Turning combined machine tool with retractable tool

A combined machine tool and cutting tool technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems that affect the processing efficiency, the length of the turning tool cannot be adjusted, and the efficiency is low, so as to improve the turning positioning accuracy and surface turning accuracy , improve turning efficiency and tool life, and avoid major losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

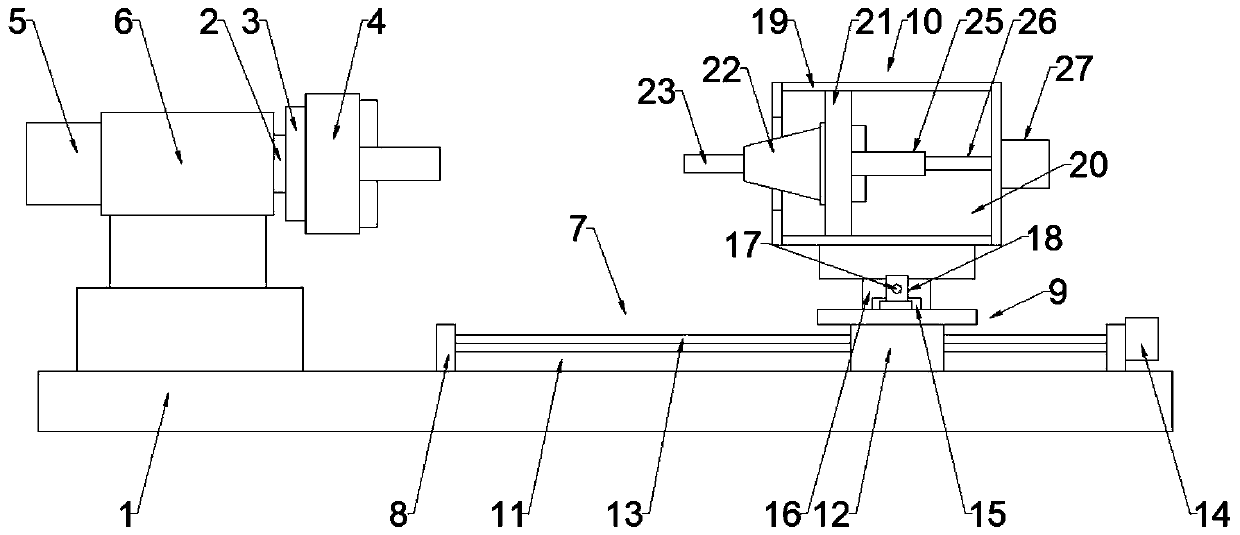

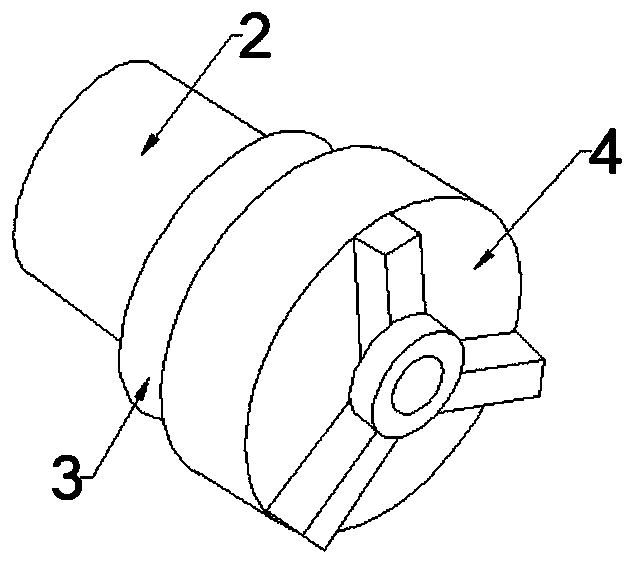

[0027] see Figure 1 to Figure 5 As shown, a turning combination machine tool with shrinkable cutting tools includes a machine bed 1, a workpiece fixture 4 and a CNC tool holder 7, the workpiece fixture 4 is installed on a rotating disk 3, and the rotating disk 3 is fixed on one end of the machine tool spindle 2, The machine tool spindle 2 is rotatably erected in the fixed seat 6 on the machine bed 1, the other end of the machine tool spindle 2 is connected to the first motor 5, and the first motor 5 is installed on the fixed seat 6, and the workpiece is fixed on the workpiece fixture 4 during processing. When working, the first motor 5 starts and drives the machine tool spindle 2, the rotating disk 3 and the workpiece fixture 4 to rotate, thereby driving the workpiece to rotate at high speed.

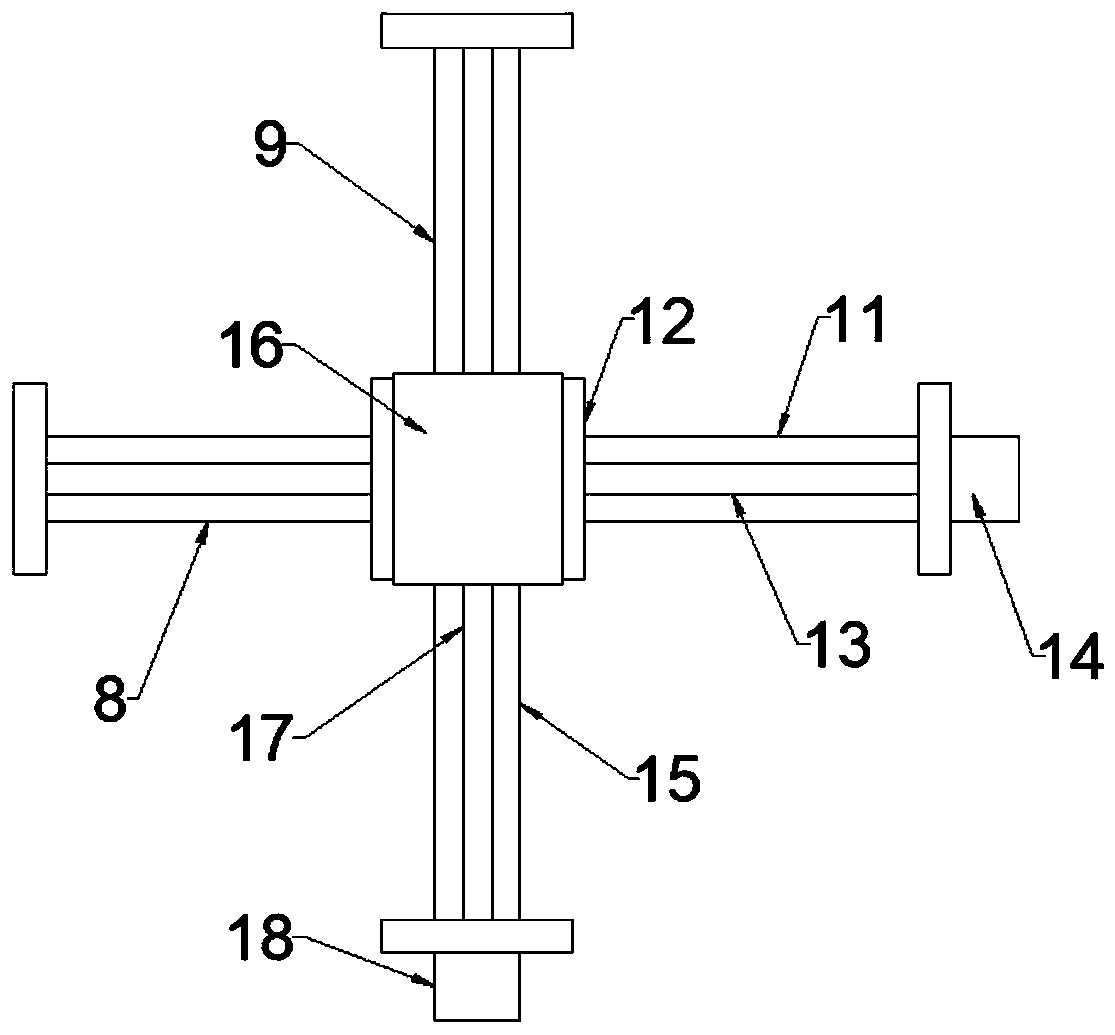

[0028] The CNC tool rest 7 is installed on the machine bed 1, and the CNC tool rest 7 includes a transverse guide rail assembly 8, a longitudinal guide rail assembly 9 and a tool assem...

Embodiment 2

[0034] see Figure 1 ~ Figure 3 As shown, a turning combination machine tool with shrinkable cutting tools includes a machine bed 1, a workpiece fixture 4 and a CNC tool holder 7, the workpiece fixture 4 is installed on a rotating disk 3, and the rotating disk 3 is fixed on one end of the machine tool spindle 2, The machine tool spindle 2 is rotatably installed in the fixed seat 6 on the machine bed 1, the other end of the machine tool spindle 2 is connected to the first motor 5, and the first motor 5 is installed on the fixed seat 6;

[0035] The CNC tool rest 7 is installed on the machine bed 1, and the CNC tool rest 7 includes a transverse rail assembly 8, a longitudinal rail assembly 9 and a cutter assembly 10; the cutter assembly 10 includes a cutter head housing 19, a tool holder 22 and a cutter Body 23, wherein the cutter head housing 19 is fixed on the longitudinal slider 16 of the longitudinal guide rail assembly 9, the cutter head housing 19 is provided with a contra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com