Construction method for making prestressed back for box-culvert jacking

A construction method and prestressing technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of heavy traffic, increased construction difficulty, and inability to provide large-area working faces, so as to achieve less investment in construction equipment and better construction efficiency. The method is simple and the damage is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

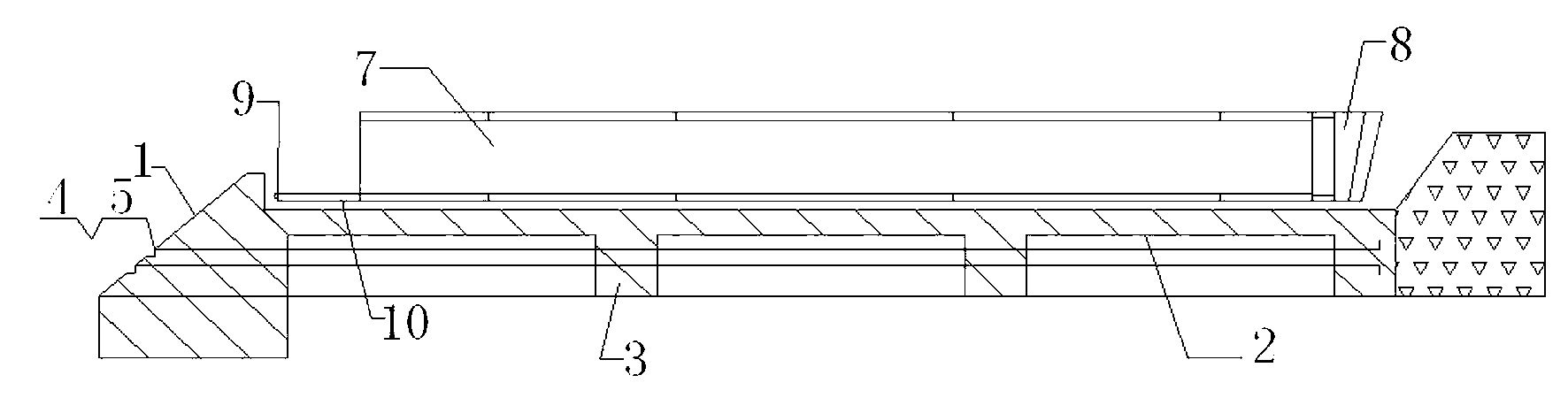

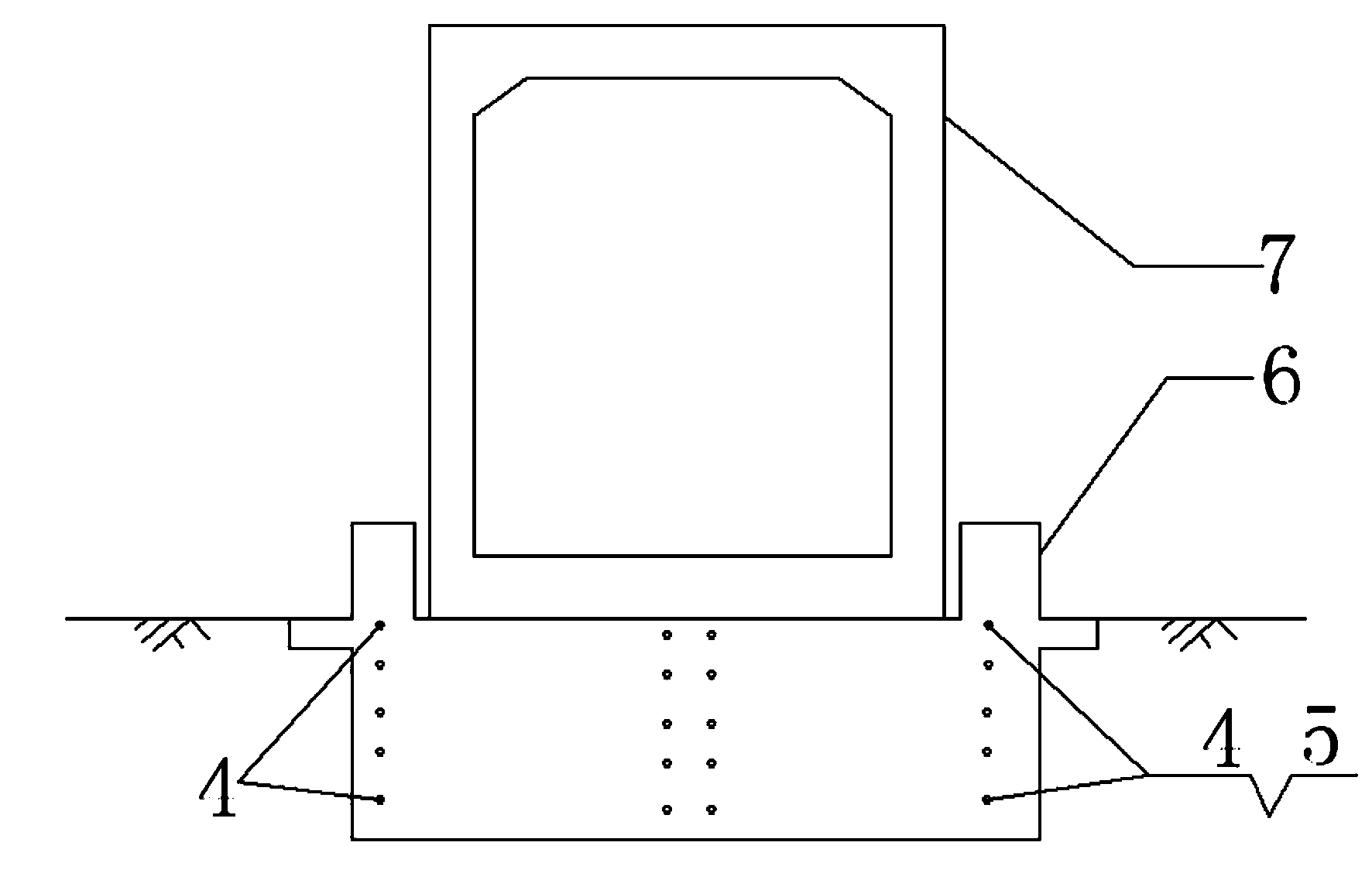

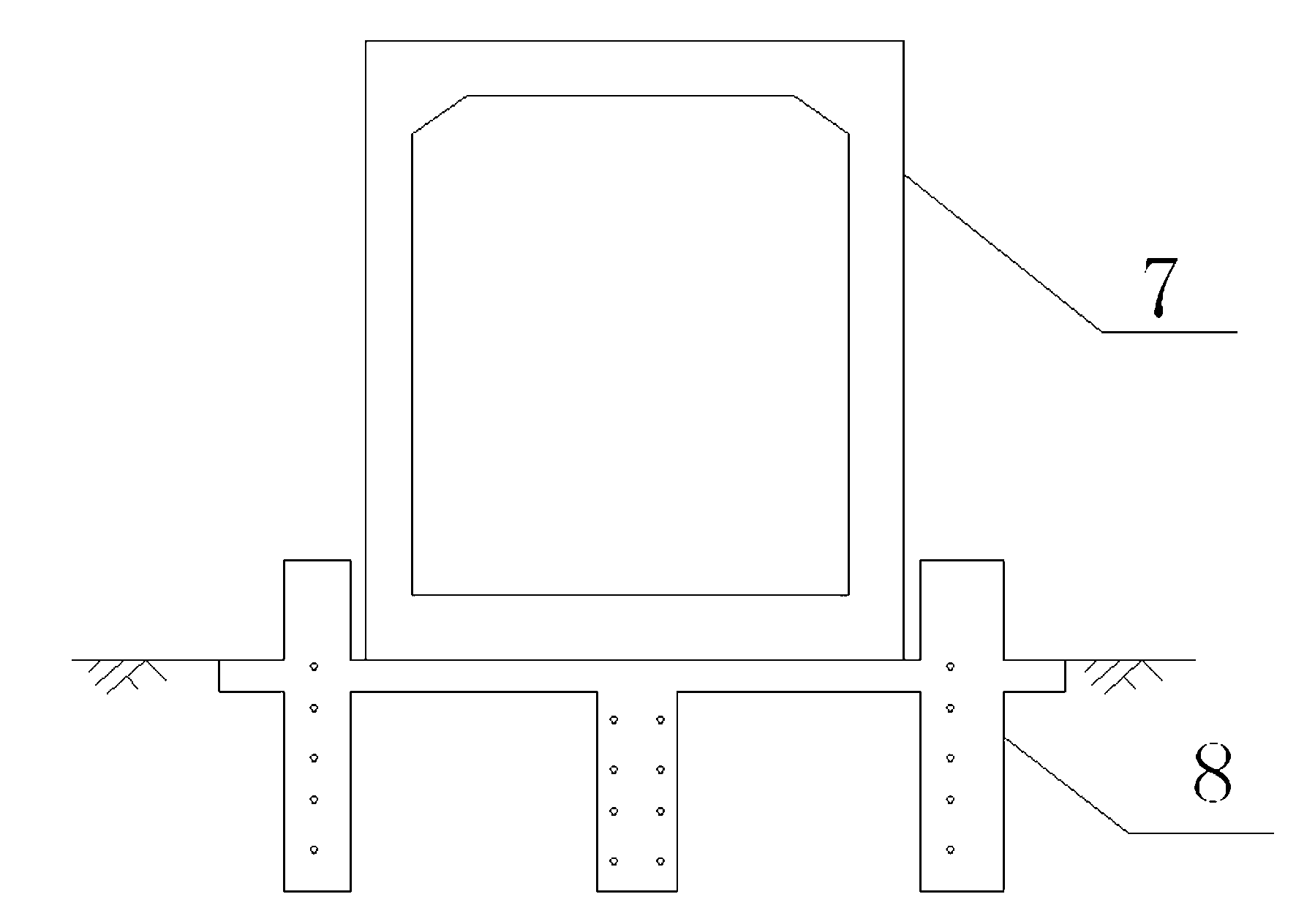

[0037] A construction method for box culvert jacking by making a prestressed back, comprising the following process steps:

[0038] 1. Carry out accurate setting-out and positioning of the prestressed back, the slide plate and the tooth wall arranged under the slide plate; dig the foundation pit, and make the prestressed back 1, slide plate 2 and multiple teeth when the foundation pit is controlled to the design requirements wall 3;

[0039] ① When making the tooth wall 3, the formwork adopts the masonry brick mold, and then pours concrete;

[0040] ② Bind the steel bars of the prestressed back, slide plate and tooth wall, and embed multiple prestressed pipes 5 with prestressed steel strands 4 in the prestressed back and slide according to the design requirements;

[0041] 2. Before pouring the prestressed back, first solidify the soil in contact with the working surface, drive anchor rods into the soil and inject cement slurry to solidify the soil; tidy up the working surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com