UHPC precast arched girder combined type aqueduct

A combined and aqueduct technology, applied in irrigation pipelines, applications, buildings, etc., can solve problems such as difficult construction, and achieve the effect of reducing construction difficulty, ensuring integrity, and relaxing construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

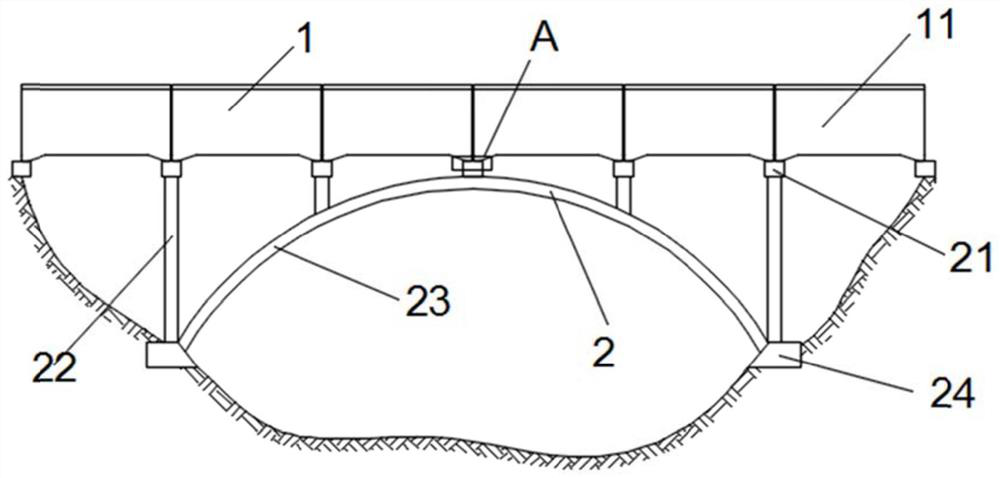

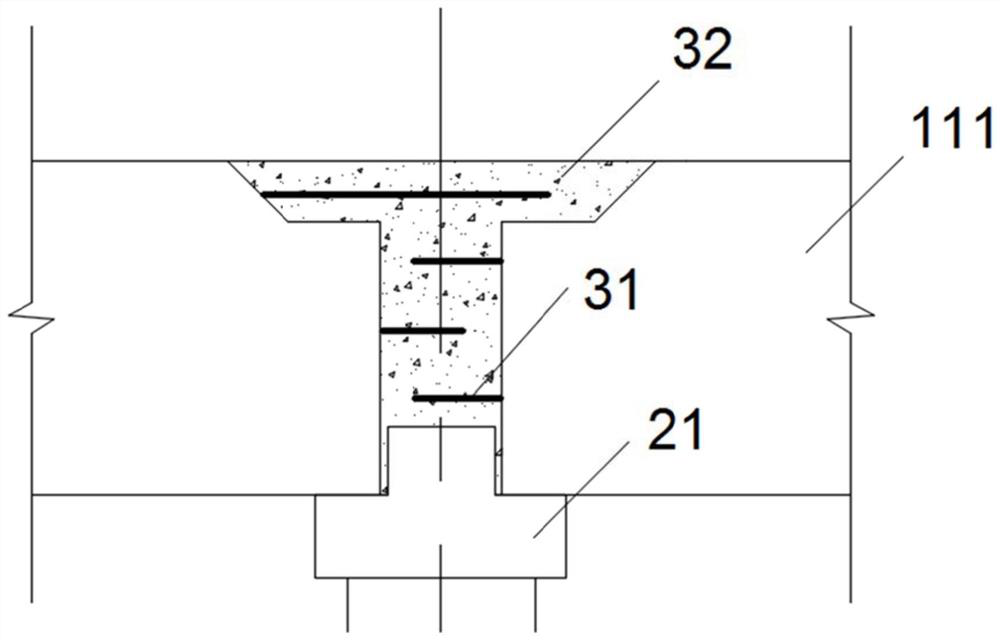

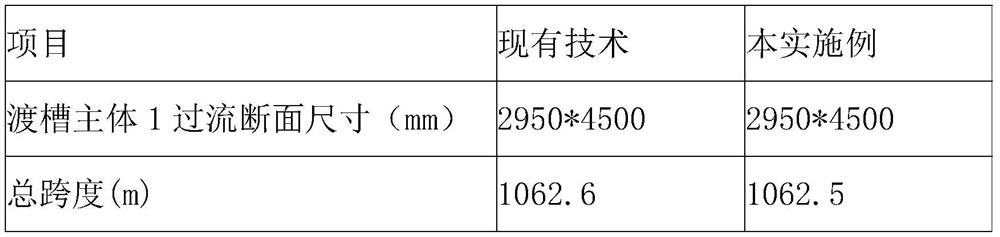

[0025] Such as figure 1 As shown, a UHPC prefabricated arch-beam combined aqueduct includes an arch structure 2 and an aqueduct body 1. The end rib 111 of the aqueduct body 1 is hinged to the top of the arch structure 2, which can reduce the size of the aqueduct body 1 and the arch structure 2. The friction between the struts 22. The main body of the aqueduct 1 includes multiple sections of prefabricated tank bodies 11 , and a wet joint structure 3 is provided between two adjacent prefabricated tank bodies 11 . The groove-arch stiffness ratio β is the ratio of the bending stiffness EJ of the main section 1 of the aqueduct to the compressive stiffness EA of the section 23 of the arch (ie β=EJ / EA). . The axis equation of the structure 2 on the arch is (where: x and y 0 is the coordinate on the axis of the arch body, f is the height of the rise, and l is the span), and the rise-span ratio (f / l) of the arch body 23 of the structure 2 on the arch is 1 / 5. The main body 1 of th...

Embodiment 2

[0036] In this embodiment, except that the following technical features are different, other technical features are the same as in Embodiment 1:

[0037] The rise-span ratio (f / l) of the arch body 23 of the arch structure 2 in this embodiment is 1 / 14 instead of 1 / 5.

[0038] In the ultra-high performance concrete in this embodiment, the steel fibers are directly 0.4 mm fine steel fibers instead of 0.15 mm fine steel fibers.

[0039] In this embodiment, carbon fibers are added instead of polyvinyl alcohol fibers and high elastic modulus polyethylene fibers, and the volumetric dosage of carbon fibers is 0.6% instead of 0.1%.

[0040] The tangent of the end tangent of the arch body 23 in this embodiment is replaced by 0.35 by 1.38.

[0041] In this embodiment, the length of the exposed end of the steel bar 31 is 550 mm instead of 250 mm; in the same horizontal plane, the width of the wet joint structure 3 is 100 mm longer than the projected length of the exposed end of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com