Ball screw device

A rolling element and lead screw technology, applied in transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of inability to balls, large number of parts, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Hereinafter, the structure and function of each part of the present invention will be described in detail with reference to the drawings. In addition, in the following description, the same code|symbol is attached|subjected to the same or a corresponding member or structure, and a repeated description is abbreviate|omitted.

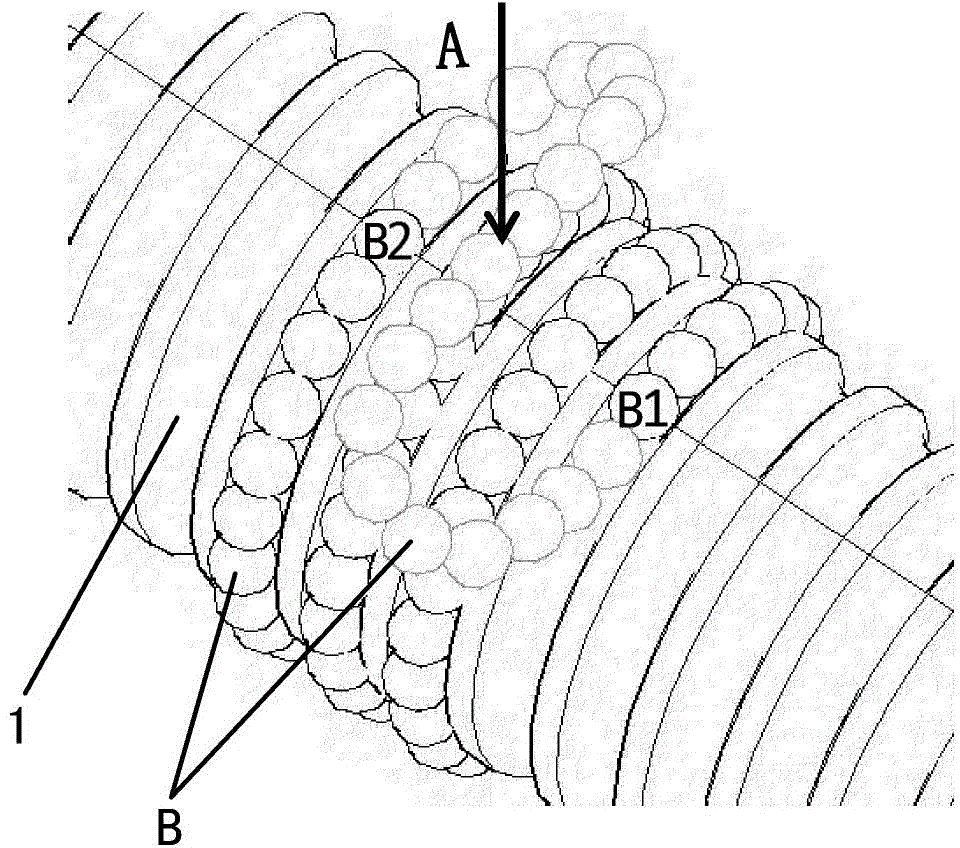

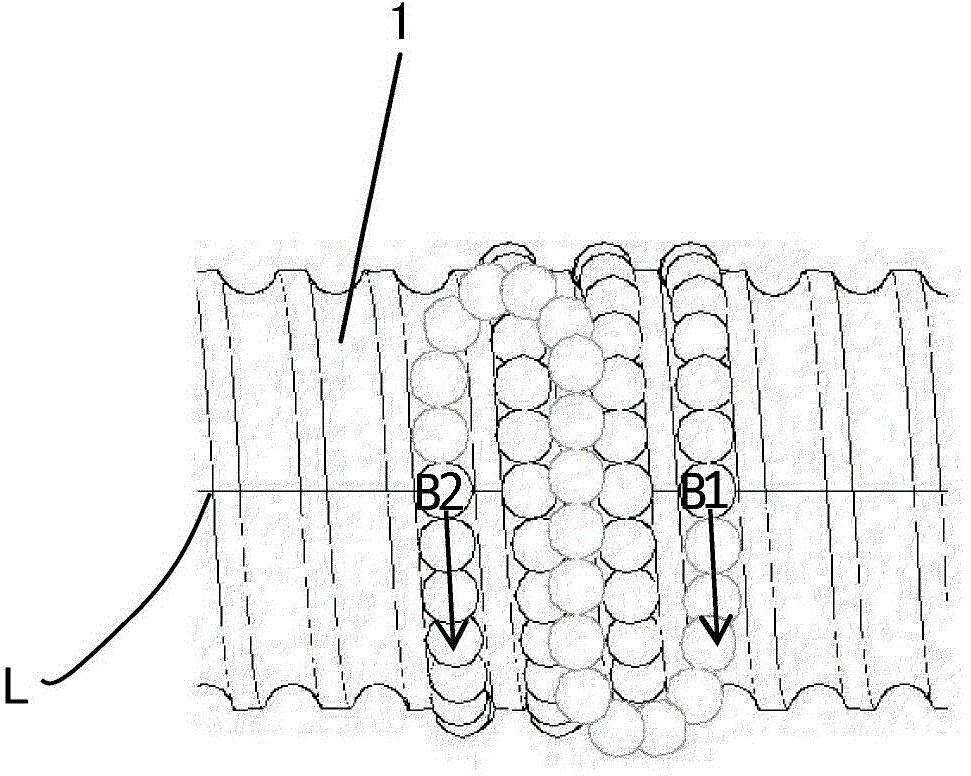

[0080] figure 1 It is a perspective view showing a ball circulation path in a state where a nut is omitted and only a screw shaft is shown in a ball screw as a rolling element screw device. figure 2 is along figure 1 A direction observation in figure 1 The obtained top view of the ball circulation path of one embodiment.

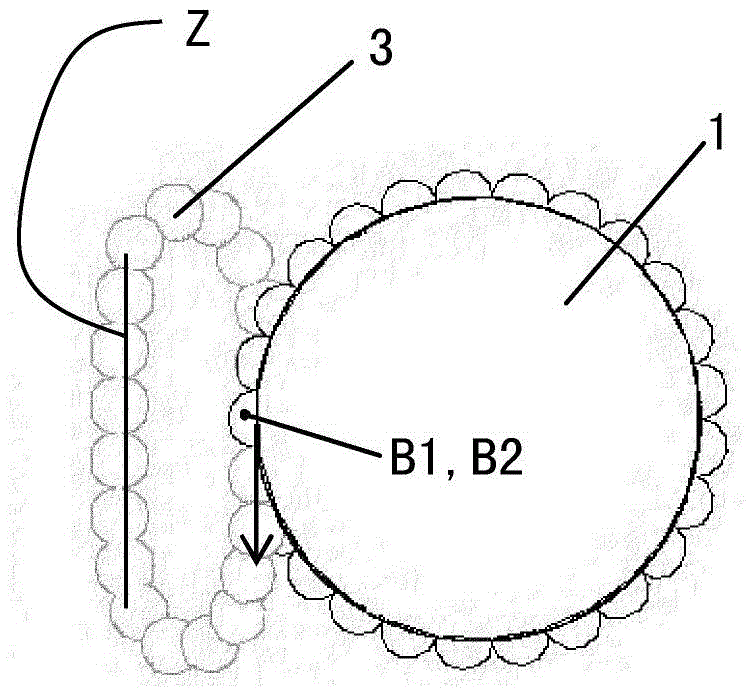

[0081] In the present invention, as shown in the description of the background technology of the present invention, in the ball screw, in order to make the ball B move between the screw shaft 1 and the nut 2 (see Figure 4 ), while the nut 2 is provided with a ball circulation path 3 for circulating the ball B rolling betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com