Construction method of aqueducts above bridge

A construction method and aqueduct technology, which is applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as unbearable and increased difficulty in the construction of aqueducts above bridges, and achieve the effects of short construction period, simple and efficient construction, and safe passage of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

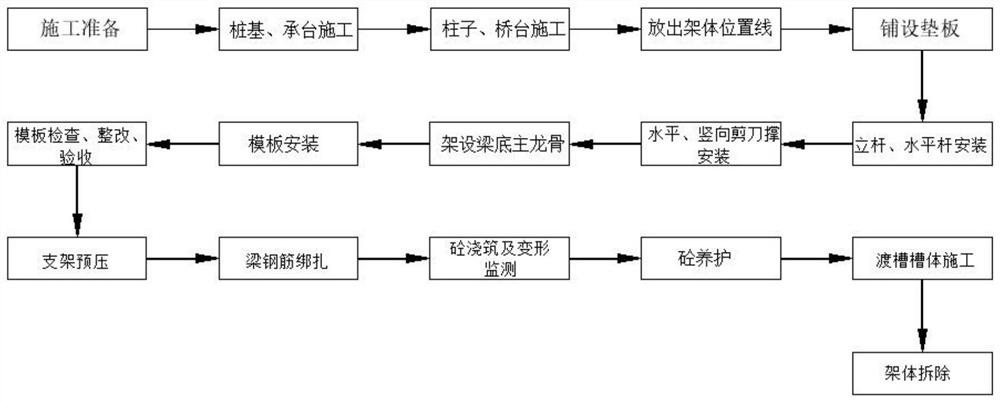

[0033] On-site layout: adopt the principle of layout;

[0034] (1) The plane layout is scientific and reasonable, and the construction site occupies a small area;

[0035] (2) Reasonable organization of transportation to reduce secondary handling;

[0036] (3) The division of the construction area and the temporary occupation of the site shall meet the requirements of the overall construction deployment and construction process, and reduce mutual interference;

[0037] (4) Make full use of existing structures and existing facilities to provide project construction services to reduce the construction cost of temporary facilities;

[0038] (5) Meet the requirements of energy saving, environmental protection, safety and fire protection.

Embodiment 2

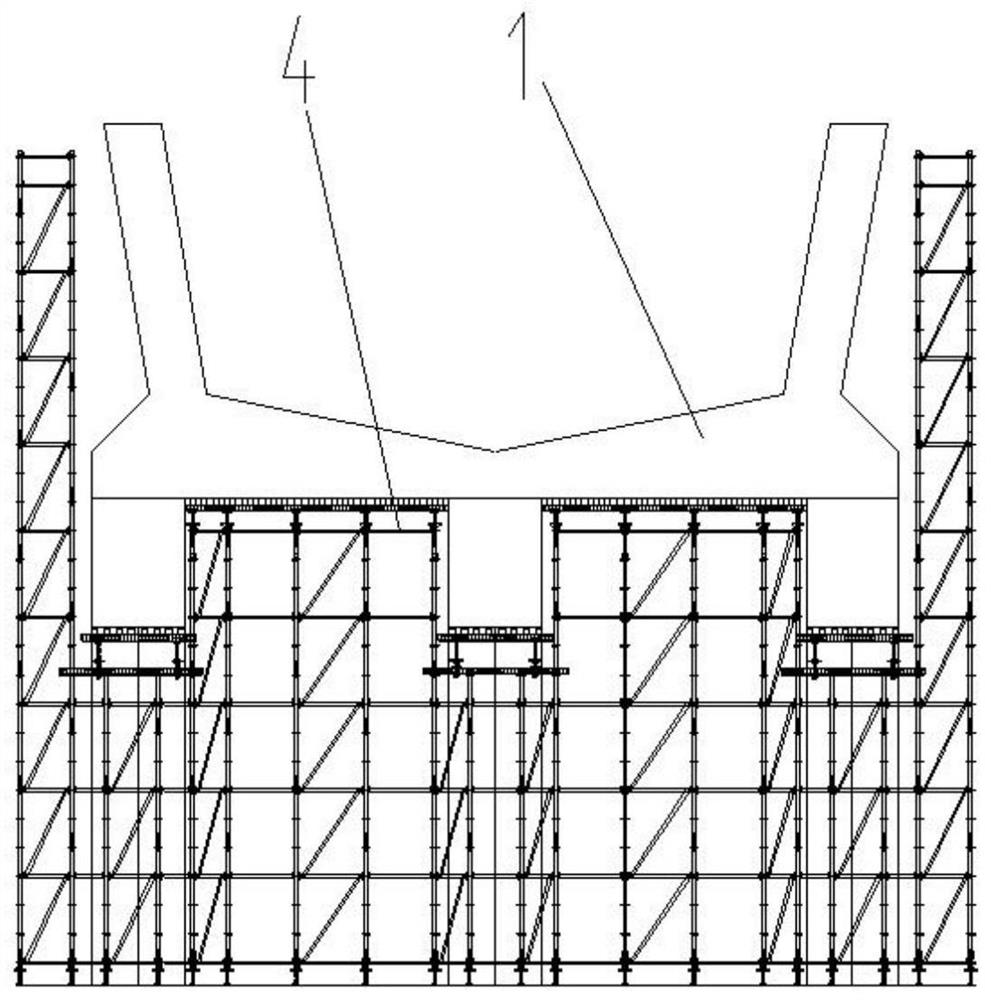

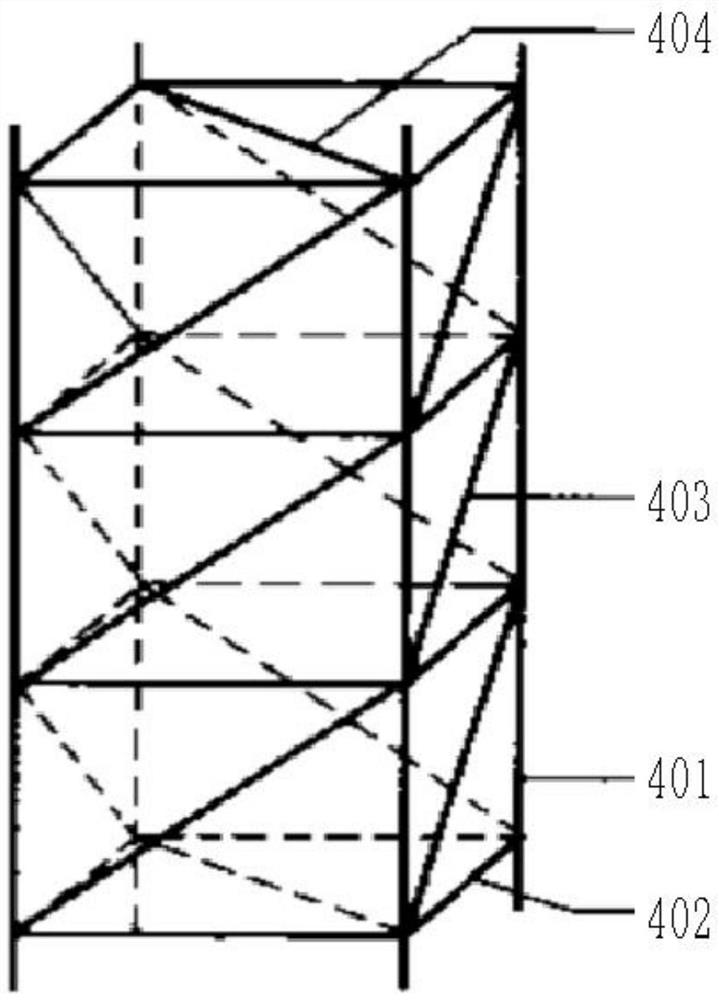

[0040]Technical parameters of oversized load formwork: maximum height of support: 12m; width of support: 16.5m; length of single span of support: 13.2m; pole: 3m / 2m; m; cross bar: set at a step distance of 1.5m; scissor brace: set at a step distance of 4; gravity abutment wall parts: set at a step of 3m; pillars: set at a step of 3m; vertically inclined Tie rods: The unit truss combination method of the truss-type support structure adopts matrix type; 100mm square wood) spacing 0.1m.

[0041] Support system design:

[0042] (1) Pole foundation: The left panel is the newly built asphalt pavement. Before the formwork support is erected, 300*300*6cm bluestone slabs are laid at the foot of the pole, and the paving is stable. The right panel is across the k5+601.3 bridge. Twenty spans, the wet joints of the bridge slabs are weak positions;

[0043] (2) Longitudinal and horizontal beam support frame pole: adopt the buckle-type full hall support frame, and the vehicle door opening...

Embodiment 3

[0049] The foundation treatment of the support system; after checking and calculating the foundation of the pole, the bearing capacity of the foundation of the vertical and horizontal beams should be greater than 101Kpa, the bearing capacity of the foundation of the vertical pole of the aqueduct body should be greater than 176Kpa, the bearing capacity of the foundation of the vertical pole of the door opening should be greater than 70Kpa, and the bedding at the foot of the pole should be 300 *300*6cm bluestone slab, after testing, the compressive strength of the bluestone slab reaches 60Mpa, and the bearing capacity meets the requirements.

[0050] The foundations of the vertical and horizontal beams and the uprights of the aqueduct body are built on the left asphalt road and the right bridge. + 16cm thick graded gravel + 45cm thick cement stabilization layer + 18cm thick asphalt layer, the bearing capacity of the foundation bearing capacity test under the road bed is above 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com