Vertical shaft wind motor three-halberd vortex-eliminating windwheel

A wind engine, vertical axis technology, applied to wind engines, wind engines at right angles to the wind direction, wind turbine components, etc., can solve the problem of reducing the size of the wind energy of the three-leaf closed cavity, reducing the power of the wind wheel, and increasing the manufacturing of the wind wheel Cost and assembly difficulty and other issues, to achieve the effect of increasing the driving torque, eliminating eddy current loss, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

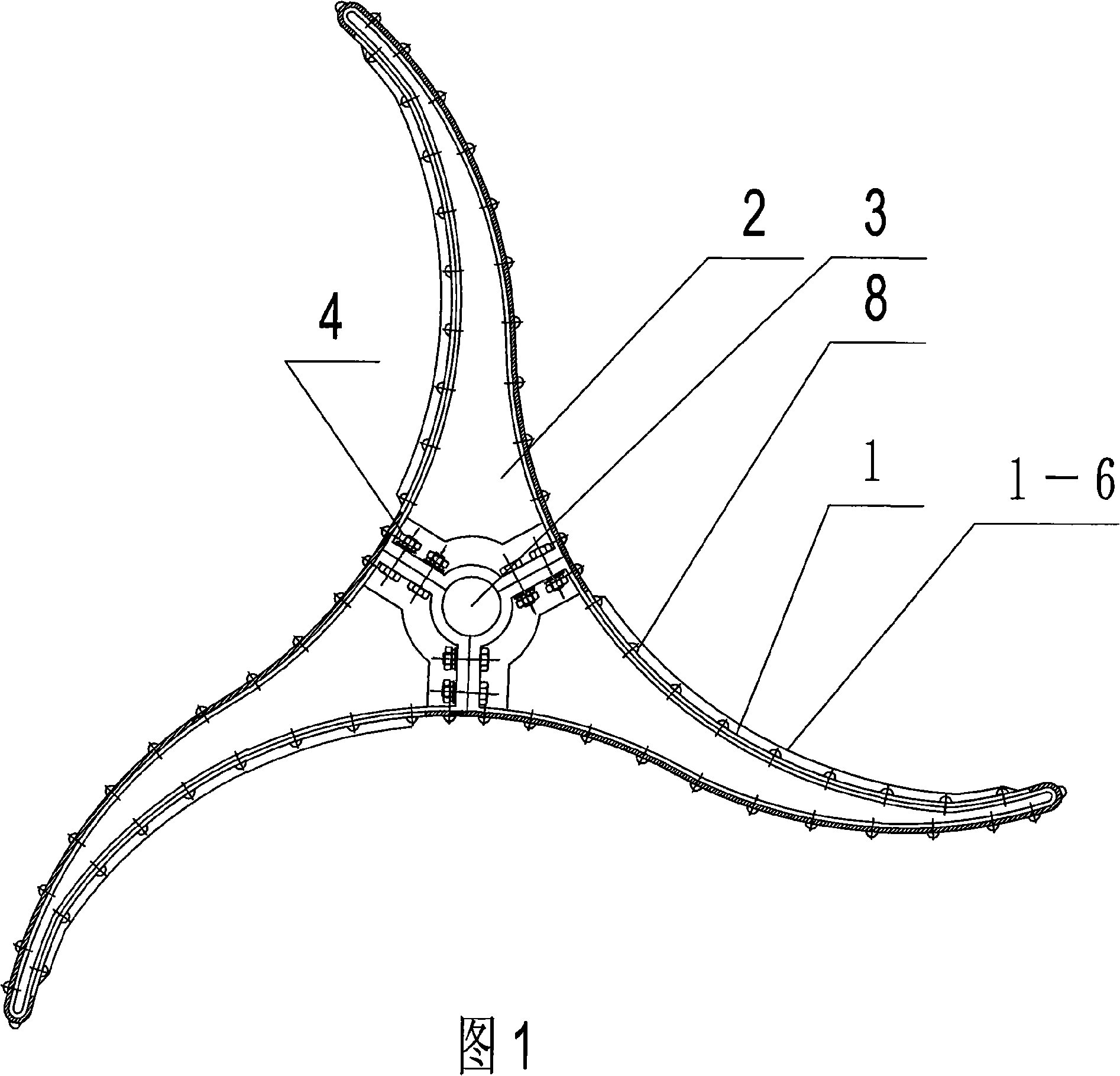

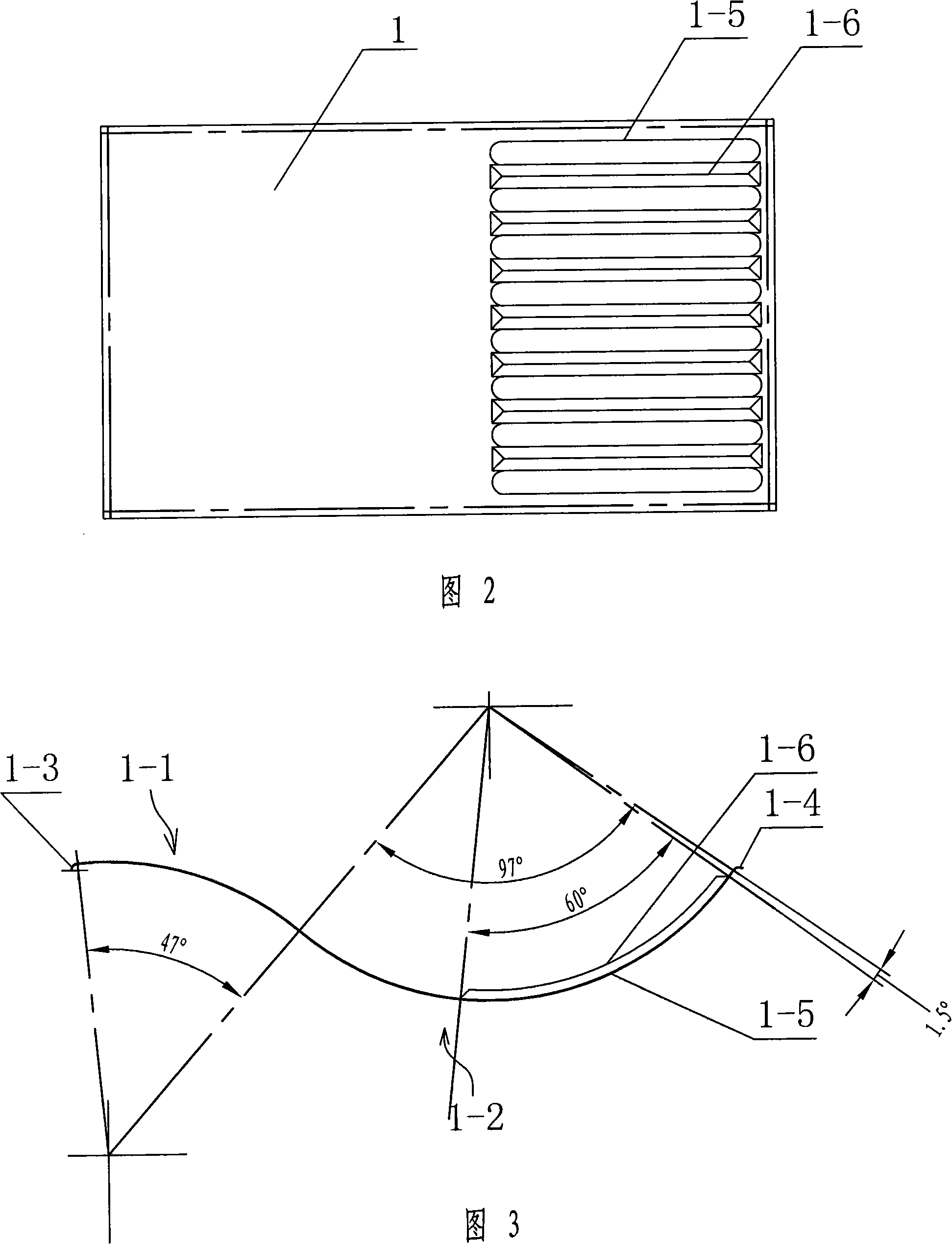

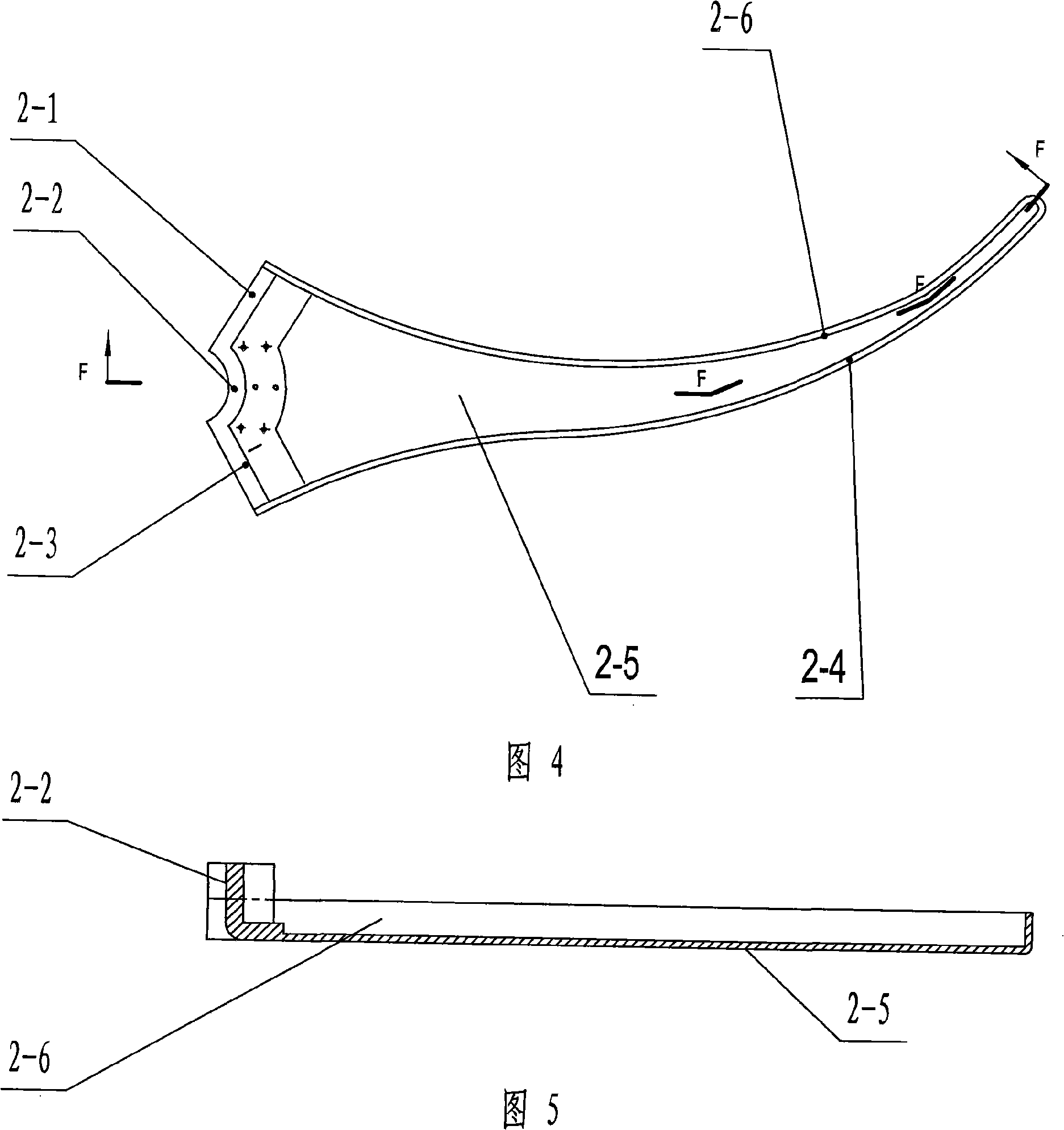

[0019] As shown in Figures 1 to 6, the wind wheel of the present invention is a trident-shaped closed cavity structure surrounded by wind blades 1 on three sides and trident-shaped cover plates on the top and bottom. It is formed by butting three halberd-shaped cover plates 2; the structure of the fan blade 1 is shown in Figures 2 and 3, and is composed of two sections of equal-diameter arc tops facing opposite arc column panels 1-1, 1-2. S-shaped arc column panels formed by smooth connection, arc column panels 1-2 are evenly distributed alternately along the height direction, air flow slots 1-5 and collector peaks 1-6, arc column panels 1-1, 1-2 The two outer ends of the arc column panel 1-2 are provided with docking arc cylinder surfaces 1-3 and 1-4 respectively, the central angle of the arc surface of the arc column panel 1-1 is 47°, and the arc surface of the arc column panel 1-2 is 47°. The central angle of the pair is 97°, the central angle of the arc surface occupied by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com