Construction method for water-cutoff-free maintenance of aqueduct connecting seams

A construction method and joint joint technology, applied in water conservancy projects, artificial waterways, infrastructure engineering, etc., can solve the problems of short service life, poor water impact resistance, poor sealing, etc., to ensure service life, reliable sealing, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

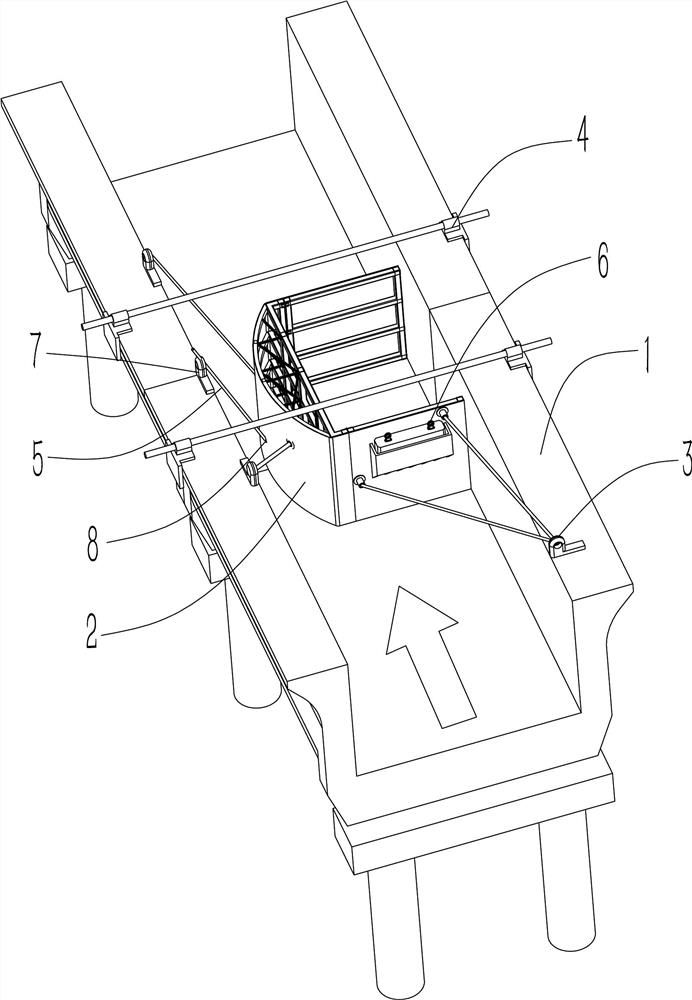

[0058] like Figure 1~12 As shown, a construction method for the continuous water repair of the aqueduct includes installing the enclosure device 2 on the aqueduct 1 for sealing, and the enclosure device 2 covers 1 / 2 of the width of the transition channel 1 on the projection plane, and the enclosure The construction area in device 2 is cleaned up, the connection joints are cut, chiseled and cleaned, and then the waterstop is replaced, concrete backfilled and the connection joints are embedded and sealed, and the operation is repeated on the other side of the aqueduct 1. The enclosure device 2 covers 1 / 2 of the width of the super transition tank 1 on the projection surface, which ensures that the enclosure device 2 can be moved to the other side for maintenance and construction after the enclosure device 2 is repaired and constructed on the other side. When the maintenance arrives, the enclosure device 2 leans against the aqueduct 1 to form a sealed construction area with an up...

Embodiment 2

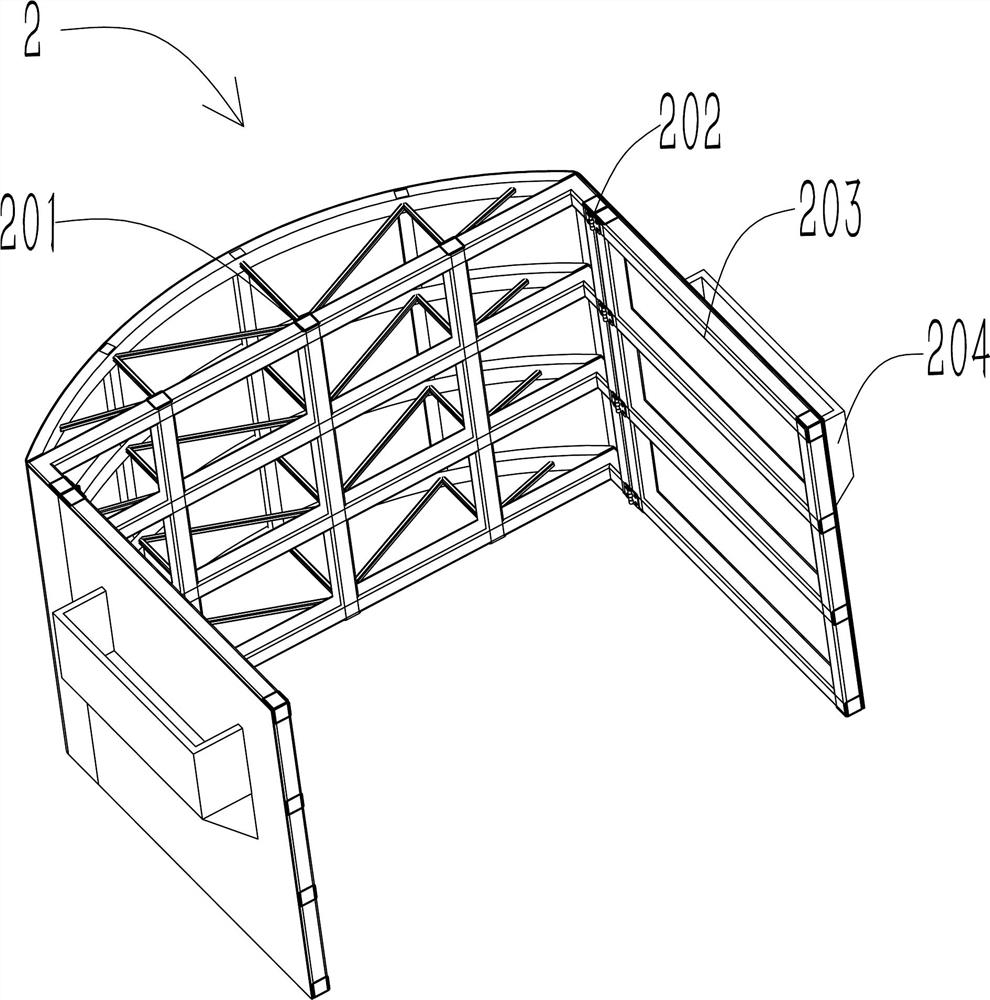

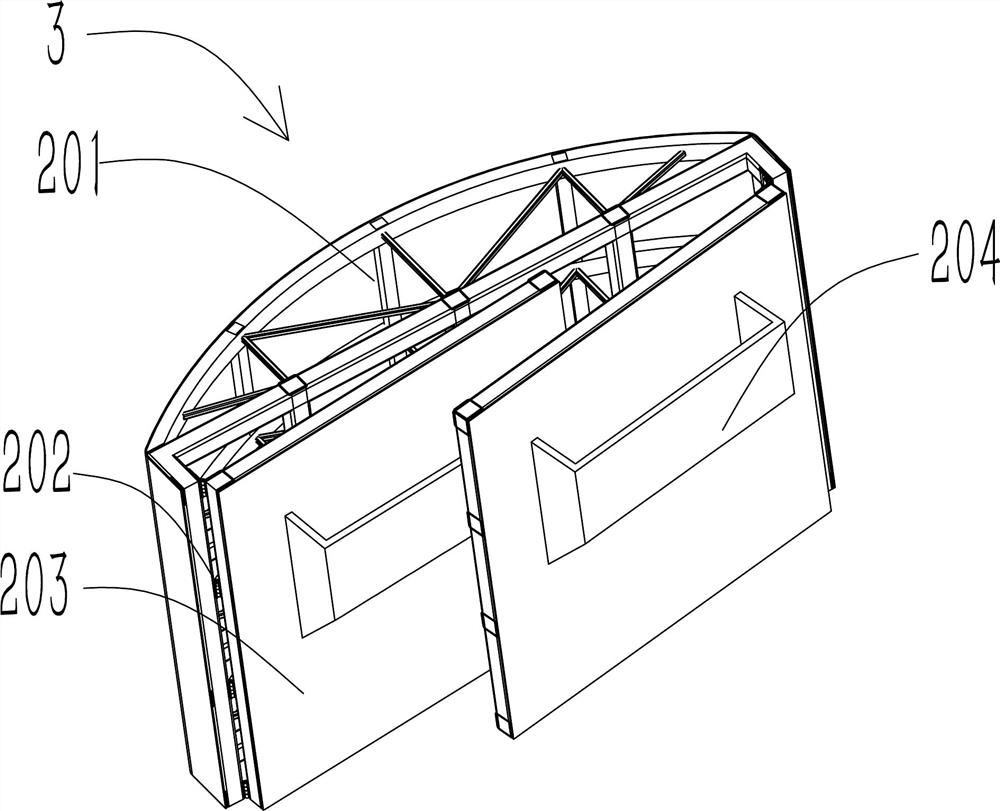

[0092] Further illustrate in conjunction with embodiment 1, as Figure 1~8 As shown, the method for sealing the enclosure device 2 on the aqueduct 1 is as follows: the folded enclosure device 2 is hoisted to the joint construction site of the aqueduct 1 by a crane, and the enclosure device 2 is lowered to the bottom of the aqueduct 1 by the crane. Sufficient space on the inner side of the aqueduct 1 is convenient for the expansion of the enclosure device 2; the second support 203 on the enclosure device 2 is opened to the state inside the vertical aqueduct 1 by pulling the rope; The containment device 2 is hoisted and translated until the end of the second support 203 abuts against the inner side of the aqueduct 1; the rope on the second support 203 is pulled and tightened and fixed in the fixed pile 3 on the aqueduct 1; the pull rod device 4 is installed On both sides of the aqueduct 1, adjust the pull rod device 4 to a tight state; by adjusting the push rod 5 in the push adj...

Embodiment 3

[0094] Further illustrate in conjunction with embodiment 1, as Figure 9~12 As shown, the method of cleaning the construction area in the enclosure device 2, cutting, gouging and cleaning the connection joints is as follows: the water in the sealed construction area in the enclosure device 2 is pumped out and discharged into the downstream through the water pump; Descend to the bottom of the aqueduct 1 through the escalator, and cut deep seams on the bottom of the aqueduct 1 and both sides of the inner connecting seam; manually use a steel needle to chisel out the concrete in the seam until the damaged waterstop is seen, and take it out Damage the waterstop, and level the ground of the slit; clean up the sand and stones and other sundries in the slit to ensure that there is no floating slurry, floating soil, and no oil in the slit, so that the slit wall must not have water and keep it as dry as possible; The method for replacing the waterstop, backfilling with concrete and emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com