Horizontal shaft type wire grinding roller planet main grinding head and dead angle-free deburring method

A technology of grinding rollers and grinding heads, applied in grinding heads, grinding machines, grinding drives, etc., can solve the problems of inability to realize deburring mechanism, inability to deburr with multiple rollers, inability to achieve clean and fast deburring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

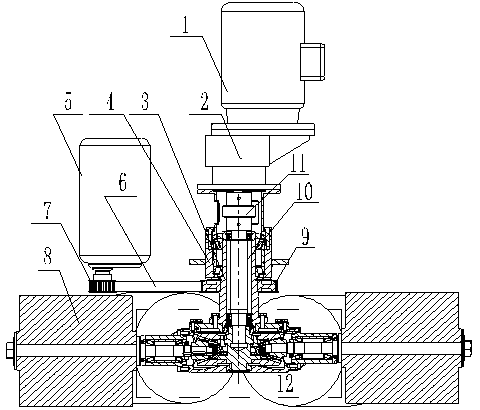

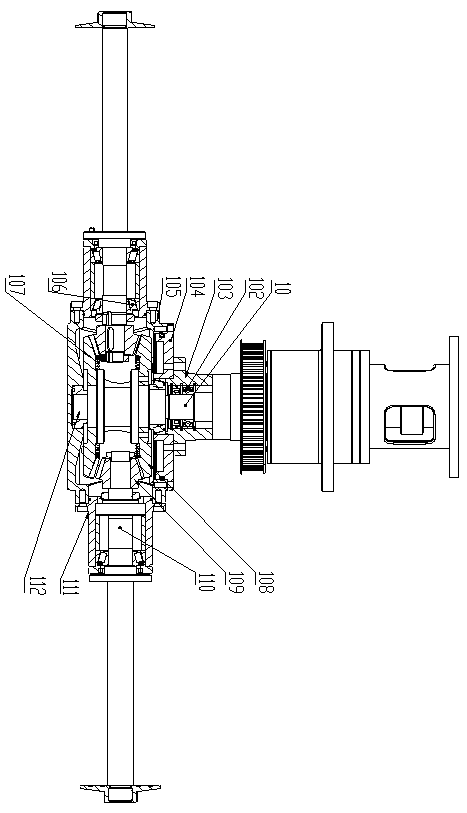

[0011] Embodiment 1: with reference to attached figure 1 and 2 . A horizontal-axis grinding roller planetary main grinding head, the power output shaft of the main motor 1 is connected to the power input end of the reducer 2, and the power output end of the reducer 2 is connected to one end of the active spindle 10 of the grinding head through a coupling 11, The other end of the grinding head active spindle 10 is connected to the power input end of the horizontal grinding head assembly 3, and the power output ends of the horizontal grinding head assembly 3 are six adjacent positive and negative rotation power output ends, and the six power output ends are connected to the grinding head assembly respectively. One end of the roller shaft 110 is connected, and the other end of the grinding roller shaft 110 is covered with a grinding roller 8. The large revolving synchronous pulley 9 and the small revolving synchronous pulley 7 are fixed on the horizontal grinding head assembly ...

Embodiment 2

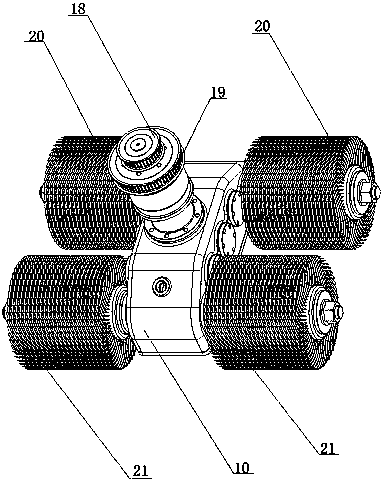

[0013] Embodiment 2: On the basis of Embodiment 1, a method for deburring a horizontal shaft type grinding roller planetary main grinding head without dead angle, the rotational torque output by the main motor 1 drives the main shaft 14 of the grinding head to rotate through the coupling 15, The grinding head driving spindle 10 drives a pair of lower conical gears 107 and upper conical gears 108 in the horizontal grinding head assembly 12 with opposite tooth surfaces and opposite tooth phases to rotate. The lower conical gears 107 and upper conical gears 108 are respectively Drive the three grinding roller pinion gears 109 meshing with it to make horizontal rotation movement, the grinding roller pinion 109 meshing with the lower conical gear 17 and the grinding roller pinion 9 meshing with the upper cone gear 108 respectively drive their respective grinding rollers. While the wire roller shaft 110 and the grinding roller 8 set on the grinding roller shaft 110 perform horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com