Electric control air flow driving mechanical grinding machine

A technology of airflow drive and airflow tube, which is applied in the direction of grinding drive devices, manufacturing tools, and grinding machine parts, etc. It can solve the problems of motor jamming, grinder grinding, motor burnout, etc., and achieves simple structure and design. Scientific and reasonable, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and example.

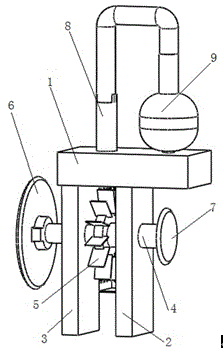

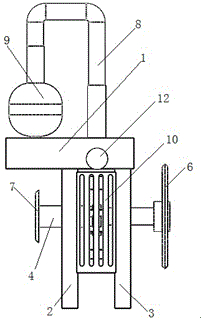

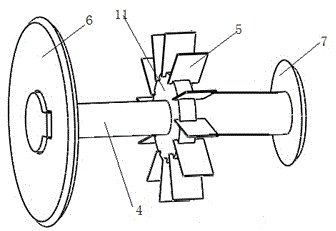

[0017] like figure 1 , figure 2 and image 3 As shown, an electrically controlled airflow-driven mechanical grinder, its structure includes: mounting base 1, right support plate 2, left support plate 3, grinding wheel rotating shaft 4, airflow driving blade 5, large grinding wheel 6, small grinding wheel 7 , power air flow pipe 8, high-pressure gas cylinder 9, protective cover 10, impeller mounting plate 11, air flow control valve 12, the mounting seat 1 is fixed on the left support plate 3 and the right support plate 2, and the grinding wheel rotating shaft 4 is installed On the left support plate 3 and the right support plate 2 and the grinding wheel rotating shaft 4 passes through the left supporting plate 3 and the right supporting plate 2, one end of the grinding wheel rotating shaft 4 is installed with a large grinding wheel 6, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com