High-temperature-resistant bionic driver as well as preparation method, preparation system and test method thereof

A technology for preparing a system and a driver, applied in the field of material science, can solve the problems of less research on the dynamic driving performance and cycle stability of the bionic driver, narrow operating temperature range, limited heat exchange process, etc., to achieve excellent driving performance and improve driving performance. , the effect of changing the coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The special fiber used in the preparation method provided by the embodiment of the present invention can be a commercial special fiber, which can be mass-produced, and the preparation process of the bionic actuator provided by the embodiment of the present invention is simple, easy to use, and suitable for high-temperature environments. Working drives offer more options.

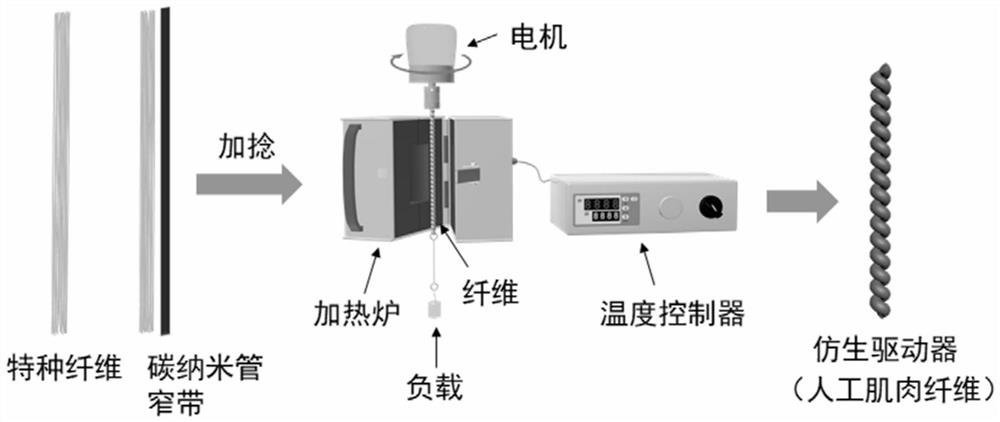

[0046] An embodiment of the present invention provides a method for preparing a high-temperature-resistant bionic driver, including:

[0047] Twisting the polymer fiber under the first temperature condition until the polymer fiber completely forms a helical structure;

[0048] annealing the twisted polymer fiber under a second temperature condition to obtain a high temperature resistant biomimetic actuator;

[0049] The first temperature condition is around a transition temperature of the polymer fiber and the second temperature is lower than the first temperature.

[0050] In a more specific embodi...

Embodiment 1

[0081]A preparation method of a bionic driver, the specific preparation steps are as follows:

[0082] Step 1: extract poly-p-phenylene benzobisoxazole fibers with different filament numbers from the poly-p-phenylene benzobisoxazole (PBO) fiber filament bundle, and intercept 10 cm; adopt floating catalytic chemical vapor deposition method from Cut 15cm from the prepared carbon nanotube narrow strip;

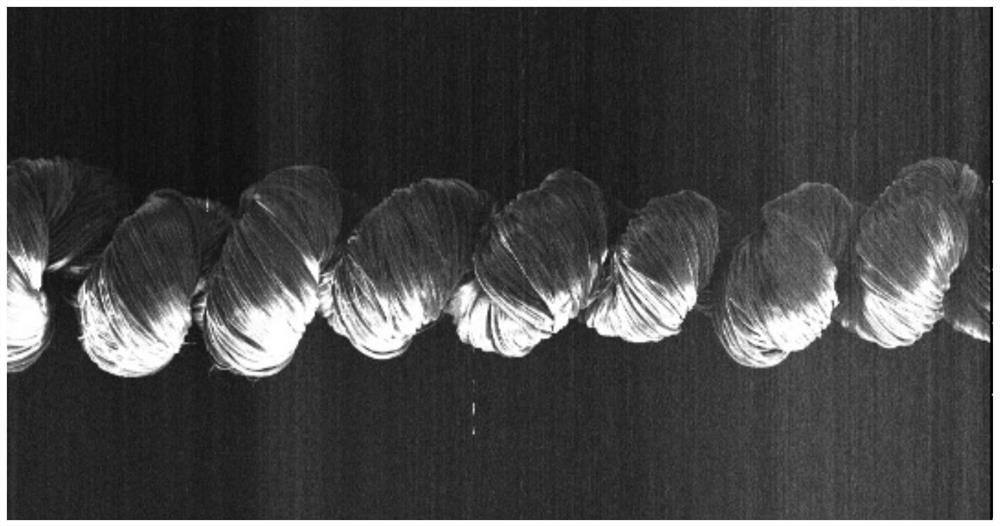

[0083] Step 2a: Set the temperature of the heating furnace to 450°C. After the temperature of the furnace body is stable, turn on the heating furnace and fix one end of the PBO fiber on the motor shaft above the heating furnace, hang a weight on the other end, and close the heating furnace. After the temperature of the furnace is stable, keep it warm for 5 minutes to make the PBO fibers evenly heated; then set the motor to an appropriate speed to twist the PBO fibers until the PBO fibers completely form a uniform spiral structure, thereby forming PBO artificial muscle fibers; the...

Embodiment 2

[0086] A preparation method of a bionic driver, the specific preparation steps are as follows:

[0087] Step 1: extract polyimide fibers with different filament numbers from the polyimide (PI) fiber filament bundle, and intercept 10 cm; intercept 15 cm from the narrow strip of carbon nanotubes prepared by floating catalytic chemical vapor deposition;

[0088] Step 2: Set the temperature of the heating furnace to 220°C. After the temperature of the furnace body is stable, turn on the heating furnace, fix one end of the PI fiber on the motor shaft above the heating furnace, hang a weight on the other end, and close the heating furnace , after the temperature of the furnace body is stable, keep it warm for 5 minutes, then set the motor to an appropriate speed to twist the PI fibers until the PI fibers completely form a uniform spiral structure, thereby forming PI artificial muscle fibers. After the twisting is completed, the PI artificial muscle fibers are twisted from Remove fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com