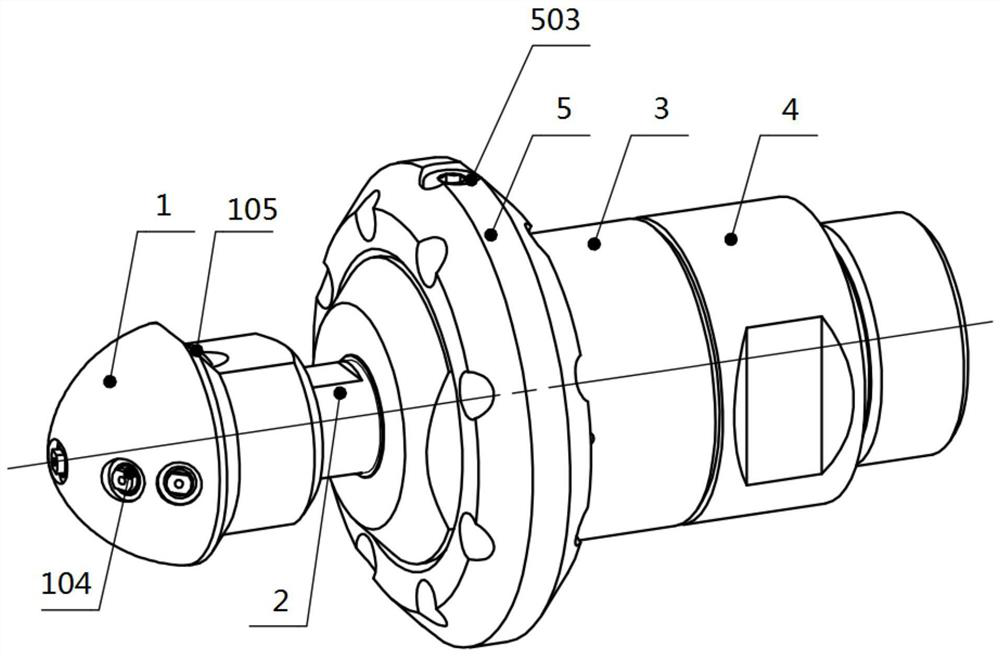

A two-way self-balancing rotary water jet drilling device with adjustable propulsion

A drilling device and self-balancing technology, which is applied in the direction of drilling with liquid/gas jets, etc., can solve the problems of the impossibility of adjusting the range of the propulsion force, the self-balancing of the nozzle, and achieve the effect of improving convenience and ensuring regularity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

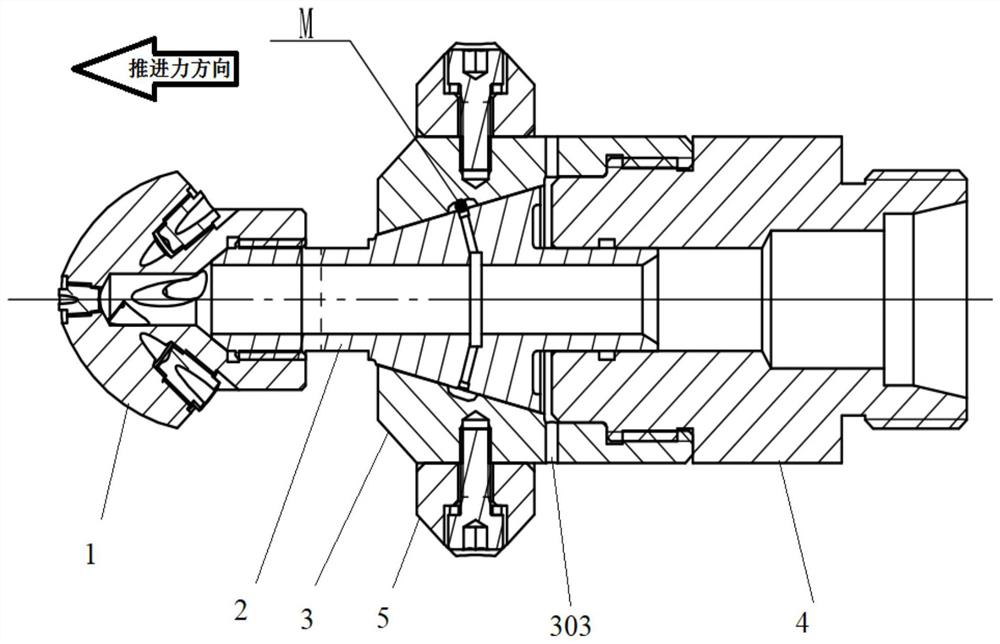

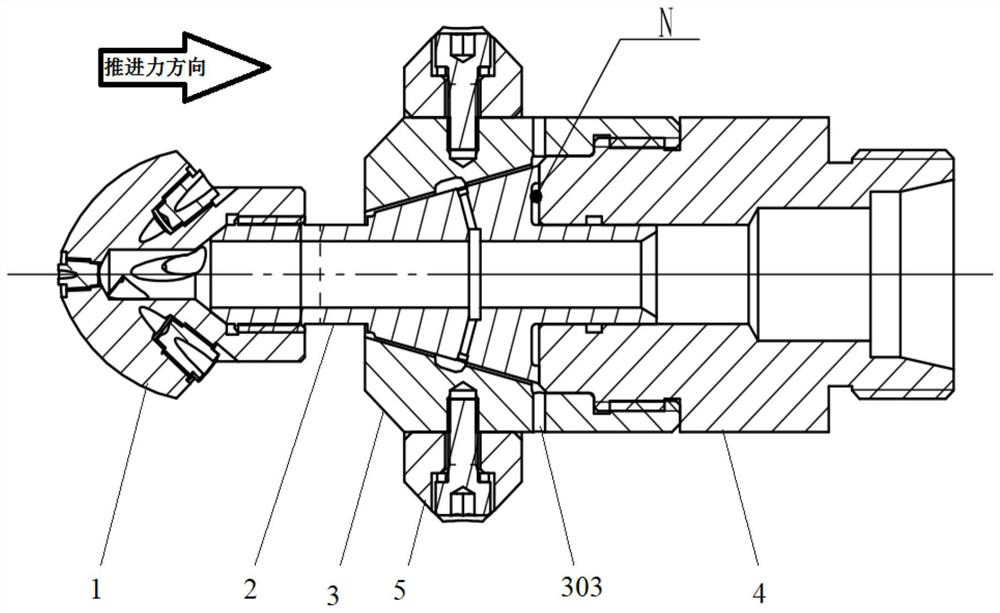

[0046] In the present invention, the equivalent area of a single front nozzle hole along the axial direction is represented by S 前j said, S 前j It refers to the area obtained by dividing the reaction force produced by the jth front nozzle hole jet water on the device along the axial component of the device rotation axis 2 by the pressure in the device cavity; the pressure in the device cavity corresponding to each front nozzle hole is equal. In the present invention, the pressure in the device cavity can be obtained by installing a pressure gauge at the end of the joint 4, or the pump pressure of the water pump can be used as the pressure in the device cavity.

[0047] In the present invention, the equivalent area of a single rear injection hole along the axial direction is S 后i said, S 后iIt refers to the area obtained by dividing the reaction force produced by the i-th rear spray hole jet water on the device along the axial component of the device rotation axis 2 by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com