Static and dynamic load test method suitable for large steel aqueduct structure

A test method, a large-scale technology, applied in the direction of testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/compression, and measuring devices, which can solve the problems affecting the accuracy of load tests, the lack of experimental data, Time-consuming and labor-intensive problems, to achieve the effect of saving test cost, simple loading method, and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Aqueduct static and dynamic load test process

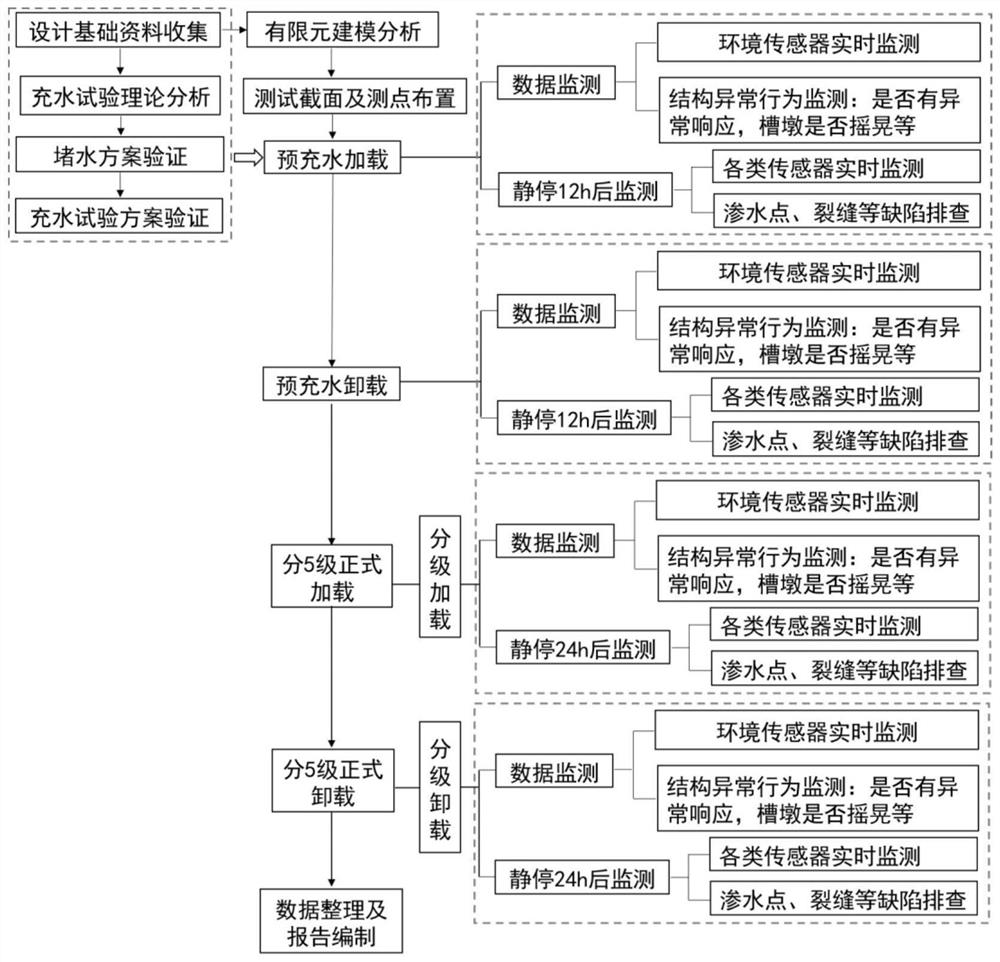

[0046] For the load test of the aqueduct structure, the test procedure is as follows figure 1 As shown, the static and dynamic information of the steel aqueduct structure is collected, and the data monitoring process is as follows:

[0047] (1) Various monitoring equipment should be arranged in place before formal water injection, that is, start monitoring and recording data.

[0048] (2) After the monitoring equipment is arranged, the monitoring work should be carried out in time, and the changes of each part of the aqueduct should be understood according to the real-time monitoring data. When the monitoring data are within the allowable range of the design, and there is no obvious fluctuation for 1 hour, it means that the structural coordination deformation has been stabilized, and the water filling test can be carried out. The monitoring data at this time can be used as the initial data of the water filli...

Embodiment 2

[0054] Embodiment 2 Determination of test section and measuring point

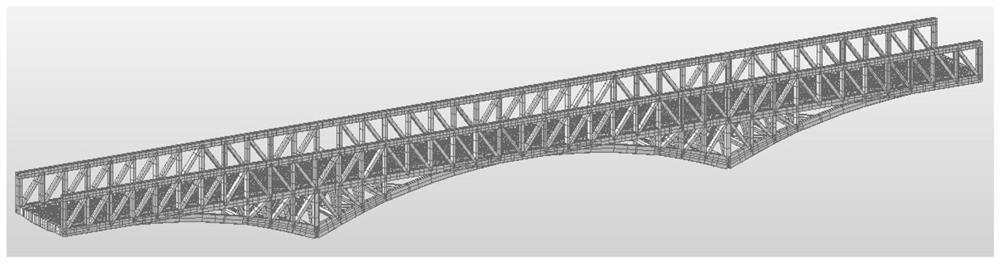

[0055] The selection of the test section and the arrangement of the measuring points are a key step in the early stage of the aqueduct load test. For the steel aqueduct structure, the purpose of the water filling test is to test whether the stress of the key section of the aqueduct structure meets the requirements of the code. According to the finite element model analysis, Focus on selecting the most unfavorable force-bearing position of the structure as the test section. The layout of measuring points should follow the following principles:

[0056] (1) Under the design load, the test section with the maximum positive bending moment;

[0057] (2) Under the design load, the test section with the maximum negative bending moment;

[0058] (3) Under the design load, the maximum tensile and compressive stress positions of the rigid aqueduct;

[0059] (4) Displacement monitoring and measuring points for aqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com