Flue non-return valve

A check valve and flue technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of hindering the rise of smoke in the vertical flue, degrading the effect of oil fume exhaust, and affecting the smooth flow of the vertical flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

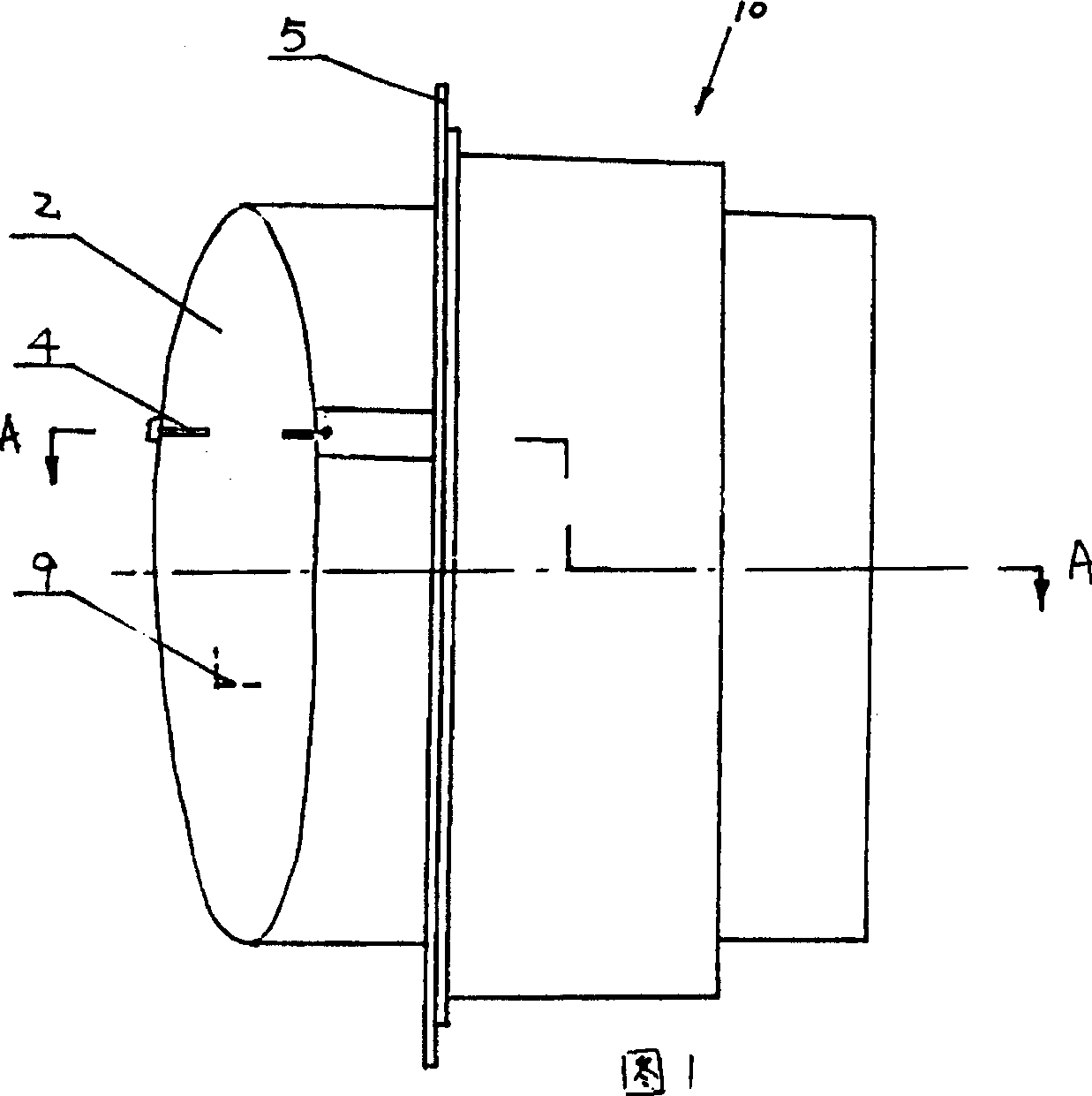

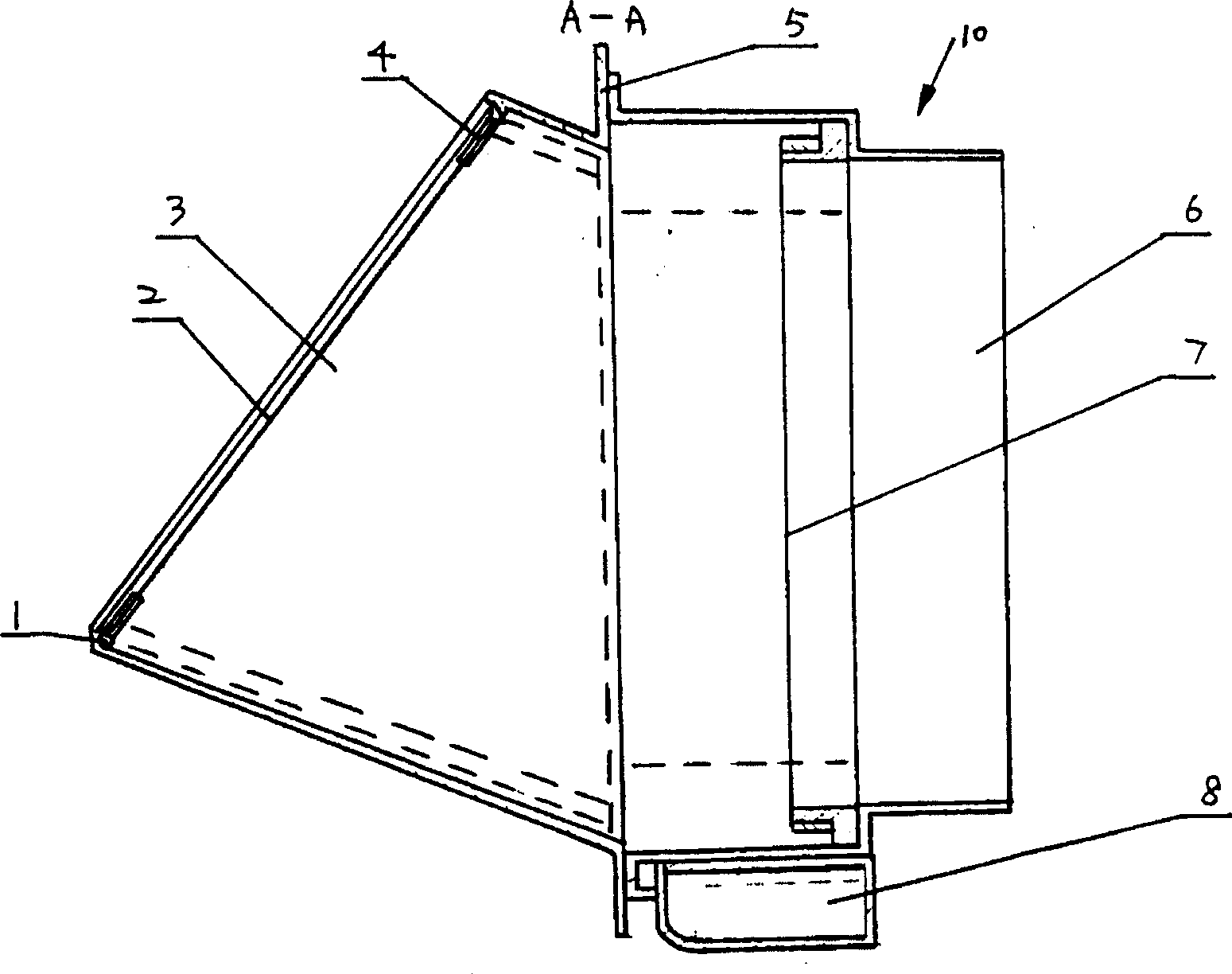

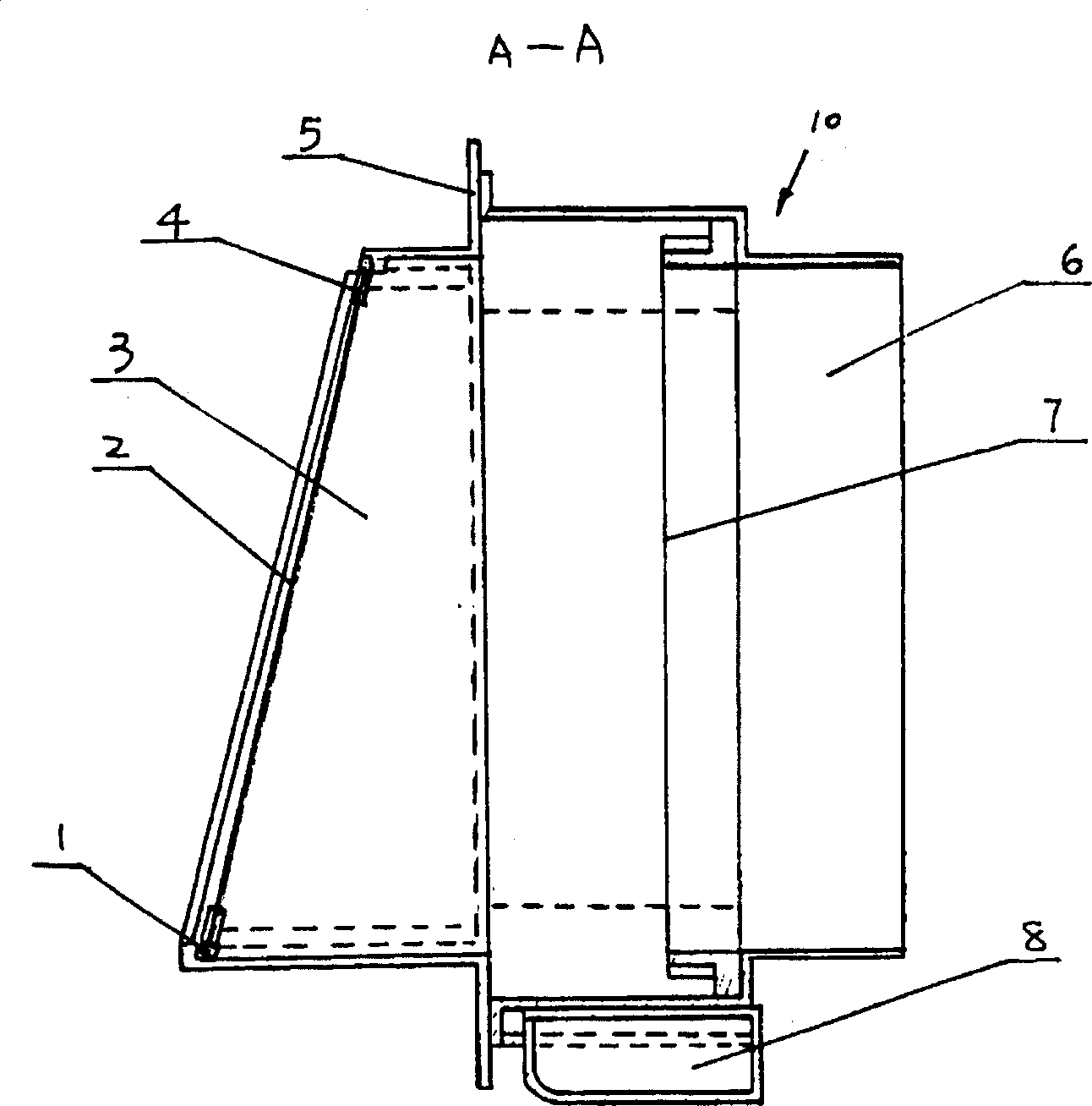

[0012] See attached drawings 1 to attached Figure 4 , a flue check valve, comprising a casing 10 and a fume passage arranged in the casing 10, the two ends of the fume passage are respectively provided with an air inlet 6 and an air outlet 3, and the valve plate 2 is arranged on the said fume passage The mouth of the air outlet 3, and the valve plate 2 is rotatably connected to the housing 10 through the valve plate rotating shaft 4; the valve plate 2 has two working positions, and the first working position is that the valve plate 2 is in the Closed state, at this time the valve plate 2 covers the mouth of the air outlet 3; the second working position is that the valve plate 2 is in an open state, at this time the valve plate 2 moves to expose the air outlet 3; the valve plate 2 The plane where it is located is substantially perpendicular to the horizontal plane in the second working position, the axis line of the valve plate rotating shaft 4 intersects the horizontal plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com