Method for manufacturing particle reinforced metal-based composite part through double-wire plasma arc surfacing

A plasma arc and composite material technology, applied in plasma welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problems of low utilization rate of ceramic powder and difficulty of ceramic powder entering the molten pool, so as to improve production efficiency , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

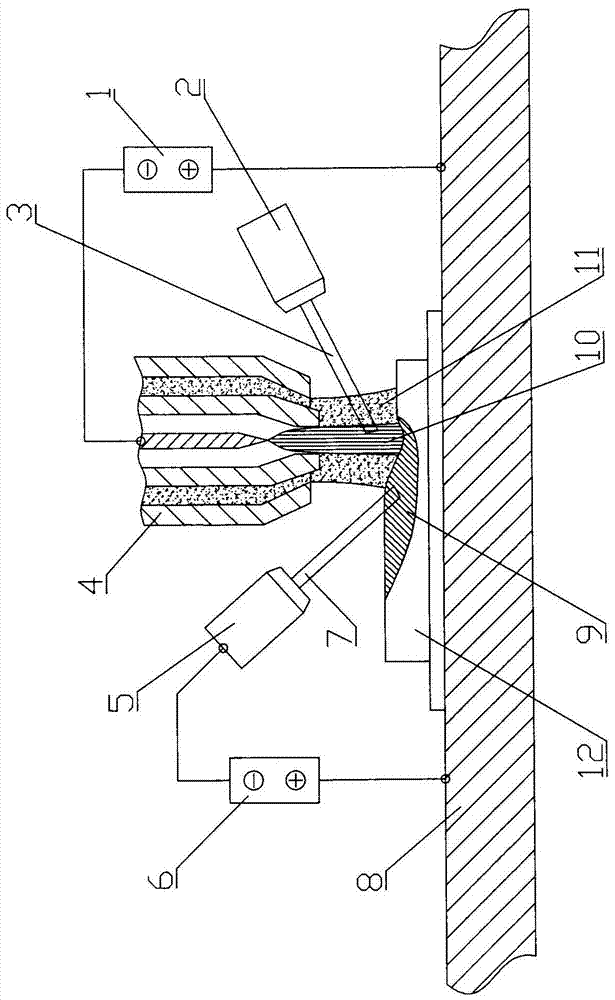

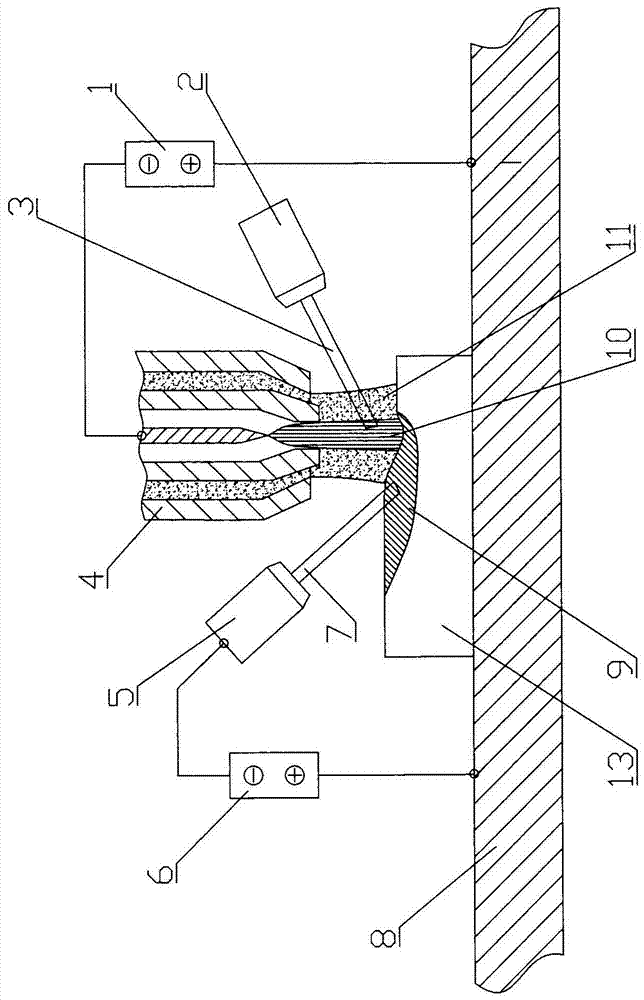

[0035] Embodiment 1: In this embodiment, silicon carbide particle-reinforced aluminum matrix composite parts are manufactured by using twin-wire plasma surfacing additive, and the specific steps are as follows:

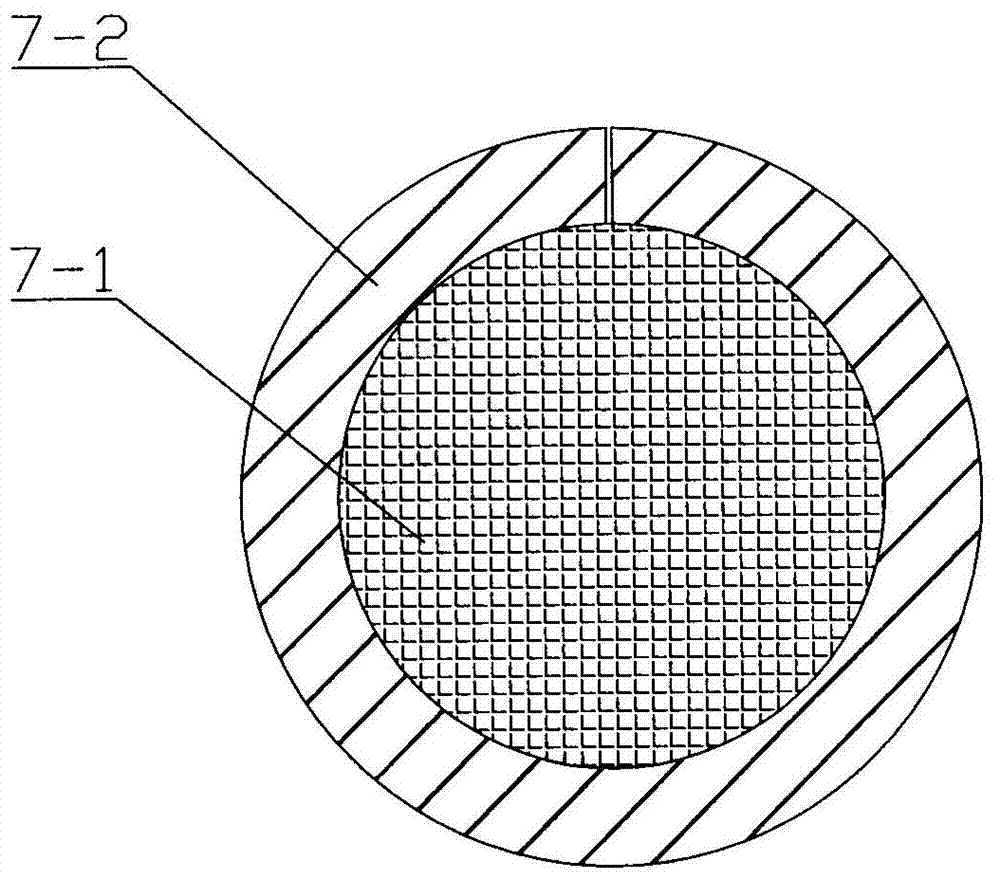

[0036] A. Preparation of flux-cored welding wire: the flux-cored welding wire 7 is prepared by rolling and drawing method, and the flux-cored welding wire 7 includes a flux core 7-1 and a shell 7-2. According to the components of the target composite material, the material of the drug core 7-1 and the material of the metal matrix of the shell 7-2 are selected. The component of the target composite material in this embodiment is a silicon carbide particle reinforced aluminum matrix composite material, and the drug core 7-1 is The mixture of silicon carbide ceramic powder and aluminum powder, the silicon carbide ceramic powder and aluminum powder are fully mixed by ball milling method, the ratio of silicon carbide ceramic powder and aluminum powder content is 1:2, the po...

Embodiment 2

[0047] Embodiment 2: In this embodiment, twin-wire plasma surfacing is used to add material to manufacture titanium carbide particle reinforced Inconel 625 alloy matrix composite material parts, and the specific steps are as follows:

[0048] A. Preparation of flux-cored welding wire: Prepare flux-cored welding wire 7 by rolling and drawing method. Flux-cored welding wire 7 includes flux core 7-1 and shell 7-2. Select the material and shell of flux core 7-1 according to the components of the target composite material 7-2 The material of metal matrix, the component of target composite material of this embodiment is titanium carbide particle reinforced Inconel 625 alloy matrix composite material, drug core 7-1 is titanium carbide ceramic powder and Inconel 625 alloy powder, adopts ball milling method to carbonize Titanium ceramic powder and Inconel 625 alloy powder are fully mixed, the content ratio of titanium carbide ceramic powder and Inconel 625 alloy powder is 1:3, the powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com