Preparation method for anti-oxidation composite hard coating

A hard coating and anti-oxidation technology, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problem that the oxidation resistance is difficult to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

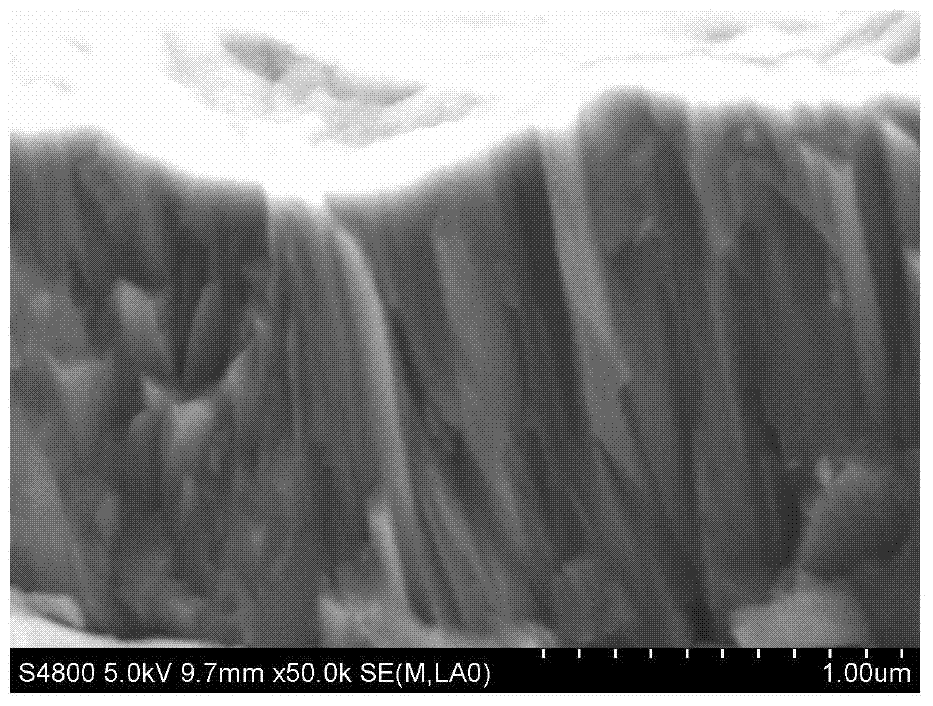

Embodiment 1

[0031] Carbide milling cutters are degreased, sandblasted and ultrasonically cleaned by conventional methods and placed in the coating chamber, and then the coating chamber is evacuated to 5.0×10 -3 pa, argon is introduced to make the total pressure in the vacuum chamber 4.0×10 -1 pa, and control the column arc current to 150A to heat the tool to be plated for 150min; at a pressure of 1.8×10 -1 Under the protection of Pa argon gas, the DC bias voltage of the control tool is -200V, the pulse bias voltage is -600V, the arc current of the control column is 120A, and the tool is cleaned with 7.0KW plasma for 30min; 2 =1 / 2 of Ar and N 2 The mixed gas, keep the pressure at 3.0×10 -1 pa, heat the Ti ingot with a column arc, the current of the column arc is 180A, the power is 11.0KW, and it is plated for 10min at DC bias voltage -200V, pulse bias voltage -400V; keep Ar / N 2 =i / 2 and 3.0×10 -1 The pressure of Pa is sputtering the composite alloy target material of Ti:Al:La=69:30:1 b...

Embodiment 2

[0035] Carbide turning tools are degreased, sandblasted and ultrasonically cleaned by conventional methods and placed in the coating chamber, and then the coating chamber is evacuated to 5.0×10 -3 pa (claim is 5.0×10 -3 pa), and argon gas was introduced to make the total pressure in the vacuum chamber 4.0×10 -1 pa, and control the column arc current to 160A to heat the tool to be plated for 80min; at a pressure of 1.5×10 -1Under the protection of Pa argon gas, the DC bias voltage of the control tool is -200V, the pulse bias voltage is -500V, the arc current of the control column is 130A, and the tool is cleaned with 8.0KW plasma for 30min; 2 =1 / 3 of Ar and N 2 The mixed gas, keep the pressure at 3.5×10 -1 Pa, heat the Ti ingot with a column arc, the current of the column arc is 200A, the power is 12.0KW, and it is plated for 10min at DC bias voltage -200V, pulse bias voltage -500V; keep Ar / N 2 =1 / 3 and 3.5×10 -1 The pressure of pa is sputtering the composite alloy target ...

Embodiment 3

[0039] The high-speed steel taps are degreased, sandblasted and ultrasonically cleaned by conventional methods and put into the coating chamber, and then the coating chamber is evacuated to 5.0×10 -3 pa, argon gas is introduced to make the total pressure in the vacuum chamber 3.0×10 -1 Pa, and control the column arc current to 140A to heat the tool to be plated for 40min; at a pressure of 1.5×10 -1 Under the protection of pa argon gas, the DC bias voltage of the control tool is -100V, the pulse bias voltage is -500V, the arc current of the control column is 140A, and the tool is cleaned with 9.0KW plasma for 15 minutes; 2 =1 / 1.5 of Ar and N 2 The mixed gas, keep the pressure at 3.0×10 -1 pa, heat the Ti ingot with a column arc, the current of the column arc is 180A, the power is 13.0KW, and it is plated for 5min under DC bias voltage -100V, pulse bias voltage -500V; keep Ar / N 2 =1 / 1.5 and 3.0×10 -1 The pressure of Pa is sputtering the composite alloy target of Ti:Al:La=69:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com