Telescopic device, aqueduct and installation method of telescopic device

A telescopic device and aqueduct technology, applied in the field of aqueducts, can solve the problems of aqueduct gaps, water seepage, poor temperature performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

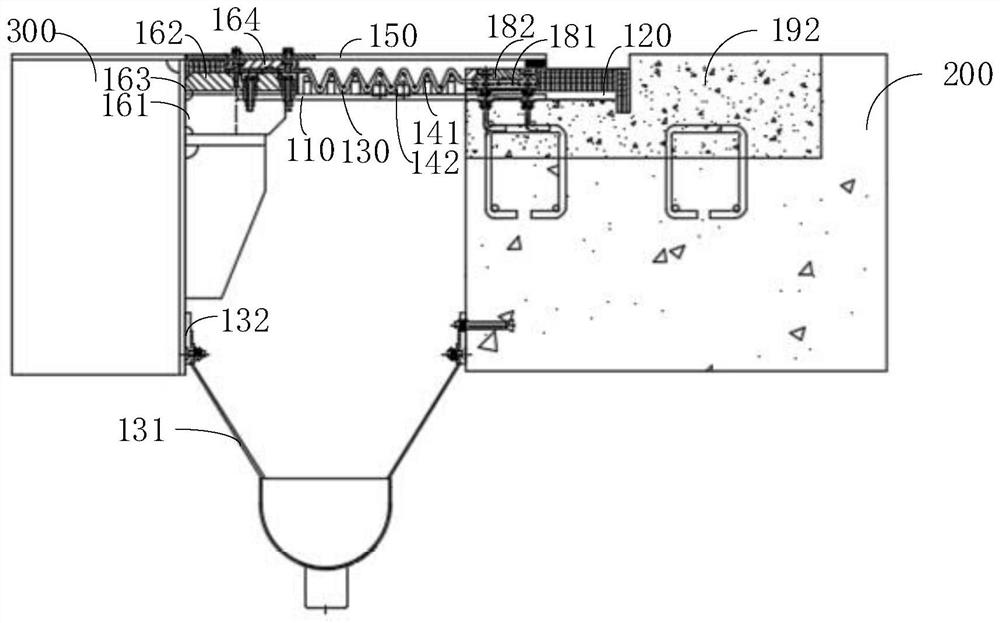

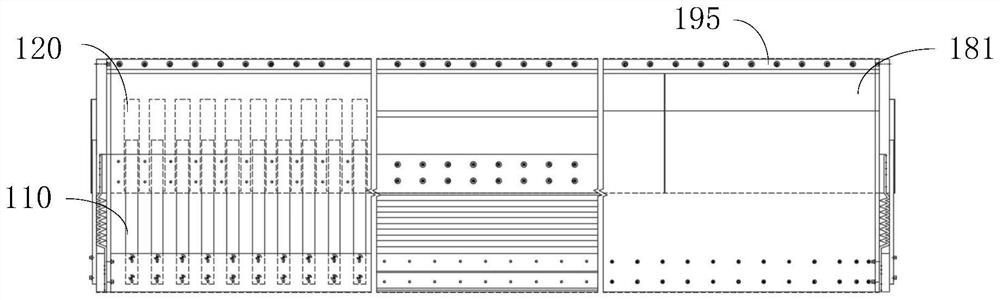

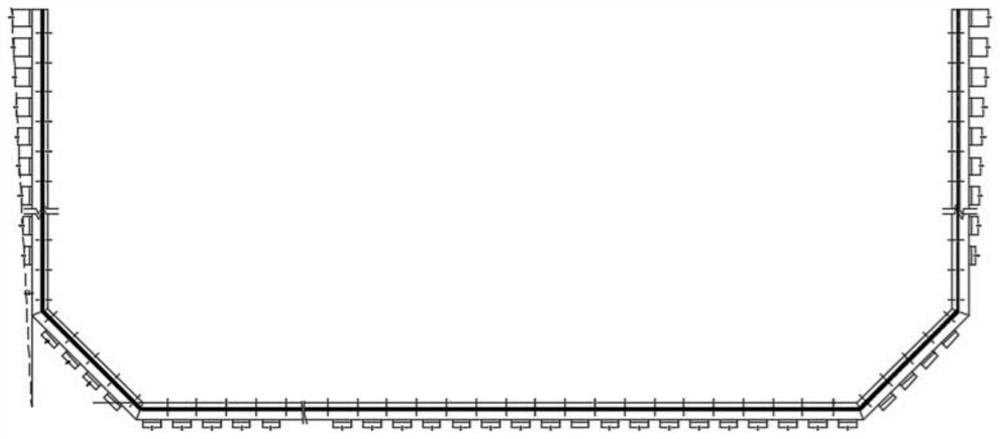

[0118] This embodiment provides an aqueduct, including a steel aqueduct 300, a concrete aqueduct 200 and the telescopic device described in Embodiment 1, the steel aqueduct 300 and the concrete aqueduct 200 are arranged at relative intervals, and an expansion joint is formed between the two; the telescopic device One end is fixed to the concrete aqueduct 200 , and the other end is fixed to the steel aqueduct 300 . Therefore, the beneficial effects mentioned in the first embodiment are also provided, and will not be repeated here.

Embodiment 3

[0120] This embodiment provides an installation method of Processing Embodiment 1, including the following steps:

[0121] Fix the sliding box 120 to the concrete aqueduct 200, install the first end of the telescopic bar 110 on the end of the steel aqueduct 300, and make the second section of the telescopic bar 110 slide and fit with the sliding box 120;

[0122] Install the first waterstop 130;

[0123] sealing the telescopic strip 110 and the first end of the first waterstop 130;

[0124] sealing the telescopic strip 110 and the second end of the first waterstop 130;

[0125] Install the cover plate 150 .

[0126] The sliding box 120 and the telescopic bar 110 are slidably matched to realize the telescopic connection between the steel aqueduct 300 and the concrete aqueduct 200; the first water stop 130 is installed to realize the formation of closed water conditions; the telescopic bar 110 and the first water stop 130 Both ends of the waterstop are sealed to form an anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com