Grease homogenizing mechanism of pneumatic bearing oil-filling grease-homogenizing machine for railway wagon

A railway freight car, pneumatic technology, applied in the field of grease leveling mechanism, pneumatic bearing oiling grease leveling machine, can solve the problem of not realizing the relative rotation of the inner and outer rings of the bearing, not having the grease leveling function, etc., and achieve a simple structure. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

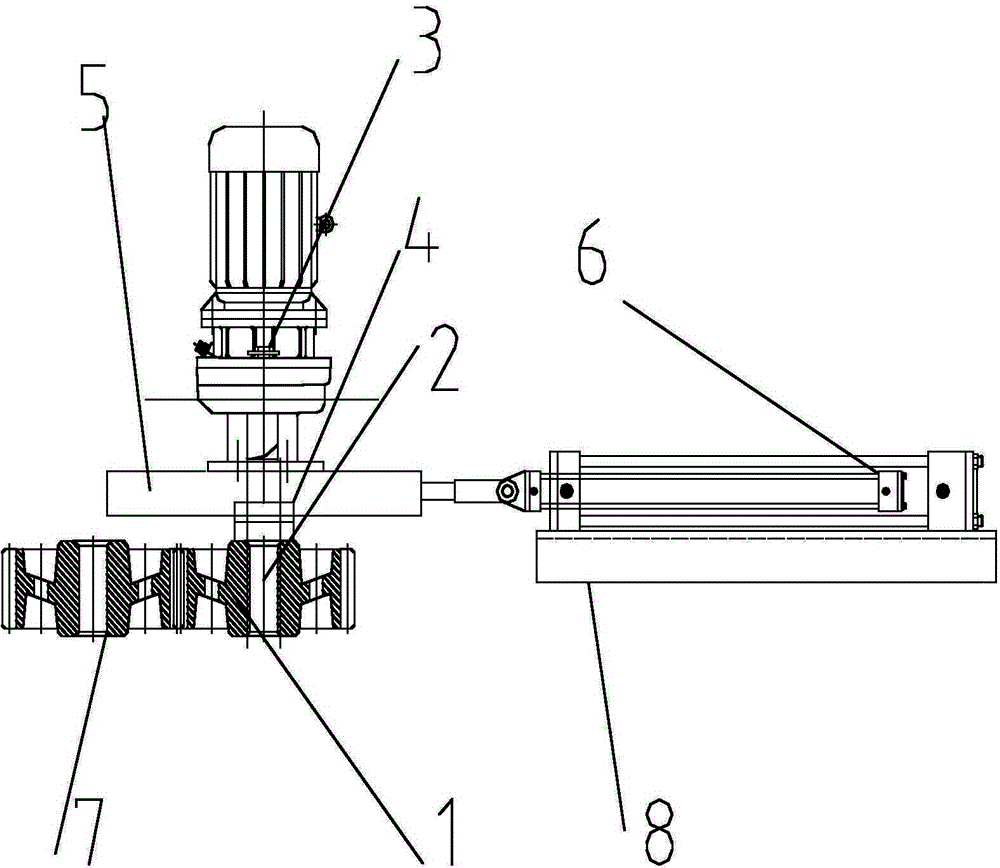

[0010] Embodiment 1 Composition and function of various components of the grease equalizing mechanism of a pneumatic bearing grease injection machine for railway freight cars:

[0011] The grease equalizing mechanism consists of coupling shaft gear 1, coupling shaft 2, reducer and motor 3, coupling 4, grease equalizing mechanism frame 5, grease equalizing mechanism frame pushing cylinder 6, oil injection head assembly gear 7, and cylinder mounting frame 8 components, characterized in that the grease equalizing mechanism of the pneumatic bearing oil injection and grease homogenization machine for railway wagons cooperates with the gear 7 of the bearing oil injection head assembly through the gear 1, and moves in the circumferential direction under the action of the reducer and the motor 3 Evenly grease. The coupling shaft gear 1 is installed on the coupling shaft 2 . The coupling shaft 2 is connected with the output shaft of the reducer and the motor 3 through a shaft coupli...

Embodiment 2

[0012] Example 2 The working principle of the grease equalizing mechanism of a pneumatic bearing grease injector for railway wagons:

[0013] After the grease injection machine is filled with grease, the oil injection head assembly still acts on the outer ring of the bearing, and the frame of the grease equalization mechanism pushes the cylinder 6 to push the homogenization mechanism forward, so that the coupling shaft gear 1 and the oil injection head assembly gear 7 are matched, and the deceleration is started Machine and motor 3, so that the coupling shaft gear 1 drives the oil injection head assembly gear 7 to rotate at high speed, and then realize the uniform effect of bearing grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com