Non-contact electrical discharge machining system

A non-contact, machining system technology, applied in electric machining equipment, metal machining equipment, circuits, etc., can solve problems such as restricting EDM machining efficiency and improving surface integrity, limiting spindle speed and rotation accuracy, etc. The effect of concentrated discharge and abnormal arc discharge, improved precision and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

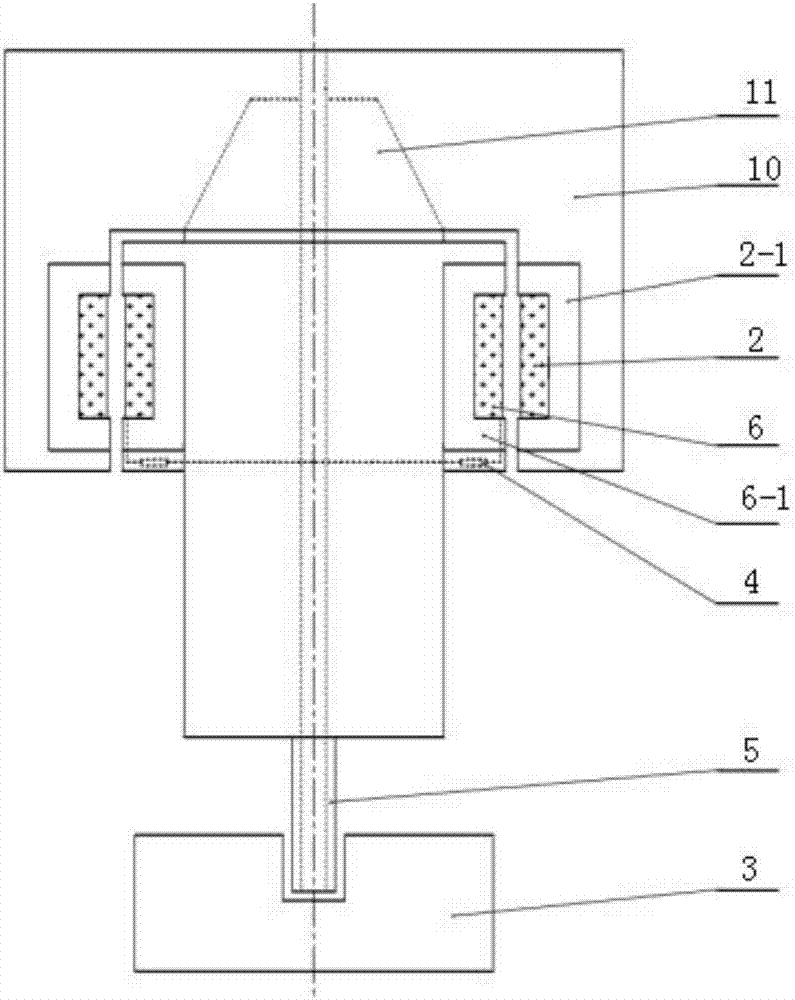

[0023] In order to make the technical means, creation features, work flow, use method, purpose and effect of the present invention easy to understand and understand, the following combination Figure 1 to Figure 4 , to further illustrate the present invention.

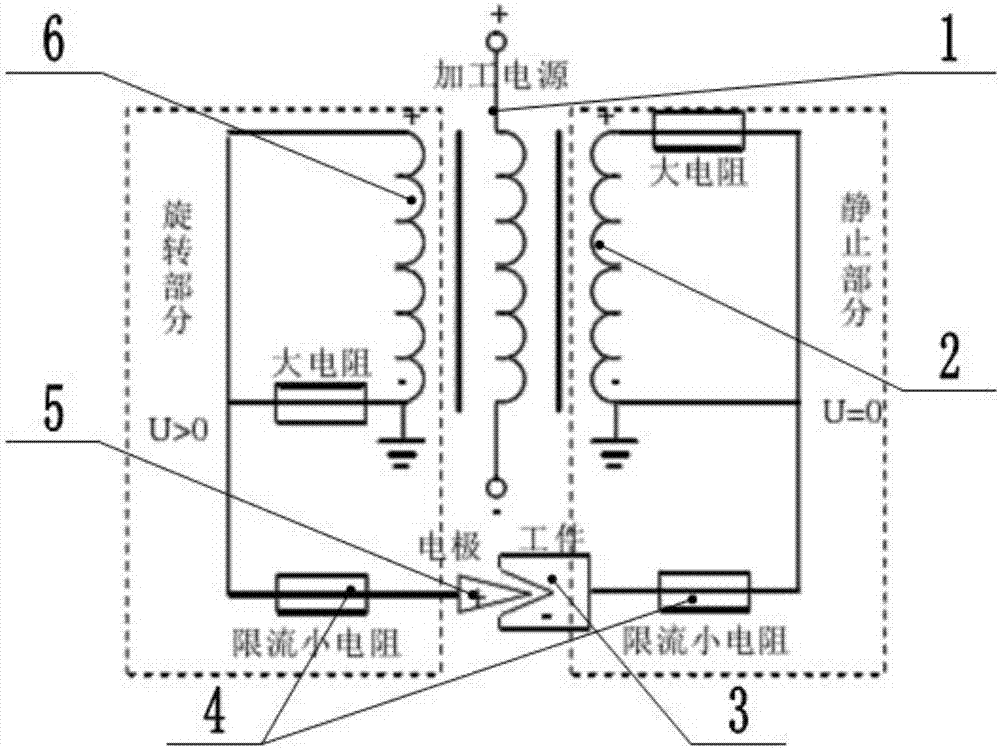

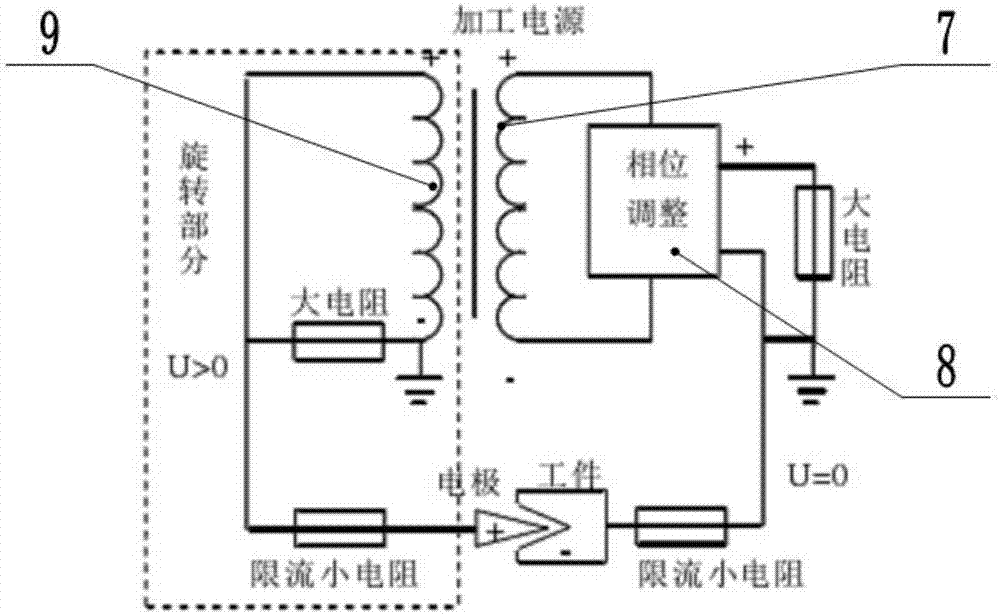

[0024] In this embodiment, the first scheme adopts the principle of double induction, and the transformation method is through a loosely coupled designed transformer coil, and its magnetic core is a special-shaped ferrite material. like figure 1 As shown, the medium induction coil (1) is fixed on the stationary end of the main shaft (9) and does not rotate with the main shaft. The dielectric induction coil (1) is connected to a pulse power source that generates a certain frequency, and a changing voltage and current are generated in the coil, and a certain electromotive force and current are generated in the dielectric induction coil (1) through the principle of electromagnetic induction, so as to transmit energy from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com