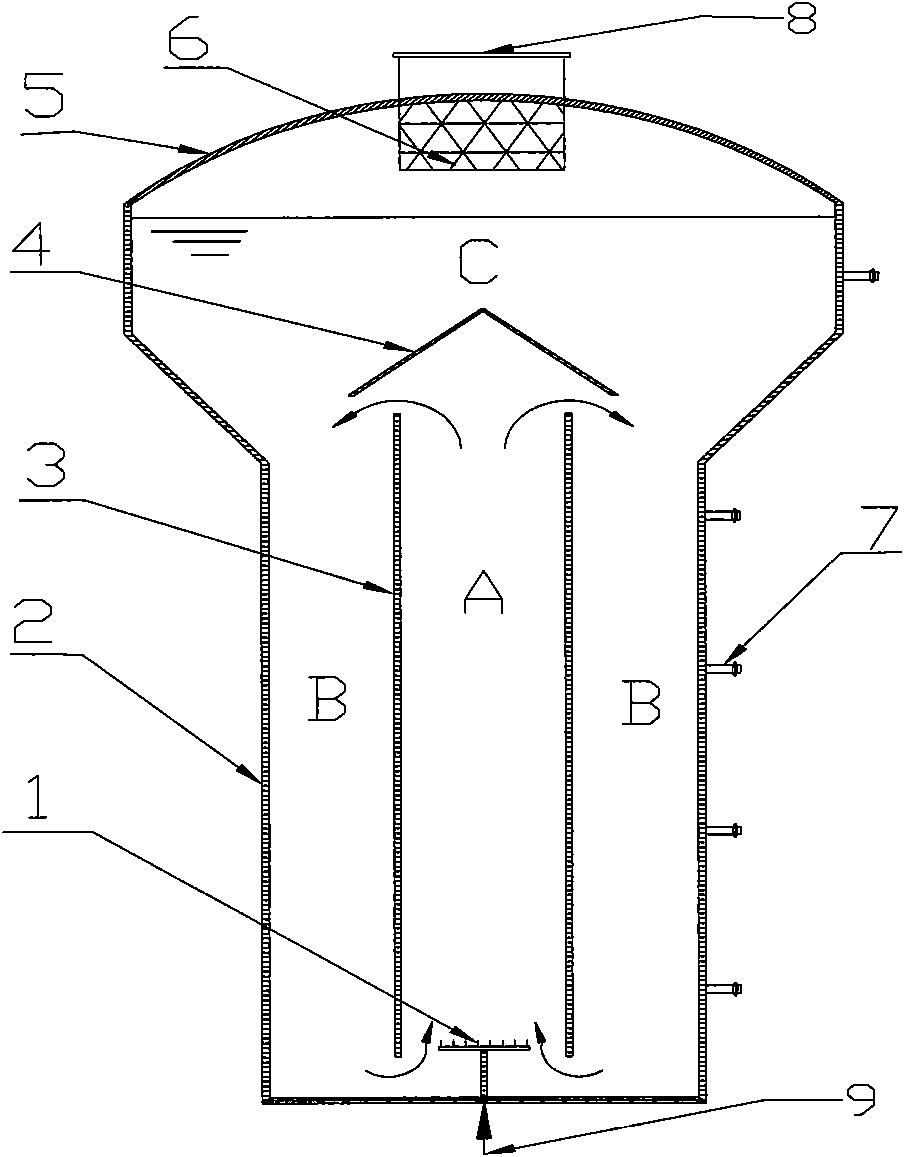

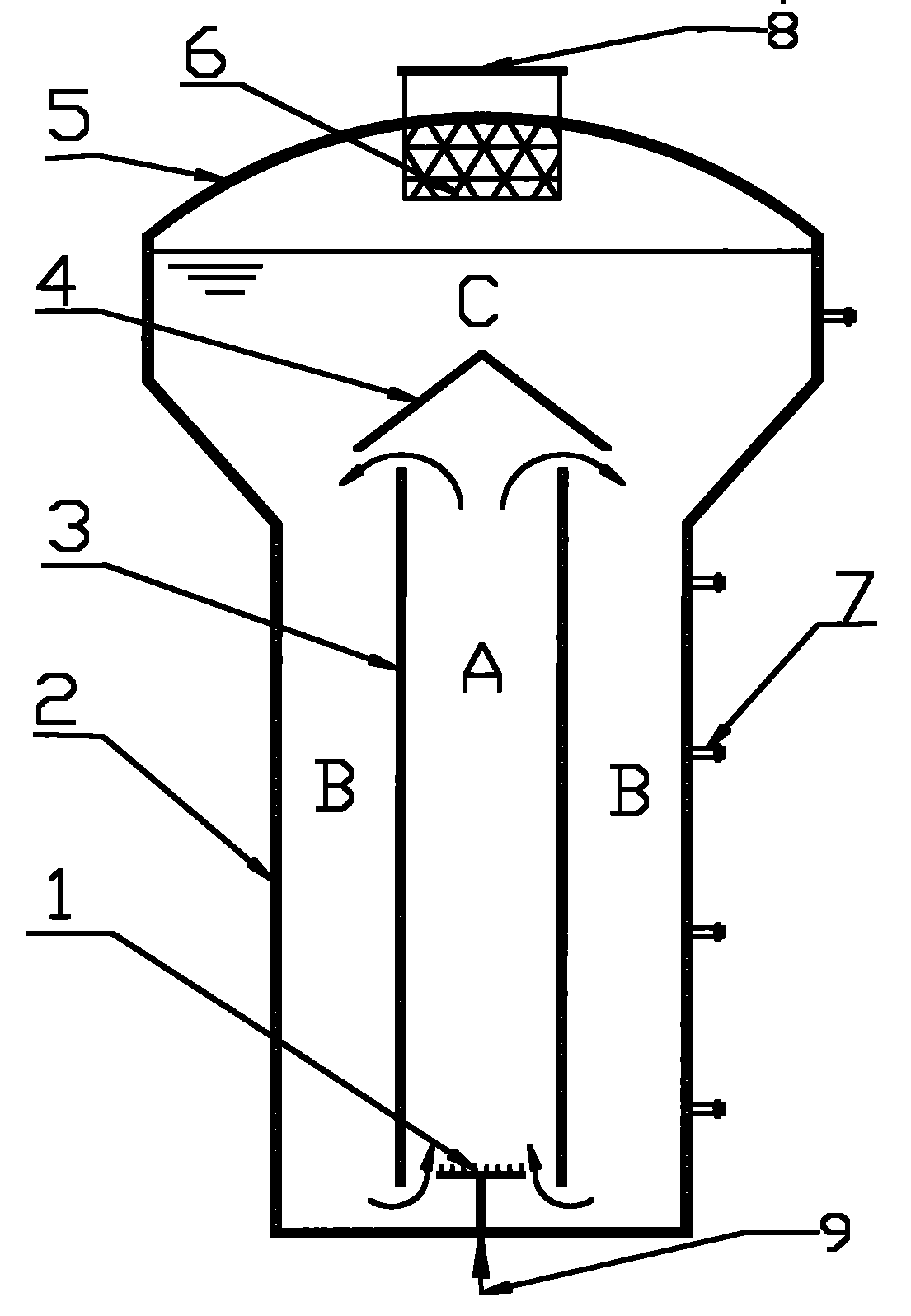

[0028] refer to figure 2 , in the above process, the pressurized waste gas containing pollutants enters from the air inlet 9 at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com