Cam-retractable paddy field driving wheel

A drive wheel, telescopic technology, applied in the direction of the wheel with shovel grip teeth, etc., can solve the problems of increased power consumption, long working hours, increased self-weight of the drive wheel, etc., to achieve the reduction of total power consumption and production efficiency Improve and increase the effect of running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

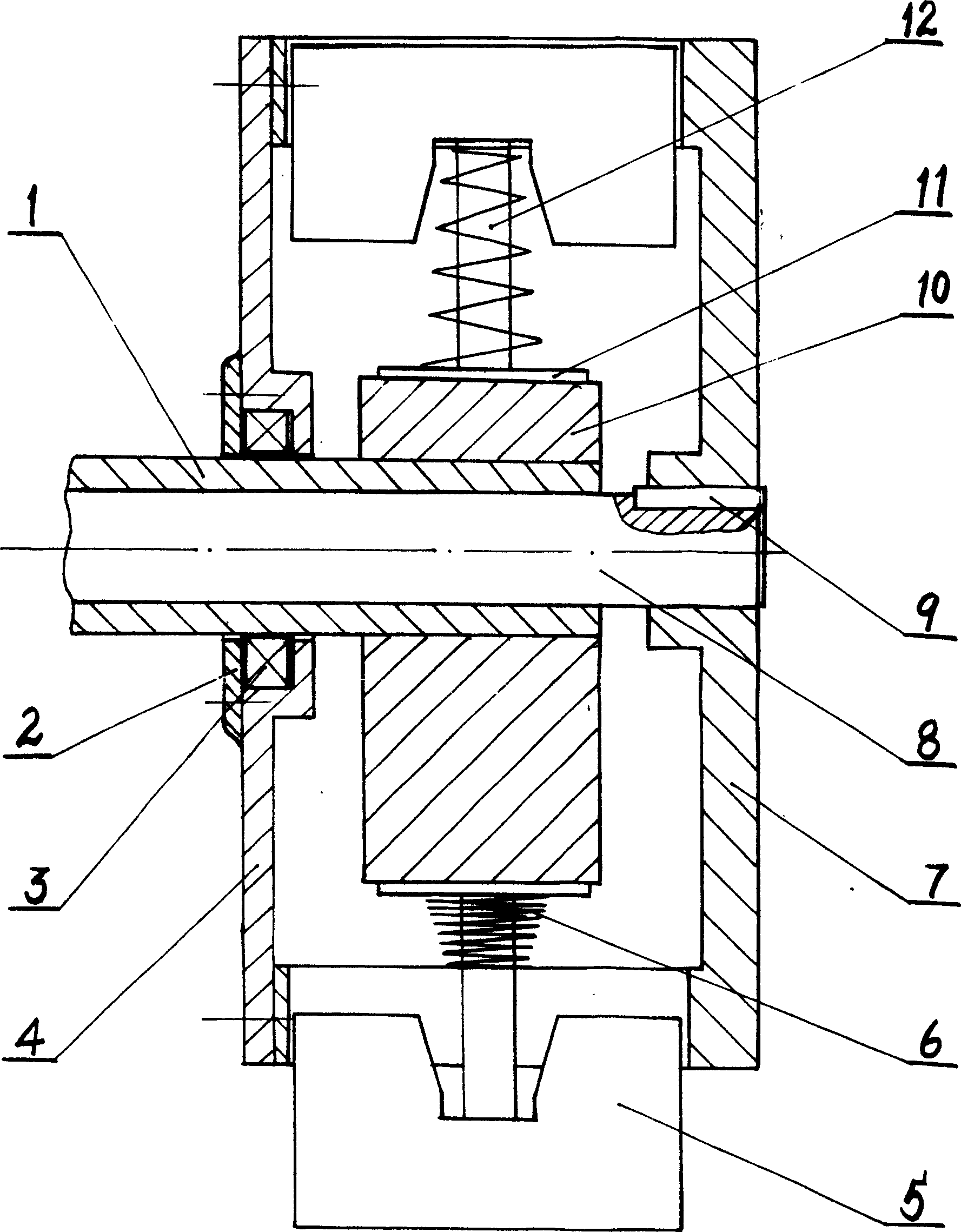

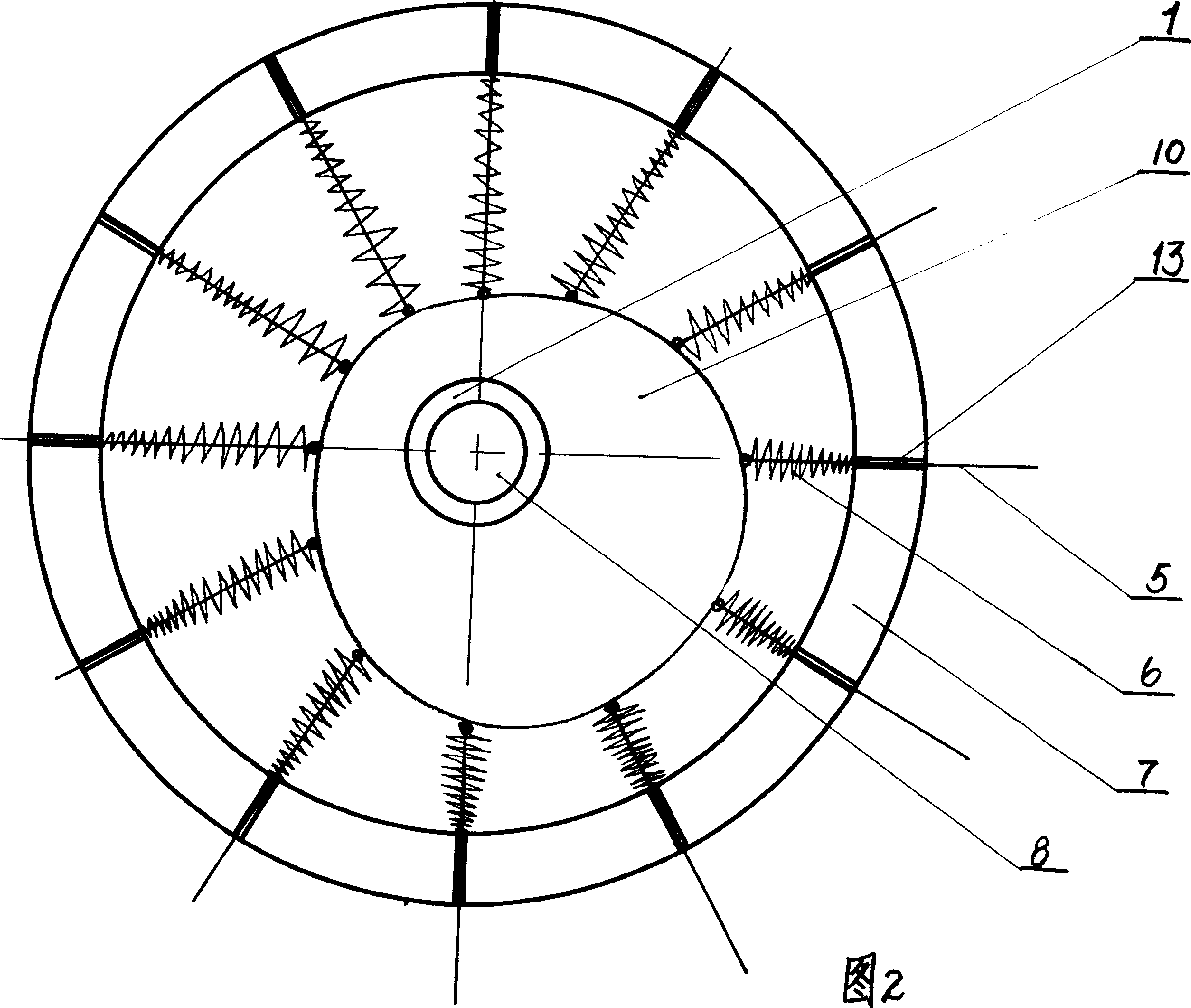

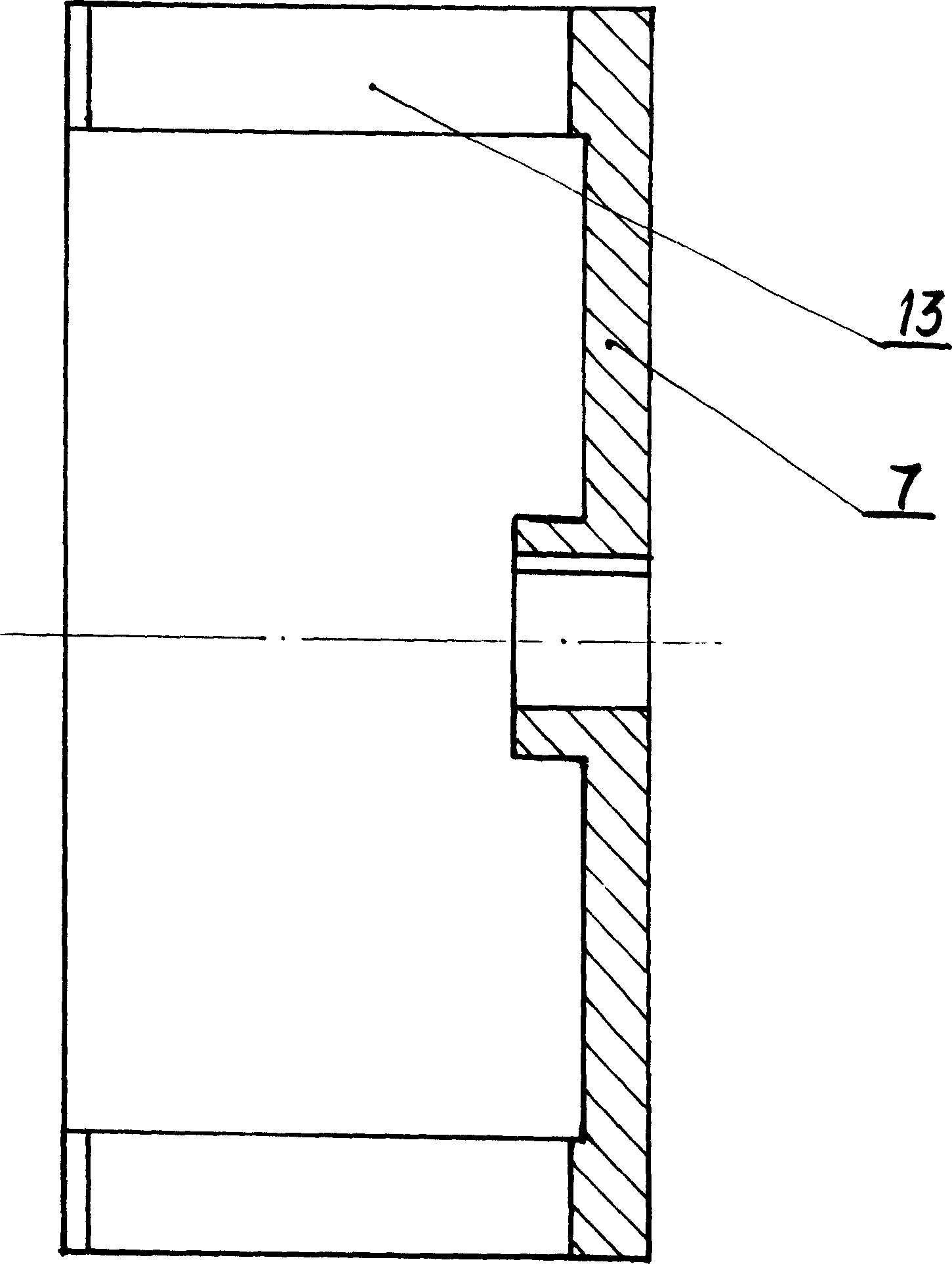

[0023] As shown in the figure, the present invention includes a main drive wheel 7 and a drive shaft 8, both of which are connected with a flat key 9. There is a telescopic opening 13 on the main drive wheel 7, and the telescopic blade 5 expands and contracts in the telescopic opening 13 under the action of the elastic force. The generation of the elastic force and the telescopic movement depend on the shape of the conical compression spring 6, the cam 10 and the rotation of the main driving wheel 7. The other links are formed in cooperation with each other. The contact pressure plate 11 forms a whole with the blade connecting shaft 12 and the telescopic blade 5. The conical compression spring 6 is mounted on the blade connecting shaft 12. The small-diameter end of the conical compression spring 6 contacts the inner circle surface of the main driving wheel 7, and the large-diameter end exerts pressure on the contact platen 11 so that it remains in contact with the cam 10 all t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com