Novel process for extracting alginate-derived oligosaccharide from sea tangles by enzyme hydrolysis method

A technology of alginate oligosaccharide and enzymatic hydrolysis method, which is applied in the field of extraction technology of alginate oligosaccharide, can solve problems such as reducing the use of chemical reagents, and achieve the effects of improving product yield, beautiful appearance, and contributing to degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

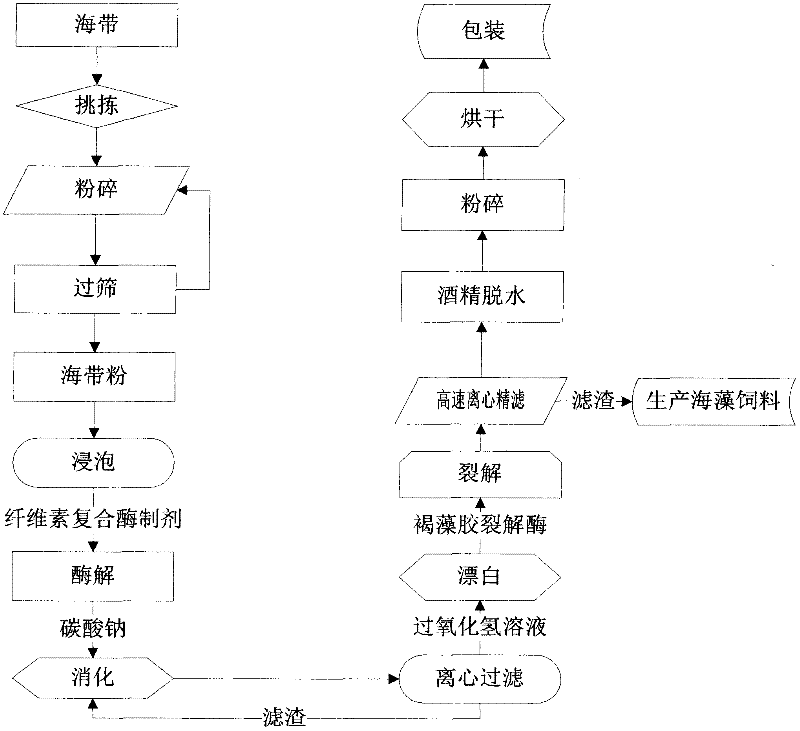

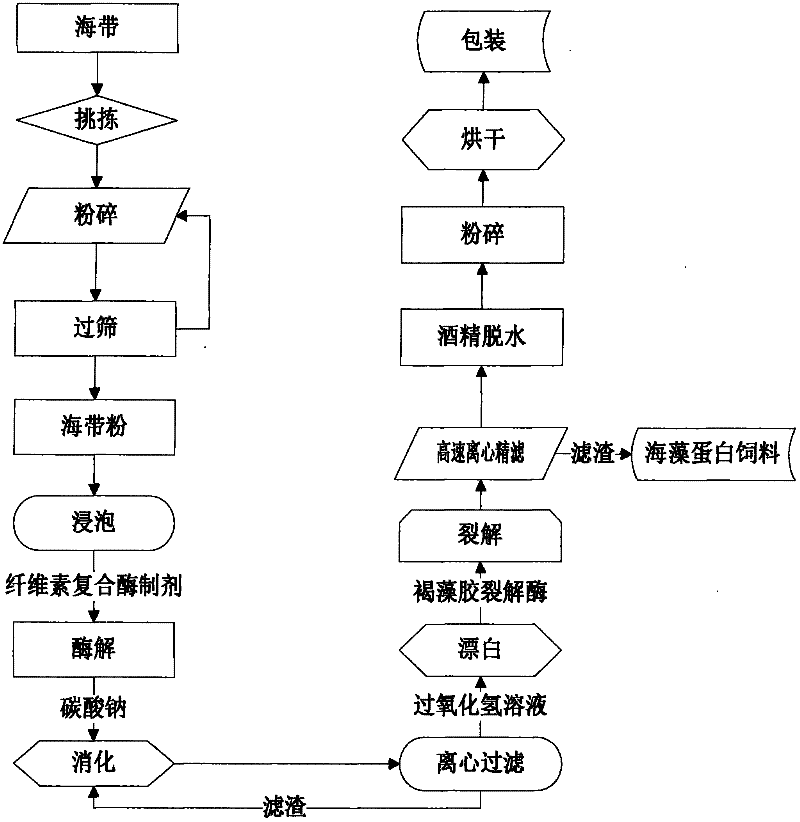

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare sea-tangle powder: cut the washed sea-tangle into pieces, pulverize and sieve to obtain sea-tangle powder, re-grind and sieve the unsifted sea-tangle, and use a 100-mesh sieve for sieving;

[0026] (2) Soaking: put the kelp powder into the enzymolysis tank, add water 8 times the weight of the kelp powder, and stir until fully soaked;

[0027] (3) Cellulase enzymolysis: put 1600U / g cellulase preparation into the enzymolysis tank, the addition is 8% of the weight of kelp powder, stir well, add 10% hydrochloric acid solution to adjust the pH to 4-5 , enzymatic hydrolysis at a temperature of 55° C. for 3 hours to obtain a cellulase hydrolysis product;

[0028] (4) Digestion: Add 8% sodium carbonate by weight of kelp powder and hot water 10 times the weight of kelp powder to the cellulase hydrolyzate, and digest for 2 hours at a temperature of 50°C to obtain sodium alginate gel thing;

[0029] (5) Centrifugal filtration: the obtained sodium alginate jelly is se...

Embodiment 2

[0036] (1) Prepare sea-tangle powder: cut the washed sea-tangle into pieces, pulverize and sieve to obtain sea-tangle powder, and re-grind and sieve the unsifted sea-tangle; sieve with a 60-mesh sieve;

[0037] (2) Soaking: put the kelp powder into the enzymolysis tank, add water 12 times the weight of the kelp powder, and stir until fully soaked;

[0038] (3) Cellulase enzymolysis: put 1200U / g cellulase preparation into the enzymolysis tank, the addition is 12% of the weight of kelp powder, stir well, add 10% hydrochloric acid solution to adjust the pH to 4-5 , enzymatic hydrolysis at a temperature of 65° C. for 4 hours to obtain a cellulase hydrolysis product;

[0039] (4) Digestion: Add 13% sodium carbonate of kelp powder weight and 15 times hot water of kelp powder weight to the cellulase hydrolyzate, and digest for 3 hours at a temperature of 80° C. to obtain sodium alginate gel thing;

[0040] (5) Centrifugal filtration: the obtained sodium alginate jelly is separated ...

Embodiment 3

[0047] (1) Prepare sea-tangle powder: cut the cleaned sea-tangle into pieces, pulverize and sieve to obtain sea-tangle powder, and re-grind and sieve the unsifted sea-tangle; sieve with a 90-mesh sieve;

[0048] (2) Soaking: Put the kelp powder into the enzymolysis tank, add water 10 times the weight of the kelp powder, and stir until fully soaked;

[0049] (3) Cellulase enzymolysis: put 1400U / g cellulase preparation into the enzymolysis tank, the addition is 10% of the weight of kelp powder, stir well, add 10% hydrochloric acid solution to adjust the pH to 4-5 , enzymolysis at 60°C for 3.5 hours to obtain a cellulase hydrolysis product;

[0050] (4) Digestion: Add 11% sodium carbonate of kelp powder weight and 12 times hot water of kelp powder weight to the cellulase enzymolysis product, and digest for 150 minutes at a temperature of 60°C to obtain sodium alginate gel thing;

[0051] (5) Centrifugal filtration: the obtained sodium alginate jelly is separated from the residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com