Printing and dyeing wastewater autotrophic denitrification denitriding device and method

A technology for autotrophic denitrification, printing and dyeing wastewater, applied in the textile industry wastewater treatment, anaerobic digestion treatment and other directions, can solve the problem of TN exceeding the standard in the effluent, and achieve the effects of short residence time, low operating cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

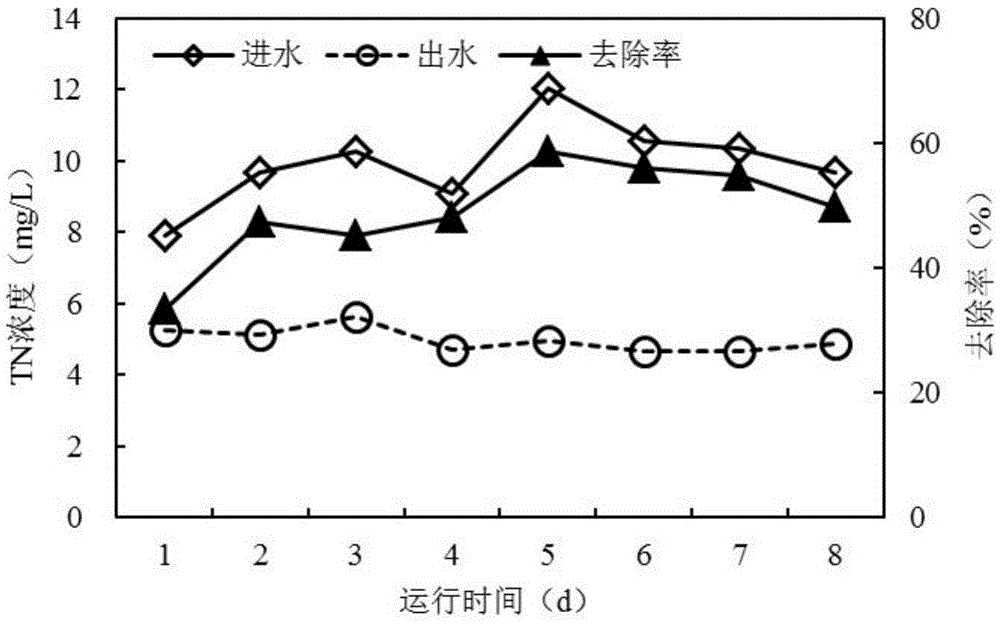

[0024] Example 1: Rapid start-up of the reactor

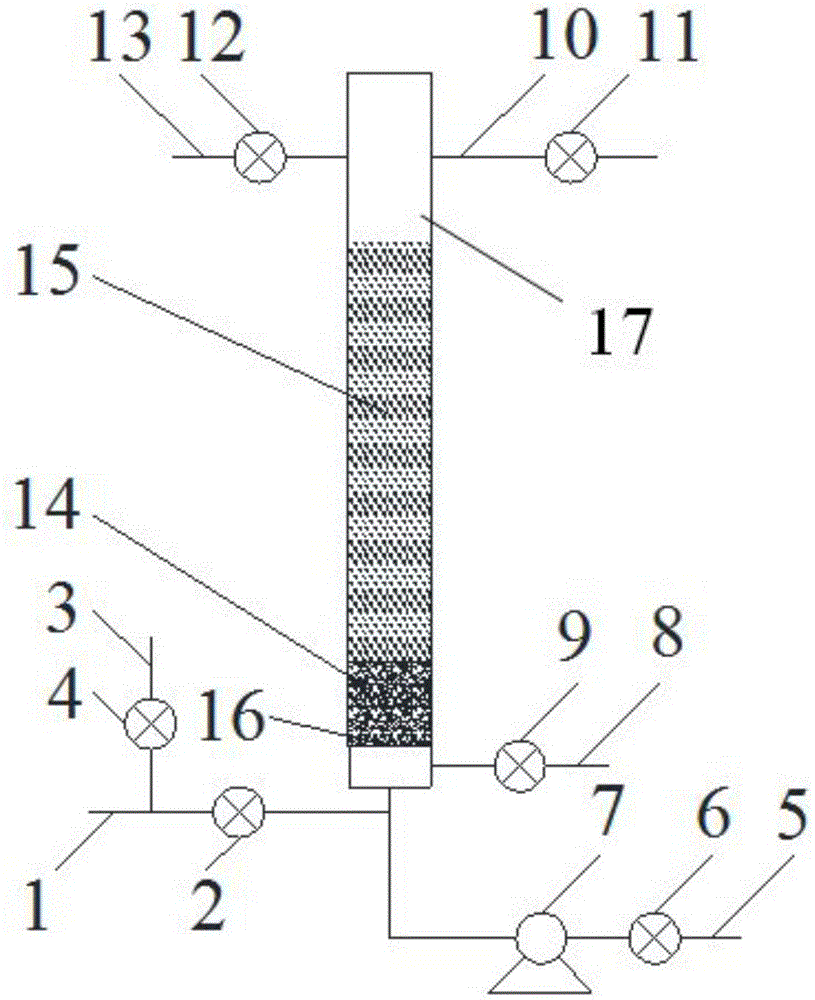

[0025] The test equipment used in the test is as figure 1 As shown, the device takes the secondary effluent of a printing and dyeing wastewater treatment plant in Wuxi as the treatment object. Close all valves on the device first, then fill pyrite and sulfur fillers in layers at a volume ratio of 1:5, first fill pyrite and then sulfur, and the distance between the top layer of filler and the water outlet accounts for 10% of the height of the entire reactor. After the packing is filled, open the water inlet valve 2 and the water outlet valve 11, and the override pipe valve 4, the backwash water inlet valve 6, the vent valve 9 and the backwash water outlet valve 12 are still closed, and the secondary outlet water enters the reaction device through the water inlet pipe 1 , and pass through the filter plate and the long-handle filter head 16, the pyrite packing layer 14 and the sulfur packing layer 15 in turn, and finally discharg...

Embodiment 2

[0027] Example 2: Denitrification of printing and dyeing wastewater with high hydraulic load

[0028] After the successful start-up of the reactor in Example 1, the test was continued.

[0029] The device takes the secondary effluent of a printing and dyeing wastewater treatment plant in Wuxi as the treatment object. The operating parameters are: empty bed residence time 20min, hydraulic load 43.2m 3 / (m 2 d), influent TN is 19.53mg / L, NO 3 - -N is 17.78mg / L, effluent TN is 5.93mg / L, TN removal rate is 69.7%, effluent TN is far better than the first-class A standard and Discharge standards in "Discharge Limits of Main Water Pollutants from Urban Sewage Treatment Plants and Key Industries in Taihu Lake Area" (DB32 / T1072-2007).

Embodiment 3

[0030] Example 3: Nitrogen removal of simulated wastewater with high hydraulic load

[0031] After the successful start-up of the reactor in Example 1, the test was continued.

[0032] The test water is artificially prepared simulated wastewater, and the operating parameters are: the empty bed residence time is 20 minutes, and the hydraulic load is 43.2m 3 / (m 2 d), influent TN is 25.35mg / L, NO 3 - The -N is 23.43mg / L, the effluent TN is 2.16mg / L, and the TN removal rate is 91.5%, realizing efficient denitrification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com