Automobile gear shifting mechanical hand based on space parallel connection four-connecting-rod mechanism and control method of automobile gear shifting mechanical hand

A technology of a four-bar linkage mechanism and a manipulator, which is applied to the mechanical device for automatic shifting of automobile gearboxes, the automatic shifting manipulator of automobile gearboxes and its control field, and can solve the problem of being unable to complete the vertical movement of the shift lever and occupying driving. The space of the passenger seat, the inability to drive manually, etc., achieve the effect of high starting speed and position control accuracy, small overall weight, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

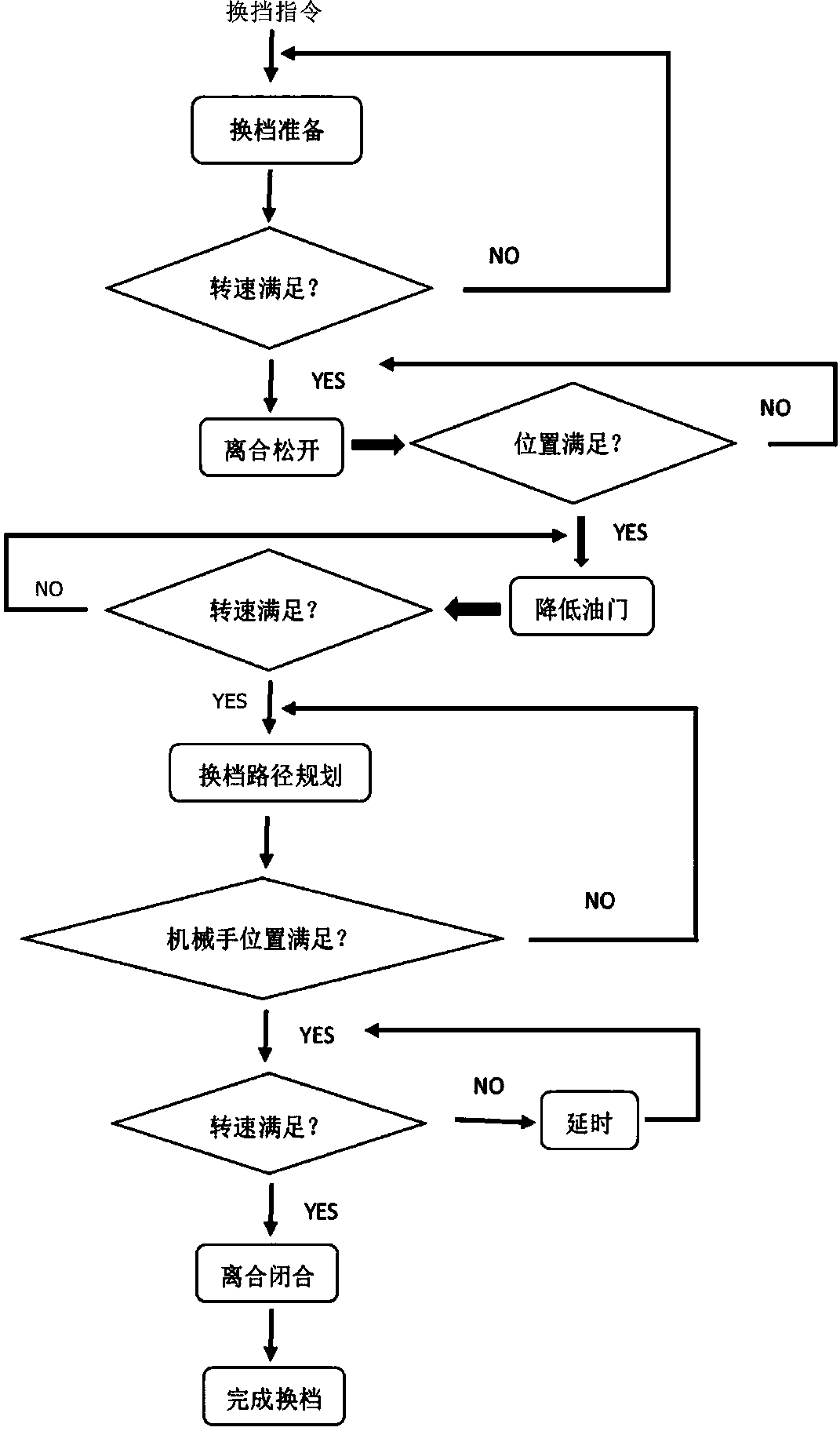

[0037] The invention provides an automobile shift manipulator. The shift manipulator is realized based on a space-parallel four-bar linkage mechanism, has multiple degrees of freedom in space, and can perform efficient shift operations on a gearbox without affecting driving. Under the normal driving conditions of the driver, on the basis of not modifying the vehicle body, the automatic shifting action of the car can be realized.

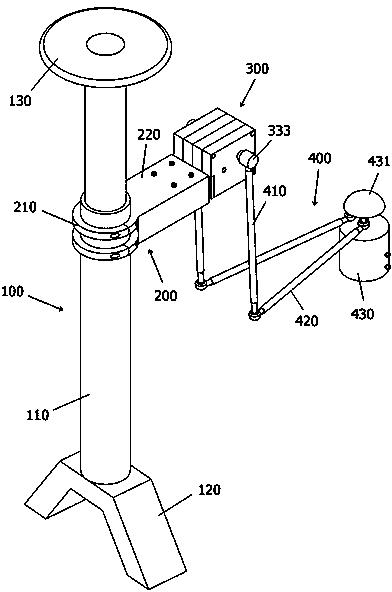

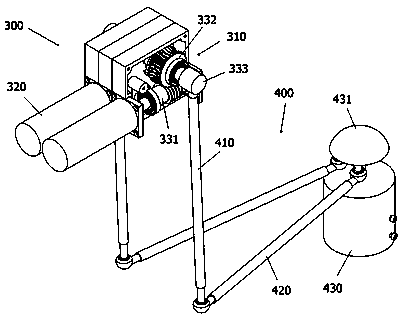

[0038] Such as figure 1 As shown, the shift manipulator includes a fixing device 100, a clamping device 200, a driving device 300, a shifting device 400 and a control system.

[0039] Wherein the fixing device 100 includes a fixing rod 110 vertically arranged in the vehicle, the fixing rod has a telescopic function, and the height can be adjusted according to different vehicle models. The lower end of the fixed rod is provided with a mounting bracket 120, and the upper end is provided with a ceiling cup 130, wherein the mounting bracket can be desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com