Supercritical carbon dioxide compression cycle test bench

A carbon dioxide, compression cycle technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of low acquisition accuracy, complex structure, low replaceability, etc., and achieve the effect of increasing replacement modules, simplifying structure, and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

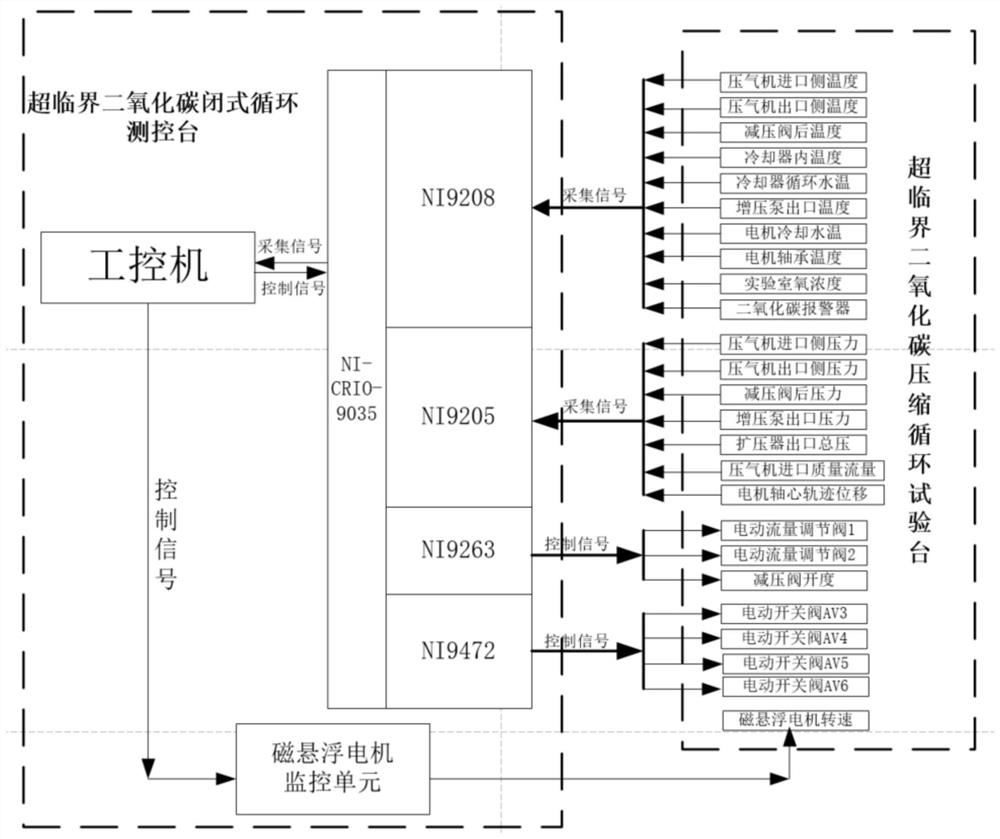

[0035] The invention provides a supercritical carbon dioxide compression cycle test bench, which includes a supercritical carbon dioxide compression cycle test bench and a supercritical carbon dioxide closed cycle measurement and control bench.

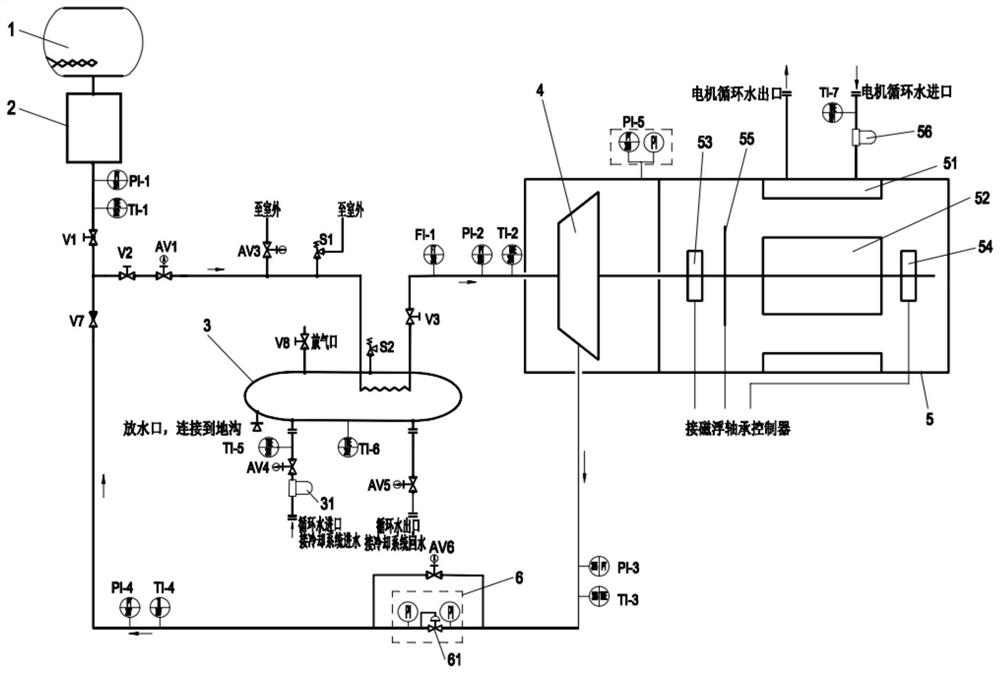

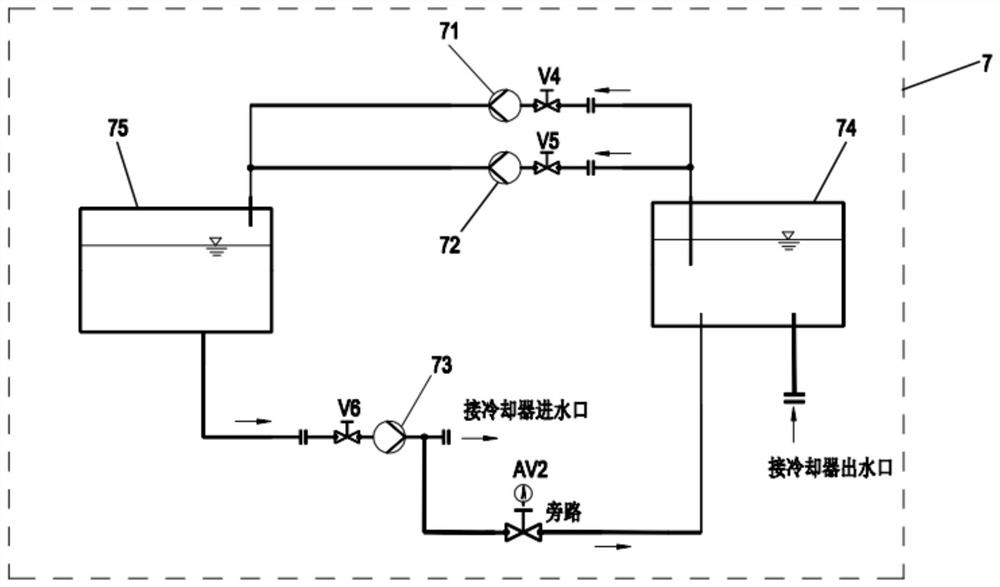

[0036] Such as figure 1 As shown, the supercritical carbon dioxide compression cycle test bench is placed on the shock absorber as a whole, including a carbon dioxide gas storage tank 1, a booster pump 2, a cooler 3, a compressor 4, a magnetic levitation motor module 5 and a pressure reducing valve module 6. The decompression valve module 6 includes a decompression valve 61 and two pressure sensors respectively disposed on both sides of the decompression valve 61 . The carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com