Construction method of thin-wall prestressed concrete aqueduct

A construction method and concrete technology, applied in artificial waterways, water conservancy projects, buildings, etc., to achieve the effect of good application value, low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

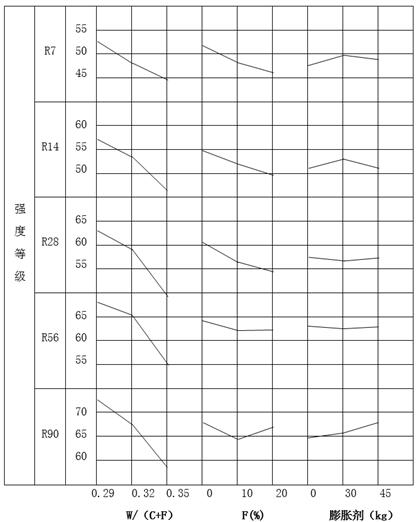

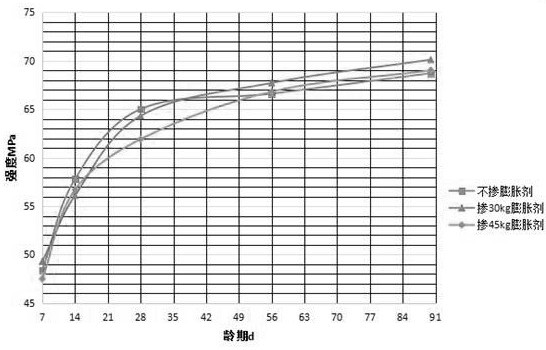

[0023] Since there are so many factors that can cause cracks in concrete, cracking in ordinary concrete is almost inevitable. When the shrinkage value of concrete is greater than the ultimate deformation value, and the tensile stress caused by shrinkage deformation is greater than the ultimate tensile strength of concrete, cracks will occur in concrete, resulting in a decrease in the integrity and durability of concrete. Cracking and shrinkage are caused by different reasons. People need a new type of concrete that can reduce cracking and shrinkage. Therefore, expansive concrete came into being. One type of expansive concrete is to add expansion agent during the concrete preparation process to make shrinkage-compensating concrete. The theoretical basis for the application of shrinkage-compensated concrete in my country is the theory of compensation for shrinkage proposed by Academician Wu Zhongwei. He pointed out that the final deformation value D of concrete (limited expansi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com