Cast-in-situ concrete filling component

A technology of filling components and cast-in-place concrete, which is applied to building components, building structures, floor slabs, etc., can solve the problems of surface damage of solid lightweight material components, affecting the construction quality of the floor, and easy damage to the outer surface, reducing the The effect of production time, convenient construction and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

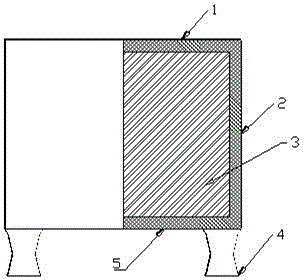

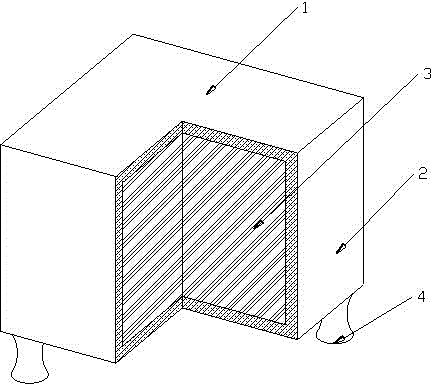

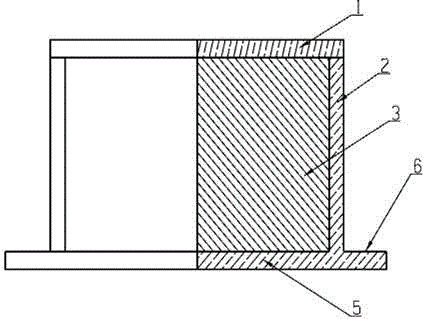

[0019] The present invention comprises a cover plate 1, surrounding sides 2, lower bottom plate 5, filling material 3, such as figure 1 , figure 2 As shown, it is a cavity with an opening formed by the lower bottom plate 5 and the surrounding sides 2, and the filling material 3 is inserted into the cavity, and then the lower bottom plate 5 and the surrounding sides 2 are surrounded by the opening end of the hollow shell and the cover plate 1 connection, so that the cover plate, the surrounding side 2, the lower bottom plate 5, and the filler are sealed and stacked into a solid whole. The shell formed by the cover plate 1, the surrounding sides 2, and the lower bottom plate 5 contains cement concrete, early Strong agent, quick-setting agent, bubble seal, cellulose ether, polycarboxylate high-performance water reducer, polymer anti-cracking mortar, at least one or more or all of them; the filling material 3 is formed by AB foam Hard resin, polystyrene sheet mixed extrusion. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com