Energy-saving rice milling and hulling equipment

An energy-saving, rice-based technology that can be used in energy-saving measures, agricultural machinery and equipment, grain processing, etc., and can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

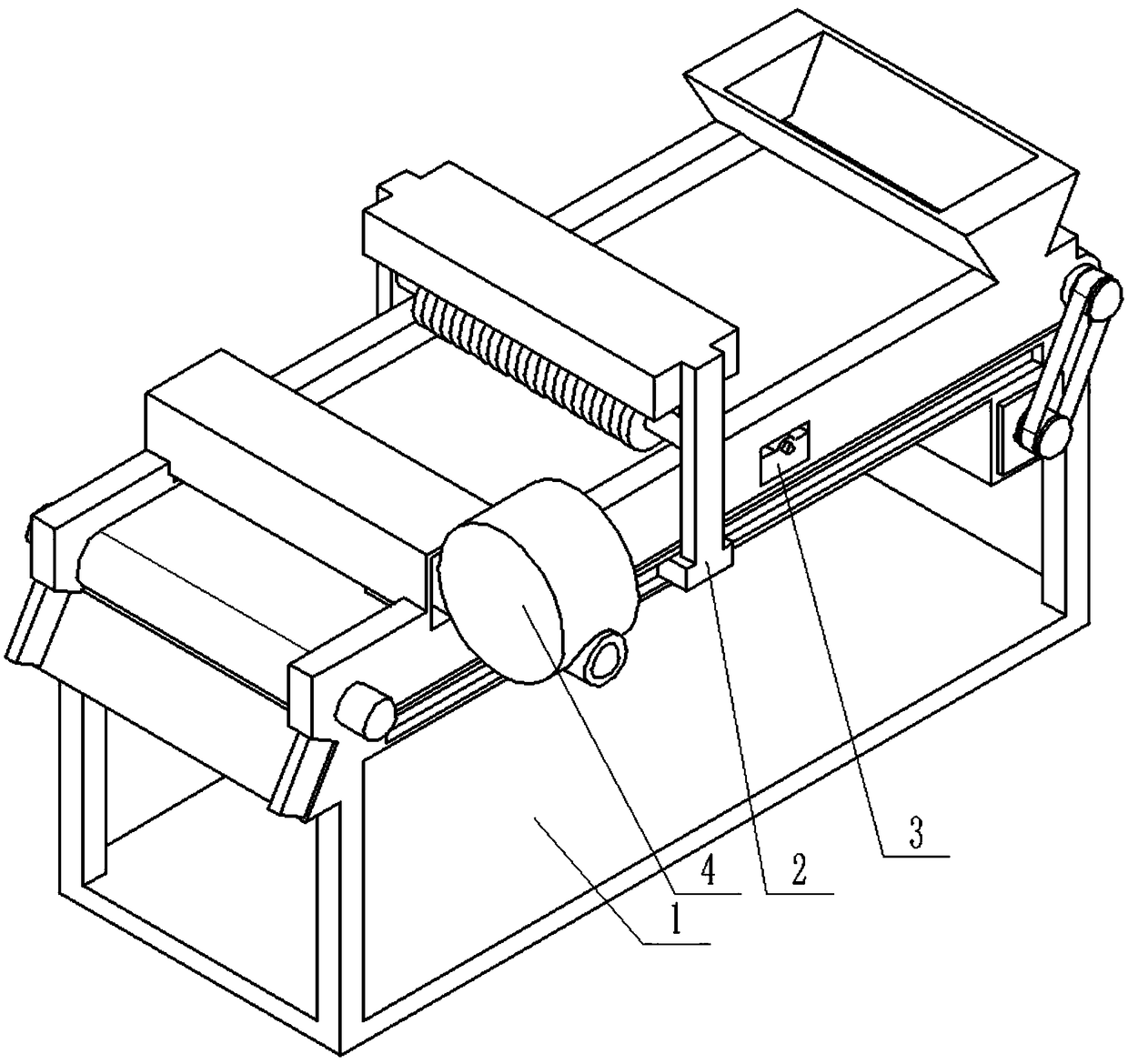

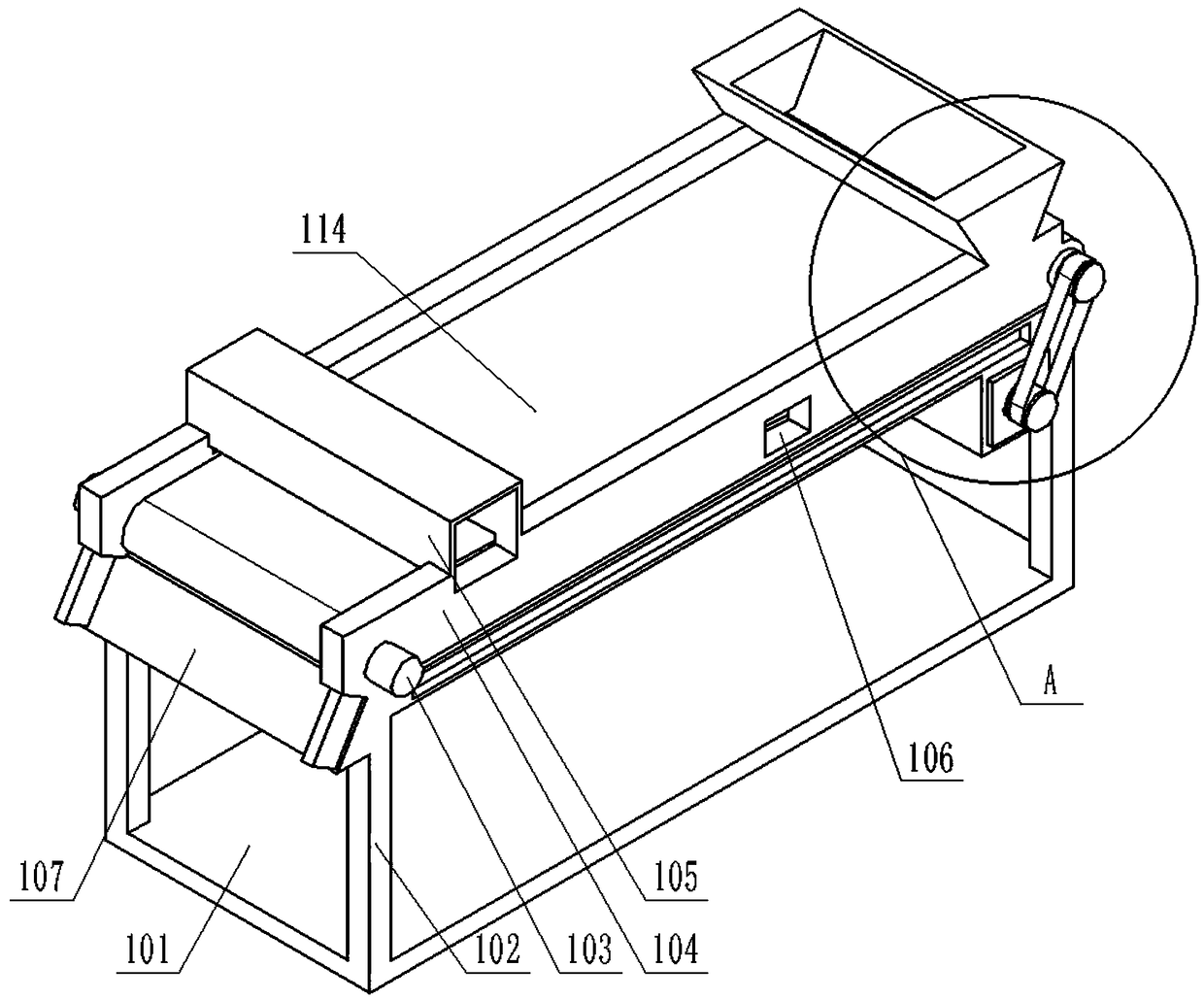

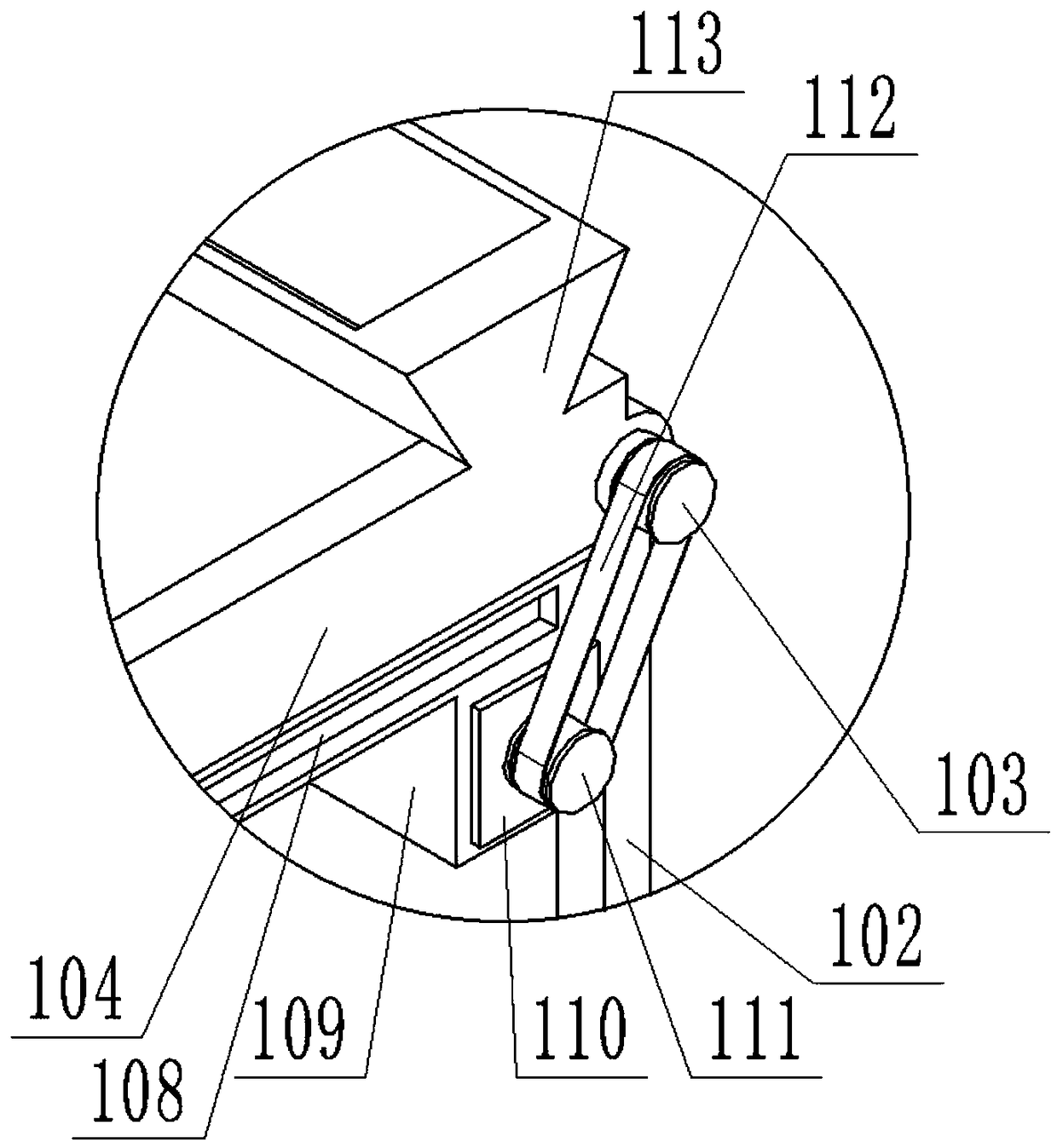

[0022] An energy-saving rice milling and peeling equipment is composed of a transmission mechanism 1, a rolling mechanism 2, a vibration mechanism 3 and an air blowing mechanism 4. The transmission mechanism 1 is respectively installed and fixed with a rolling mechanism 2 and a vibration mechanism. 3 and the blowing mechanism 4, the transmission mechanism 1 is composed of a base plate 101, a pillar 102, a pulley 103, a side plate 104, a peeling chamber 105, a rectangular hole 106, a U-shaped inclined plate 107, a traverse track 108, and a main motor Frame 109, main motor 110, motor shaft 111, wide chain 112, rice inlet 113 and conveyor belt 114 are formed, and described rolling mechanism 2 is made up of linear motor 201, vertical frame 202, top block 203, drying lamp 204 , grinding wheel 205 and central shaft 206, and the vibration mechanism 3 is composed of a vibration motor housing 301, a vibration motor 302, a vibration shaft 303 and a cam 304, and the blast mechanism 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com