Patents

Literature

32results about How to "Achieve high-speed rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

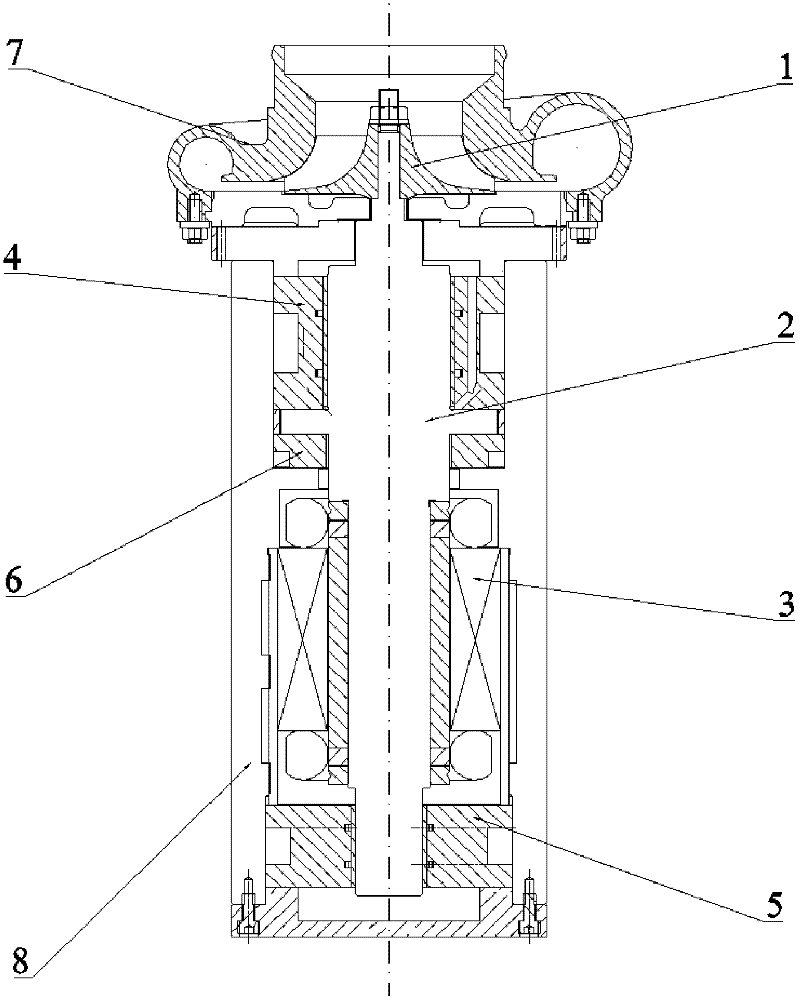

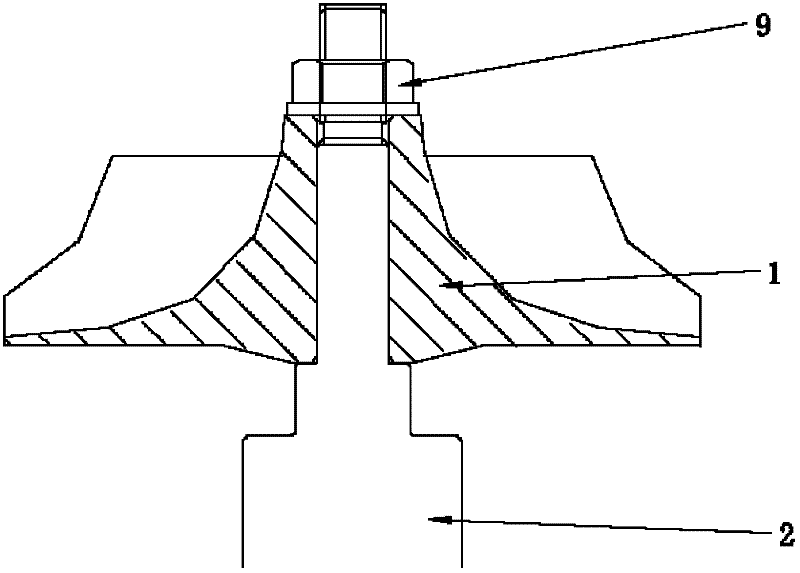

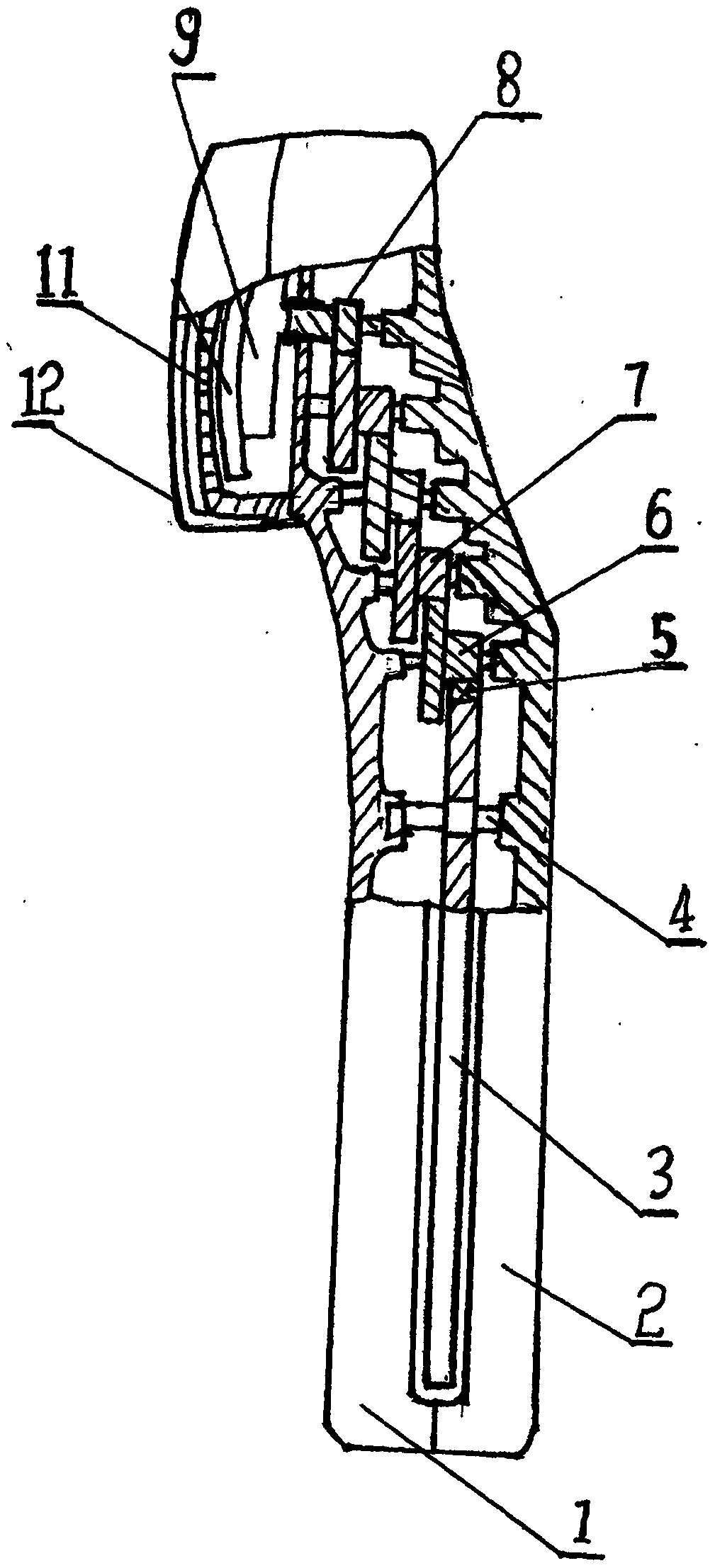

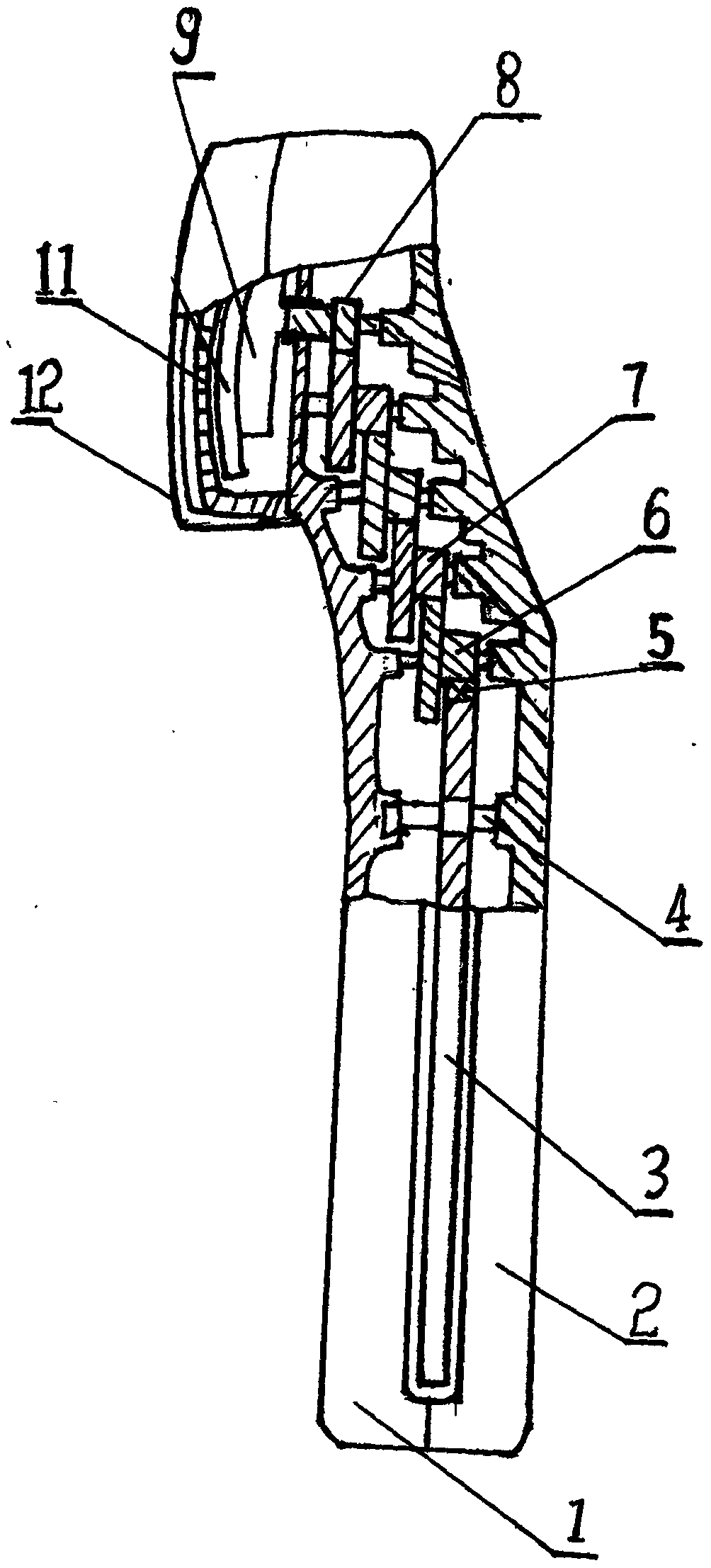

Air-suspension air-supply-adjustable air blower directly driven by high-speed electric machine

ActiveCN102200136AReduced noise and mechanical lossesImprove machine efficiencyPump componentsPump installationsSynchronous motorImpeller

The invention discloses an air-suspension air-supply-adjustable air blower directly driven by a high-speed electric machine. The air blower comprises a compressor impellor, a permanent magnetic synchronous motor rotor, a motor stator, a front radial air bearing, a rear radial air bearing, an axial thrust air bearing, a scroll and a motor shell; one end of the permanent magnetic synchronous motor rotor is connected with the compressor impellor; the rotor stator drives the permanent magnetic synchronous motor rotor to rotate; the front radial air bearing, the rear radial air bearing and the axial thrust air bearing support the permanent magnetic synchronous motor rotor in a suspension mode; the scroll is arranged at the periphery of the compressor impellor; and the motor shell is positioned at the peripheries of the motor stator, the front radial air bearing, the rear radial air bearing, the axial thrust air bearing and the permanent magnetic synchronous motor rotor. According to the invention, through driving the compressor impellor directly by the permanent magnetic synchronous motor rotor of the high-speed electric machine, a complex and expensive speeding system is omitted, noises and mechanical loss are reduced, the integral machine efficiency can be improved, the system is simple, and the air blower provided by the invention is convenient to install and transport.

Owner:宁波虎渡能源科技有限公司

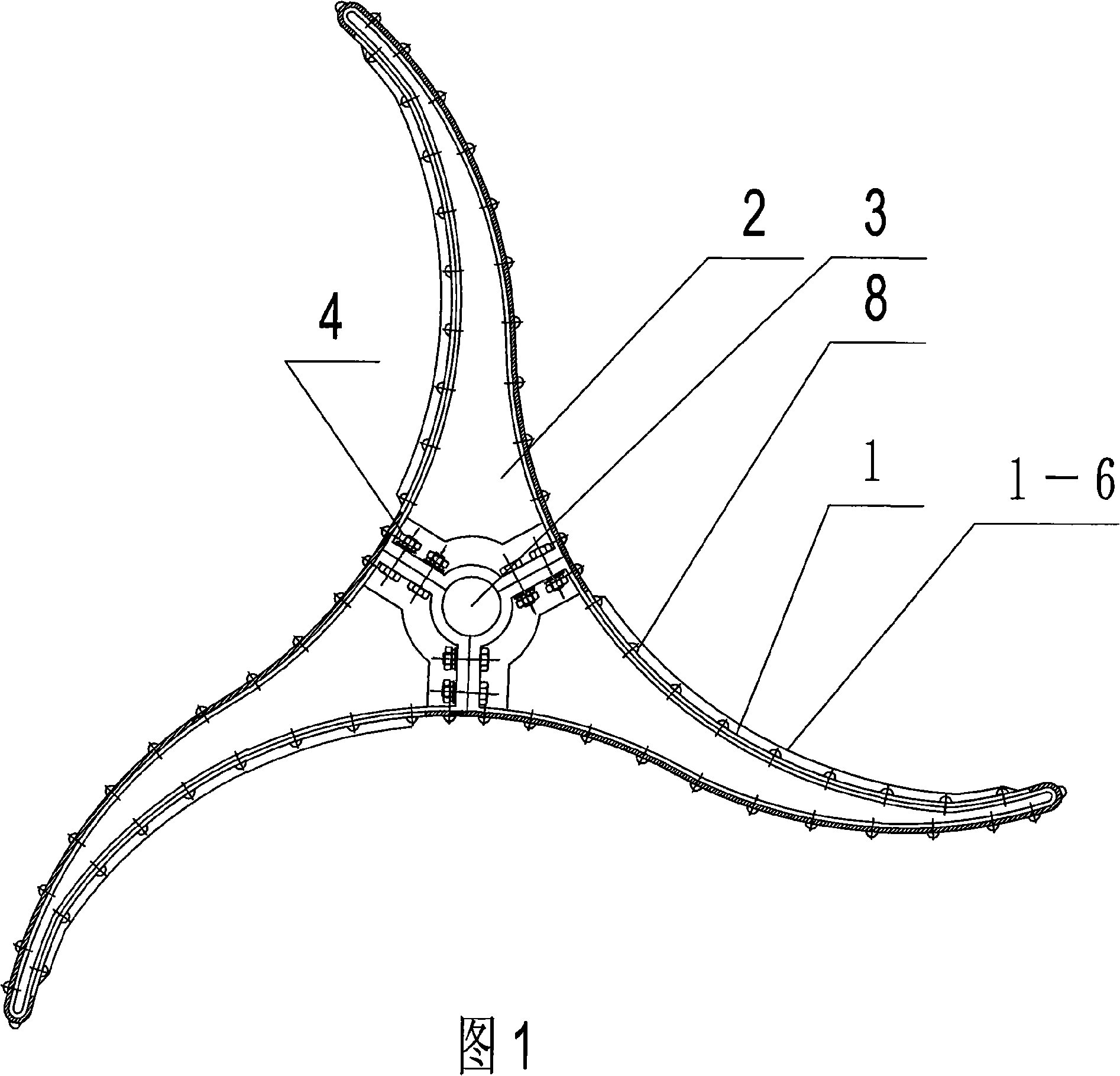

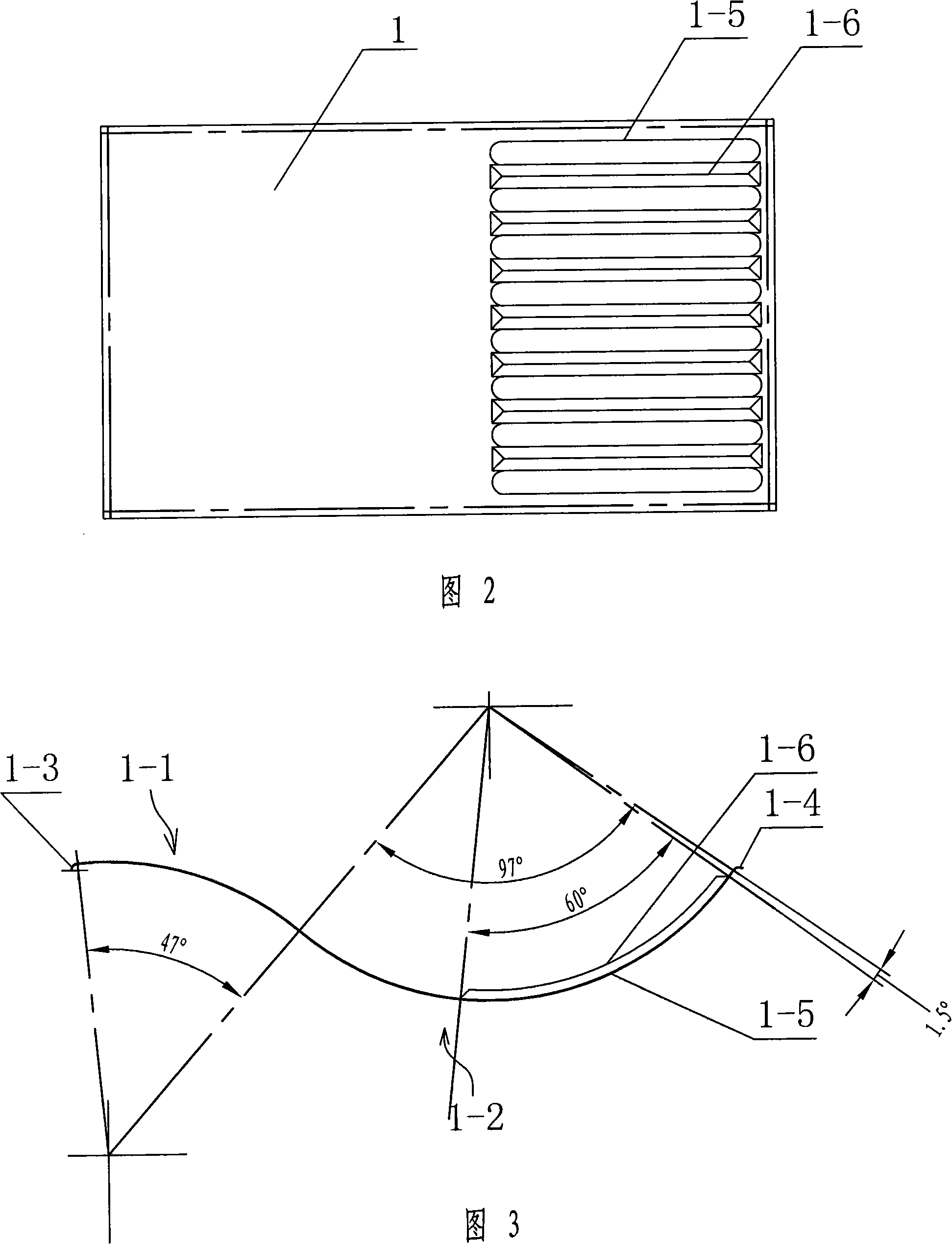

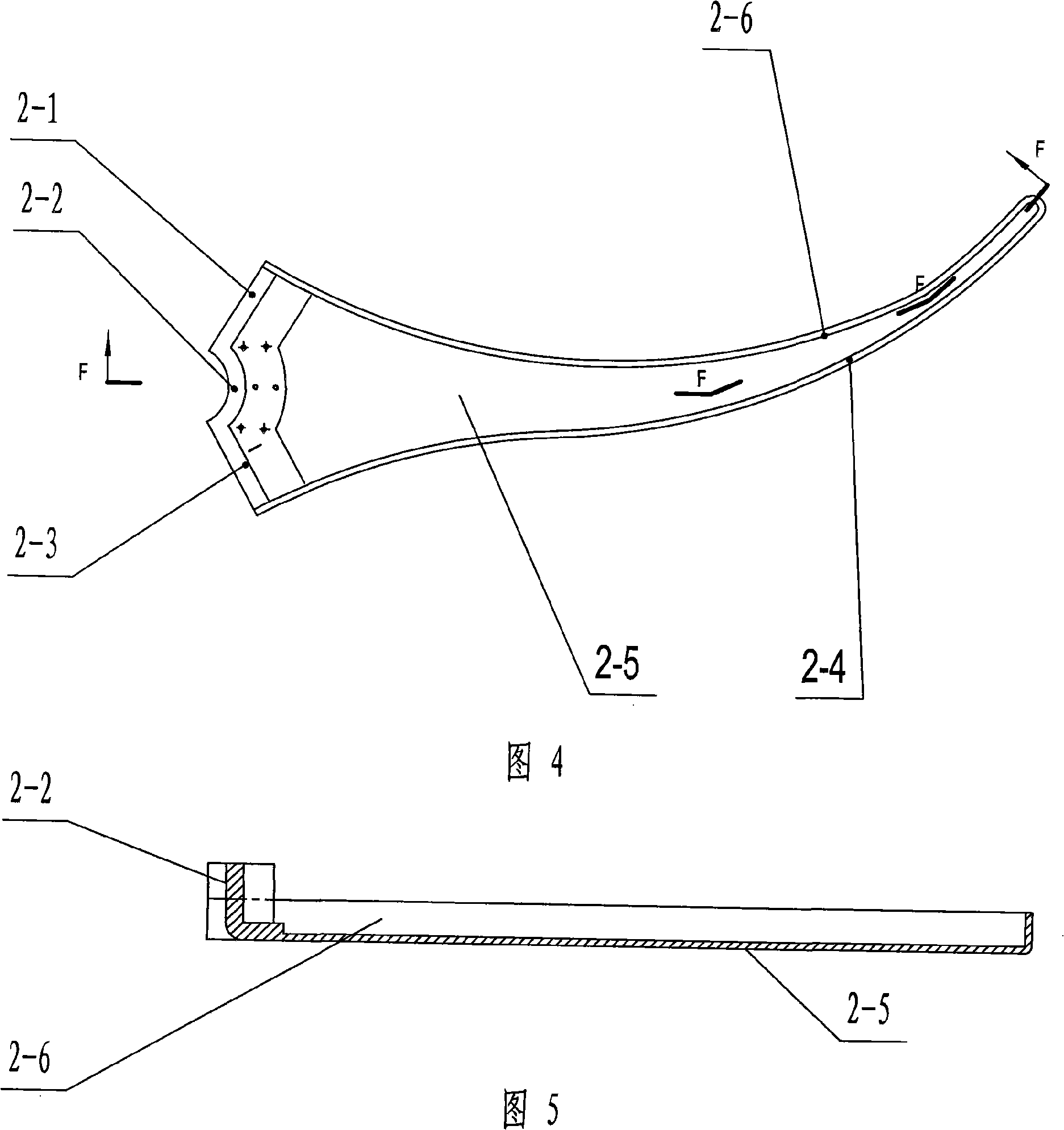

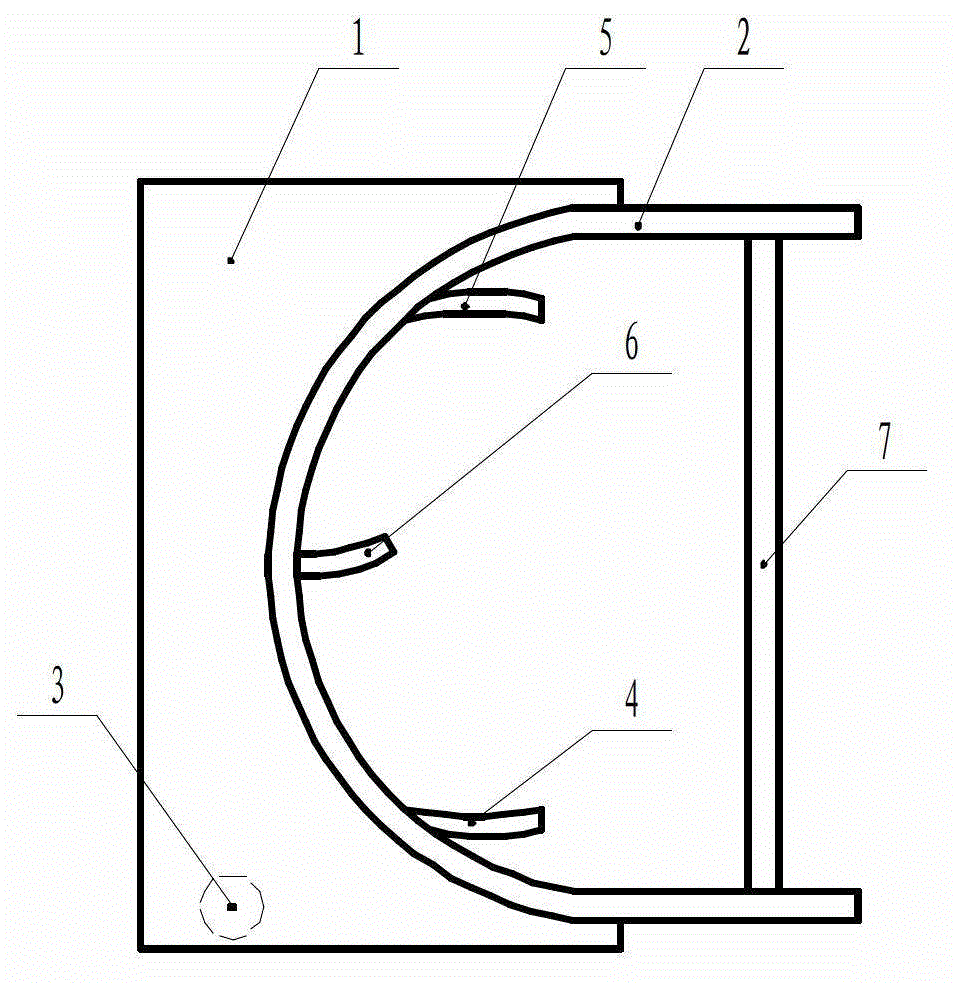

Vertical shaft wind motor three-halberd vortex-eliminating windwheel

ActiveCN101260864ALarge driving torqueAchieve high-speed rotationRenewable energy generationMachines/enginesButt jointEngineering

The invention discloses a three-halberd vortex elimination wind wheel for a vertical shaft wind motor, wherein, the structure of a three-bladed closed cavity is formed by enclosure of vane plates on three side faces and three-halberd cover plates on the top and at the bottom; a vane plate is an S-shaped circular arc column panel which is formed by smooth connection of two sections of circular arc column panels the arc roofs of which face to opposite directions; air flow slots are uniformly distributed on one section of the circular arc column panel along the height direction; two outer ends of various vane plates are respectively provided with butt-joint arc cylinders which are mutually butted; arcs on both sides of various halberd arms of the three-halberd cover plates on the top and the bottom of the wind wheel respectively are matched with and correspond to arcs of the two sections of circular arc column panels of the vane plates; head peripheral surfaces of various halberd arms of the halberd arm shaped cover plates form circular curved surfaces which correspond to the butt-joint circular cylinders of the vane plates. The wind wheel is characterized by low eddy loss, high power coefficient, simple structure, reliable operation, beautiful appearance and so on.

Owner:侯书奇 +1

Air-suspension air-supply-adjustable air blower directly driven by high-speed electric machine

ActiveCN102200136BSimple structureImprove power densityPump componentsPump installationsImpellerSynchronous motor

The invention discloses an air-suspension air-supply-adjustable air blower directly driven by a high-speed electric machine. The air blower comprises a compressor impellor, a permanent magnetic synchronous motor rotor, a motor stator, a front radial air bearing, a rear radial air bearing, an axial thrust air bearing, a scroll and a motor shell; one end of the permanent magnetic synchronous motor rotor is connected with the compressor impellor; the rotor stator drives the permanent magnetic synchronous motor rotor to rotate; the front radial air bearing, the rear radial air bearing and the axial thrust air bearing support the permanent magnetic synchronous motor rotor in a suspension mode; the scroll is arranged at the periphery of the compressor impellor; and the motor shell is positionedat the peripheries of the motor stator, the front radial air bearing, the rear radial air bearing, the axial thrust air bearing and the permanent magnetic synchronous motor rotor. According to the invention, through driving the compressor impellor directly by the permanent magnetic synchronous motor rotor of the high-speed electric machine, a complex and expensive speeding system is omitted, noises and mechanical loss are reduced, the integral machine efficiency can be improved, the system is simple, and the air blower provided by the invention is convenient to install and transport.

Owner:宁波虎渡能源科技有限公司

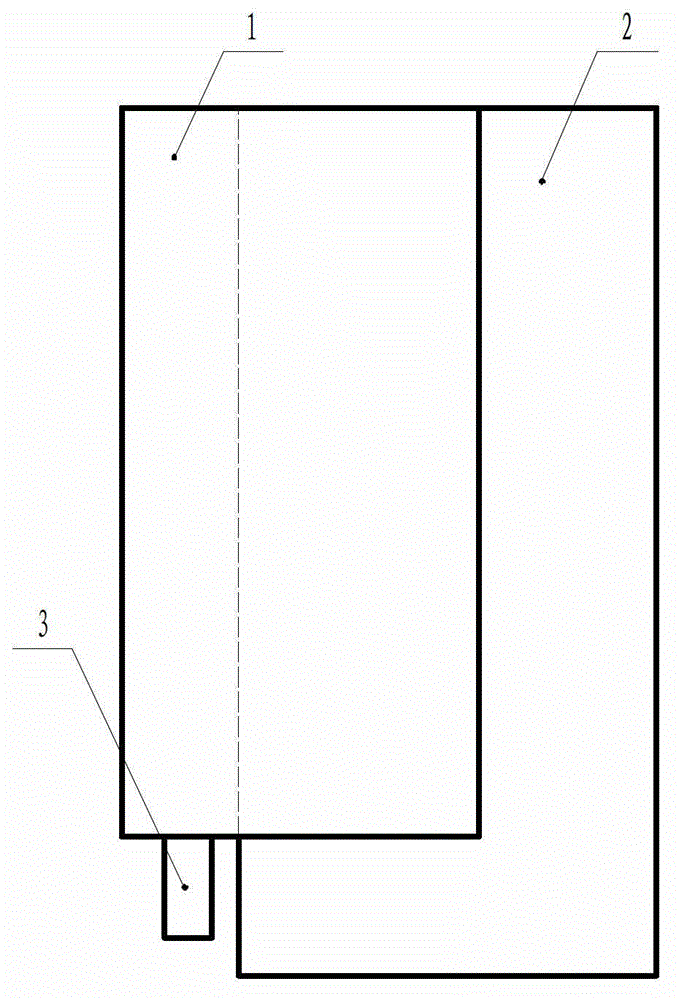

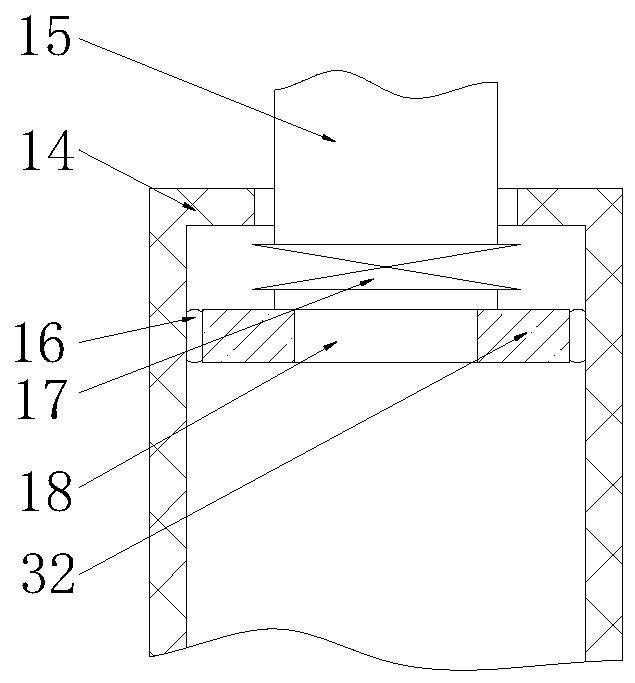

Water-saving drip irrigation system for irrigation by utilizing water source drop

ActiveCN110268947AEasy to installDrip irrigationClimate change adaptationWatering devicesWater savingWater source

The invention discloses a water-saving drip irrigation system for irrigation by utilizing the water source drop, and relates to the technical field of water-saving drip irrigation. The system comprises a first vertical plate and a second vertical plate, a fixing plate is fixedly connected between the opposite sides of the first vertical plate and the second vertical plate, a water tank is fixedly connected to the top of the fixing plate, a sliding plate is slidably connected between the two sides of the inner wall of the water tank, and a sealing pad is fixedly connected to the top of the sliding plate; fixing blocks are fixedly connected to the two sides of the bottom of the inner wall of the water tank, buffering plates are slidably connected between the opposite sides of the inner walls of the two fixing blocks, and buffering springs are fixedly connected to the two sides of the bottom of each buffering plate. The water-saving drip irrigation system for irrigation by utilizing the water source drop can achieve drip irrigation of agriculture under the pressure produced by a water source falling from a reservoir instead of using other power systems and a water pump for pressurized water supply, certain power resources are saved, the application range is wide, and the use in resource scarcity areas is facilitated.

Owner:宁夏大诚顺建设工程有限公司

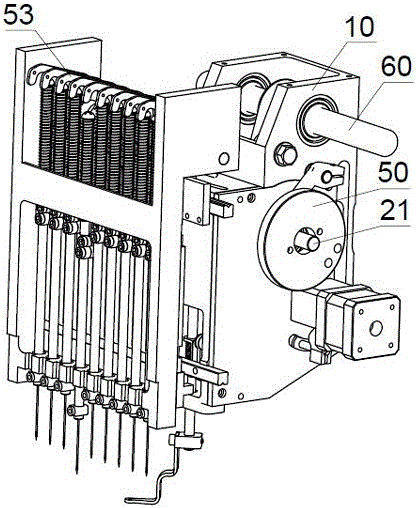

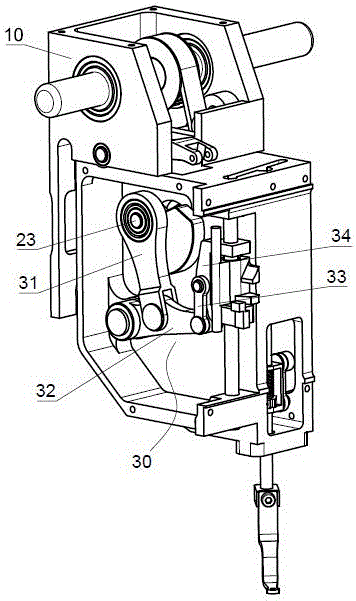

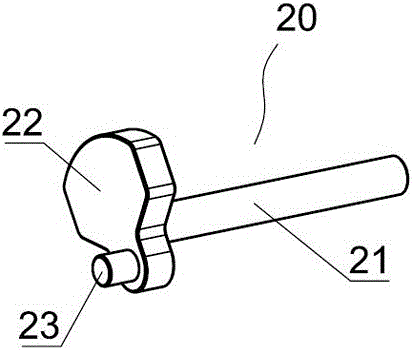

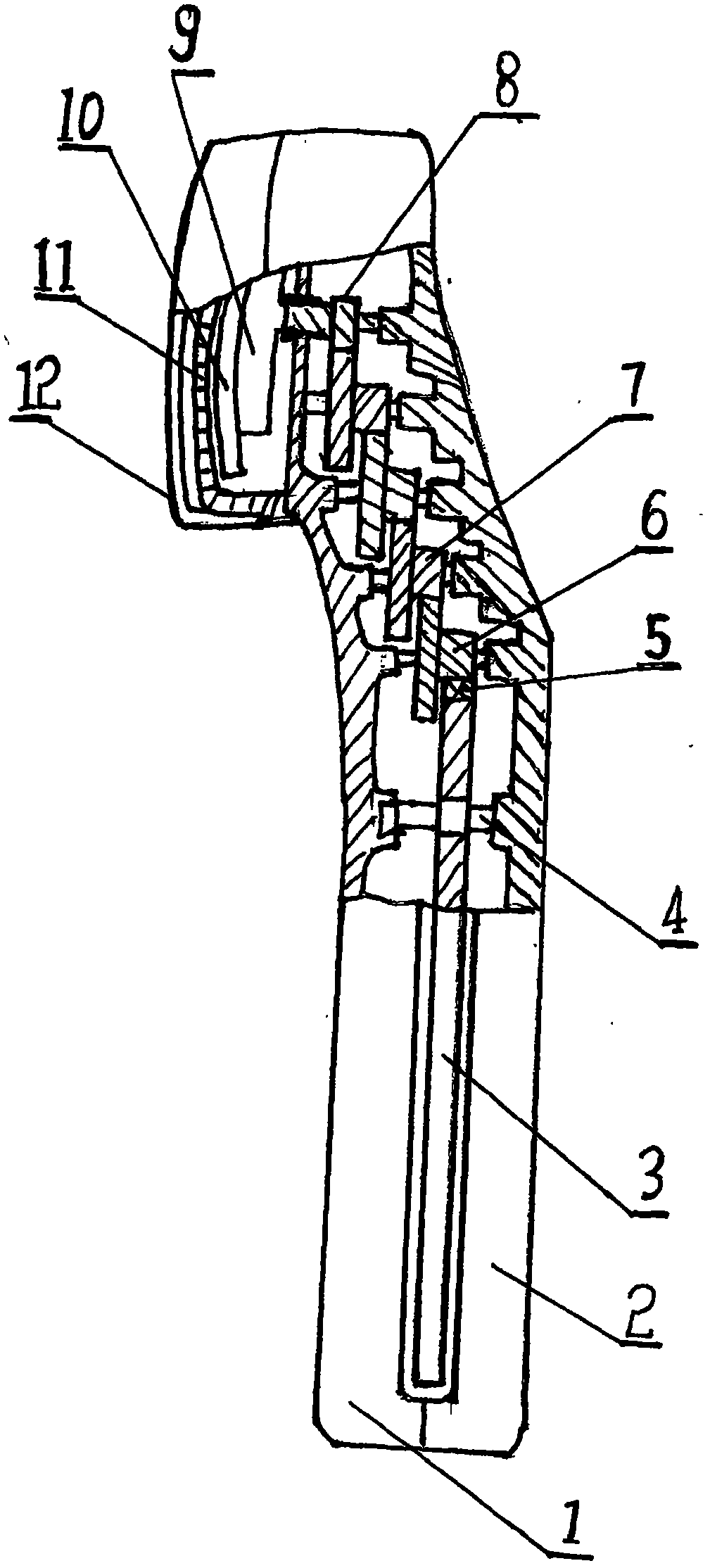

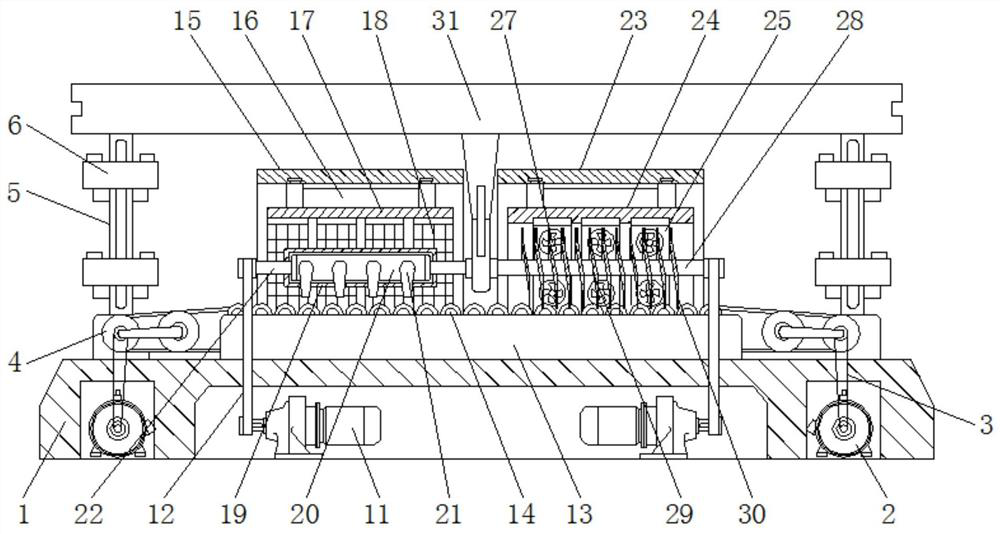

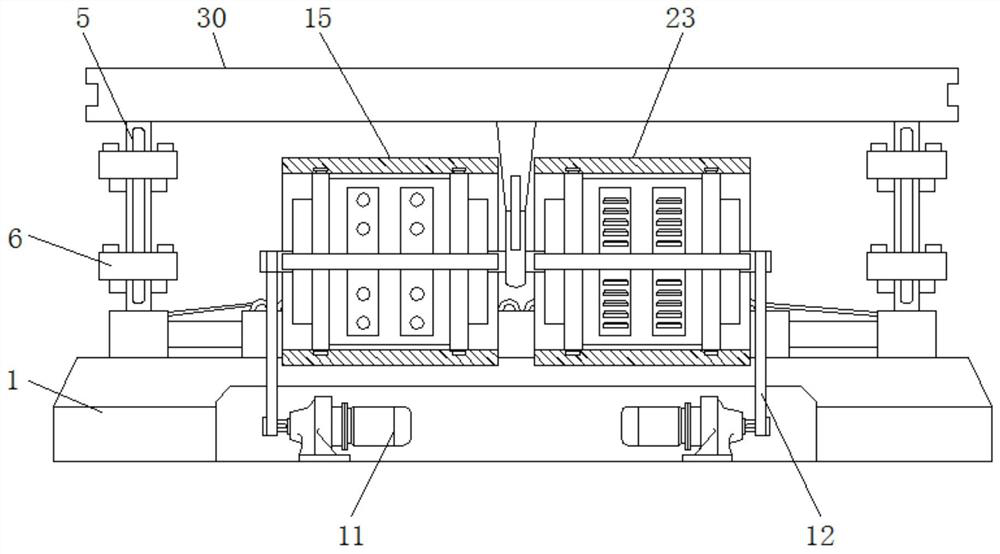

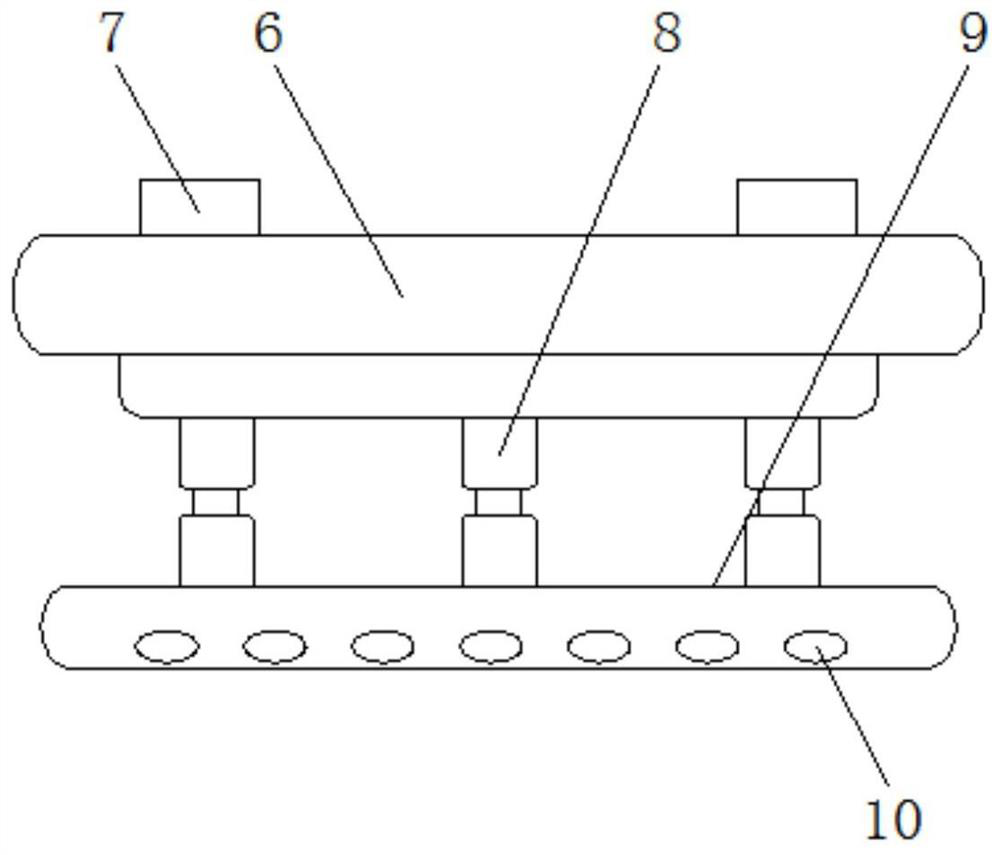

Ultrahigh-speed embroidery machine head

PendingCN106811880ALittle drive lossImprove balanceAuxillary devicesFeedersUltra high speedDynamic balance

The invention relates to the technical field of embroidery machines, and particularly discloses an ultrahigh-speed embroidery machine head. The ultrahigh-speed embroidery machine head is characterized in that a case is provided with a left chamber and a right chamber, a dynamic balance cam, a presser foot cam and a take-up-lever cam are positioned in regions on the outer sides of the left chamber, the right chamber and a right cover plate, a spindle between the dynamic balance cam and the presser foot cam is rotationally movably connected with a partition plate, and the presser foot cam and the take-up-lever cam are rotationally movably connected with the right cover plate. The ultrahigh-speed embroidery machine head has the advantages that the dynamic balance cam, the presser foot cam and the take-up-lever cam are isolated in the three regions by the partition plate and the right cover plate, every two adjacent regions are connected with each other by the spindle and the case in a supported manner, and accordingly resonance effects due to centrifugal force generated by various components can be prevented; the dynamic balance cam is integrally formed by a balance block and an eccentric column, the eccentric column can drive needle bars to move via a needle bar driving connecting rod assembly, centrifugal force generated by the balance block is used for offsetting the centrifugal force generated by the other components, accordingly, vibration can be eliminated, and the spindle can rotate at the high speeds.

Owner:诸暨市驰龙科技有限公司

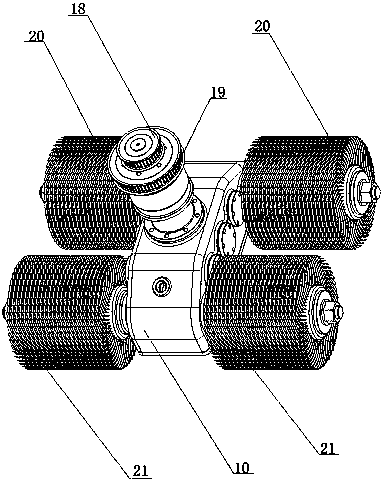

Horizontal shaft type wire grinding roller planet main grinding head and dead angle-free deburring method

InactiveCN104175215AAchieve high-speed rotationEdge grinding machinesGrinding drivesElectric machineryEngineering

The invention relates to a horizontal shaft type wire grinding roller planet main grinding head which is provided with a power input and used for driving six horizontal shaft type wire grinding rollers to rotate horizontally at a high speed, and a dead angle-free deburring method. The power output shaft of a main motor is connected with the power input end of a gear reducer; the power output end of the gear reducer is connected with one end of a grinding head main shaft through a coupling; the other end of the grinding head main shaft is connected with the power input end of a horizontal grinding head assembly; the power output ends of the horizontal grinding head assembly are six adjacent positive and negative rotation power output ends which are connected with one end of a grinding roll shaft respectively; the wire grinding roller sleeves on the other end of the grinding roll shaft; a large revolution synchronous belt wheel and a small revolution synchronous belt wheel are respectively fixed on the horizontal grinding head assembly and the power output shaft of a revolution motor in a sleeving manner; a synchronous belt sleeves the large revolution synchronous belt wheel and the small revolution synchronous belt wheel, the large revolution synchronous belt wheel is driven to rotate by the small revolution synchronous belt wheel; the horizontal grinding head assembly is driven by the large revolution synchronous belt wheel to rotate at a low speed by taking a fixed seat sleeving the horizontal grinding head assembly as the central axle.

Owner:HANGZHOU XIANGSHENG ABRASIVE MACHINE MFG

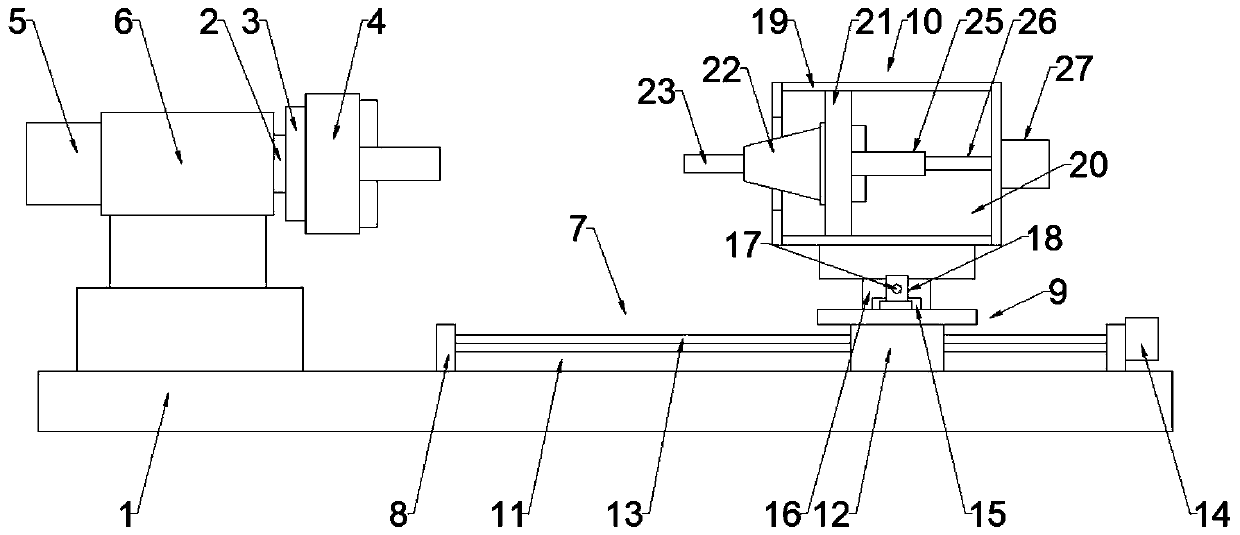

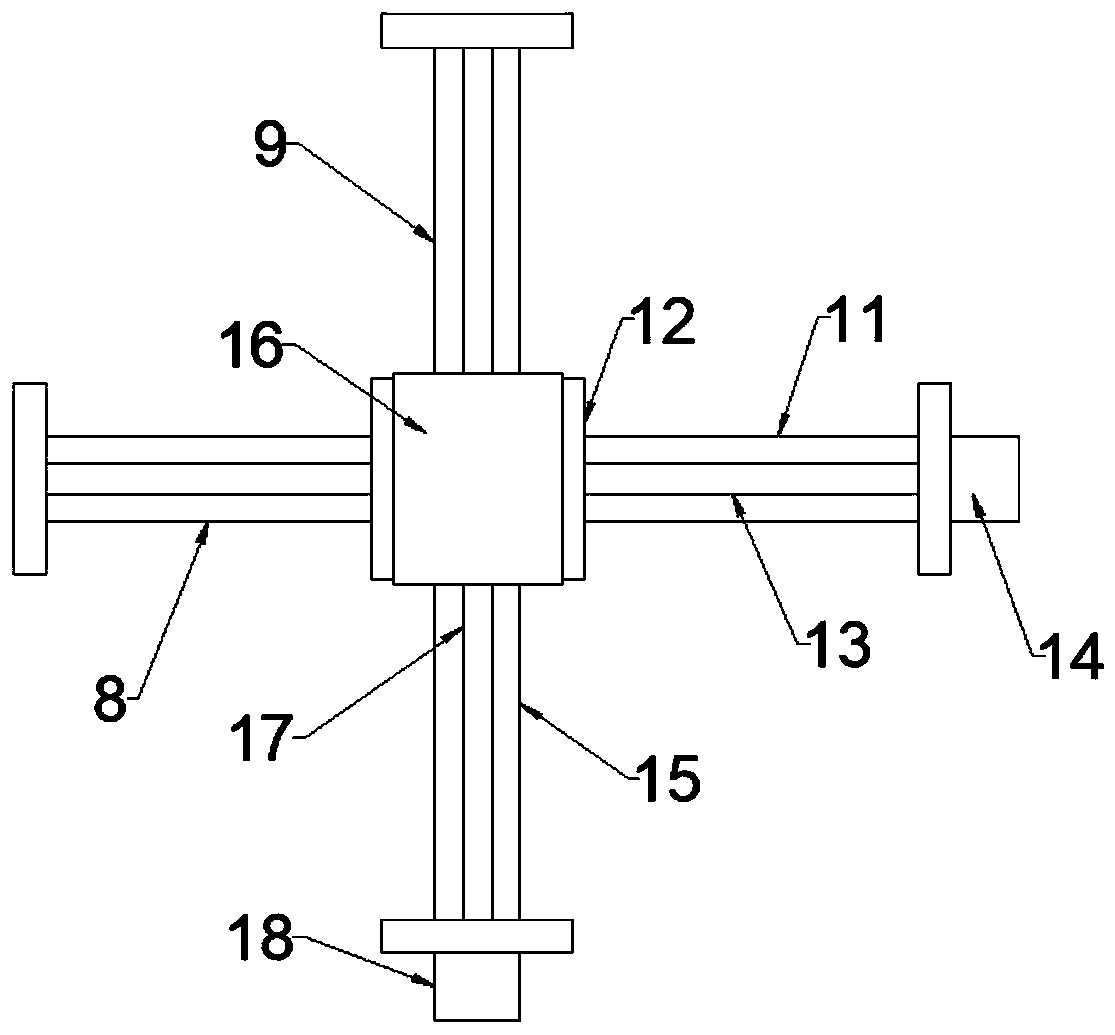

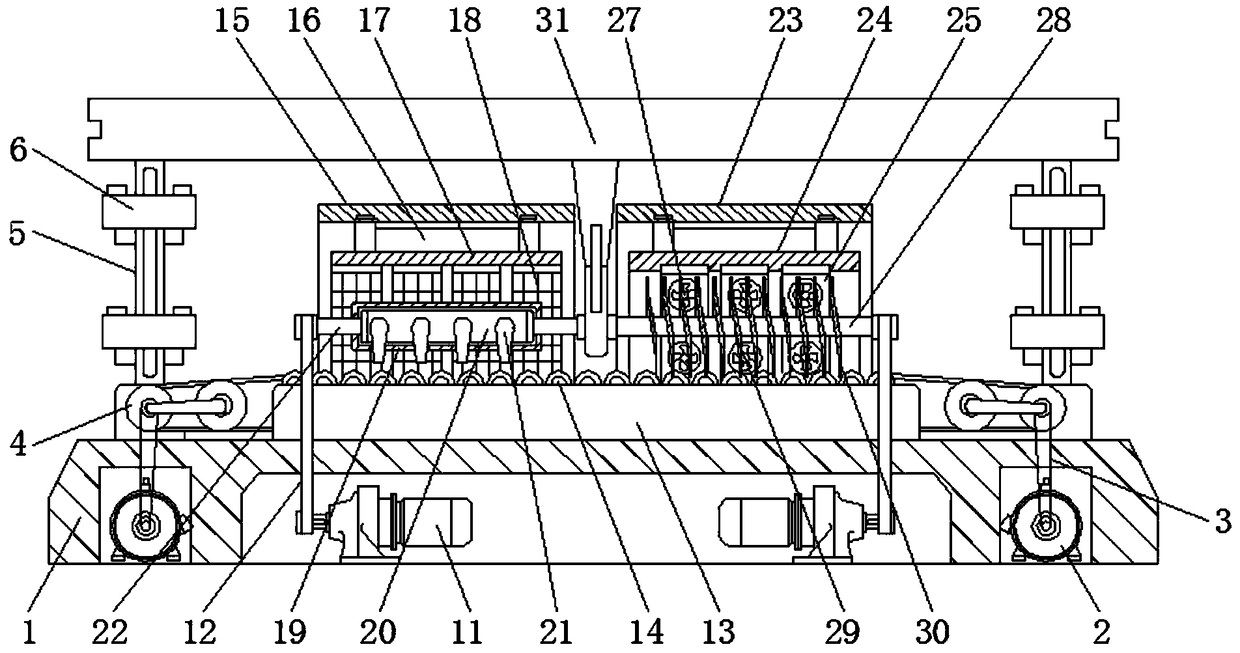

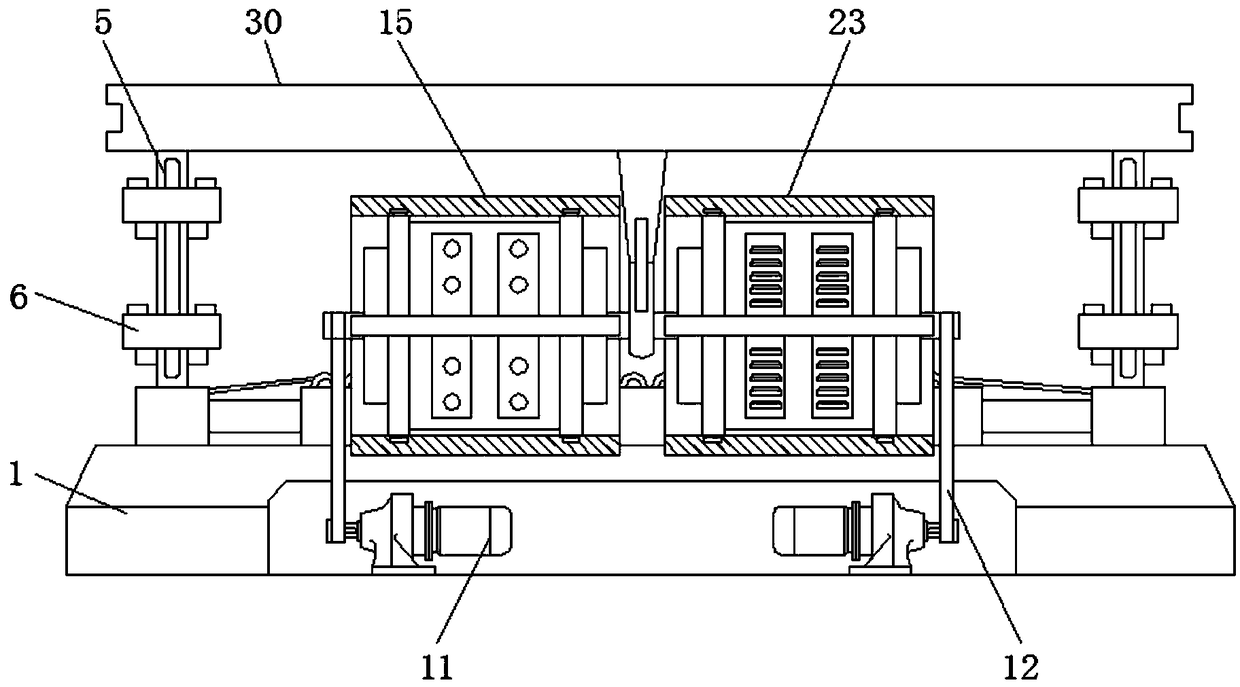

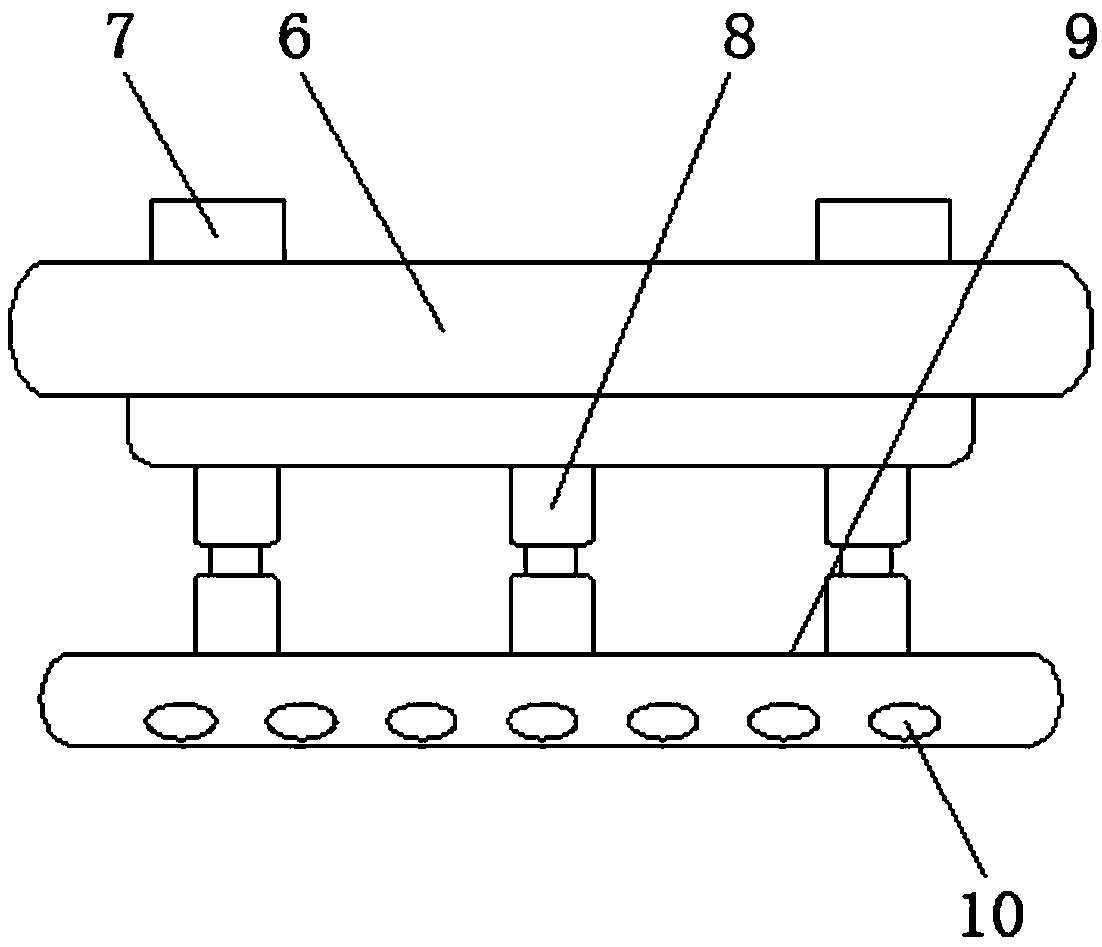

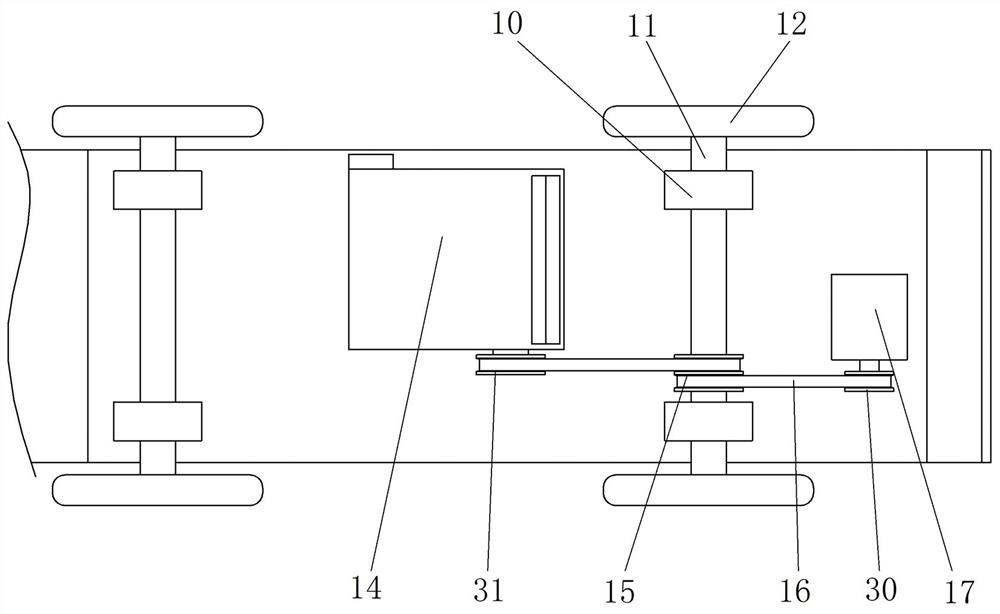

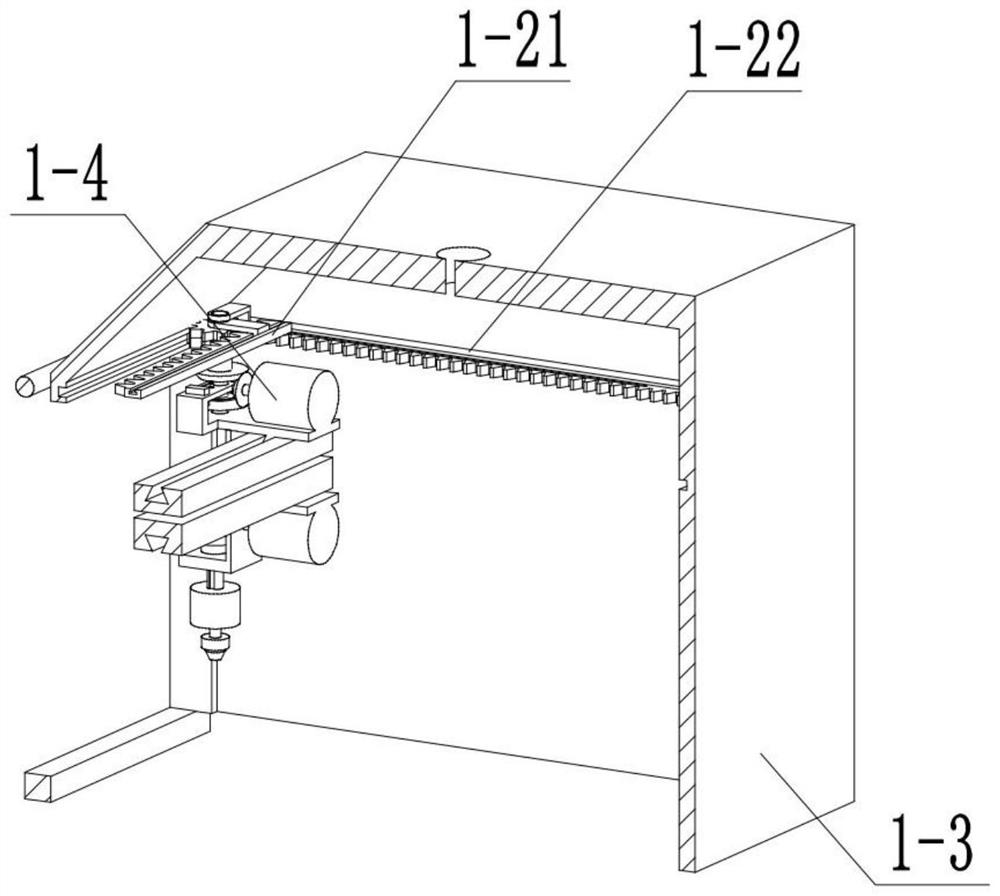

Turning combined machine tool with retractable tool

PendingCN111266607AIncrease productivityImprove Turning Positioning Accuracy and Surface Turning AccuracyFeeding apparatusPositioning apparatusTool bitManufacturing engineering

The invention discloses a turning combined machine tool with a retractable tool, belongs to the technical field of numerical control machines, and solves the problems that the length of a tool of an existing machine tool cannot be flexibly adjusted, the machine tool needs to be switched off to replace the tool, the tool replacing process is complex, the tool replacing efficiency is low, and the machining efficiency is influenced. The turning combined machine tool with the retractable tool is characterized by comprising a machine tool body, a workpiece clamp and a numerical control tool rest, wherein the numerical control tool rest is installed on the machine tool body and comprises a transverse guide rail assembly, a longitudinal guide rail assembly and a tool assembly. According to the turning combined machine tool with the retractable tool, a tool body with the retractive function is installed on the numerical control tool rest and matched with a clamp on the workpiece clamp, so thatthe machining operations of high-speed rotation, depth-controllable turning and transverse through drilling of a workpiece are realized, the production efficiency is greatly improved, meanwhile, theturning positioning accuracy and the surface turning accuracy are improved, the length of the tool extending out of a tool head shell is effectively controlled, the impact on the tool is reduced, theturning efficiency is improved, the service life of the tool is prolonged, and significant losses are avoided.

Owner:盐城威佳机床制造有限公司

Model toy processing device

ActiveCN108620268AGood rinseIncrease movement speedPretreated surfacesLiquid spraying apparatusColor effectDrive motor

The invention discloses a model toy processing device. The model toy processing device comprises a base, a first support tube and a second support tube. Driving motors are mounted on the left and right side of the interior of the base. Driving belts are arranged above the driving motors. A conveyor belt is mounted above the driving belts. Vertical frames are fixed to the left and right sides of the upper portion of the base correspondingly. Spray-washing supporting plates are mounted on the outer sides of the vertical frames. The left and right sides of the upper portion of the spray-washing supporting plates are both provided with water inlet pipe orifices. Telescopic pipes are mounted below the spray-washing supporting plates. A fixed tube is mounted in the first support tube. The firstsupport tube is located above conveying rollers. An air-drying tube is mounted in the second support tube. The second support tube is located on the right side of the first support tube. When conducting coloring processing on toy products, the model toy processing device can guarantee the coloring uniformity, is good in coloring effect and capable of conducting continuous and long-time coloring operation and conducting washing and cleaning on toys before and after coloring.

Owner:河北萨玛特儿童玩具有限公司

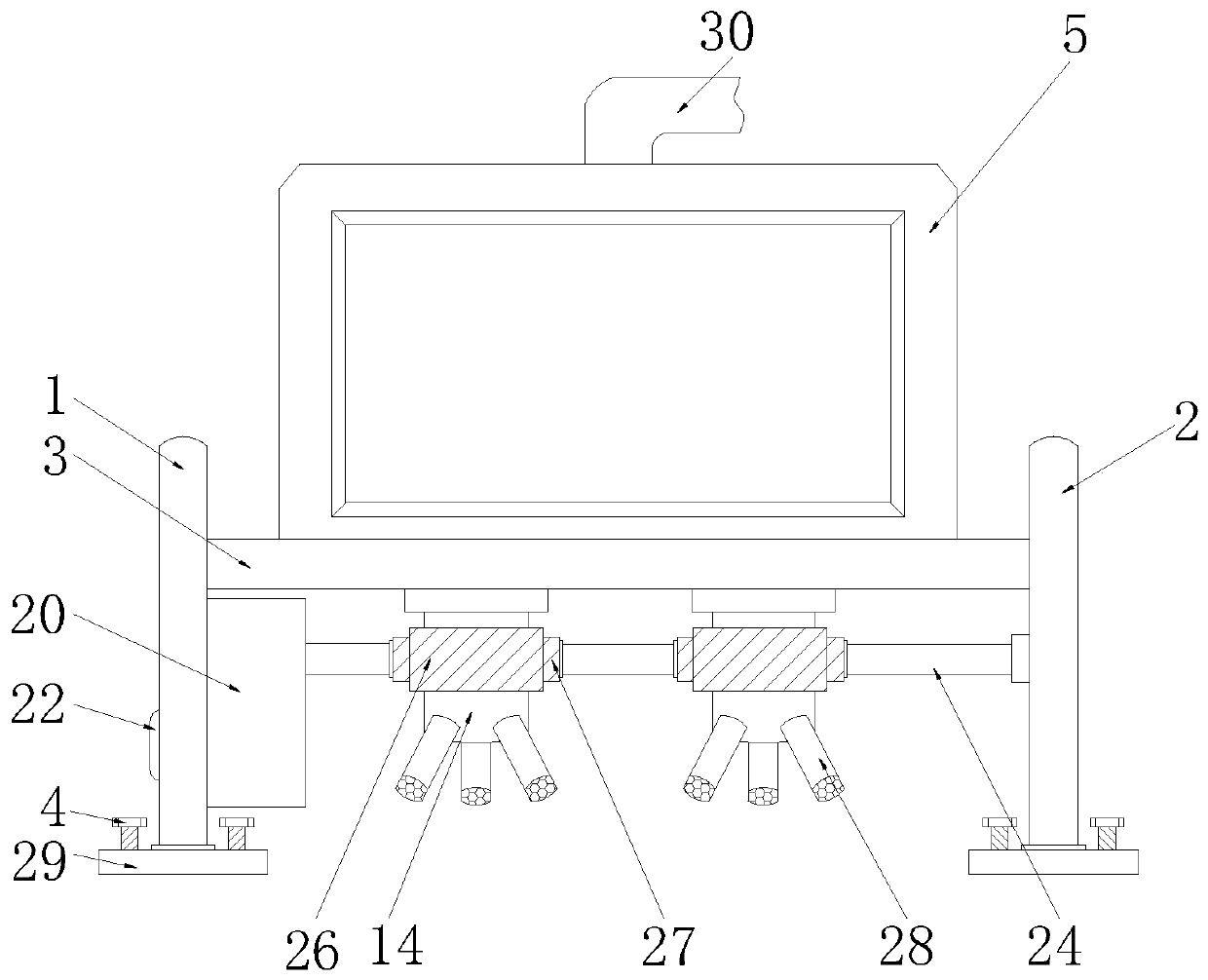

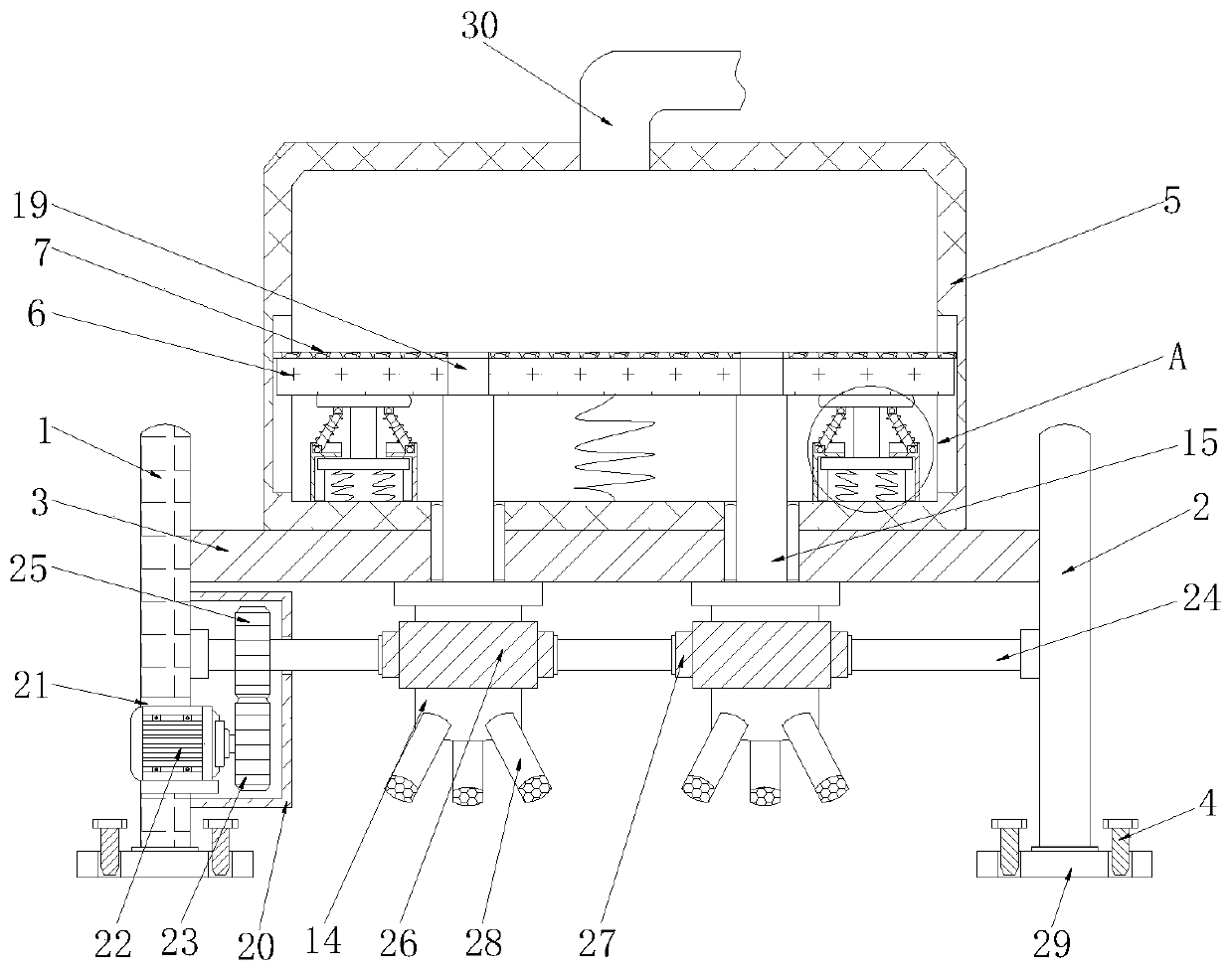

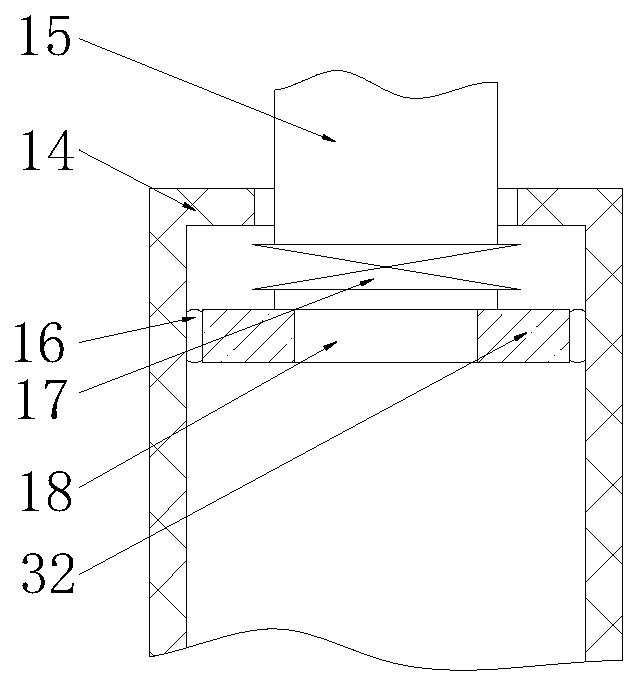

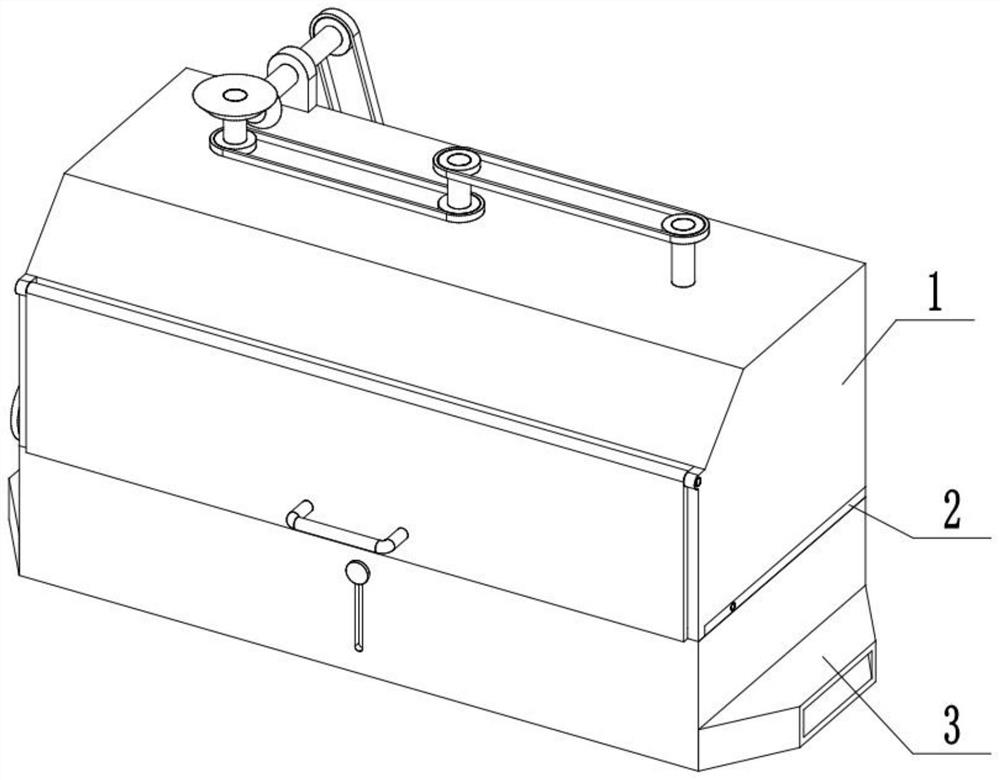

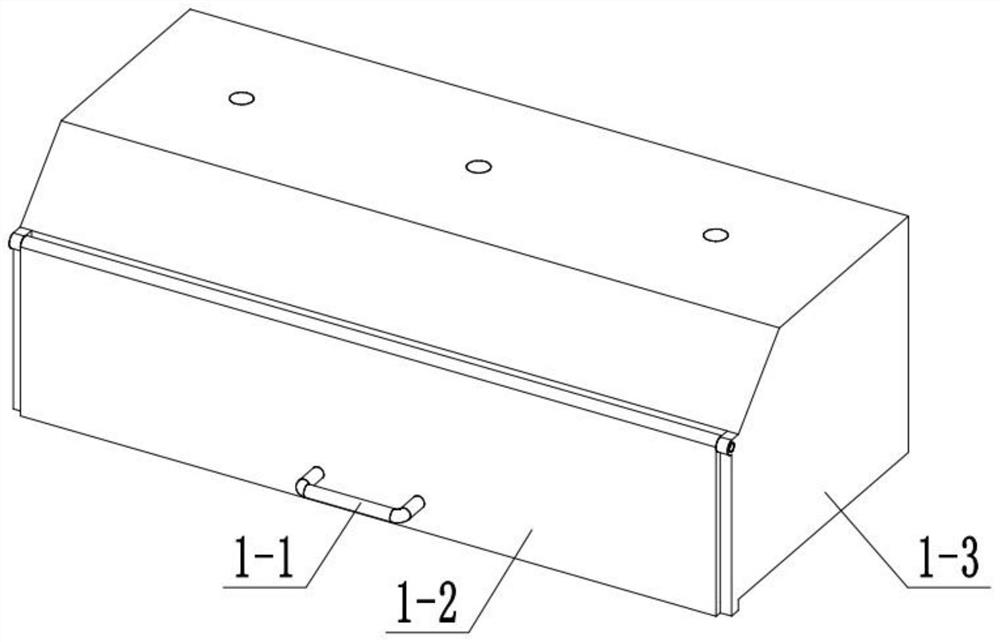

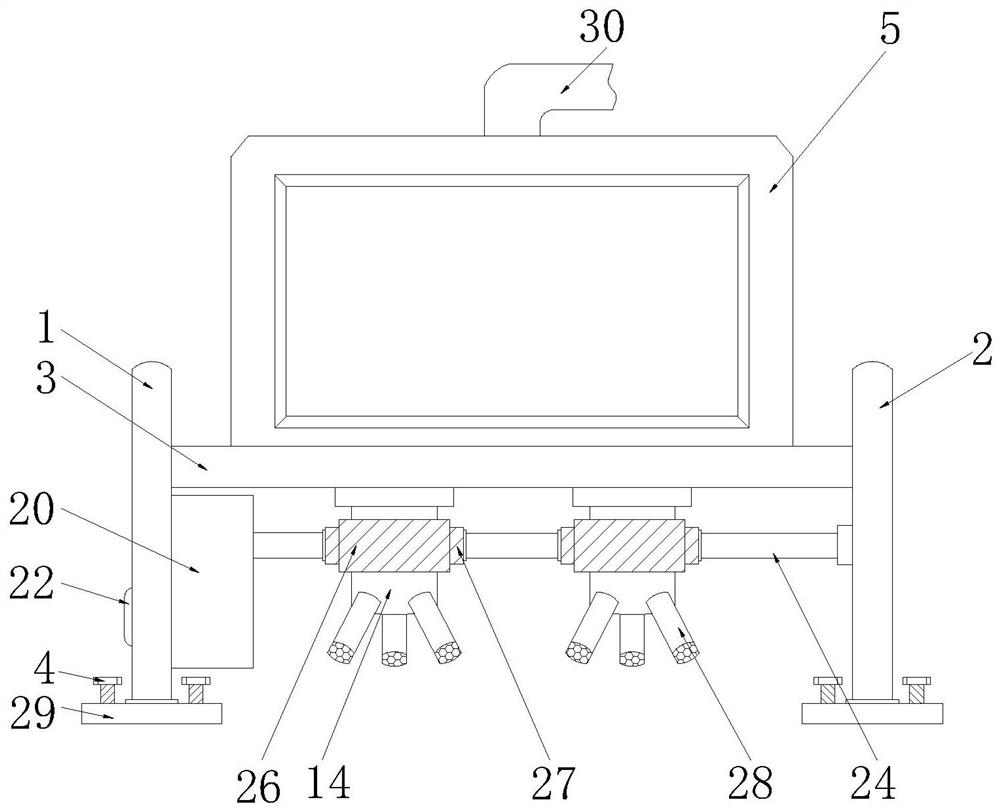

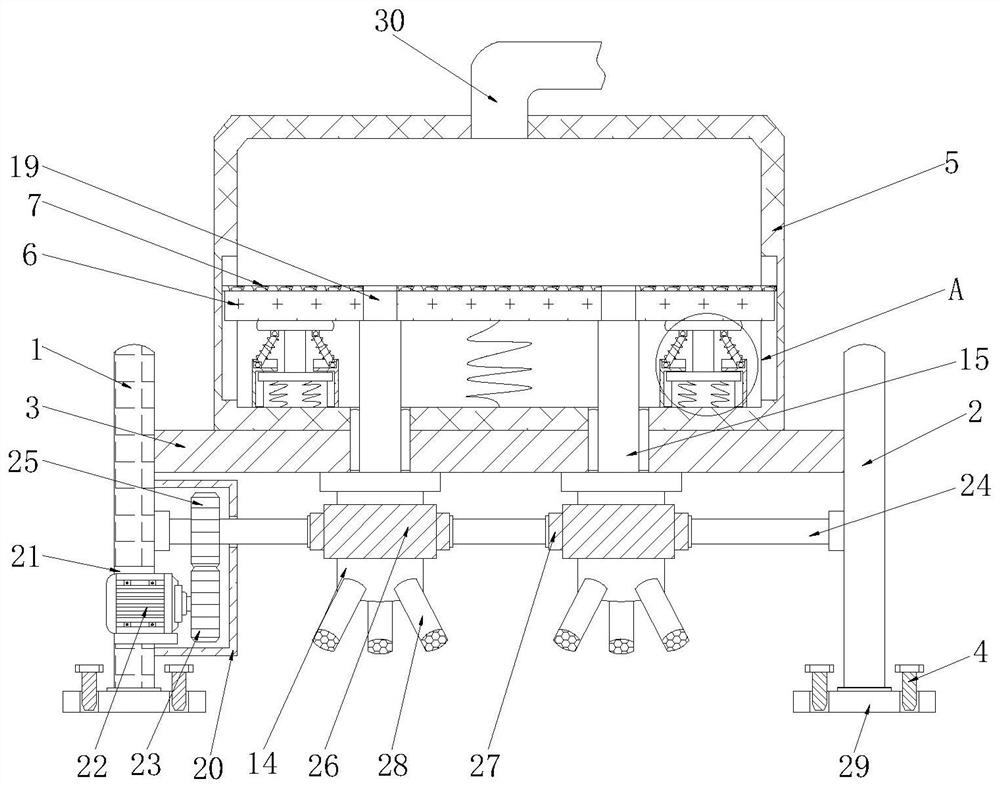

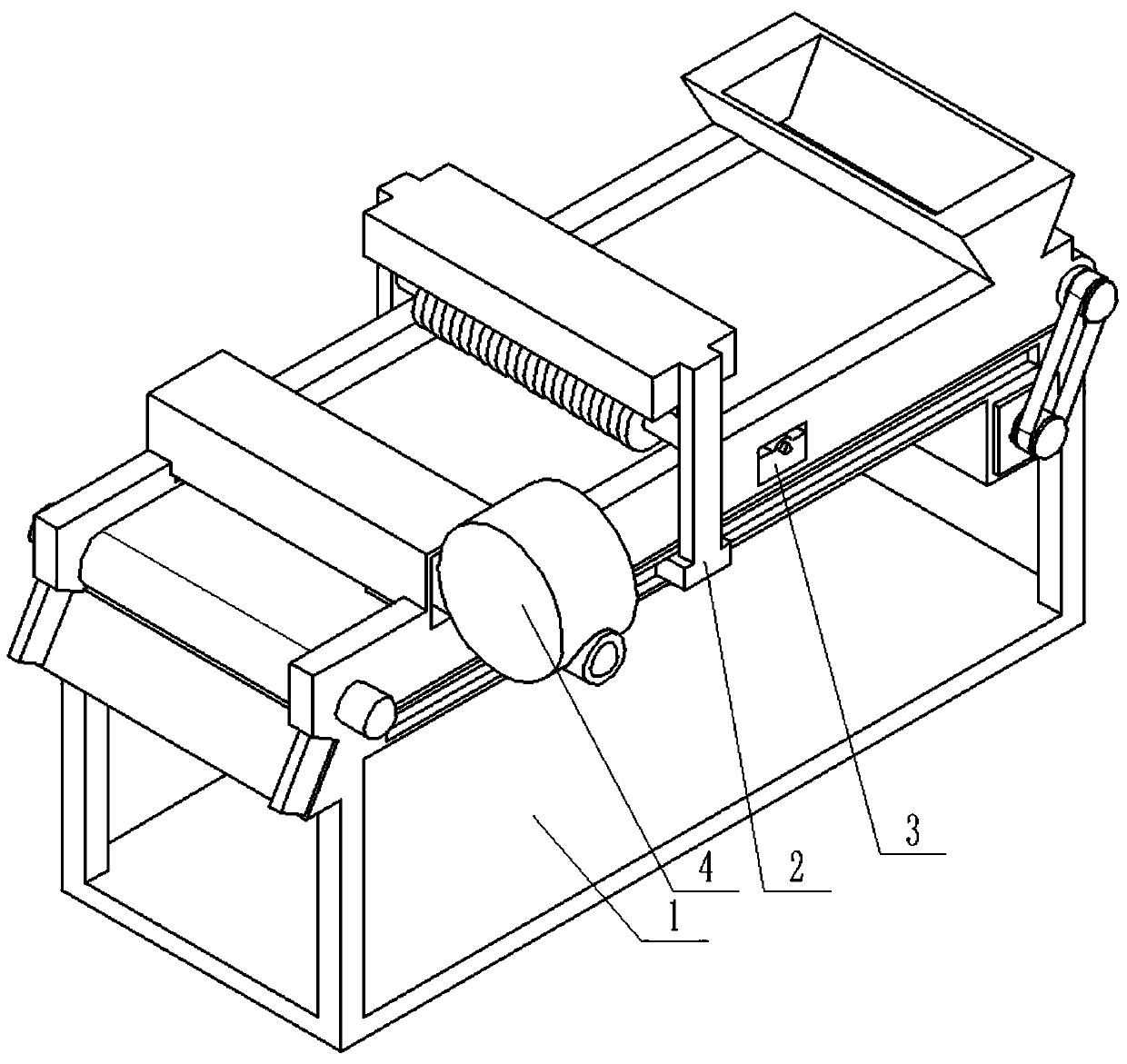

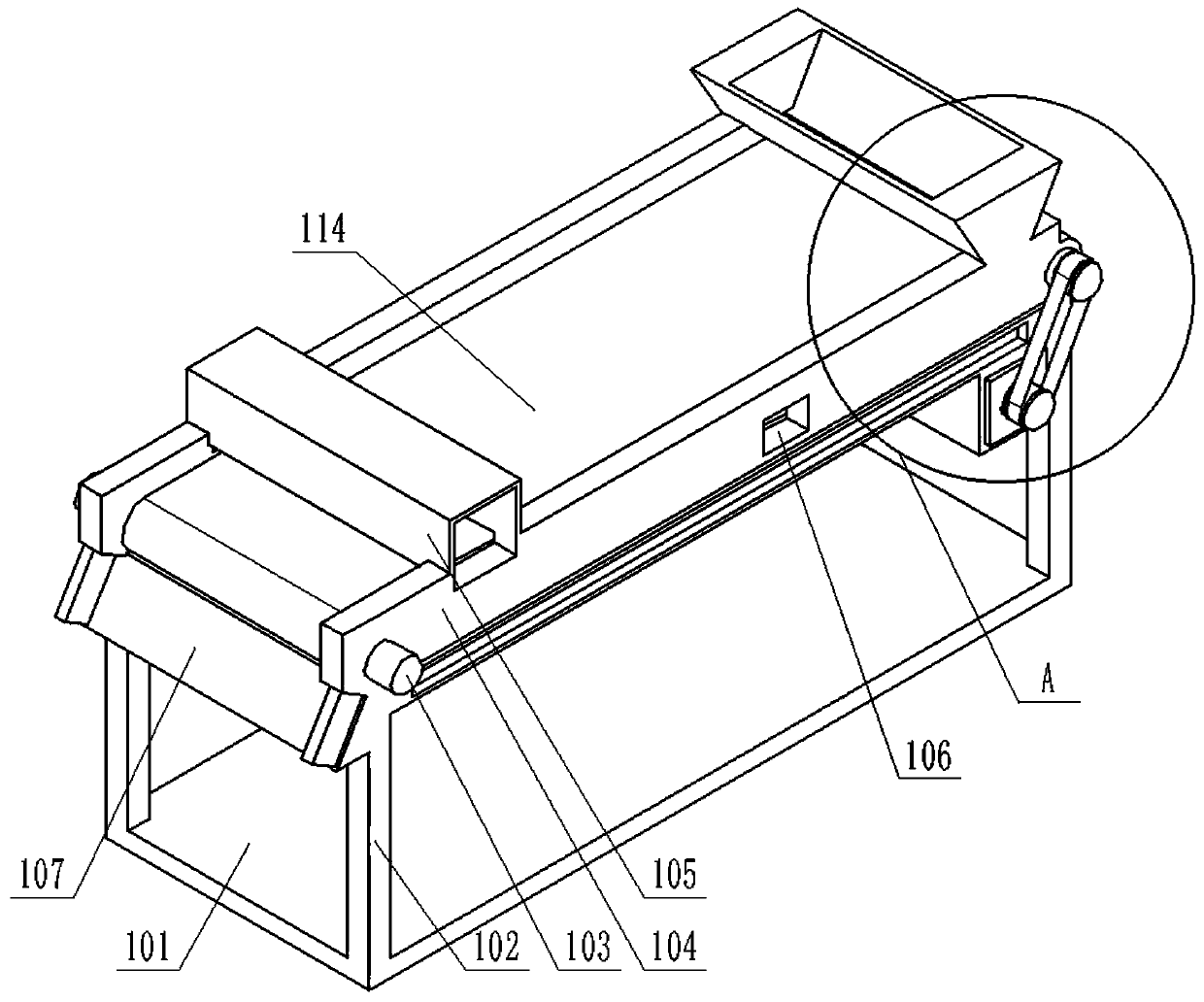

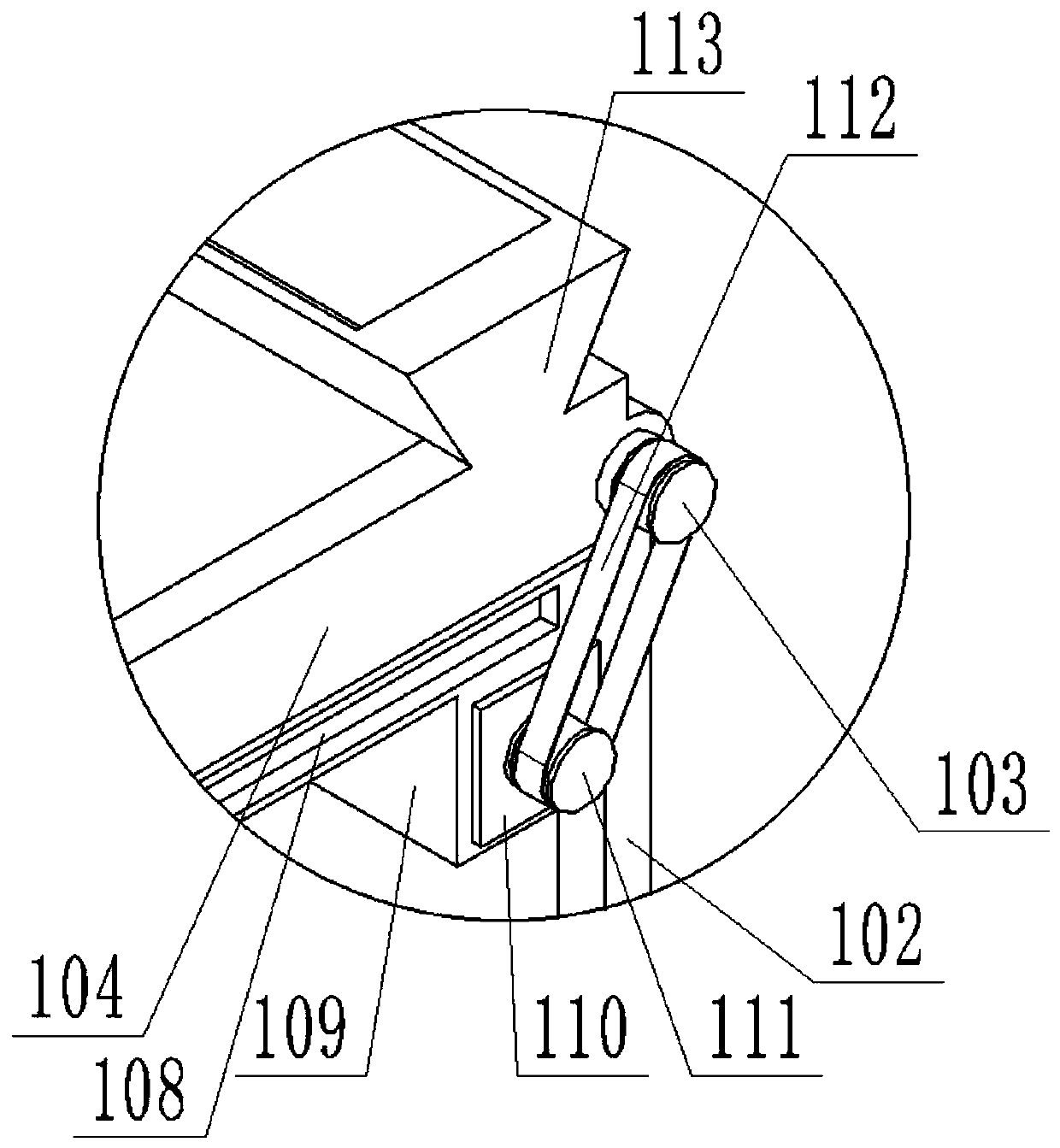

Energy-saving rice milling and hulling equipment

ActiveCN109092399AAchieve deliveryRealize rice skin separationSaving energy measuresGrain treatmentsAgricultural engineeringEngineering

The invention discloses energy-saving rice milling and hulling equipment, and belongs to the field of food machinery. The energy-saving rice milling and hulling equipment is composed of a conveying mechanism, a milling mechanism, a vibration mechanism and an air blowing mechanism. The milling mechanism, the vibration mechanism and the air blowing mechanism are mounted and fixed on the conveying mechanism. The conveying mechanism is composed of a bottom plate, supporting columns, belt pulleys, side plates, a hulling cavity, rectangular holes, a U-shaped inclined plate, a transverse moving track, a main motor frame, a main motor, a motor shaft, a wide chain, a rice inlet and a conveyor belt. The milling mechanism is composed of linear motors, vertical frames, a top block, a drying lamp, a milling wheel and a middle shaft. The vibration mechanism is composed of vibrating motor shells, vibration motors, a vibration shaft and a cam. The air blowing mechanism is composed of an air blower, anair outlet, a fixing block and an air inlet. The energy-saving rice milling and hulling equipment has the beneficial effects that through composition of the conveying mechanism, the milling mechanism, the vibration mechanism and the air blowing mechanism, especially through the linear motors and the air blower, the low-energy-consumption rice milling and hulling effects are achieved.

Owner:湖北国宝桥米有限公司

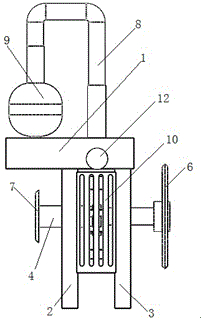

Electric control air flow driving mechanical grinding machine

InactiveCN105563327AAchieve high-speed rotationAvoid the problem of stuck and burned motorGrinding drivesImpellerMotor drive

The invention discloses an electric control air flow driving mechanical grinding machine, and belongs to the technical field of electric machinery manufacturing. An installing seat is fixed on a left support plate and a right support plate; a grinding wheel rotating shaft is arranged on the left support plate and the right support plate and penetrates through the left support plate and the right support plate; one end of the grinding wheel rotating shaft is provided with a large grinding wheel; the other end of the grinding wheel rotating shaft is provided with a small grinding wheel; an impeller installing disc is arranged in the middle position of the grinding wheel rotating shaft; air flow driving blades are arranged on the impeller installing disc; a power air flow pipe is arranged on the installing seat arranged right above the air flow driving blades, and is connected with a high-pressure air storage cylinder; and the tail end of the power air flow pipe is provided with an air flow control valve. The electric control air flow driving mechanical grinding machine has the advantages that the design that the airflow driving blades are arranged on the grinding wheel rotating shaft, and the air flow driving blades are impacted by high-pressure air flow is used, so that the goal of driving the grinding wheel rotating shaft is achieved; the high-speed rotation of the large grinding wheel and the small grinding wheel can be realized; and the problem of burnt damage of the motor due to seizurewhen the motor driving modeis used can be avoided.

Owner:HEILONGJIANG KANGGEER TECH

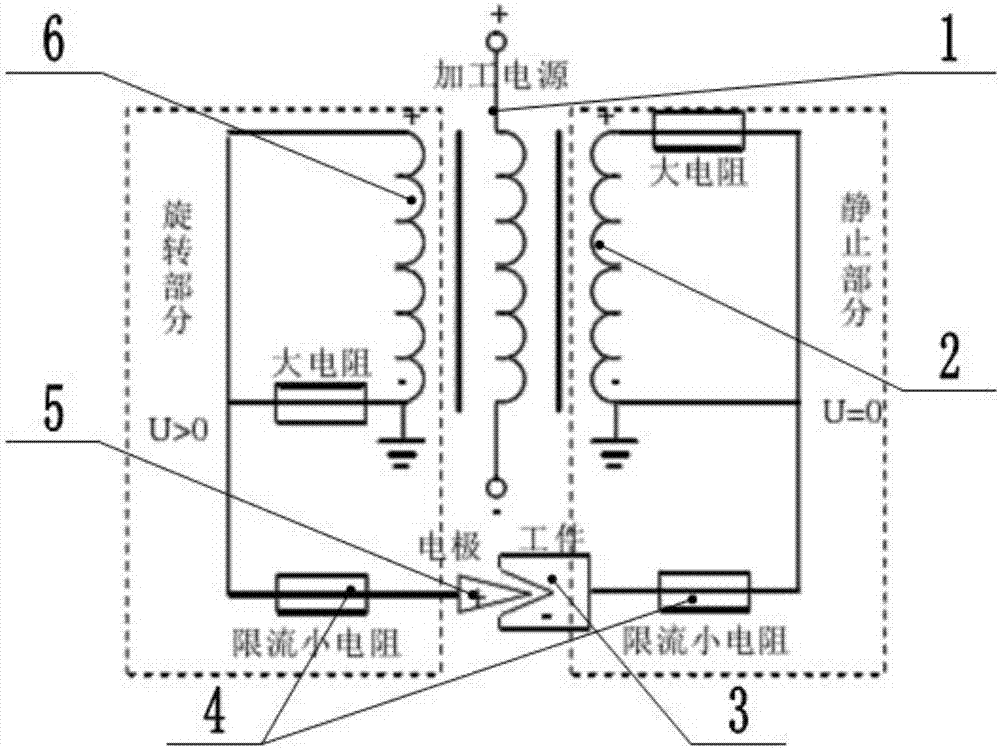

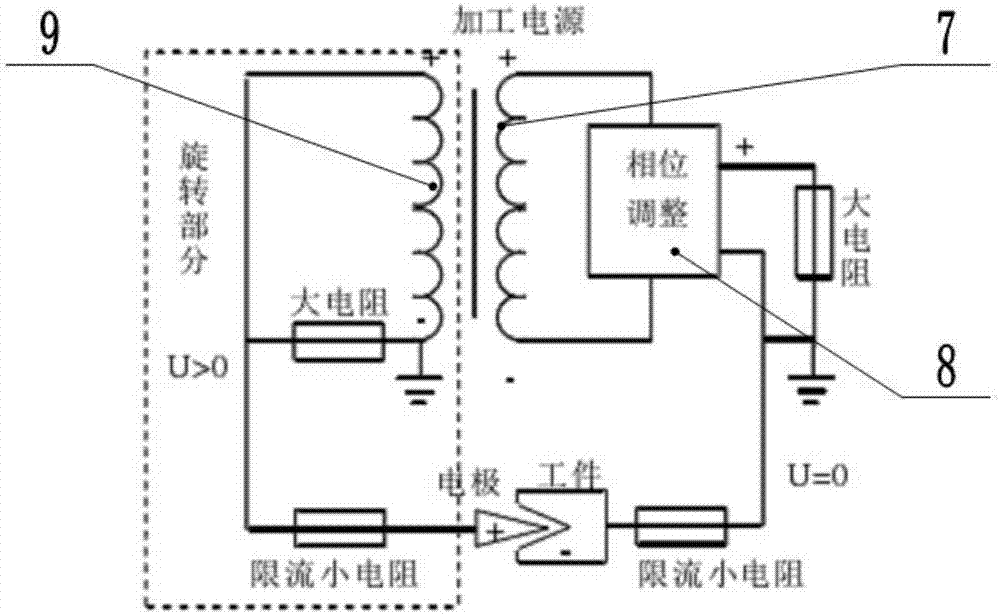

Non-contact electrical discharge machining system

ActiveCN107363350AImprove balanceSpeed up the flowElectric circuitsElectrical-based auxillary apparatusWireless transmissionMachining system

The invention relates to a non-contact electrical discharge machining system, comprising a non-contact electrical discharge machining electricity introduction system that is of inside-outside separate structure. Electricity is transferred to a tool electrode in wireless transmission manner; in this way, the structure can be compacted, good dynamic balance can be provided for a hilt, and high spindle speed can be achieved. In addition, high-speed rotation of a spindle can further accelerate flowing of an inter-electrode working fluid, discharge chips can be removed quickly, and fine electrical discharge machining efficiency is further improved. By increasing the spindle speed, it is possible to inhibit discharge concentration and abnormal arc discharge, pulse utilization rate can be increased, and machining speed is further increased.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

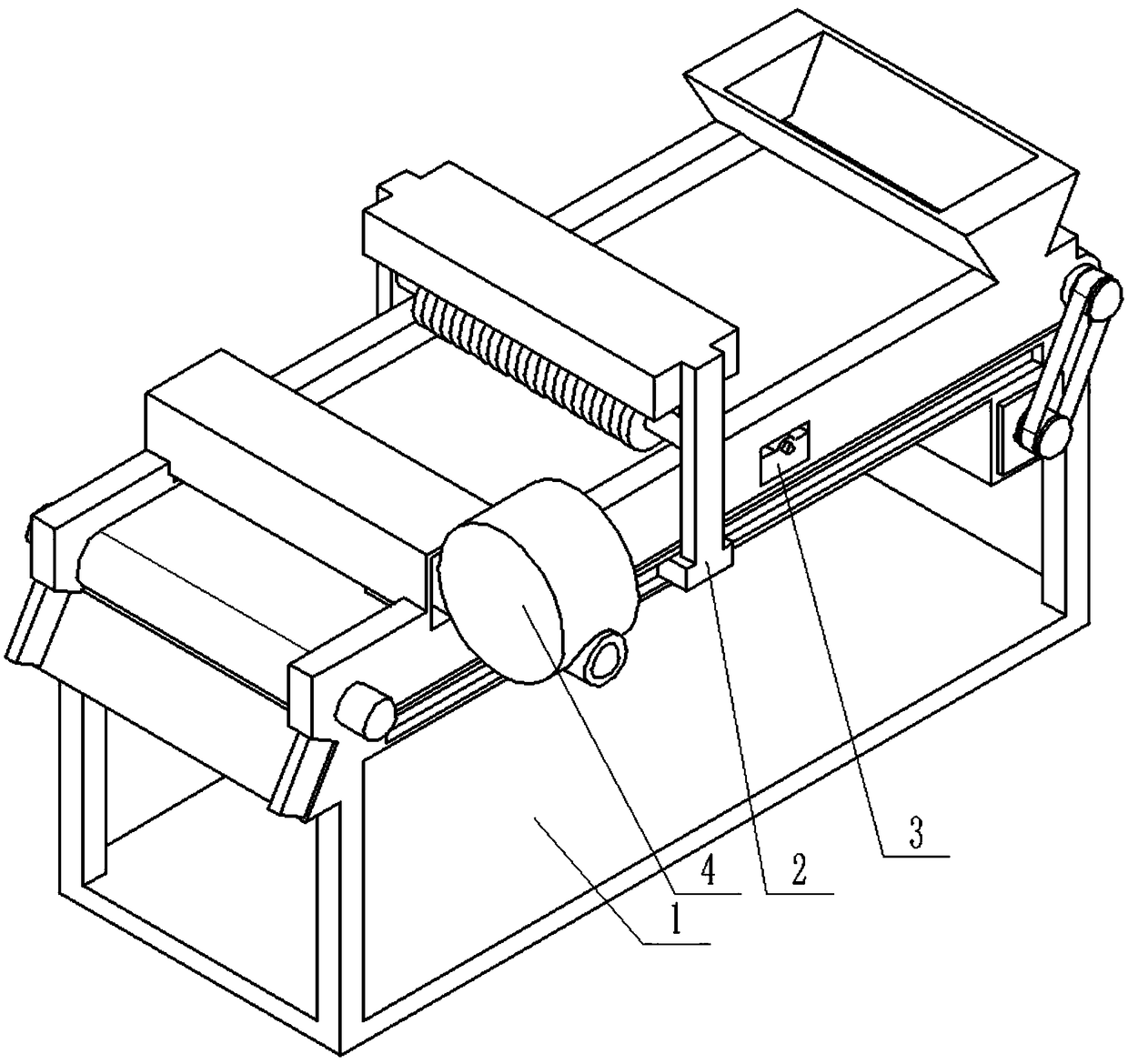

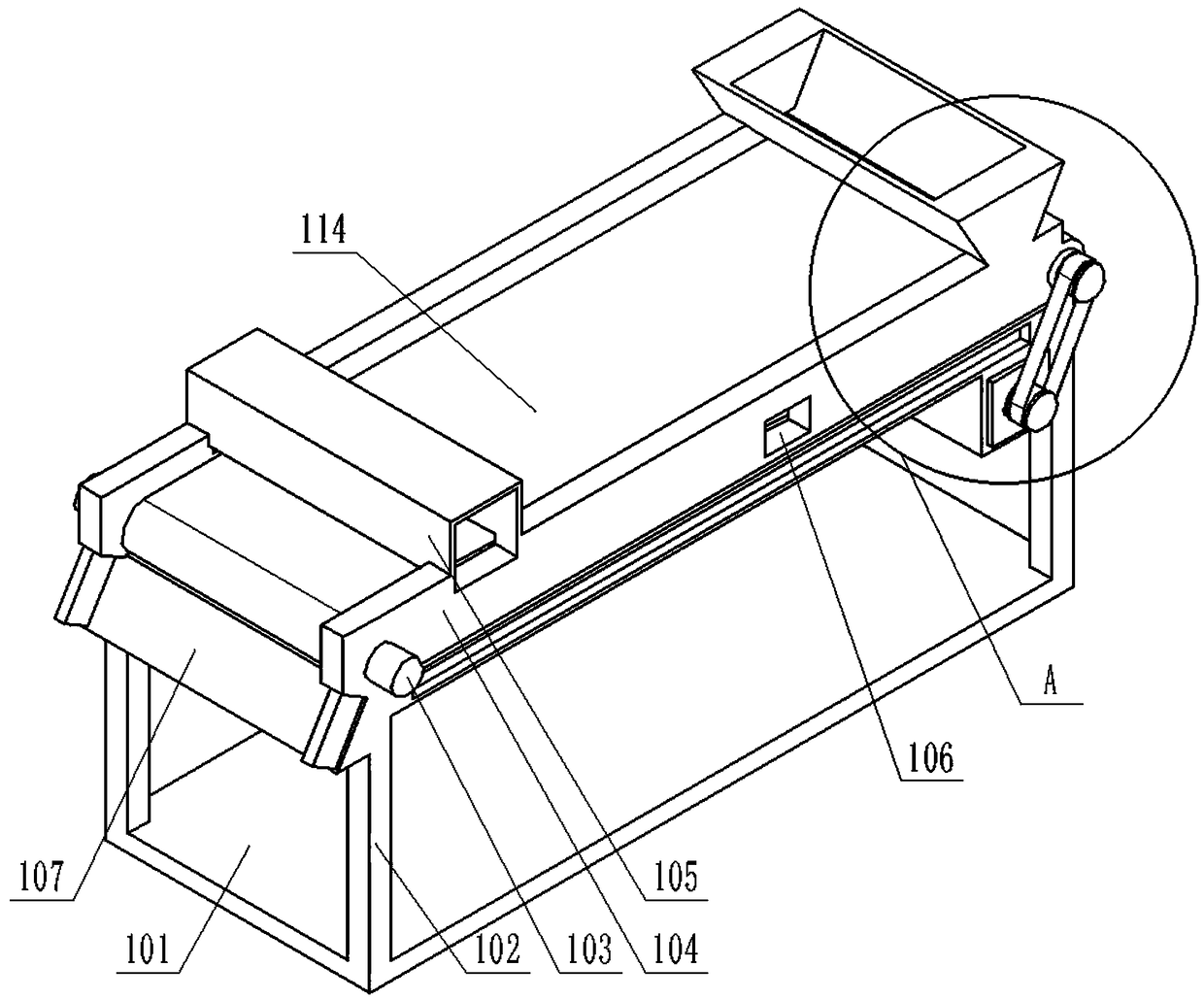

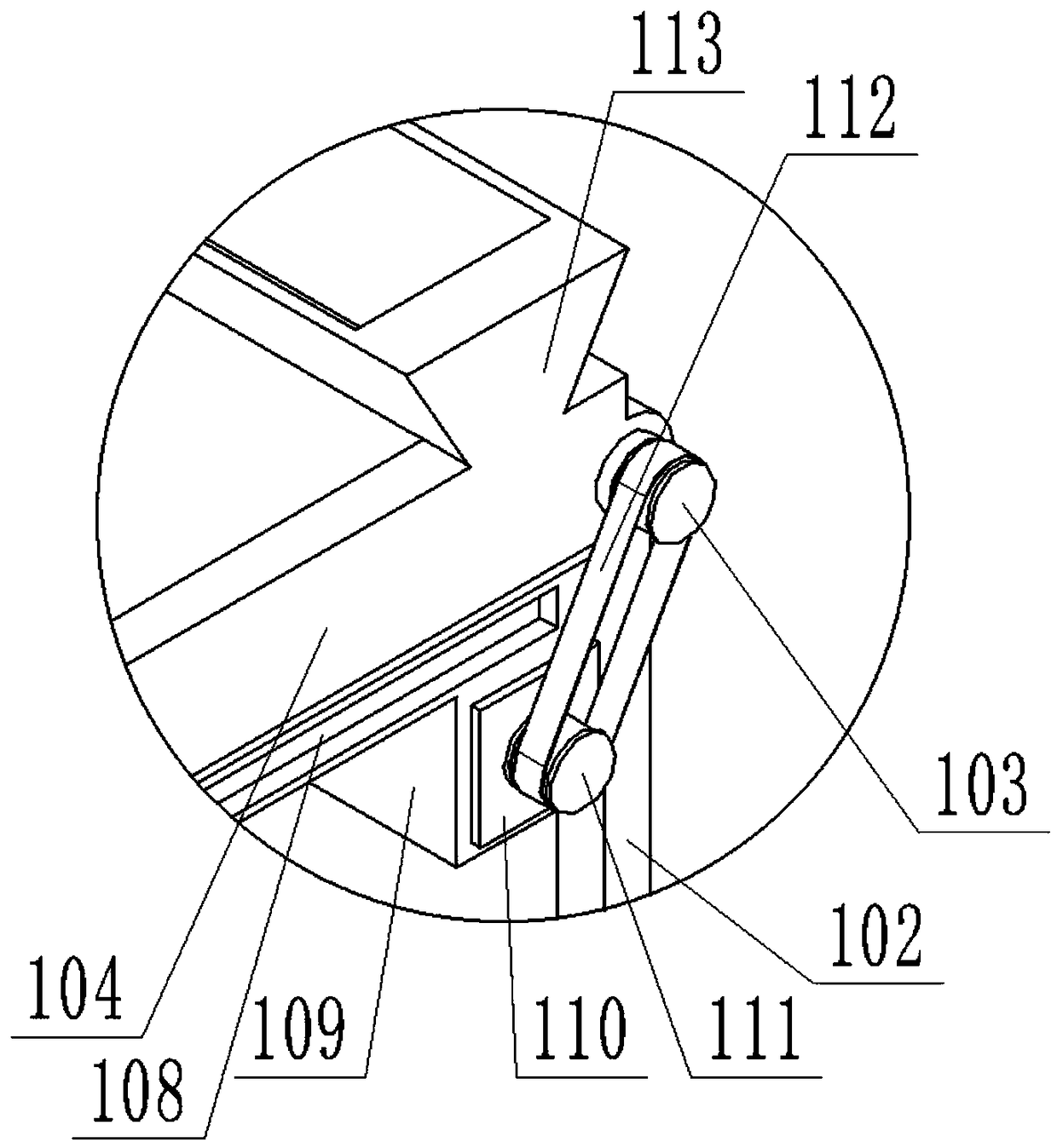

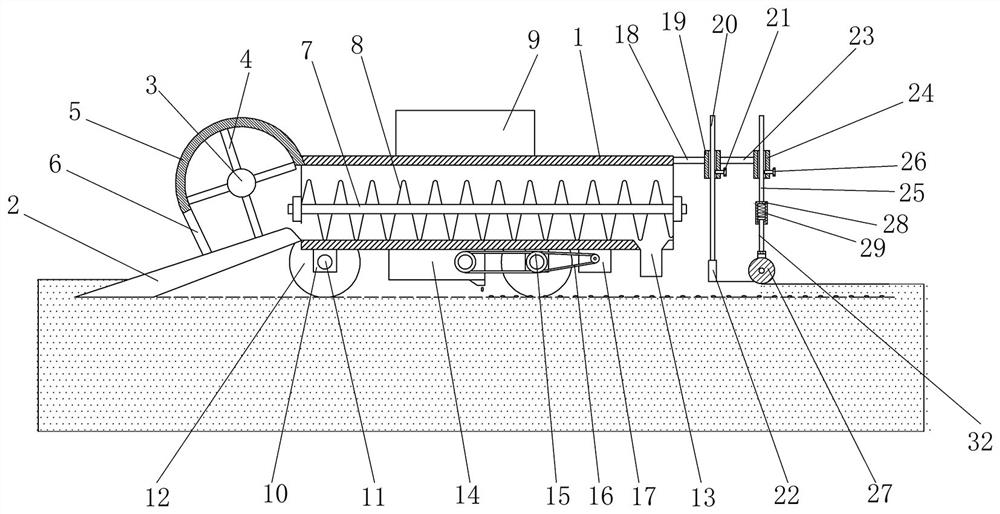

a seed planting device

ActiveCN110121956BAvoid the problem of not effectively overriding the seedEfficient crushingSpadesPlantingSeederSoil science

Owner:HENAN UNIV OF SCI & TECH

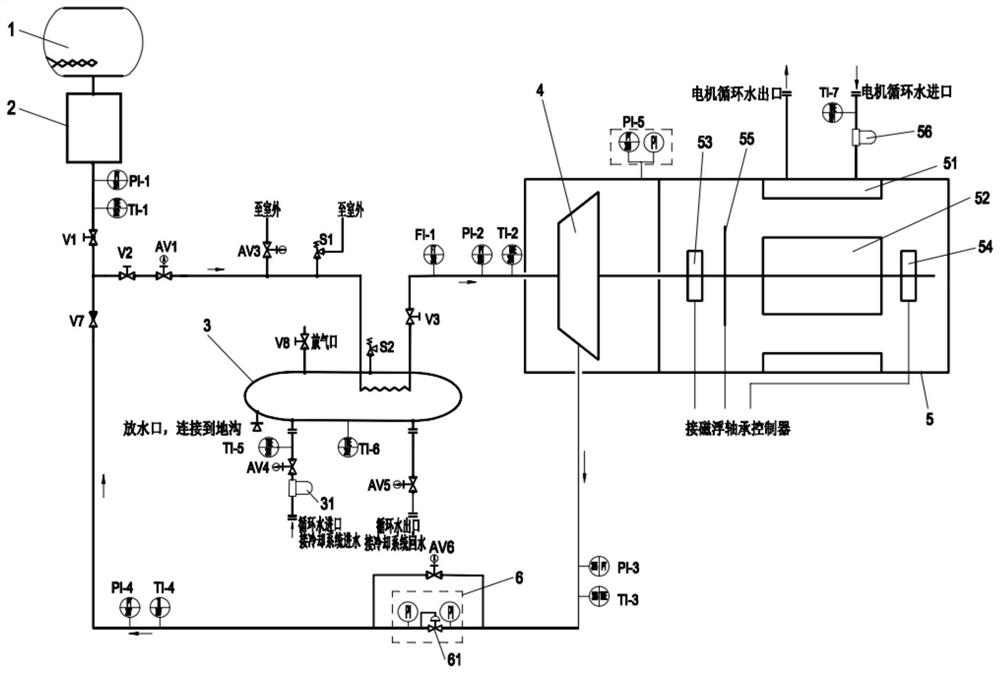

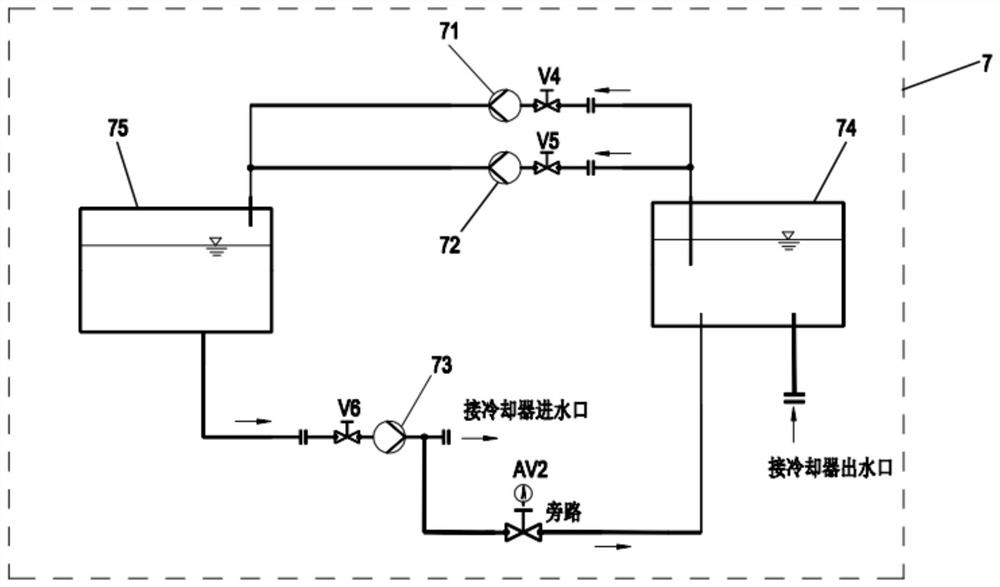

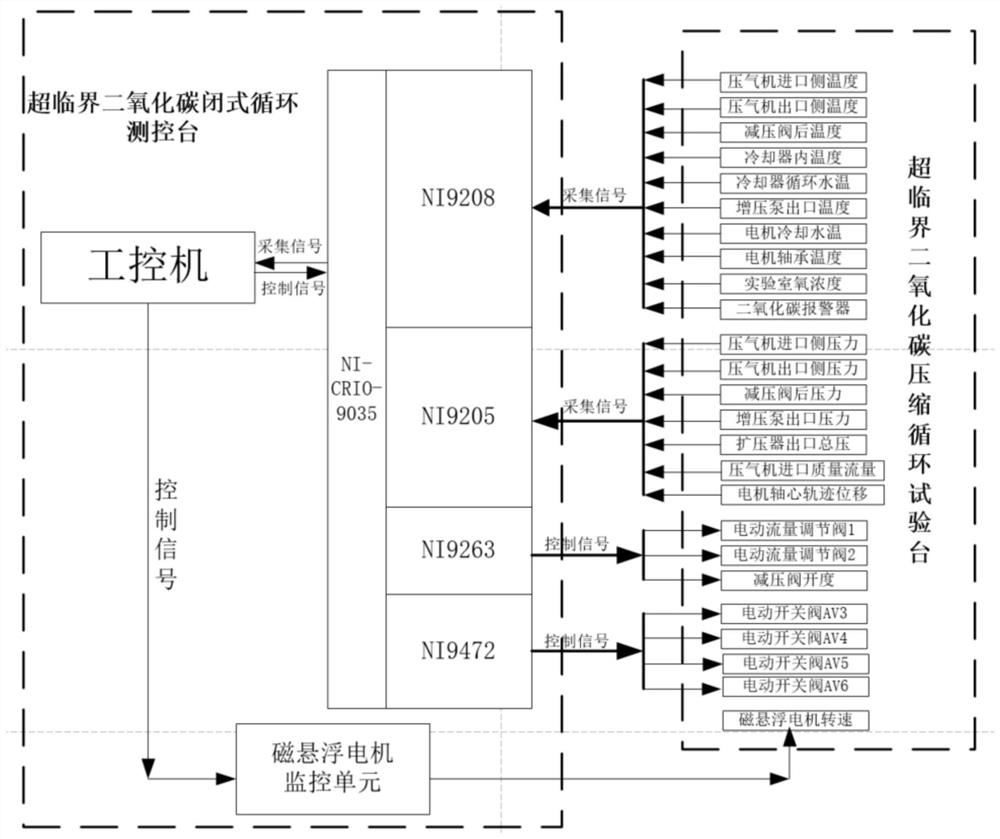

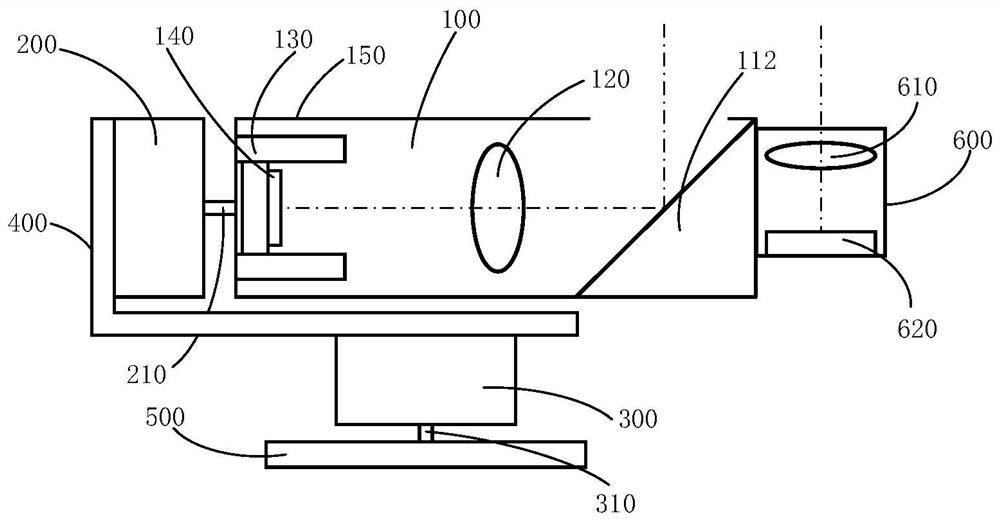

Supercritical carbon dioxide compression cycle test bench

PendingCN112834699ASimple structureDoes not affect test accuracyGas analyser construction detailsGas compressorTest bench

The invention relates to a supercritical carbon dioxide compression cycle test bench. The supercritical carbon dioxide compression cycle test bench is formed by integrating a magnetic suspension motor module, a gas compressor module, a cooling module, a pressure reducing valve module and a sensor module. The rotating speed and the load of a magnetic suspension motor are changed through a magnetic suspension motor monitoring unit in the supercritical carbon dioxide closed circulation measurement and control platform, and different degrees of supercharge ratios of a gas compressor are controlled; the heat exchange effect of the cooler is controlled by changing the opening degree of a circulating water pump in the cooler. Through the use of the pressure reducing valve, the isentropic expansion process of working of the turbine in the Brayton cycle is simulated, and the pressure reducing valve can be controlled through the industrial personal computer so as to adjust the state of an outlet working medium. By monitoring the temperature and the pressure of the key measuring point and the mass flow rate of the supercritical carbon dioxide in the pipeline, the key performance of the supercritical carbon dioxide Brayton cycle core equipment can be tested, the influence of the supercritical carbon dioxide Brayton cycle core equipment on the Brayton thermodynamic cycle is researched, and the working state of the supercritical carbon dioxide Brayton cycle core equipment is monitored.

Owner:WUHAN UNIV OF TECH

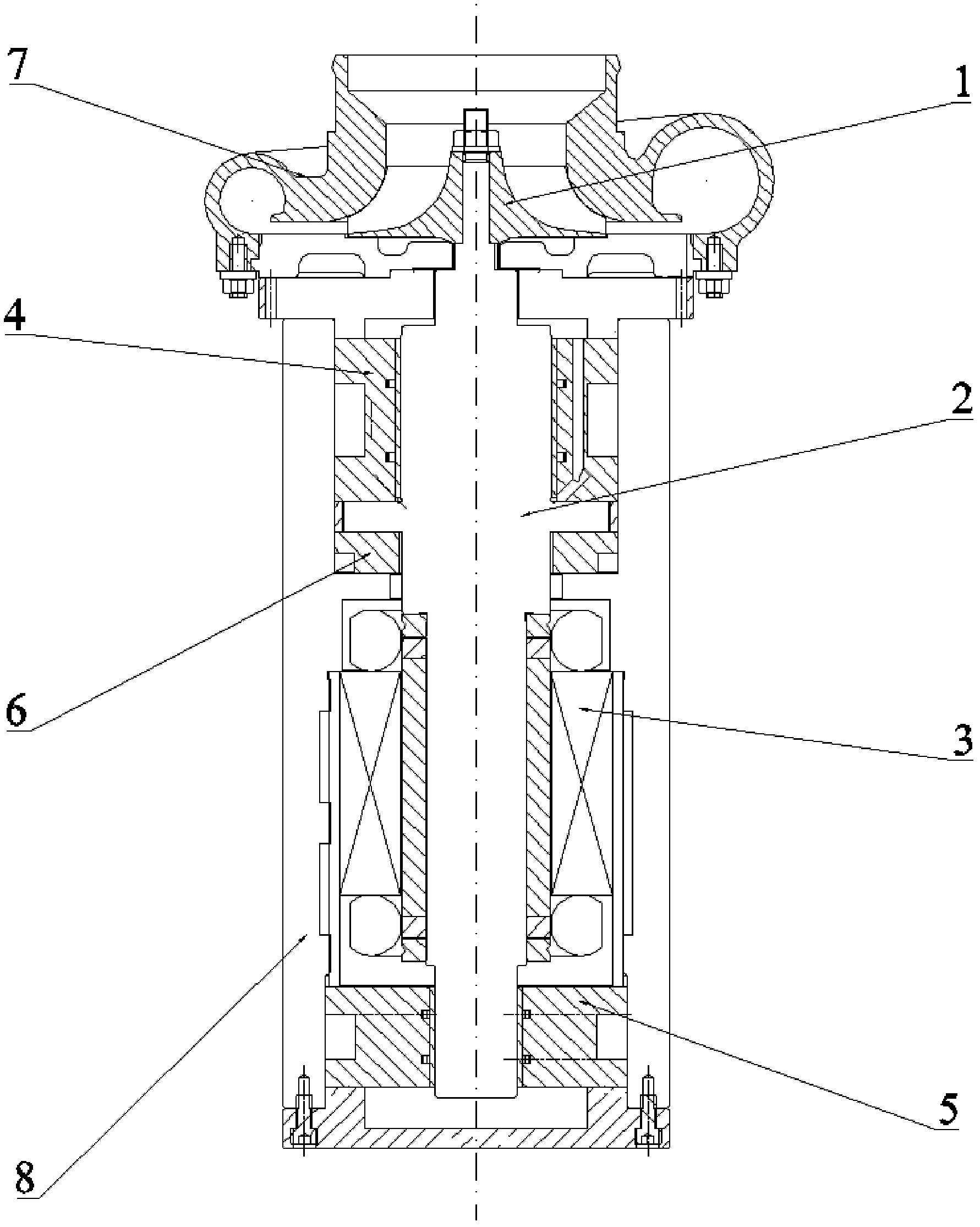

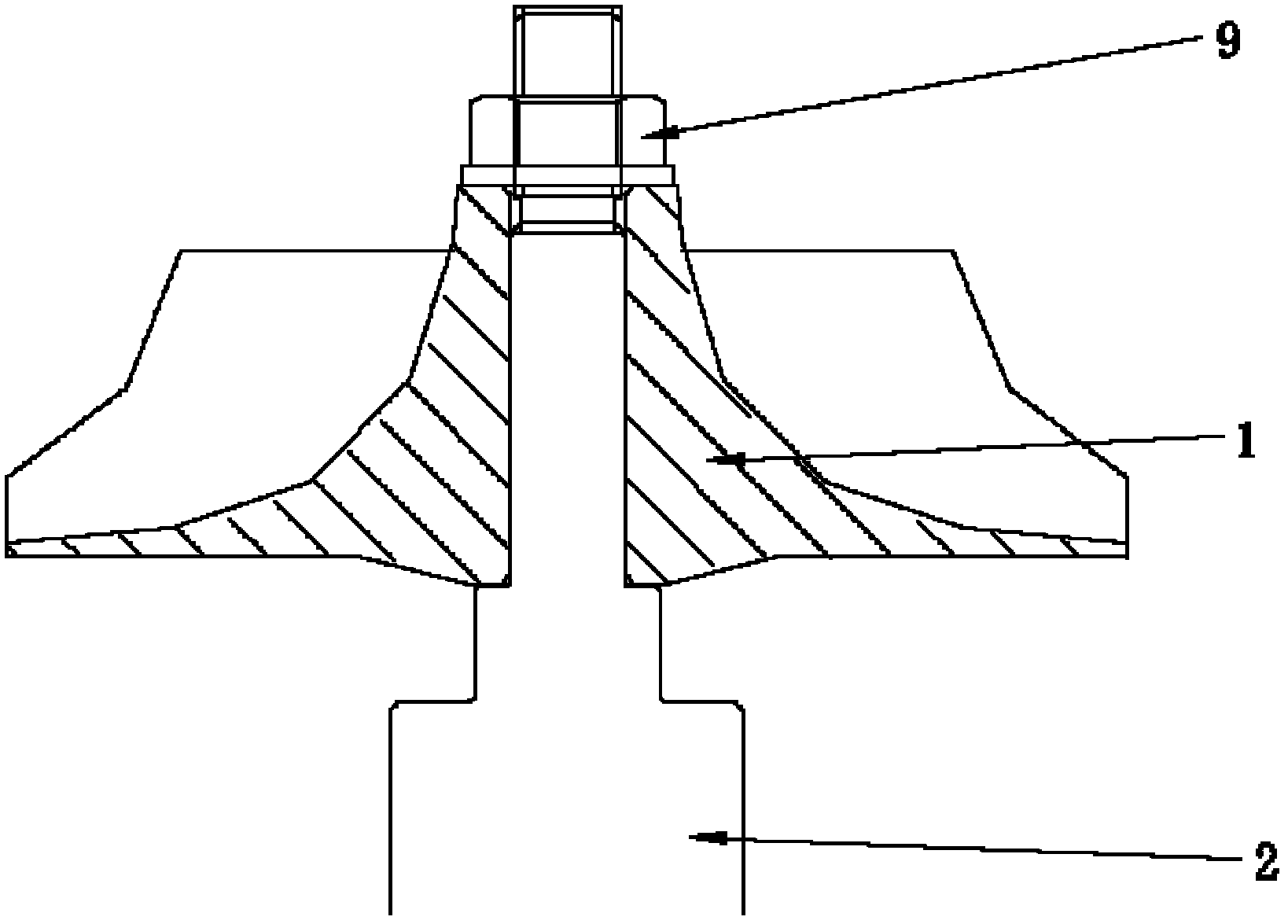

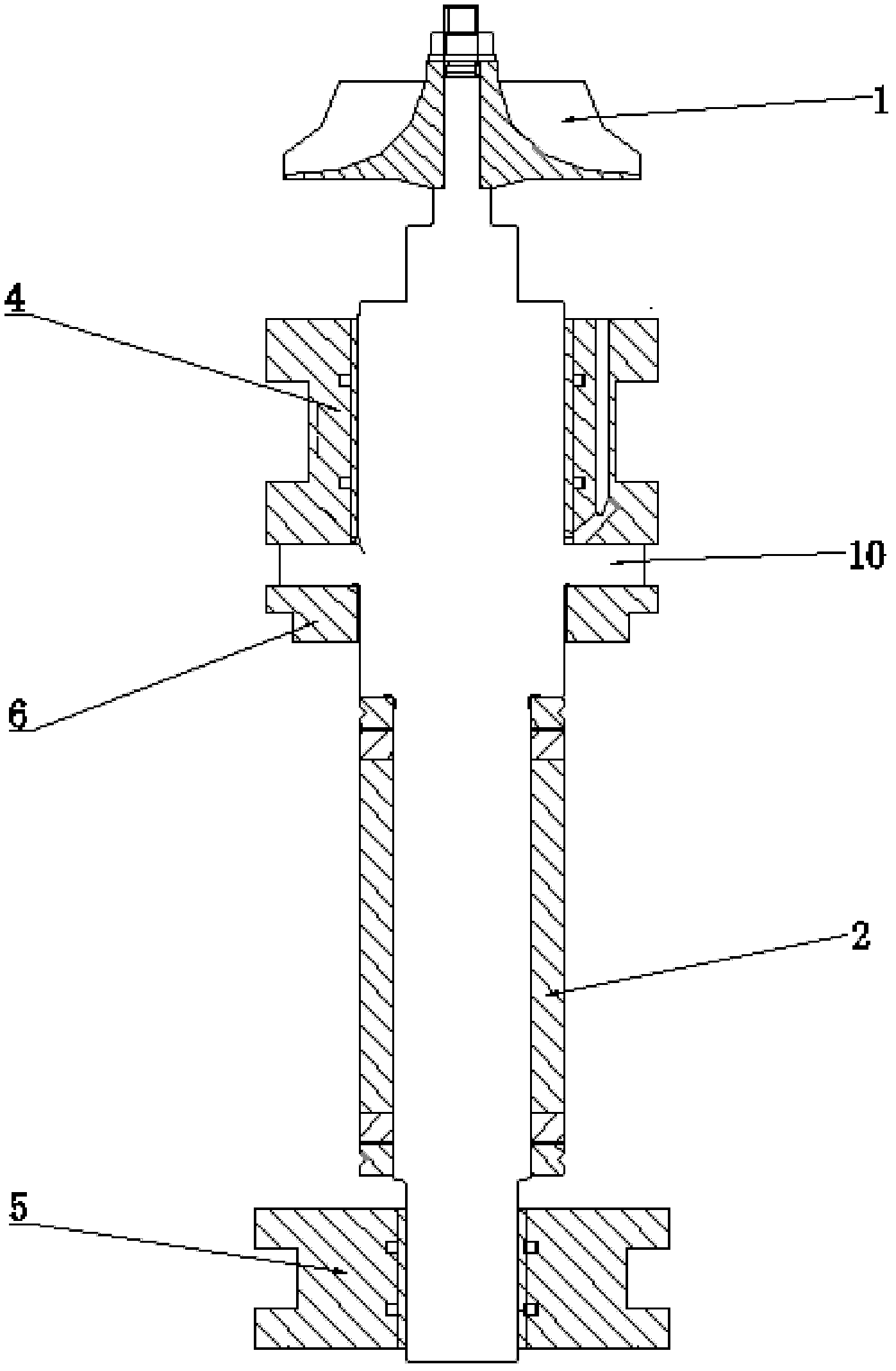

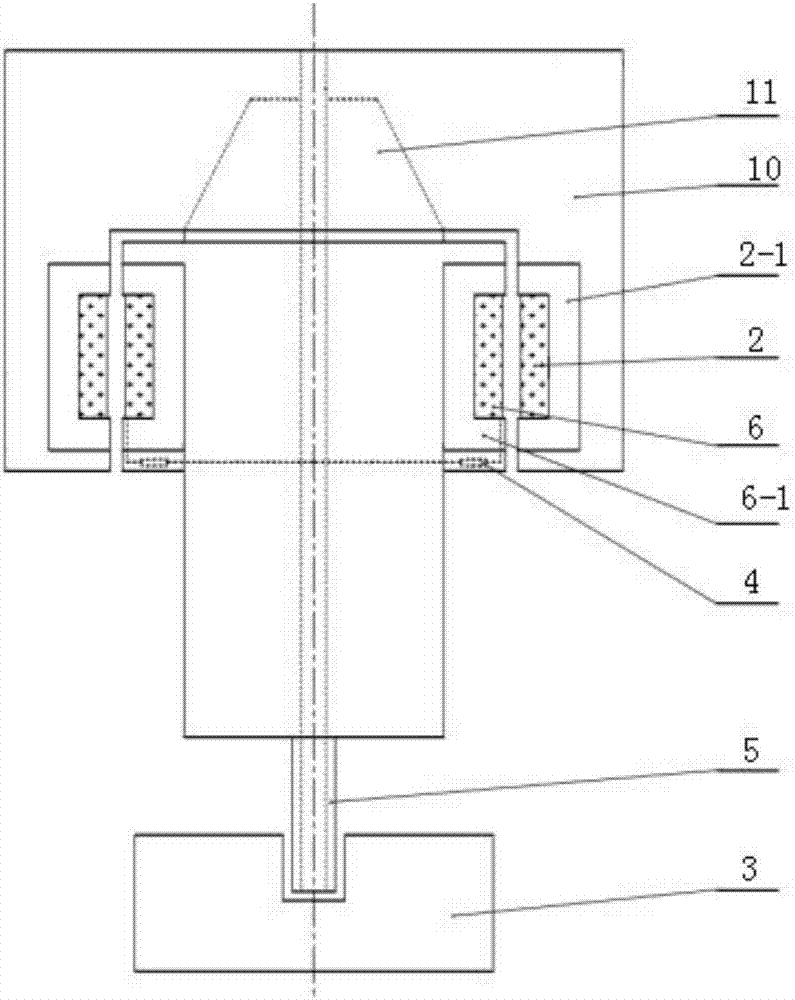

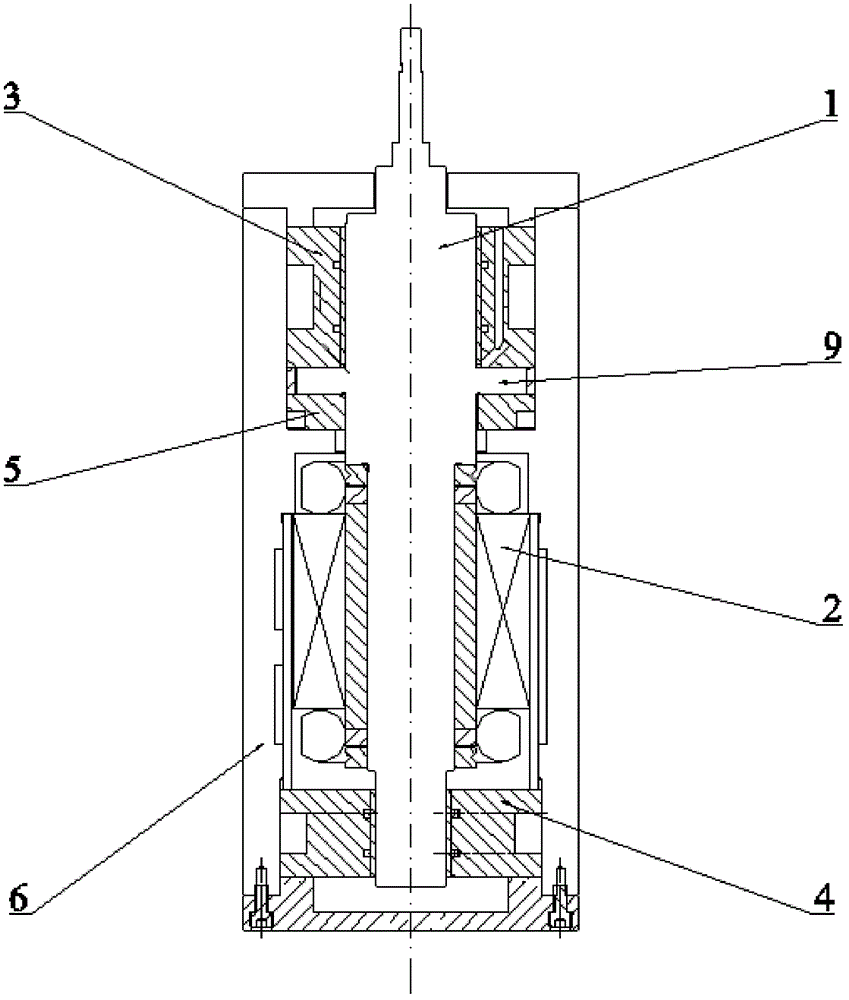

High-power air suspension permanent magnet high-speed motor

ActiveCN102290946BReduce lossImprove machine efficiencyMagnetic circuit rotating partsSupports/enclosures/casingsAir bearingPermanent magnet synchronous motor

The invention discloses a high-power air suspension permanent magnet high-speed motor, which comprises a permanent magnet synchronous motor rotor, a motor stator, a front radial air bearing, a rear radial air bearing, an axial thrust air bearing and a motor shell, wherein the permanent magnet synchronous motor rotor is driven by the motor stator to rotate and is suspended and supported through the front radial air bearing, the rear radial air bearing and the axial thrust air bearing; and the motor stator, the front radial air bearing, the rear radial air bearing, the axial thrust air bearing and the permanent magnet synchronous motor rotor are enclosed by the motor shell. Due to the application of the permanent magnet synchronous motor rotor, the magnetic field strength is higher and the size of the rotor is smaller, so that the motor is suitable for a higher rotation speed; and the power of the motor can be greatly increased by synchronously increasing the magnetic field strength andthe rotation speed.

Owner:宁波虎渡能源科技有限公司

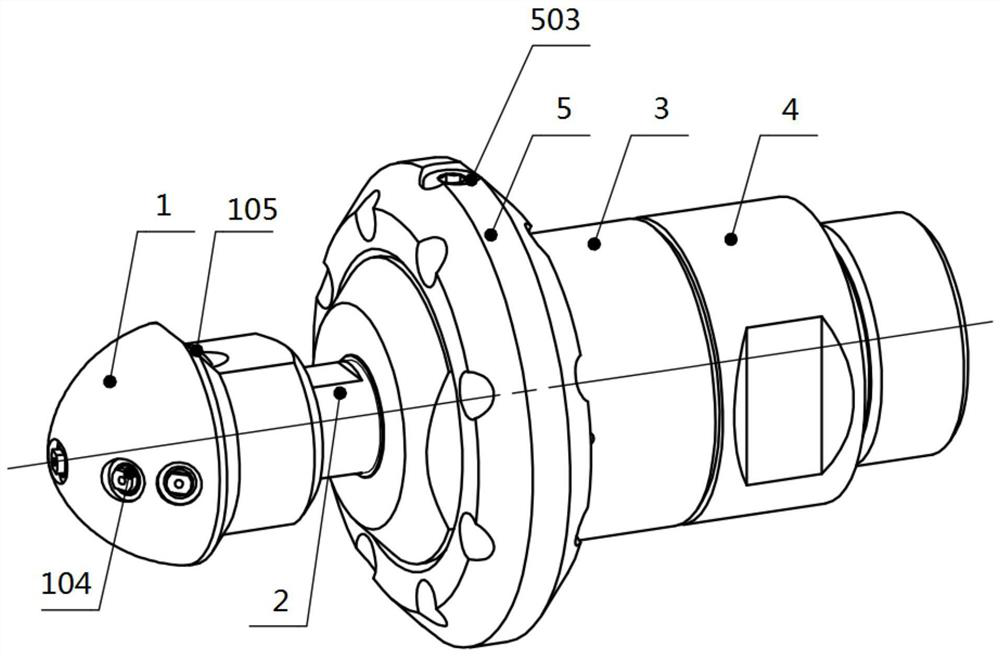

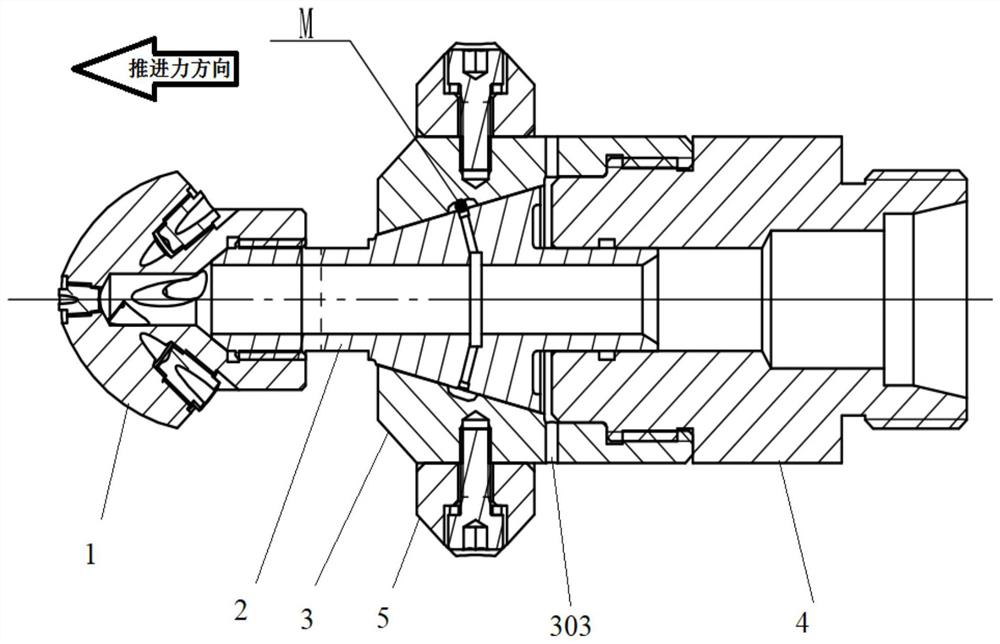

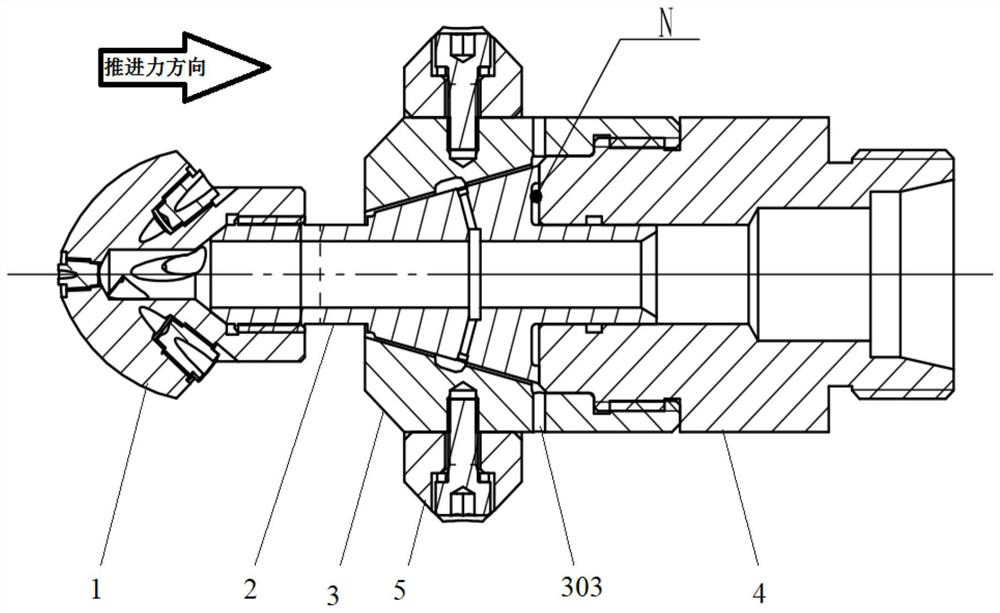

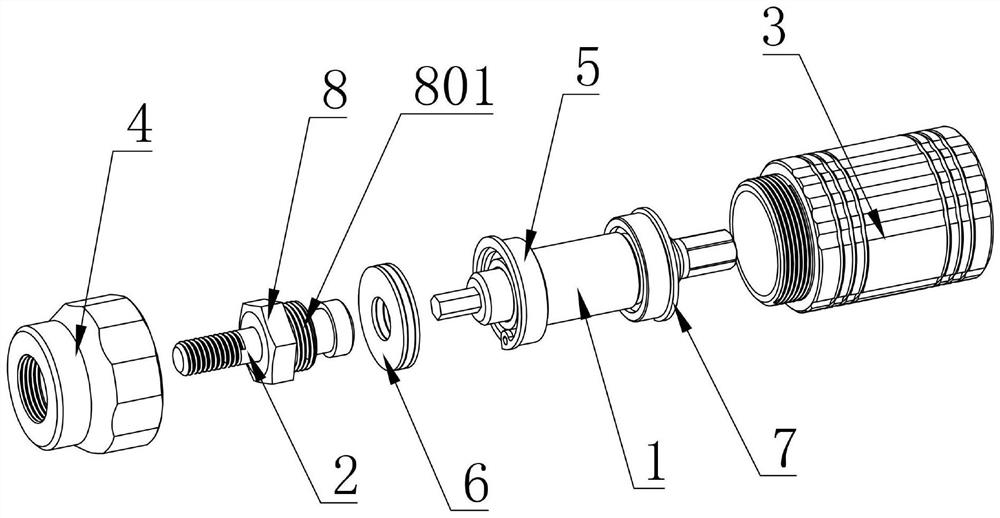

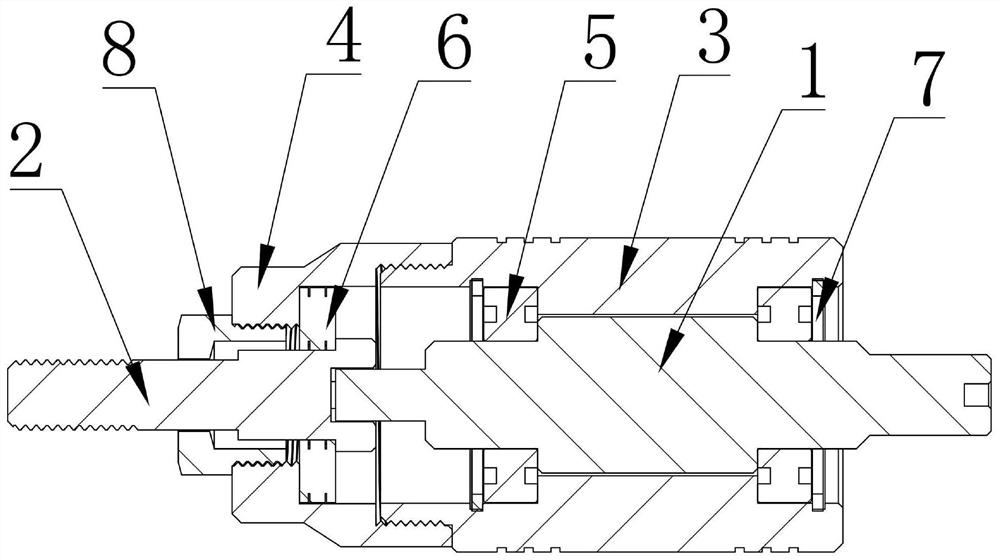

A two-way self-balancing rotary water jet drilling device with adjustable propulsion

ActiveCN110671052BImprove convenienceReduce frictionLiquid/gas jet drillingRotational axisButt joint

The invention discloses a dual-direction self-balance rotation water jet drilling device with adjustable propulsive force. The device comprises a sprayer, a rotation shaft, a shell and a joint used for being connected with a high pressure pipe; the sprayer and the joint are arranged at the two ends of the rotation shaft respectively, and the shell sleeves the rotation shaft; the sprayer is provided with a front spray hole used for being provided with a front spray nozzle and a rear spray hole used for being provided with a rear spray nozzle; the rotation shaft is provided with a first conicalface, the shell is provided with a second conical face matched with the first conical face, a first groove sunken in the second conical face is formed in the circumference of the second conical face,and a second groove sunken in the rotation shaft is formed in the butt joint face of the rotation shaft and the joint in the circumference direction. According to the dual-direction self-balance rotation water jet drilling device, the front and rear spray nozzles with holes different in diameter are selected for controlling the propulsive force and propulsive direction of the device. For the frontand rear spray nozzles different in specification and propulsive forces different in magnitude and direction, two cavities in the device can be automatically balanced, and high-speed rotation of thesprayer is guaranteed.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Cosmetic face cleaner

InactiveCN110811385AAchieve low speedAchieve high-speed rotationBrush bodiesBathroom accessoriesMechanical engineeringIndustrial engineering

The invention discloses a cosmetic face cleaner. A cleaning task is achieved through converting energy on a plurality of accelerating gear handles into kinetic energy of a hairbrush disc that is rotated at high speed, and no electricity is consumed; and the cosmetic face cleaner can be used anytime and anywhere, convenient, saving in energy and environmentally friendly.

Owner:王玲

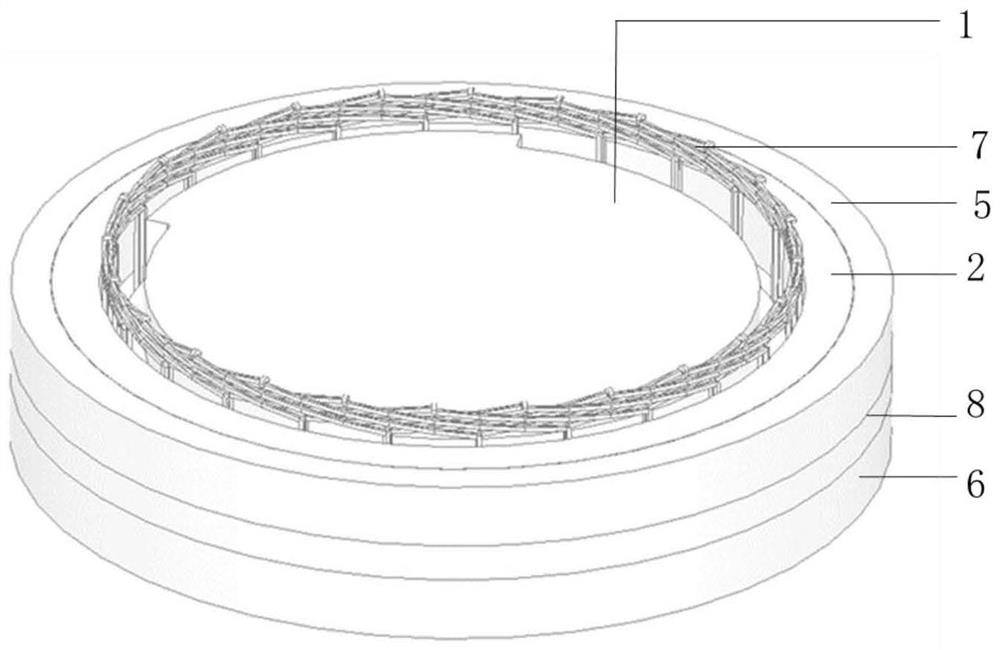

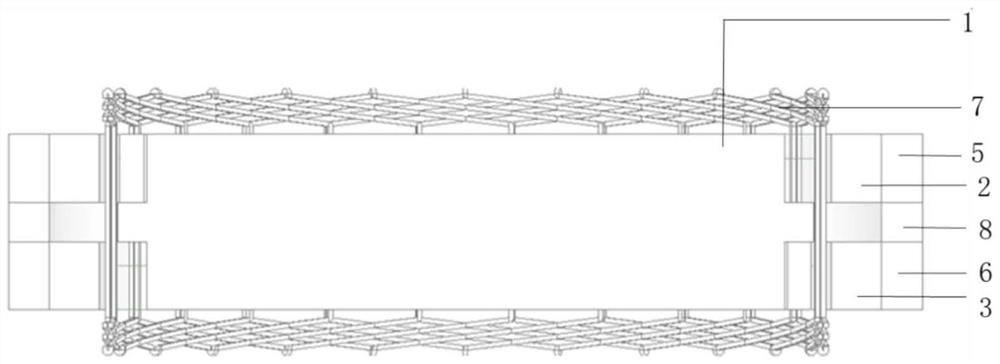

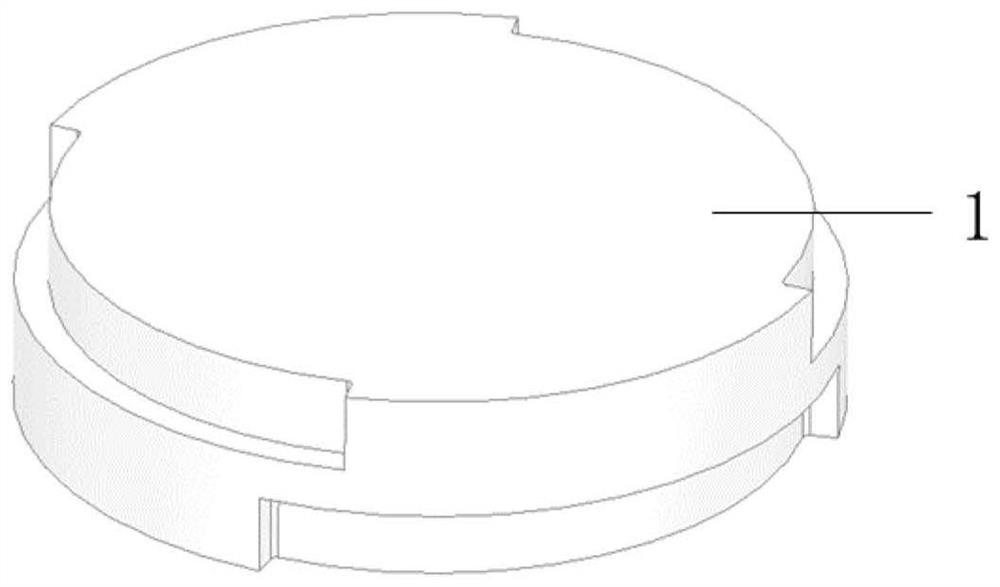

Novel homopolar inductor motor for flywheel energy storage

PendingCN114157091AImprove operational efficiencyReduce temperature riseMagnetic circuit rotating partsMagnetic circuit stationary partsFlywheel energy storageElectric machine

The invention discloses a novel homopolar inductor motor for flywheel energy storage, which comprises a rotor, an upper stator iron core, a lower stator iron core, an upper magnetic conductive ring, a lower magnetic conductive ring, a stator winding and a permanent magnet ring, and is characterized in that a stator is arranged on the outer side of the rotor and comprises an upper stator iron core, a lower stator iron core, an upper magnetic conductive ring, a lower magnetic conductive ring, a stator winding and a permanent magnet ring. A new motor working principle and a new motor structure are adopted, the motor has radial magnetic flux and axial magnetic flux, a permanent magnet excitation mode is adopted, and compared with an electric excitation like-pole inductor motor, excitation copper loss during charging / discharging operation can be eliminated, temperature rise of a stator winding is reduced, heat dissipation pressure is relieved, and therefore the operation efficiency of the motor is improved; the upper stator iron core and the lower stator iron core adopt a gullet-free structure, and a space harmonic magnetic field generated by iron core slotting is eliminated, so that the eddy current loss of the rotor can be greatly reduced.

Owner:威海奥文工业科技有限公司 +1

A fire sprinkler head with adjustable sprinkling range

The invention relates to the technical field of fire-fighting equipment, and discloses a fire-fighting sprinkler head with an adjustable sprinkling range, including a roof wall, the bottom end of the roof wall is fixedly connected with a sprinkler body, and the bottom end of the sprinkler body is movably connected with a A valve plate, the bottom end of the valve plate is movably connected with a glass ball, the interior of the glass ball is equipped with a color liquid, the bottom end of the color liquid is movably connected with a tapered sleeve, and the bottom end of the tapered sleeve is fixedly connected with a splash The water tray, the surface of the splash tray is provided with drainage grooves, and the two ends of the splash tray are movably connected with a rotating shaft and are movably connected with a bracket through the rotating shaft. In the present invention, an inclined drainage groove is arranged on the splash plate, so that when the fire-fighting water passes through the drainage groove, the splash plate is driven to rotate, and the bracket and the positioning block are driven to rotate, so that the casing moves upward along the axis of the nozzle body to a flat surface. The threaded section increases the rotational speed of the splash plate, thereby increasing the spraying area of the fire water.

Owner:马丽莉

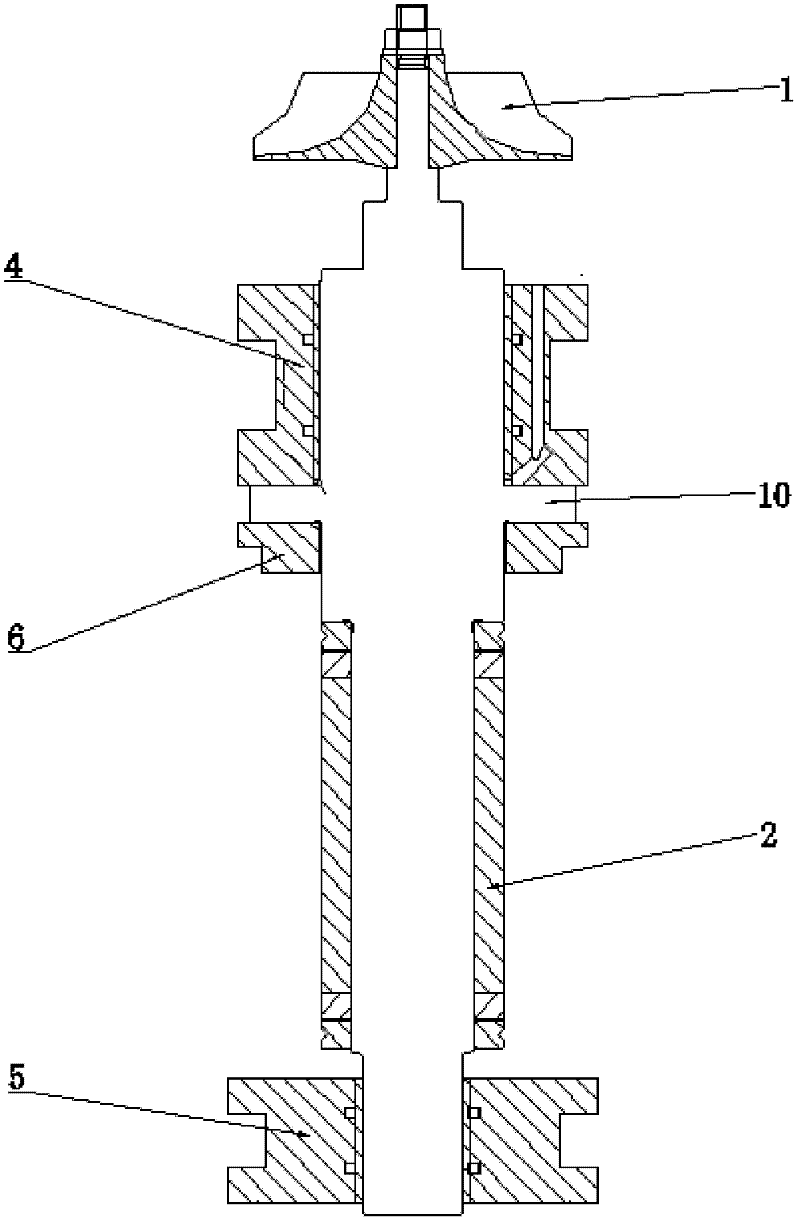

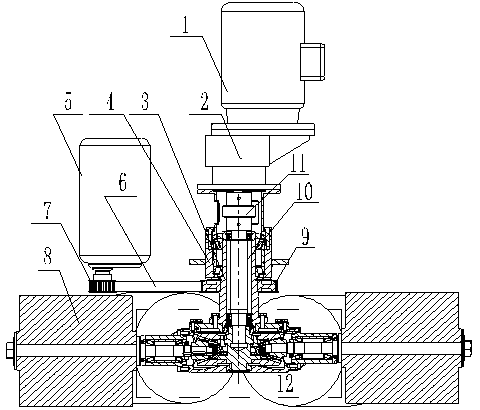

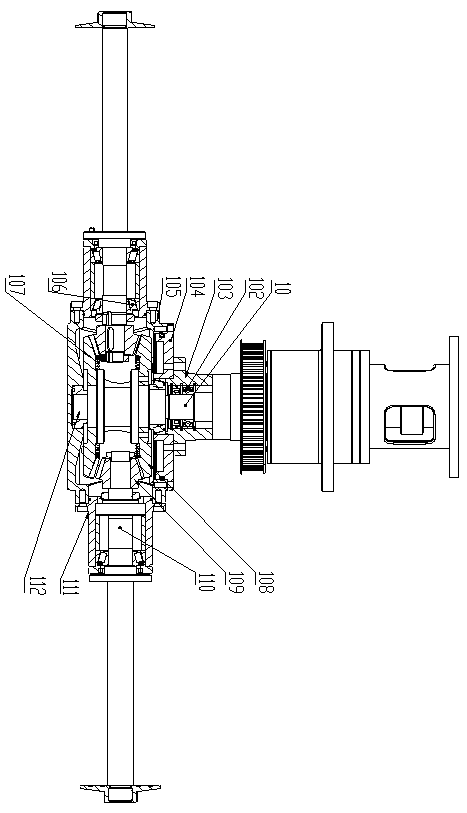

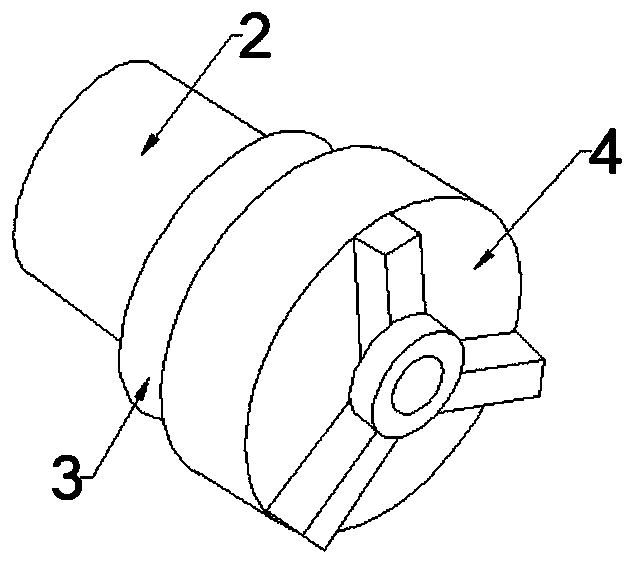

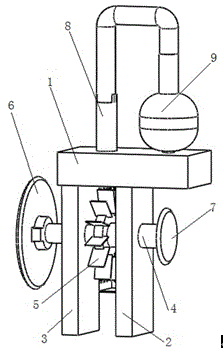

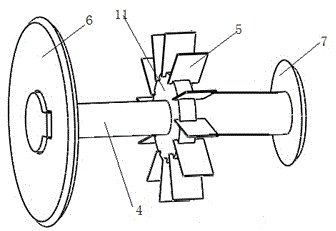

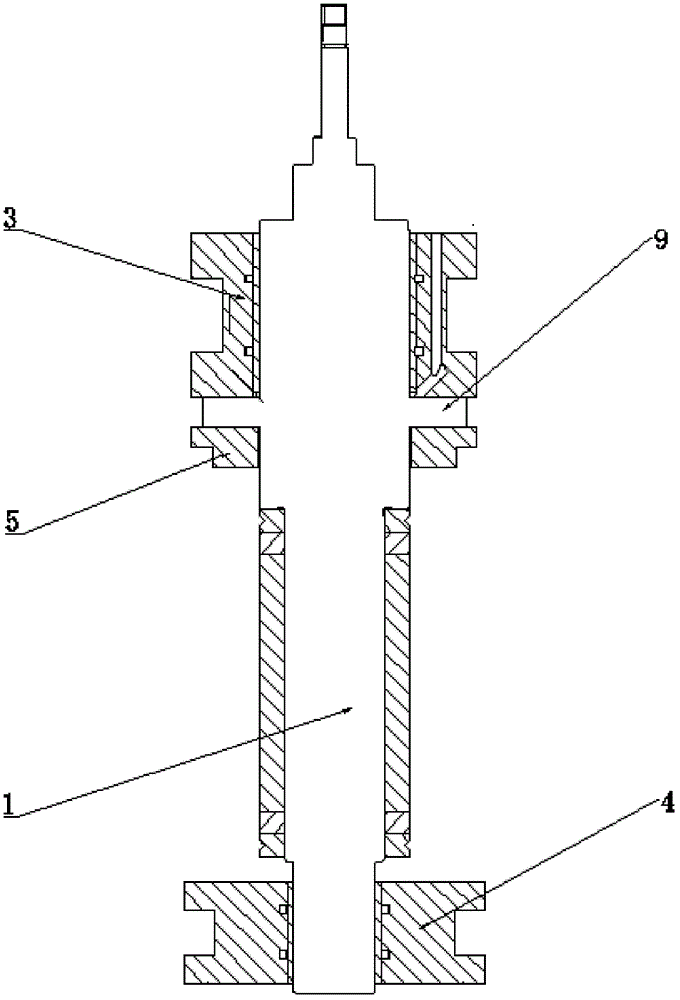

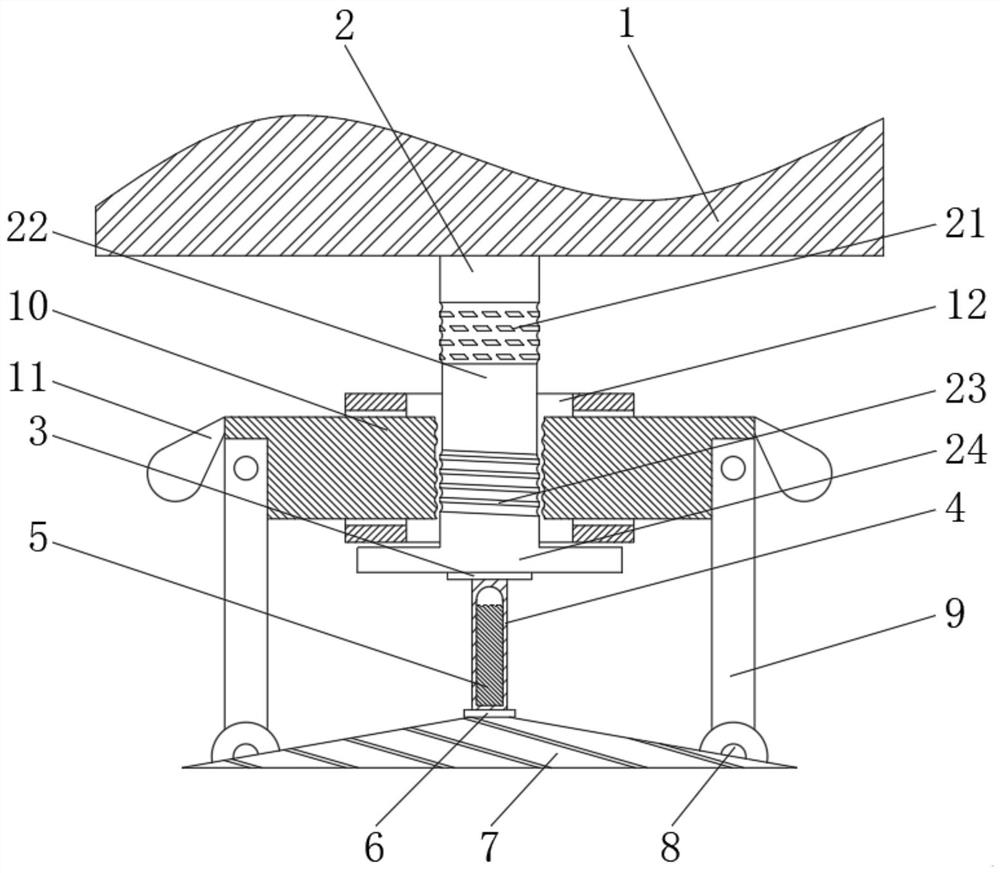

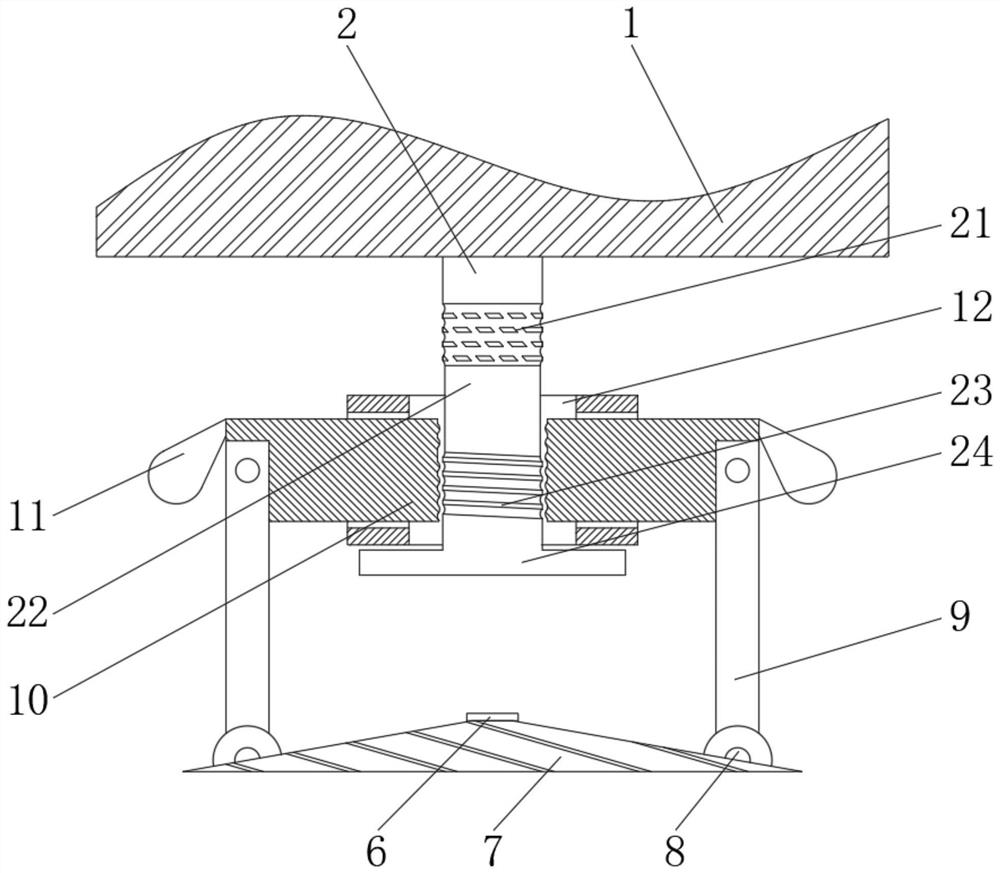

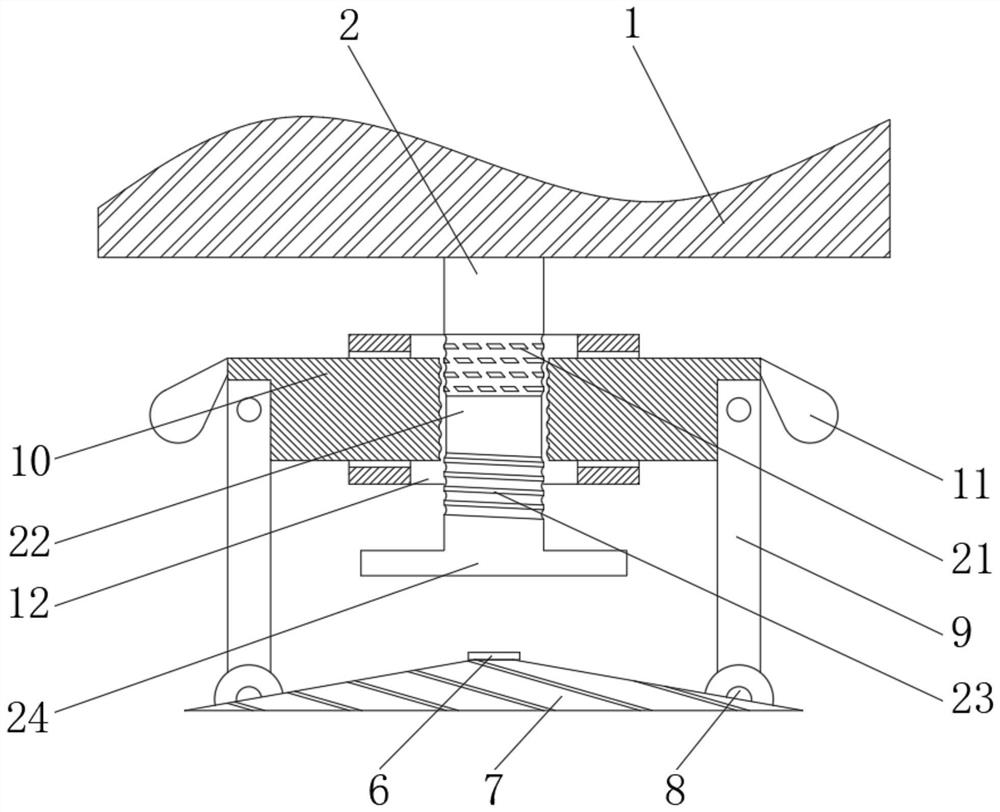

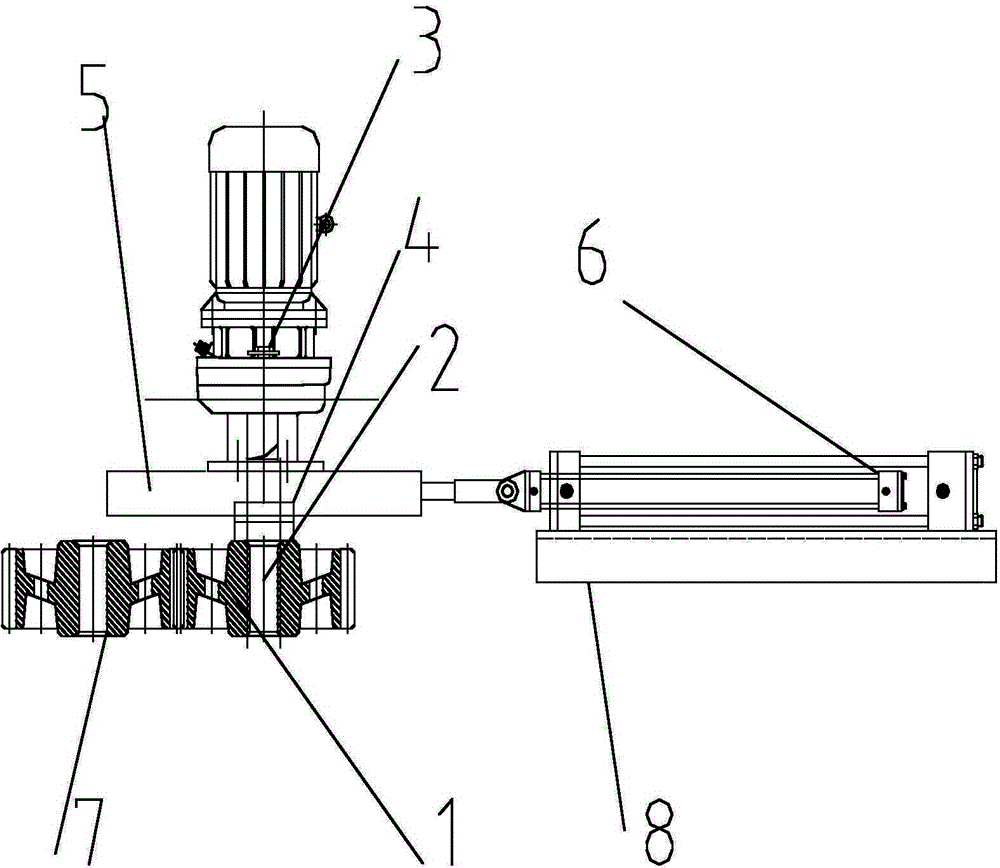

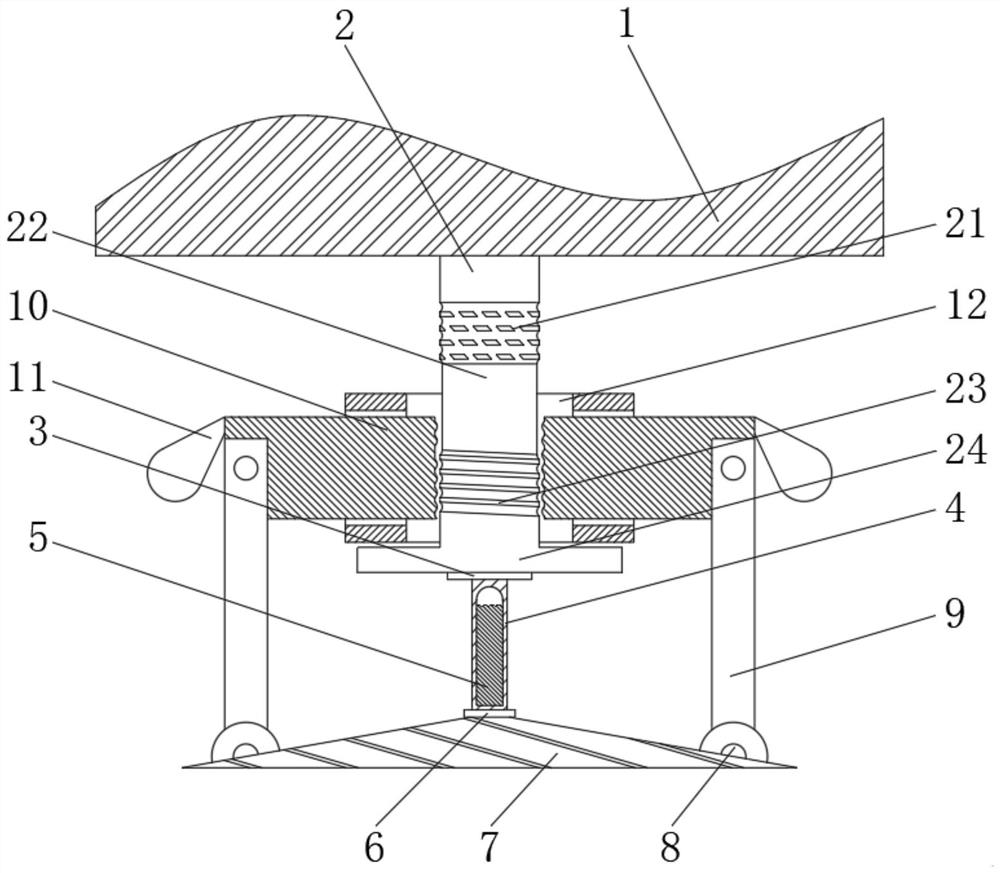

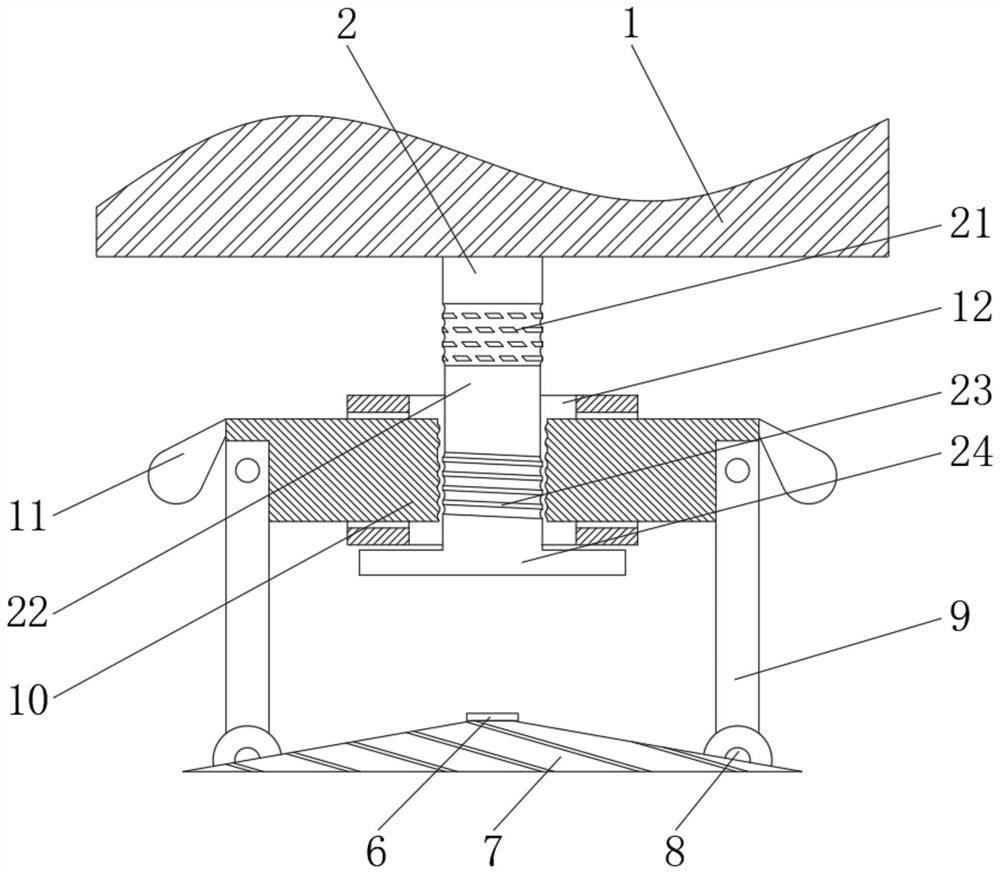

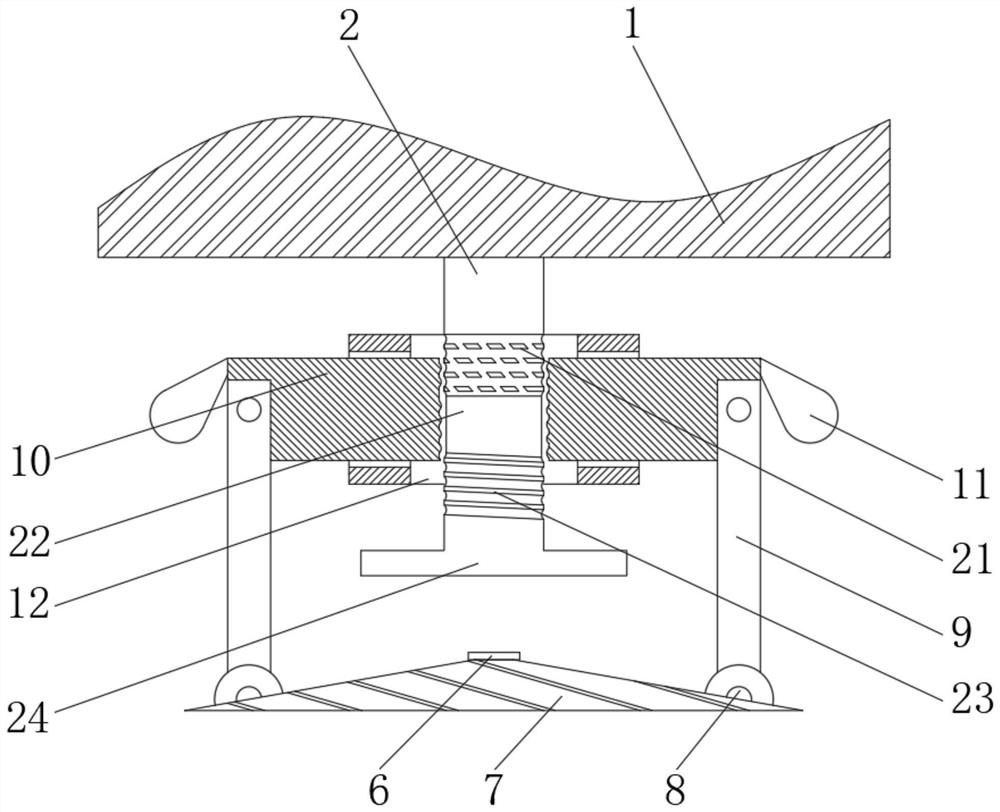

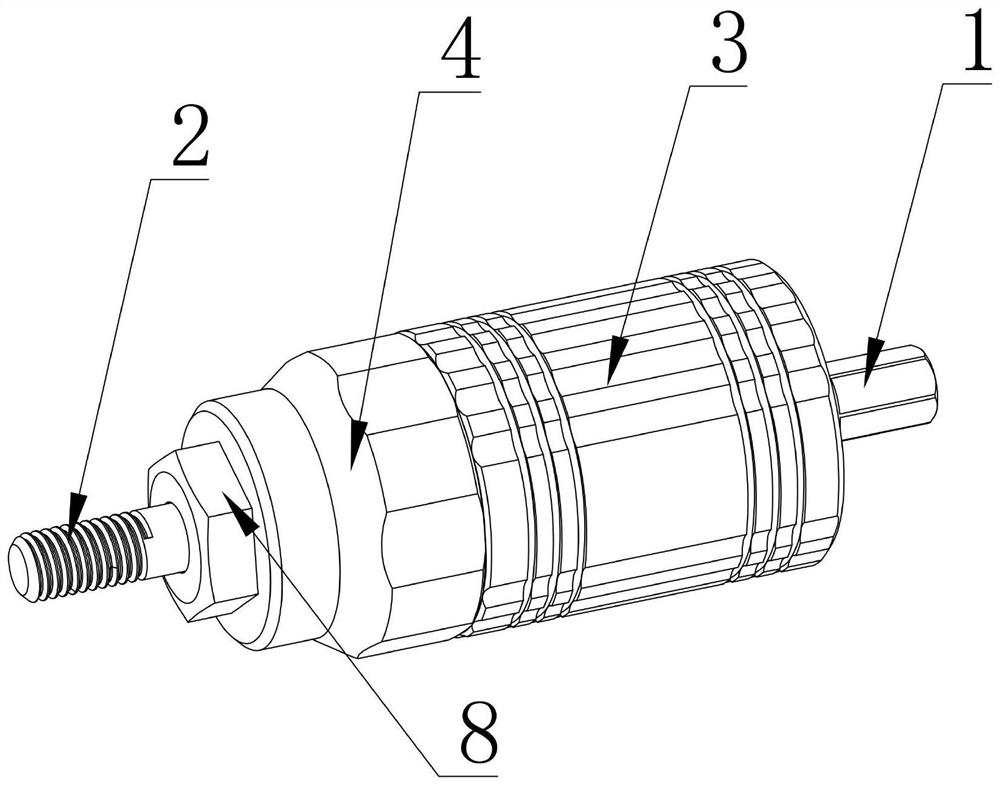

Grease homogenizing mechanism of pneumatic bearing oil-filling grease-homogenizing machine for railway wagon

InactiveCN104549910AAchieve high-speed rotationEvenly distributedLiquid surface applicatorsCoatingsOil and greaseGear wheel

The invention relates to a grease homogenizing mechanism of a pneumatic bearing oil-filling grease-homogenizing machine for a railway wagon, in particular to the grease homogenizing mechanism of the pneumatic bearing oil-filling grease-homogenizing machine for a 197726 type general overhaul bearing of the railway wagon. The grease homogenizing mechanism comprises a coupling shaft gear 1, a coupling shaft 2, a speed reducer and motor structure 3, a shaft coupler 4, a grease homogenizing mechanism frame 5, a grease homogenizing mechanism frame pushing and moving air cylinder 6, an oil-filling head assembly gear 7 and an air cylinder mounting frame 8. The grease homogenizing mechanism mainly has the advantages that the bearing can rotate at the high speed, so that grease is uniformly distributed in the circumferential direction; the grease homogenizing mechanism is simple in structure and convenient to repair.

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

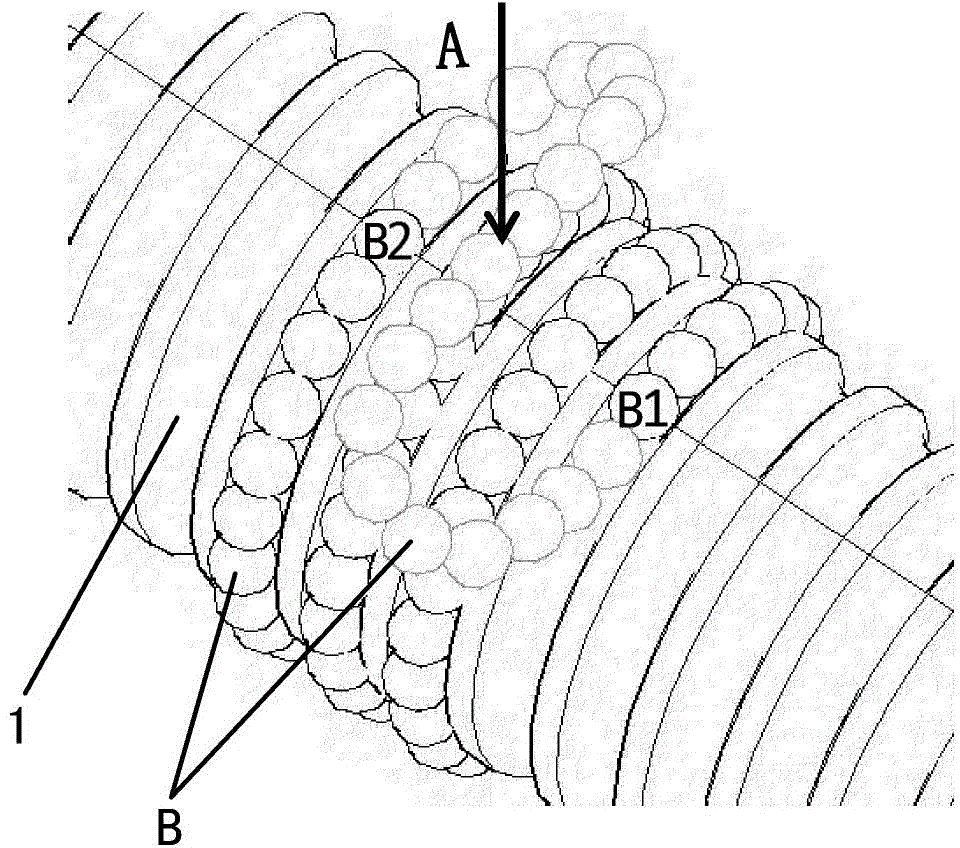

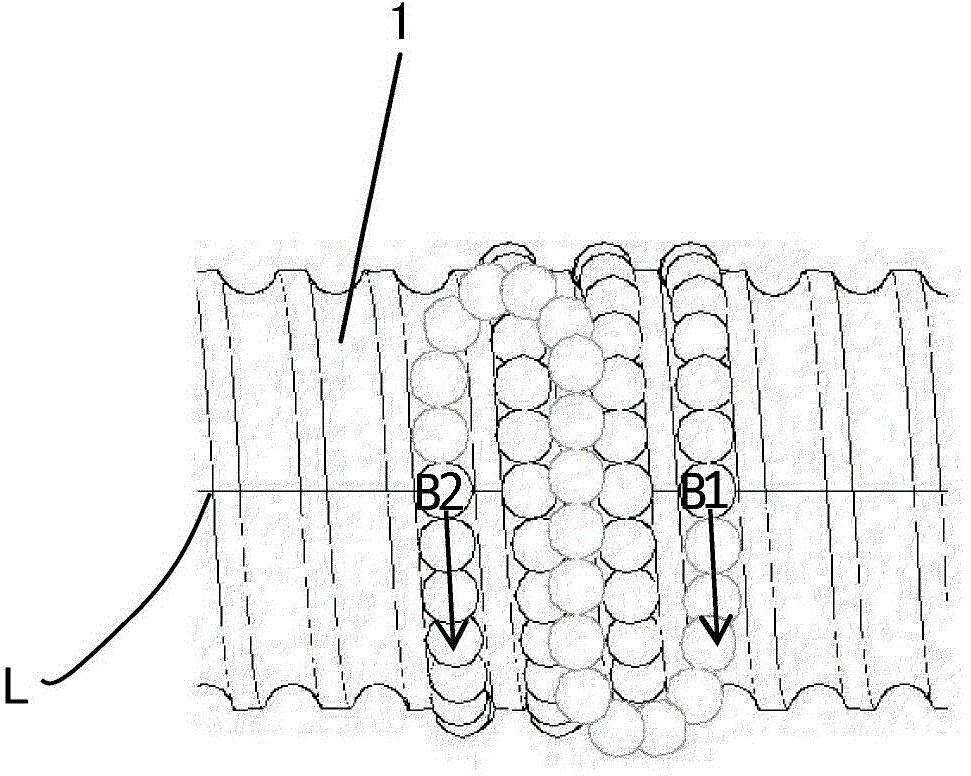

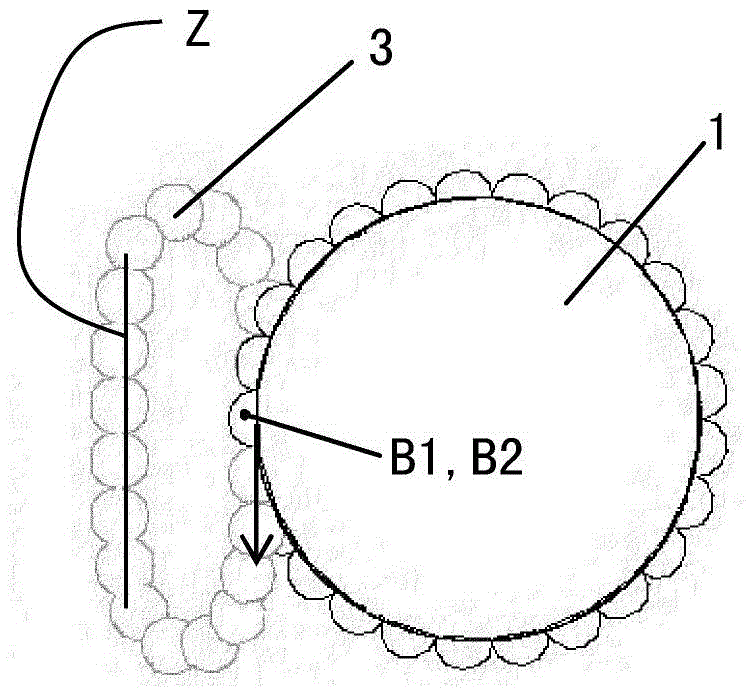

Ball screw device

The invention provides a ball screw device. The ball screw device comprises a screw shaft, a nut, a plurality of balls and a circulating member, wherein a spiral ball rolling groove is formed in the outer peripheral surface of the screw shaft; a spiral loaded ball rolling groove opposite to the ball rolling groove of the screw shaft is formed in the inner peripheral surface of the screw; the balls are located between the ball rolling groove of the screw shaft and the loaded ball rolling groove of the screw; and the circulating member is assembled on the screw, provided with a ball circulating path which enables the balls between the ball rolling groove and the loaded ball rolling groove to circulate, and also provided with a pair of guiding parts used for guiding the balls in the tangential direction of the ball rolling groove of the screw shaft and a direction changing part arranged between the pair of guiding parts and used for changing the rolling direction of the balls, and observation is carried out along the axis of the screw shaft, at least the part, close to the loaded ball rolling groove, of the pair of guiding parts are on the same tangent line relative to the ball rolling groove of the screw shaft. Therefore, the balls can be enabled to roll smoothly to realize high-speed rotation of the ball screw device, besides, the loading capacity of the ball screw device is improved, and the loading balance of the balls is favorable.

Owner:THK CO LTD

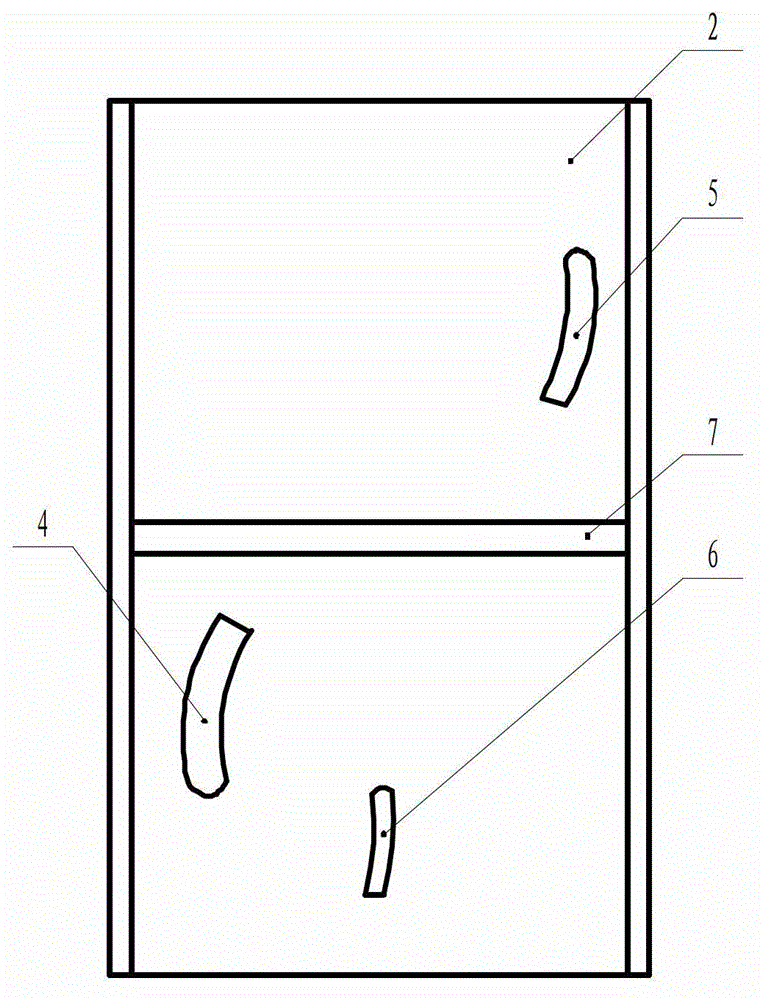

Fire-fighting spray head capable of adjusting spraying range

InactiveCN111803844AIncrease speedExpand the spraying areaFire rescueGlass ballStructural engineering

The invention relates to the technical field of fire-fighting equipment, and discloses a fire-fighting spray head capable of adjusting a spraying range. The spray head comprises a roof wall, the bottom end of the roof wall is fixedly connected with a spray head main body, the bottom end of the spray head main body is movably connected with a valve plate, the bottom end of the valve plate is movably connected with a glass ball, the glass ball is filled with a colored liquid, the bottom end of the colored liquid is movably connected with a taper sleeve, the bottom end of the taper sleeve is fixedly connected with a water splashing disc, a flow guiding groove is formed in the surface of the water splashing disc, and the two ends of the water splashing disc are movably connected with rotatingshafts and movably connected with supports through the rotating shafts. According to the spray head, the inclined flow guiding groove is formed in the water splashing disc, so that when fire-fightingwater passes through the flow guiding groove, the water splashing disc is pushed to rotate, the supports and positioning blocks are driven to rotate, the sleeve moves upwards to a flat thread sectionalong the axis of the spray head main body, the rotating speed of the water splashing disc is increased, and the spraying area of the fire-fighting water is increased.

Owner:马丽莉

Intelligent milling machine equipment

InactiveCN112404542AAchieve high-speed rotationAutomatic control devicesFeeding apparatusMachineFan blade

The invention relates to the field of intelligent manufacturing, in particular to intelligent milling machine equipment. The equipment can solve the problems that in existing industrial production, machining equipment is not intelligent enough, workpieces clamped by clamps are single in shape, and scrap iron is not easy to clean. According to the equipment, a servo motor of a tool control assemblyis controlled to achieve high-speed rotation of a tool after the tool is clamped, the tool is controlled to move in any direction to machine a workpiece through a pre-edited program in the servo motor, the rotary plate is rotated, two clamps get close to each other or get away from each other at the same time, so that the workpiece is clamped after the distance is adjusted; and after the special-shaped workpiece is clamped, sliding rod slides, all clamping points of the workpiece are clamped under the elastic force of a spring, fan blades blow scrap iron generated in the machining process into a scrap iron box, and the scrap iron is pressed into blocks to be discharged out of equipment.

Owner:广州开门红科技有限公司

Bottle cap cleaner

ActiveCN102909194AAchieve high-speed rotationIncrease productionCleaning using gasesMaterial resourcesBottle cap

The invention discloses a bottle cap cleaner which belongs auxiliary equipment on a lid maker. The invention overcomes the defects of waste on manpower and material resources, incomplete cleanness on a product, poor quality and low yield in the process of manually cleaning a tinplate and unscrewing a bottle cap in the prior art. The bottle cap cleaner mainly comprises a U-shaped plate and a control box; the control box is arranged on the U-shaped plate; the U-shaped plate is provided with air outlets; the control box is provided with an air inlet; an electromagnetic valve is arranged in the control box; the air inlet and the air outlets are respectively connected with the electromagnetic valve by air pipes; the air outlets comprise a first air outlet, a second air outlet and a third air outlet; air outlet guide pipes are respectively arranged on the first air outlet, the second air outlet and the third air outlet; the first air outlet and the second air outlet have opposite directions; and a fixed rod is arranged on the U-shaped plate. The bottle cap cleaner is mainly used for the lid maker.

Owner:SHANDONG HUANQIU TINPLATE CAN MAKING

A kind of model toy processing device

ActiveCN108620268BGood rinseIncrease movement speedPretreated surfacesLiquid spraying apparatusElectric machineryStructural engineering

The invention discloses a model toy processing device. The model toy processing device comprises a base, a first support tube and a second support tube. Driving motors are mounted on the left and right side of the interior of the base. Driving belts are arranged above the driving motors. A conveyor belt is mounted above the driving belts. Vertical frames are fixed to the left and right sides of the upper portion of the base correspondingly. Spray-washing supporting plates are mounted on the outer sides of the vertical frames. The left and right sides of the upper portion of the spray-washing supporting plates are both provided with water inlet pipe orifices. Telescopic pipes are mounted below the spray-washing supporting plates. A fixed tube is mounted in the first support tube. The firstsupport tube is located above conveying rollers. An air-drying tube is mounted in the second support tube. The second support tube is located on the right side of the first support tube. When conducting coloring processing on toy products, the model toy processing device can guarantee the coloring uniformity, is good in coloring effect and capable of conducting continuous and long-time coloring operation and conducting washing and cleaning on toys before and after coloring.

Owner:河北萨玛特儿童玩具有限公司

A water-saving drip irrigation system that utilizes water head drop for irrigation

ActiveCN110268947BDrip irrigationSave power resourcesClimate change adaptationWatering devicesWater sourceDrip irrigation

The invention discloses a water-saving drip irrigation system for irrigating by water source drop, comprising a first vertical board and a second vertical board, and a fixed plate is fixedly connected between the opposite sides of the first vertical board and the second vertical board , and the top of the fixed plate is fixedly connected with the water tank, the two sides of the inner wall of the water tank are slidably connected with the sliding plate, and the top of the sliding plate is fixedly connected with the gasket, and both sides of the bottom of the inner wall of the water tank are fixedly connected with the fixed block, two A buffer plate is slidably connected between the opposite sides of the inner wall of the fixed block, and buffer springs are fixedly connected to both sides of the bottom of the buffer plate. The invention relates to the technical field of water-saving drip irrigation. The water-saving drip irrigation system that utilizes the drop of water source for irrigation can realize drip irrigation for agriculture by its own pressure generated by the falling water source from the reservoir, without using other power systems and water pumps for pressurized water delivery, which saves a certain amount of power resources and is applicable The wide range facilitates use in resource-poor areas.

Owner:宁夏大诚顺建设工程有限公司

Makeup face cleansing device

InactiveCN109953677AAchieve low speedAchieve high-speed rotationBathroom accessoriesElectricityEngineering

The invention provides a makeup face cleansing device. The energy on the hand is converted into kinetic energy of a hair brush disc in high-speed rotation through a plurality of speed acceleration gears; the cleaning task can be realized; the electricity is not needed; the makeup face cleansing device can be used in any place at any time; the energy is conveniently saved; the environment is protected.

Owner:王玲

An energy-saving rice milling and peeling equipment

ActiveCN109092399BAchieve deliveryRealize rice skin separationSaving energy measuresGrain treatmentsAgricultural engineeringCam

The invention discloses energy-saving rice milling and hulling equipment, and belongs to the field of food machinery. The energy-saving rice milling and hulling equipment is composed of a conveying mechanism, a milling mechanism, a vibration mechanism and an air blowing mechanism. The milling mechanism, the vibration mechanism and the air blowing mechanism are mounted and fixed on the conveying mechanism. The conveying mechanism is composed of a bottom plate, supporting columns, belt pulleys, side plates, a hulling cavity, rectangular holes, a U-shaped inclined plate, a transverse moving track, a main motor frame, a main motor, a motor shaft, a wide chain, a rice inlet and a conveyor belt. The milling mechanism is composed of linear motors, vertical frames, a top block, a drying lamp, a milling wheel and a middle shaft. The vibration mechanism is composed of vibrating motor shells, vibration motors, a vibration shaft and a cam. The air blowing mechanism is composed of an air blower, anair outlet, a fixing block and an air inlet. The energy-saving rice milling and hulling equipment has the beneficial effects that through composition of the conveying mechanism, the milling mechanism, the vibration mechanism and the air blowing mechanism, especially through the linear motors and the air blower, the low-energy-consumption rice milling and hulling effects are achieved.

Owner:湖北国宝桥米有限公司

Efficient electric nut gun head with long service life

Owner:YUYAO JINMA TOOLS CO LTD

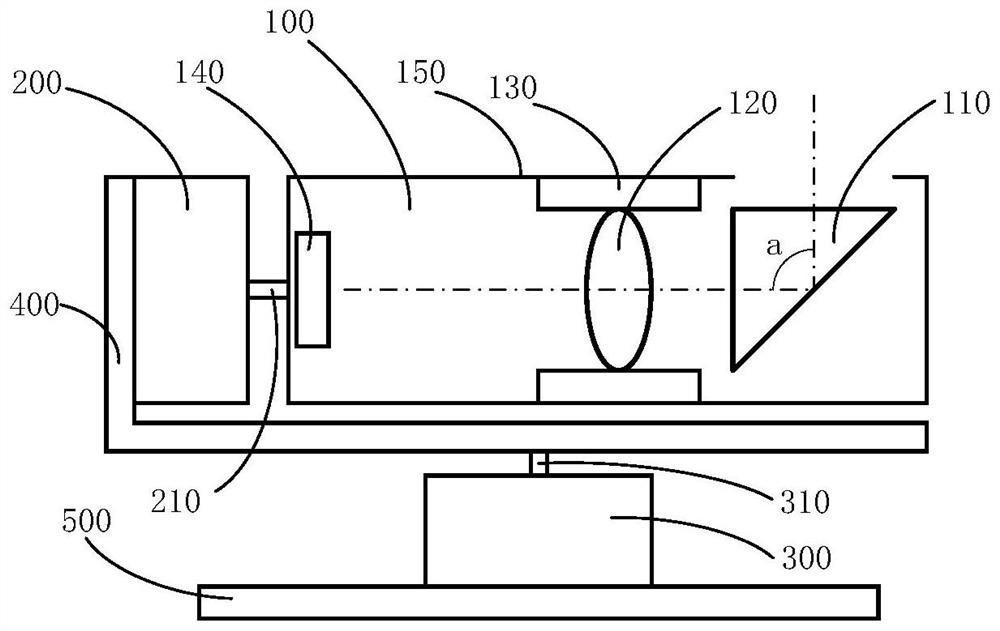

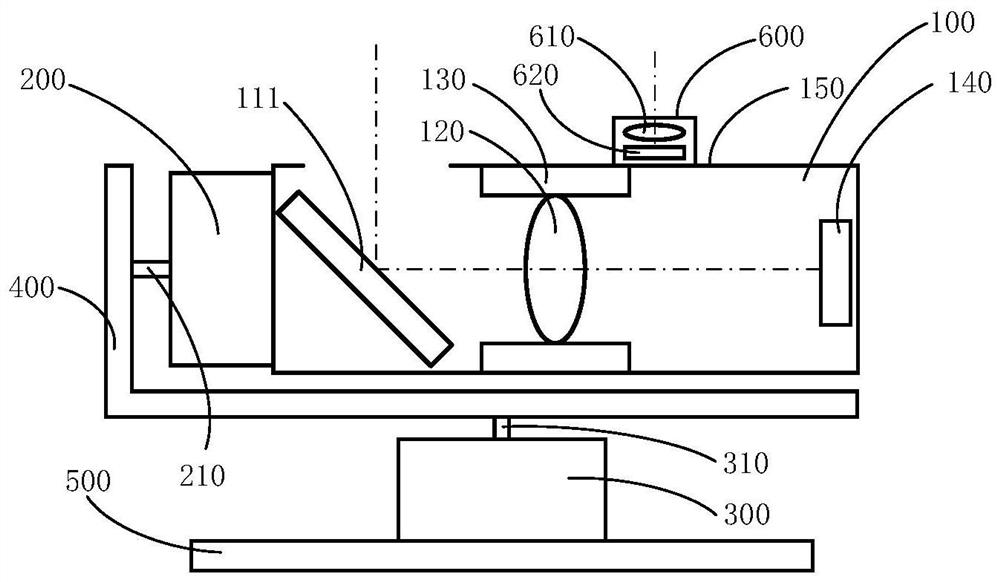

Periscopic imaging holder

PendingCN114025074AReduced torque requirementsMiniaturizationTelevision system detailsColor television detailsRotational axisOptical axis

The invention discloses a periscopic imaging holder, and the imaging holder is characterized in that the imaging holder comprises an optical movement, a first rotating mechanism, an adapter bracket and a second rotating mechanism which are connected in sequence; the optical movement comprises a reflecting element, a first imaging lens, a focusing mechanism and a first image sensor which are arranged in sequence; the reflecting element enables the light to generate angle turning; the rotating shaft of the first rotating mechanism is parallel to or coincides with the optical axis of the first imaging lens, and the rotating shafts of the first rotating mechanism and the second rotating mechanism are perpendicular to each other. Transverse arrangement of a reflection light path and the barrel length is formed, when the lens is in a long focus and the optical movement rotates around the rotating shaft, a shorter rotating force arm and smaller rotating inertia can be obtained, the shorter rotating force arm can greatly improve the stability, the smaller rotating inertia can reduce the torque requirement for the first rotating mechanism, high-speed rotation can be conveniently achieved, the the miniaturization of the first rotating mechanism is facilitated, and the second rotating mechanism is similar.

Owner:CONVERGENCE TECH CO LTD

Scaling structure type line dynamic and static pressure air bearing

ActiveCN103244560BReduce distractionsIncreased ability to withstand external loadsBearing componentsBearingsLow speedAir bearing

Scaling structure profile hydrodynamic air bearing. The traditional air bearing adopts a simple rectangular inner channel, and the profile of the channel cannot exert the best effect of dynamic pressure, which will lead to the problem of insufficient load at low speed and aerodynamic instability at high speed. The composition of the present invention includes: a bearing body (2), the inner surface of the bearing body has a dynamic pressure structure, and the dynamic pressure structure is a scaling linear pressurized channel groove (3), and the bearing body has a static Pressure structure, the static pressure structure includes an air supply hole (4), the air supply hole communicates with the throttle nozzle (5), and the elastic ring (6) is installed on the bearing body. The invention is used to support high-speed rotating machinery.

Owner:南京耦合动力工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com