Patents

Literature

39results about How to "Increase the spindle speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

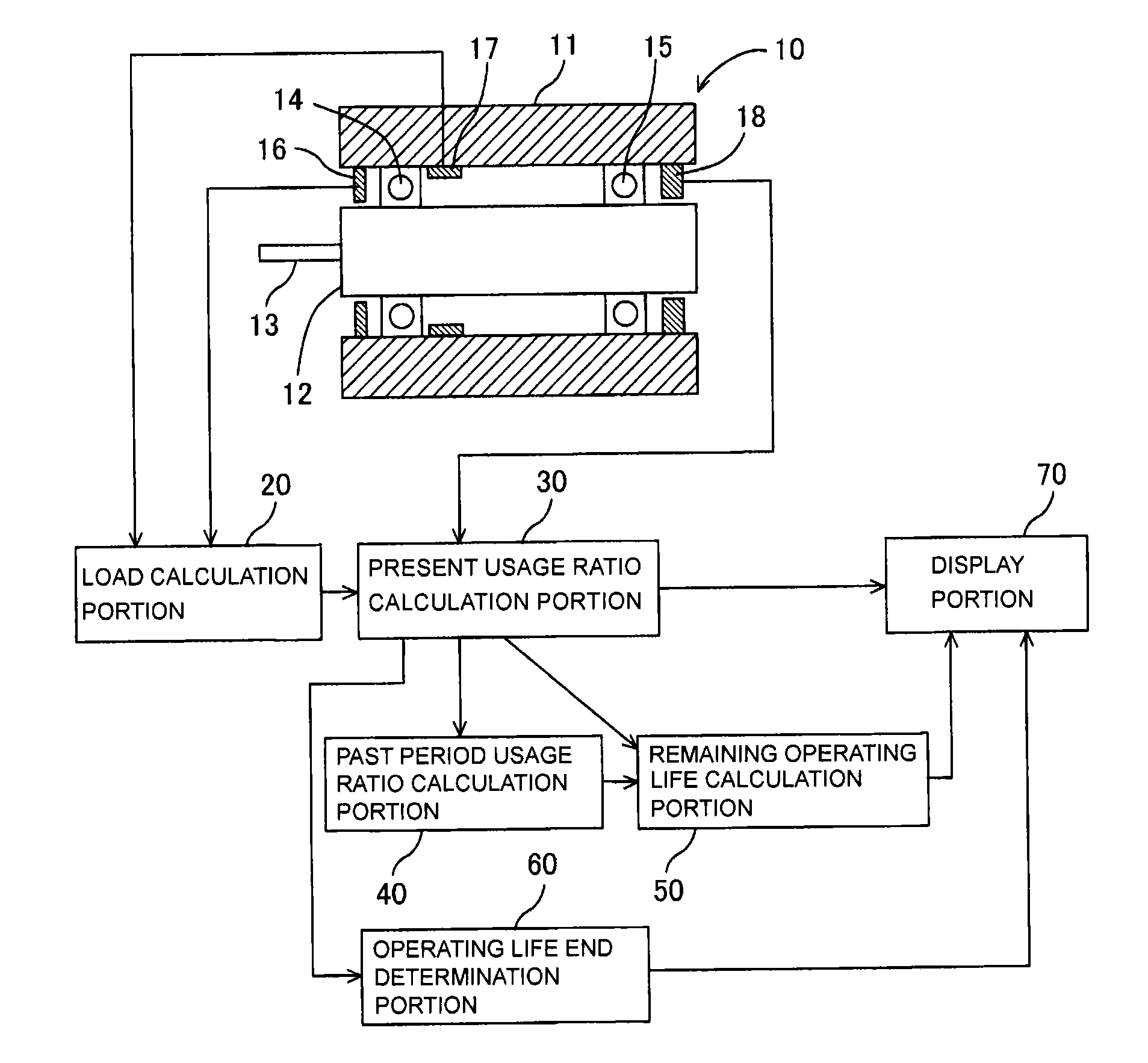

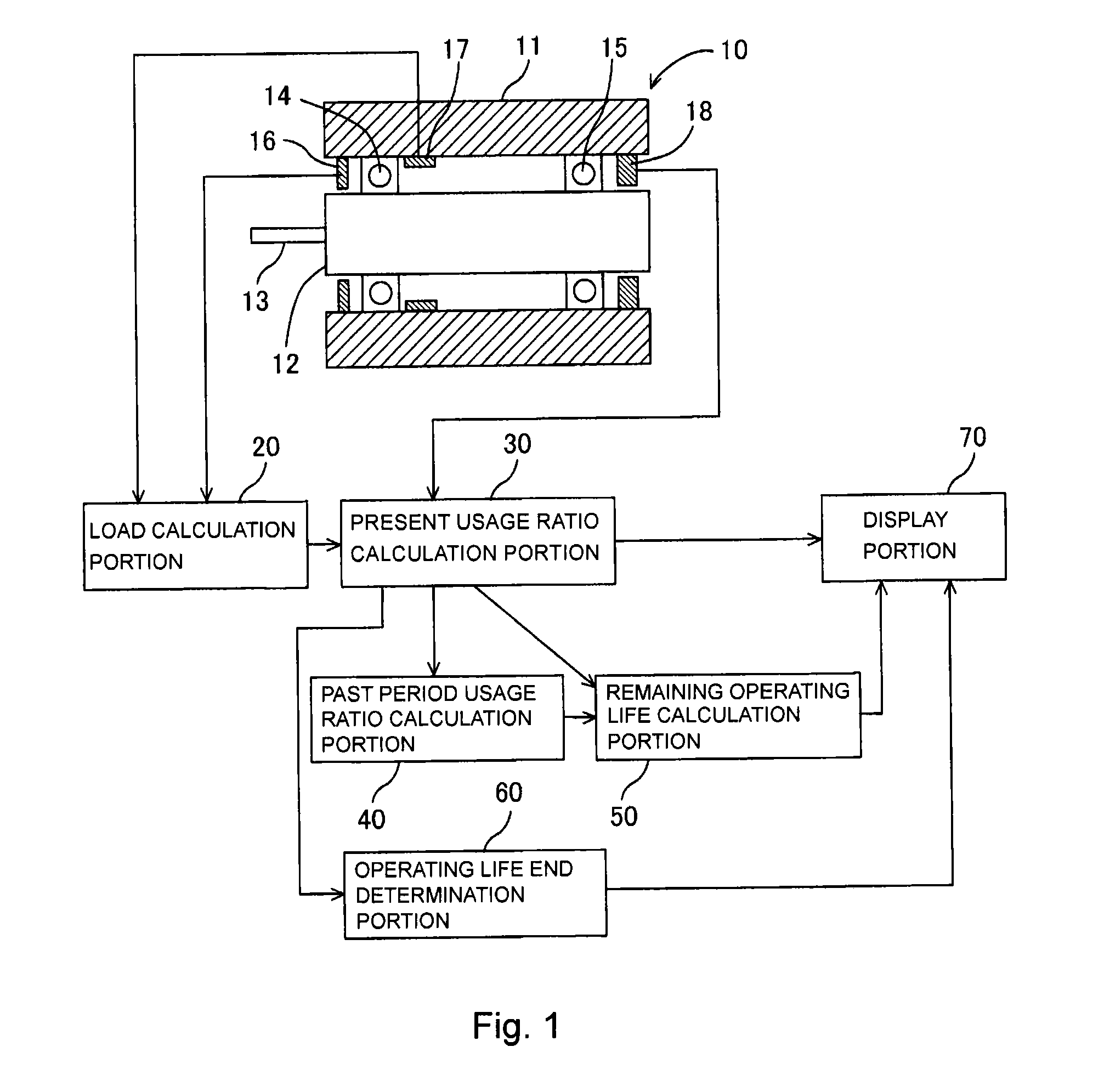

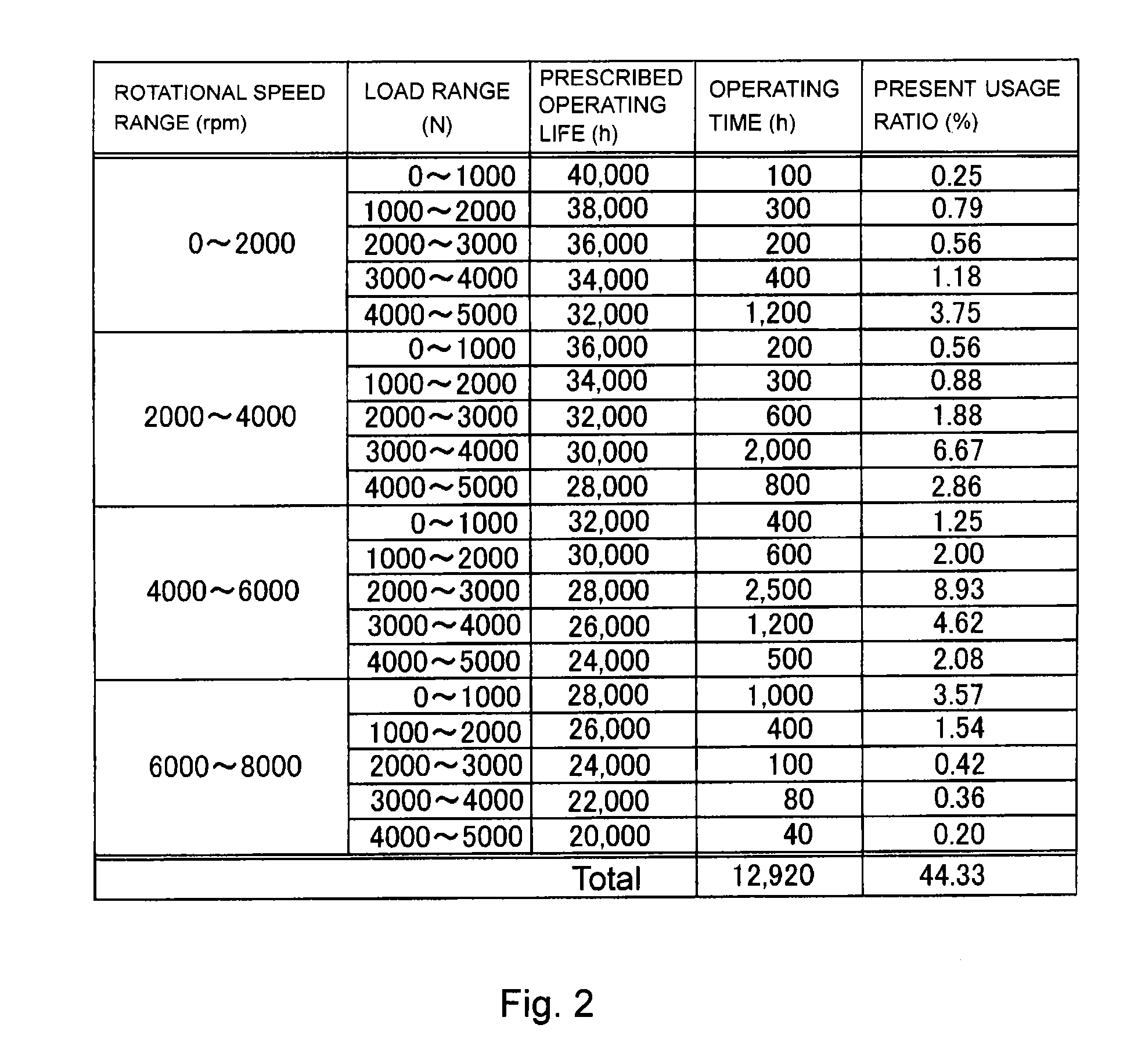

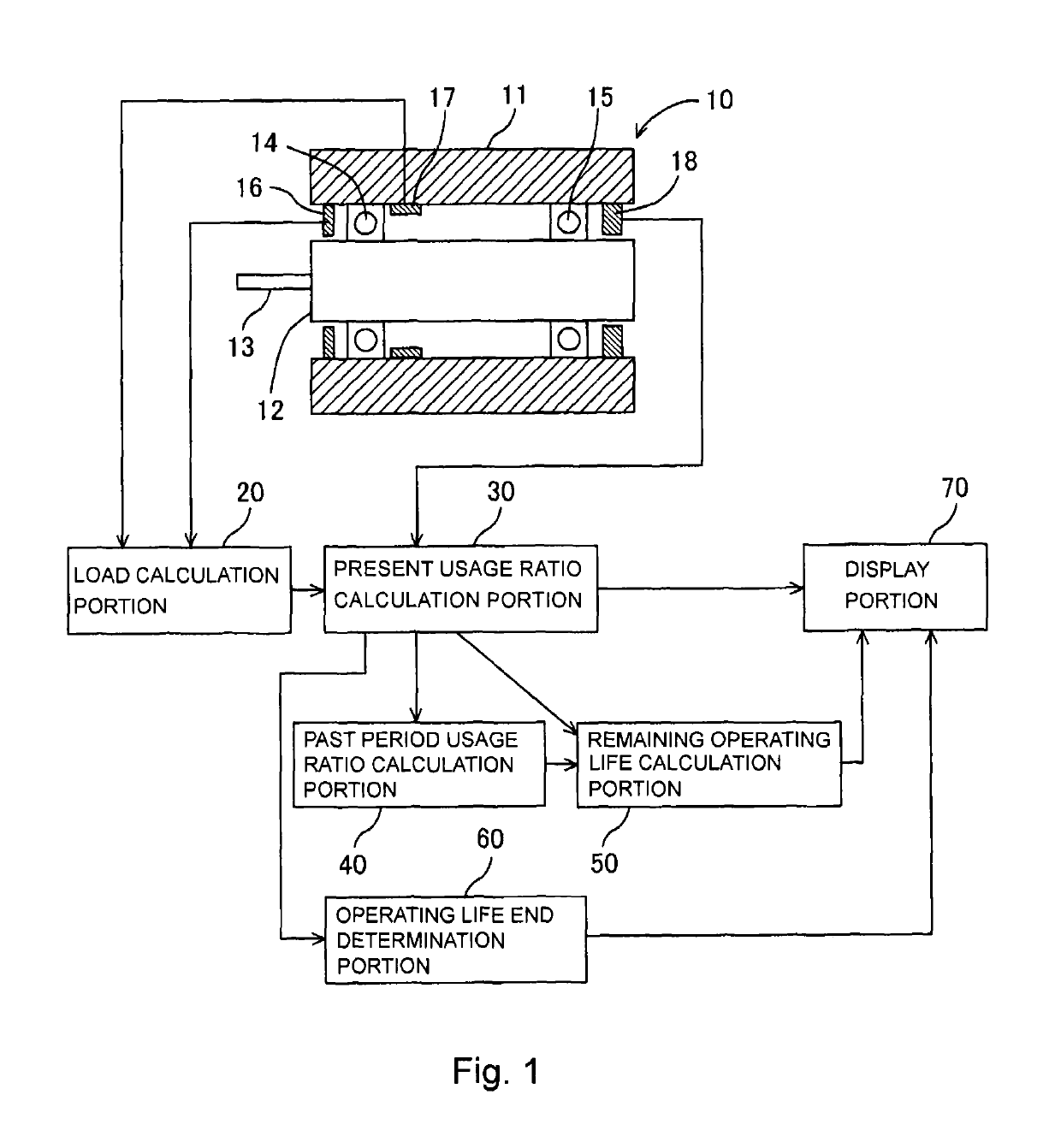

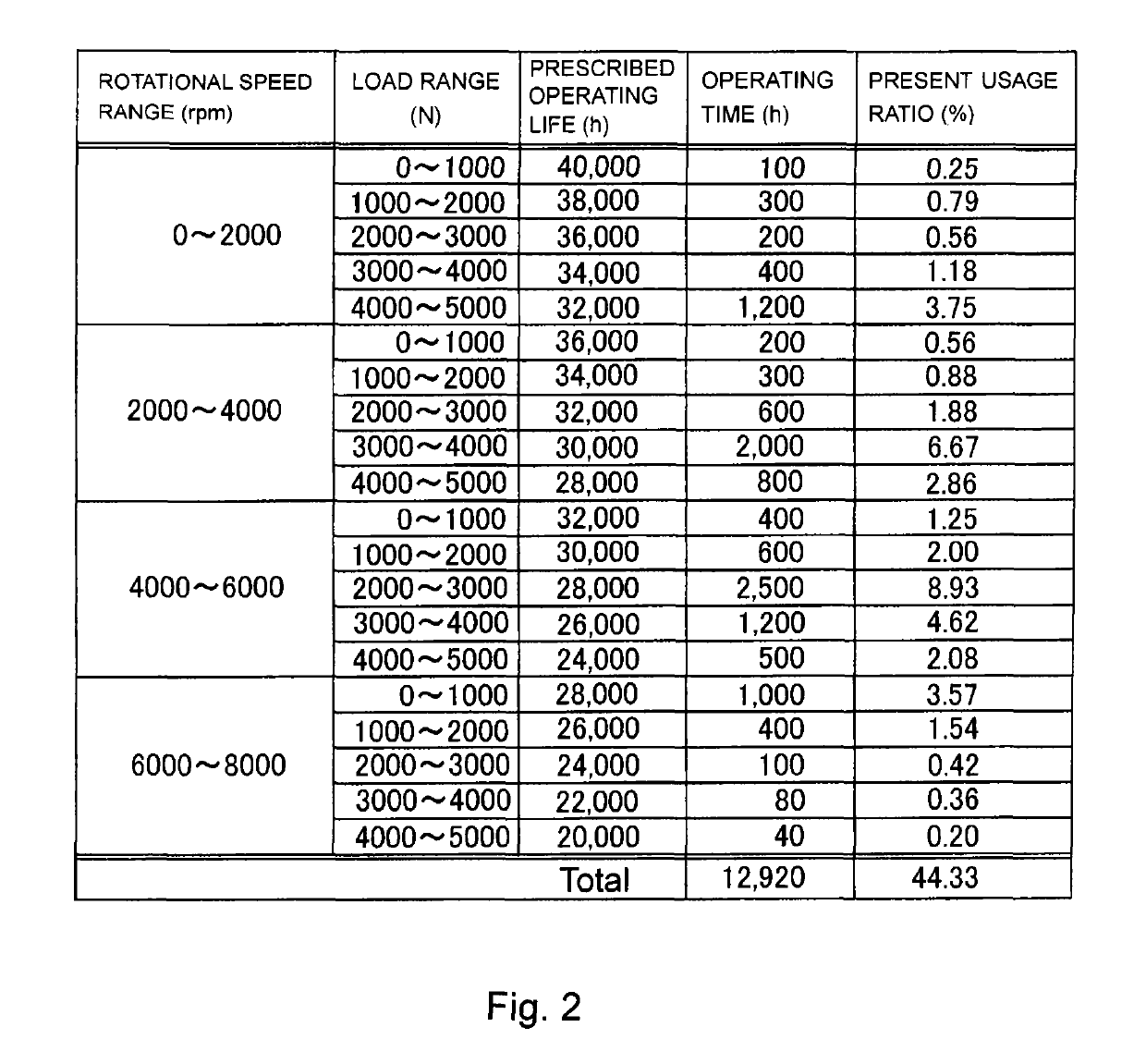

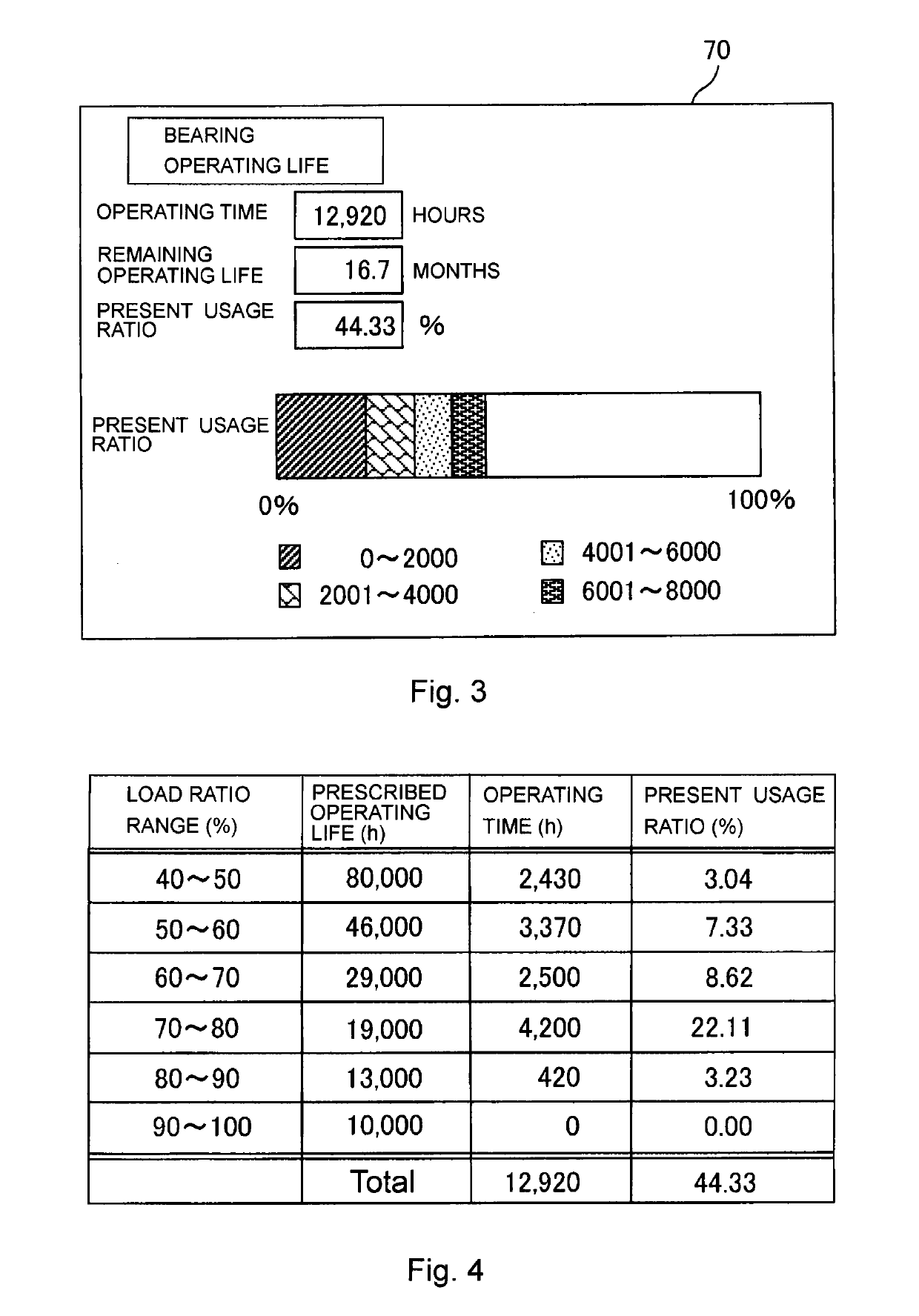

Spindle condition detection device for machine tool

ActiveUS20120109539A1Reduced service lifeImprove accuracyProgramme controlPlug gaugesPresent momentMachine tool

A spindle condition detection device for a machine tool includes: bearing load detecting means for detecting a load on a bearing that rotatably supports a spindle of a machine tool; and present usage ratio calculating means for calculating, based on the load detected by the bearing load detecting means, a present usage ratio that is a ratio of usage of the bearing with respect to a prescribed operating life of the bearing, which is achieved over a period until a present moment.

Owner:JTEKT CORP

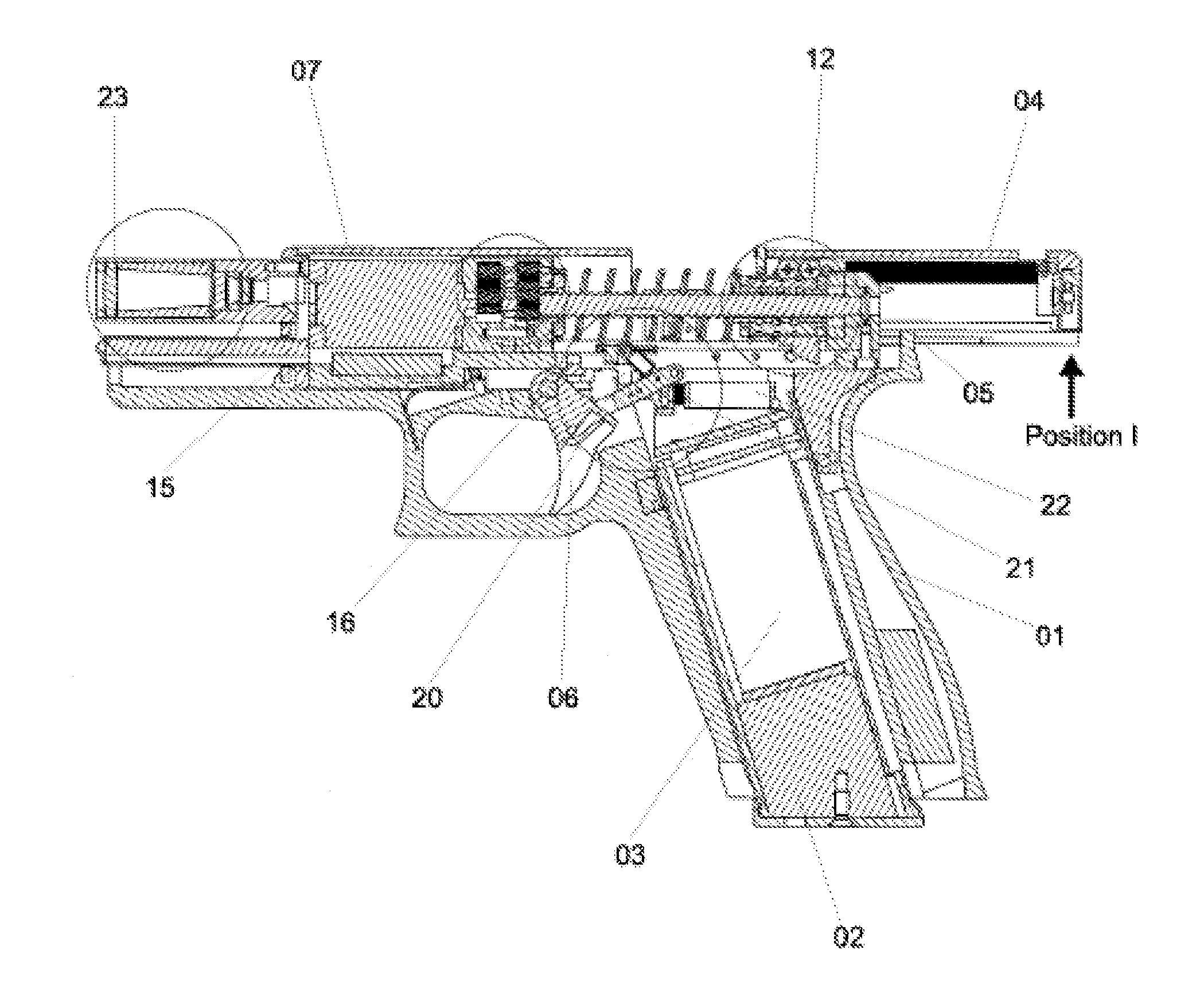

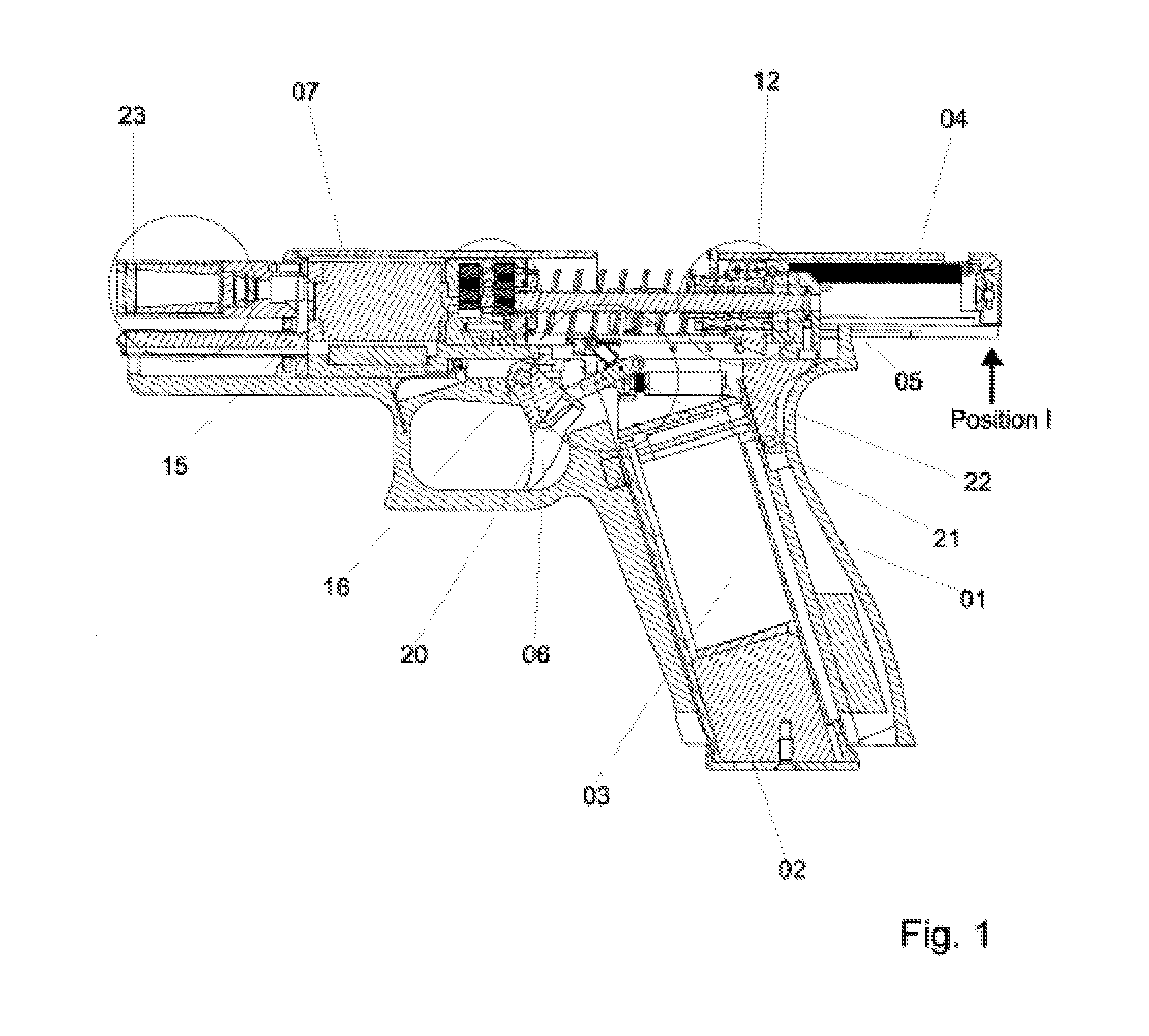

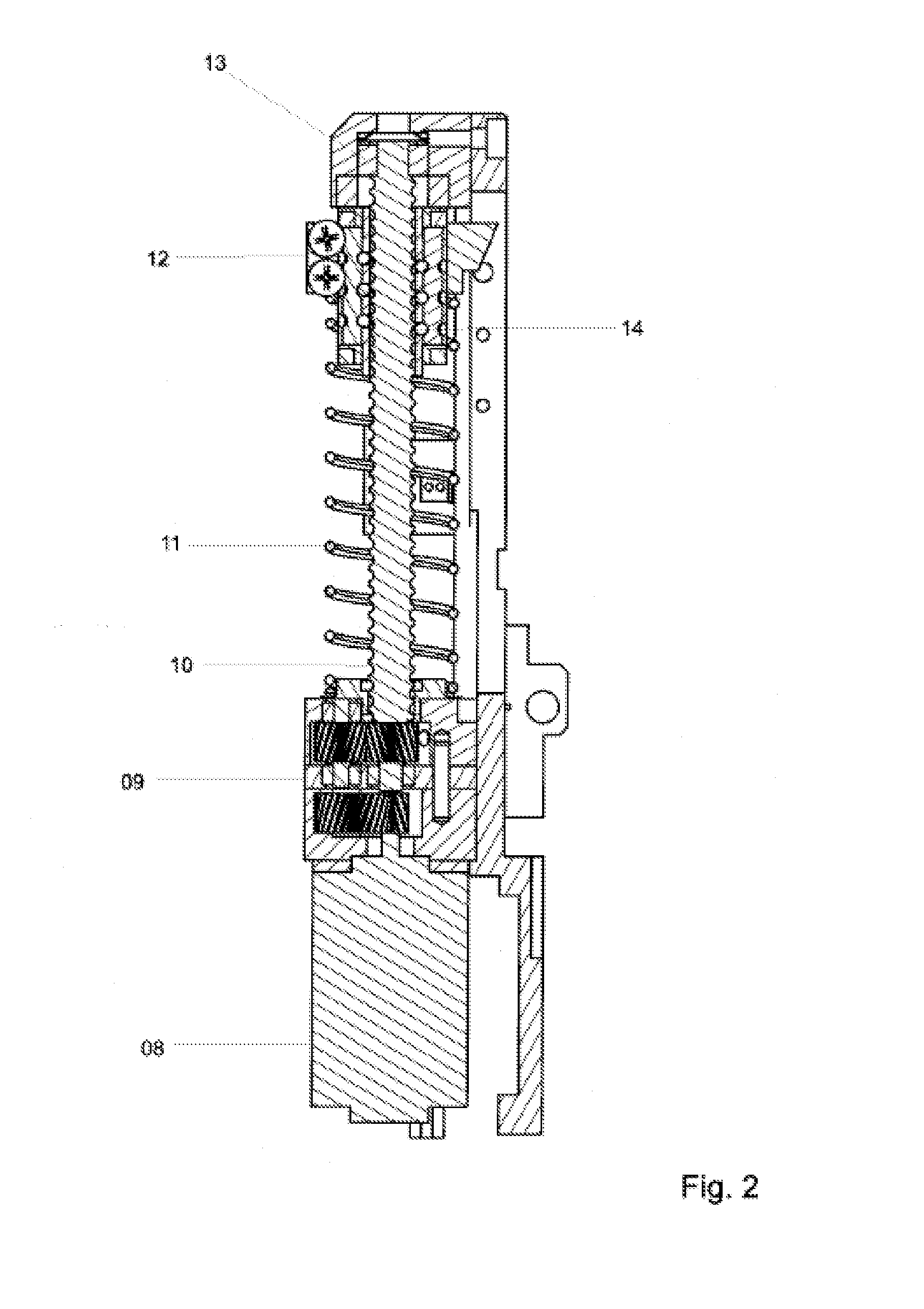

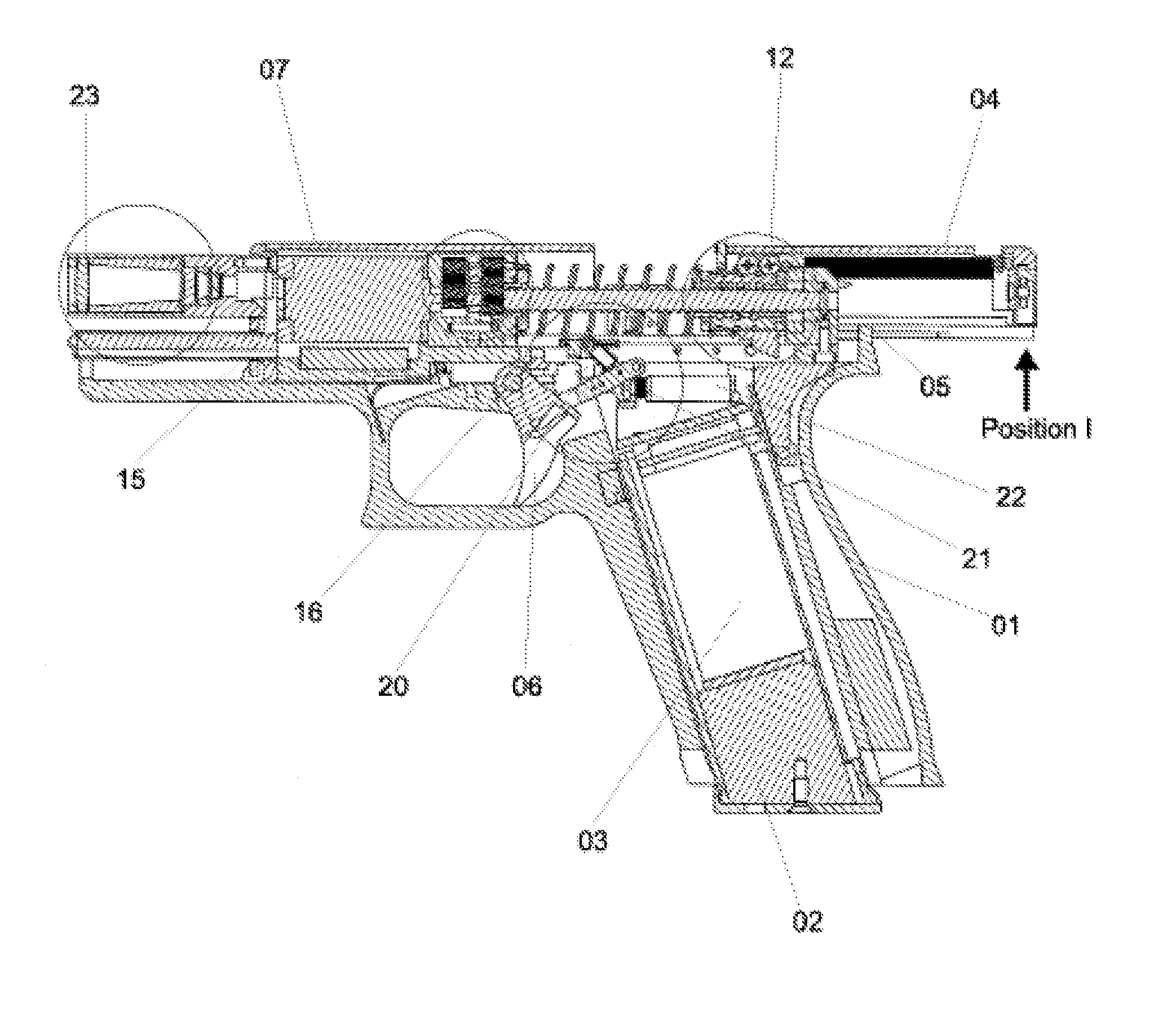

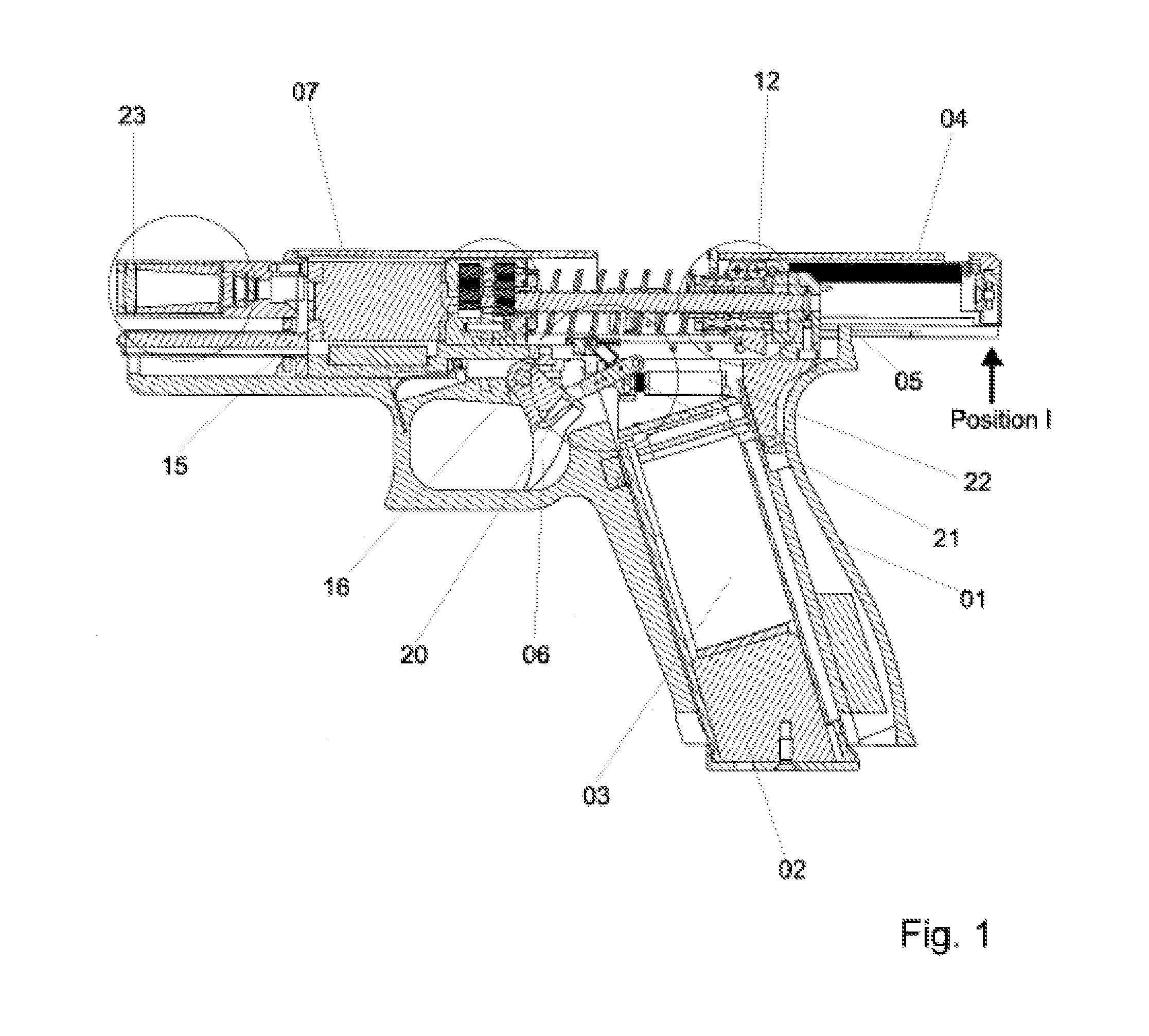

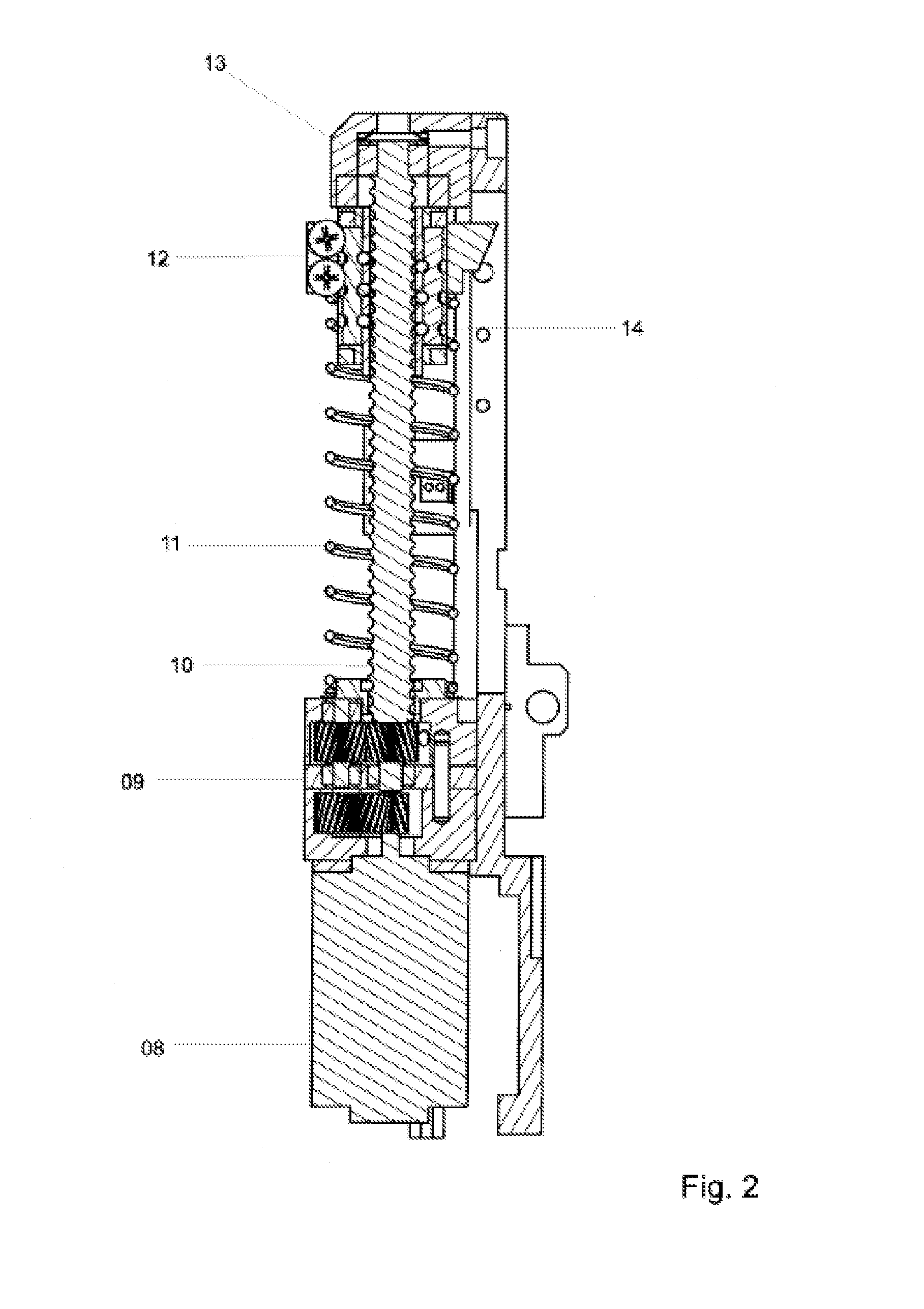

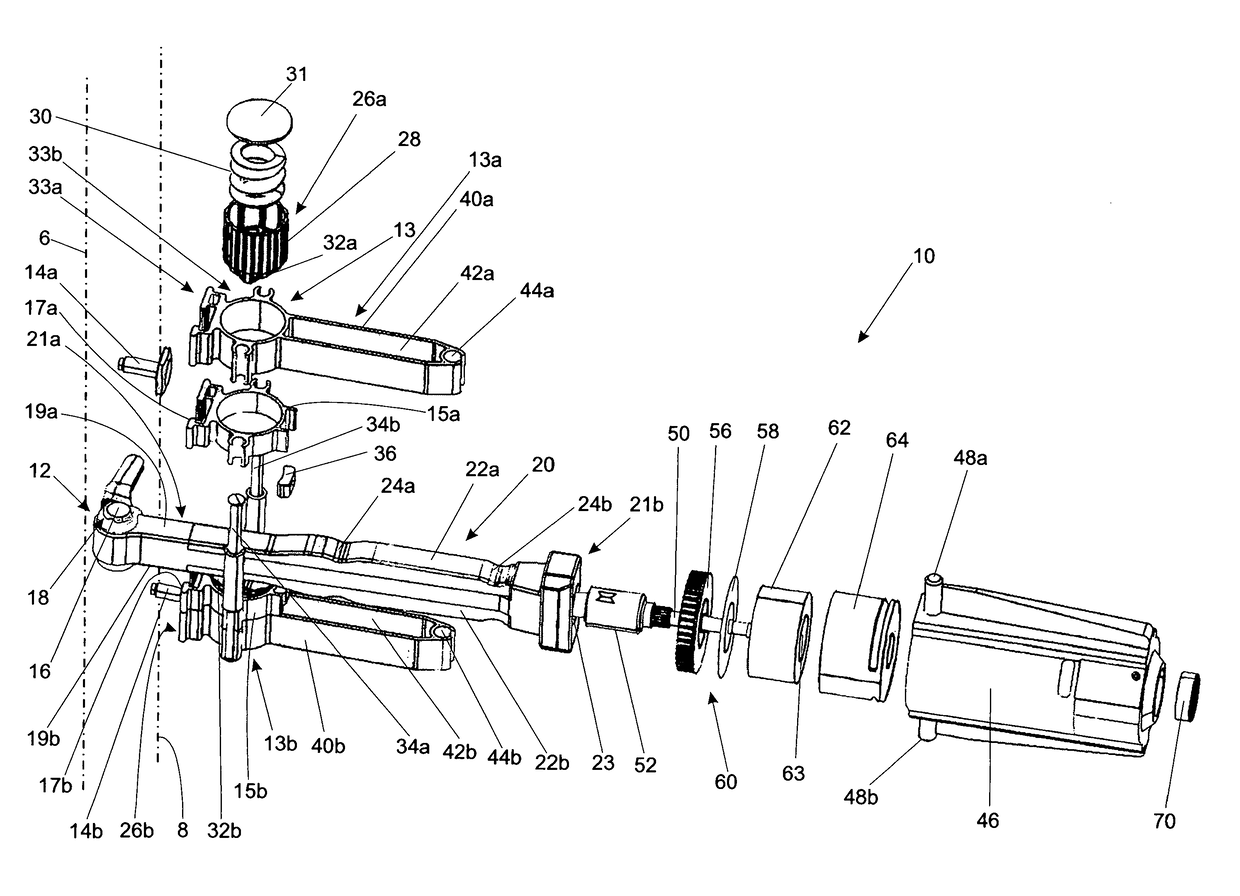

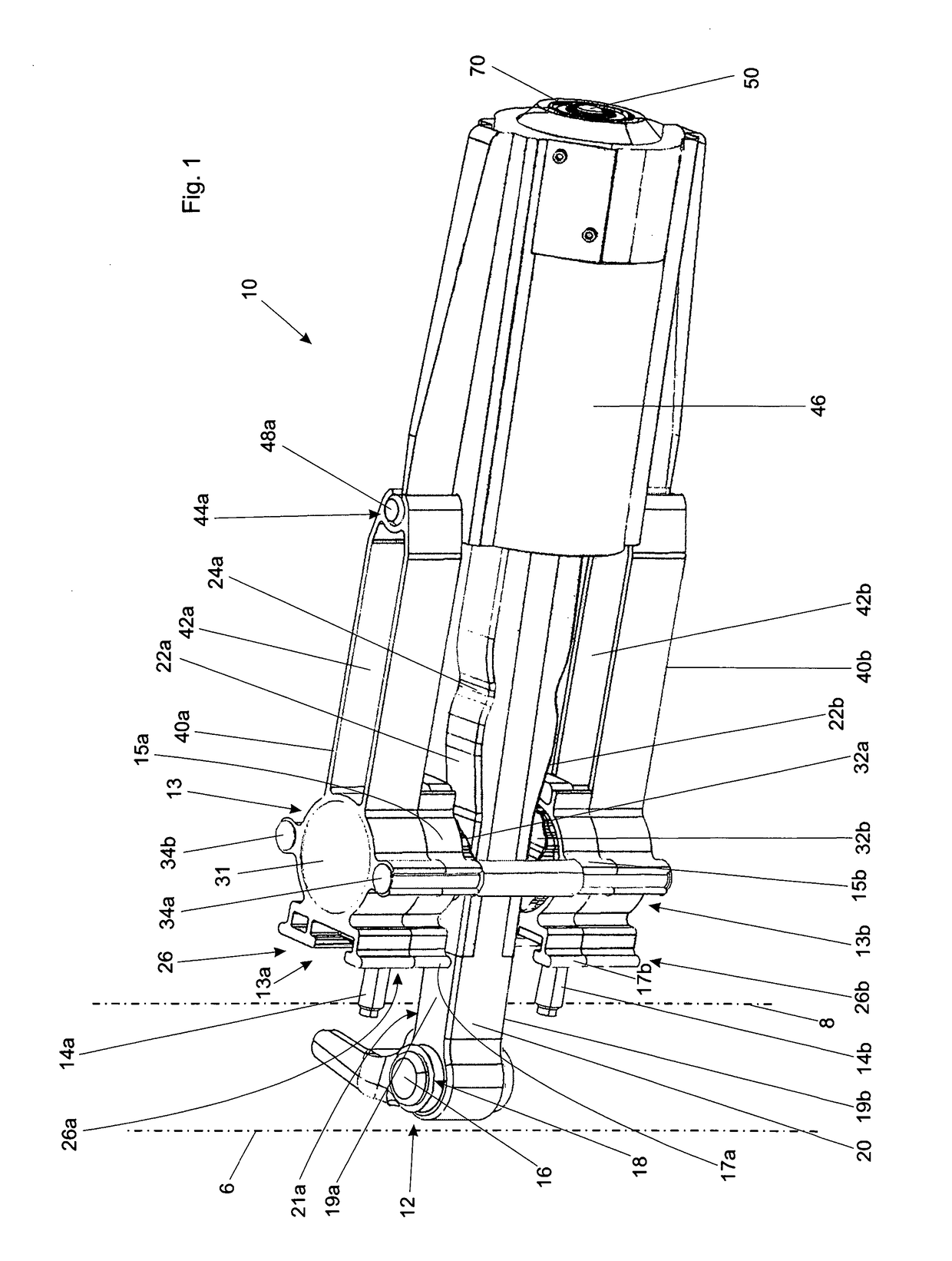

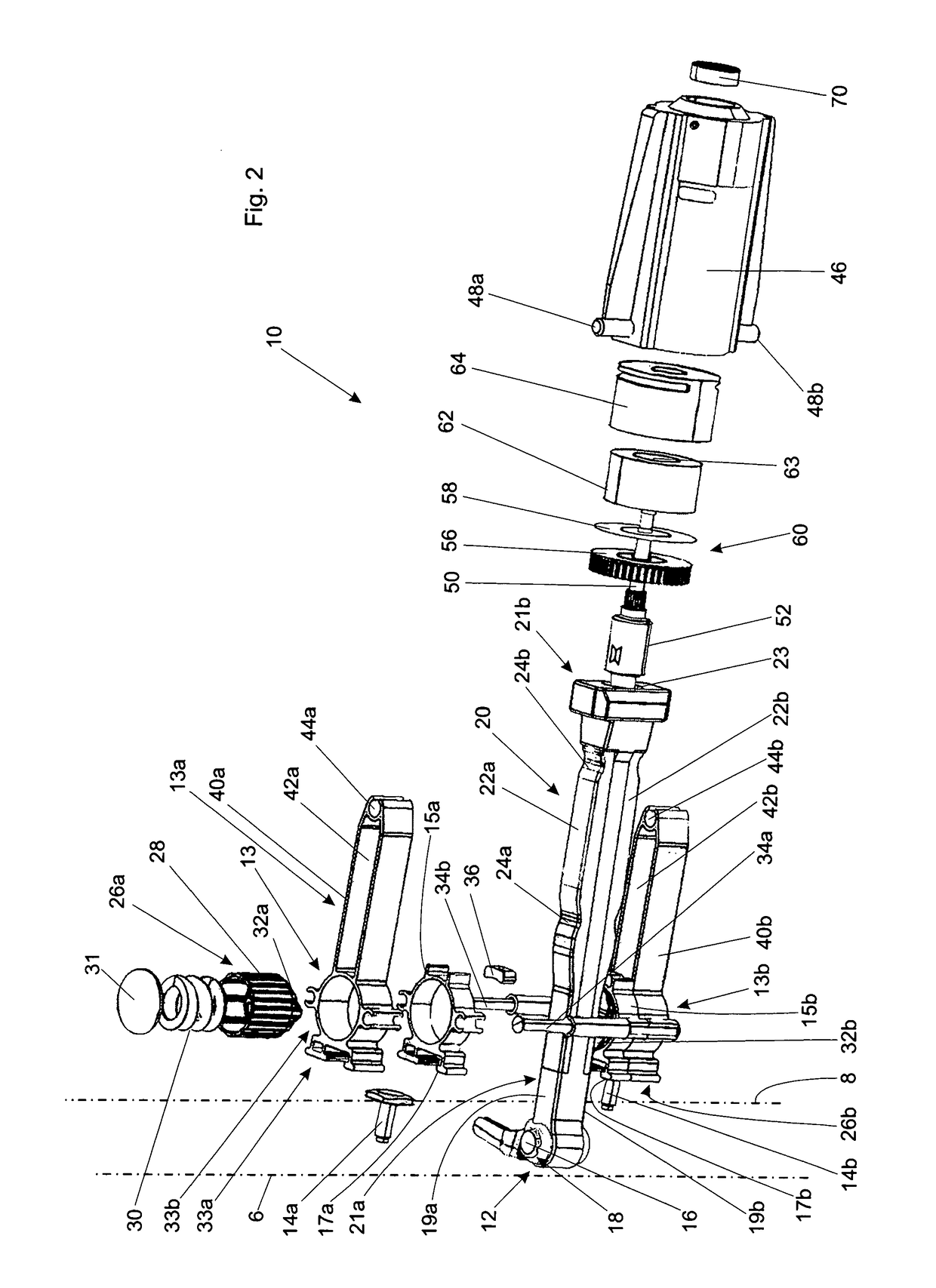

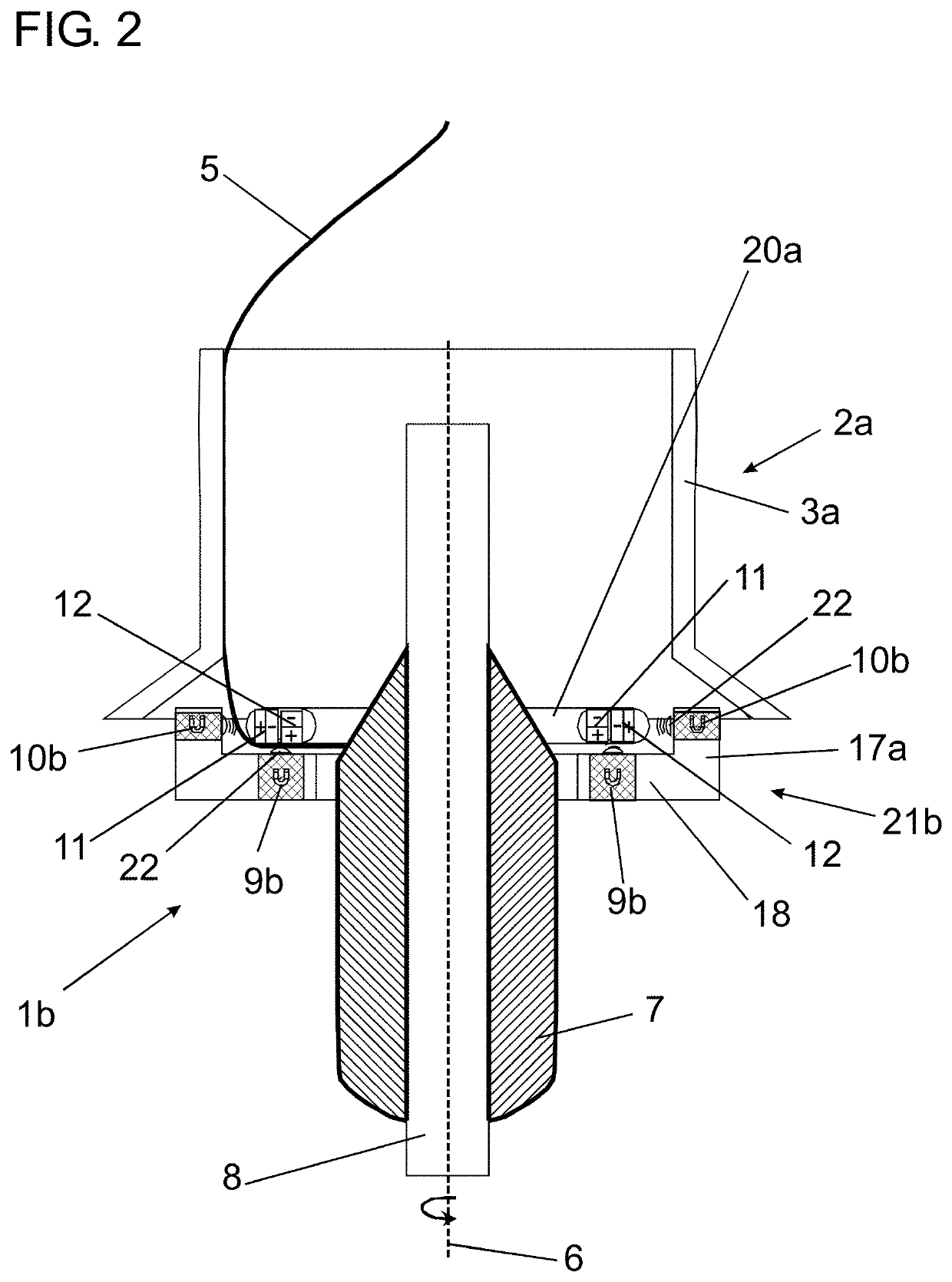

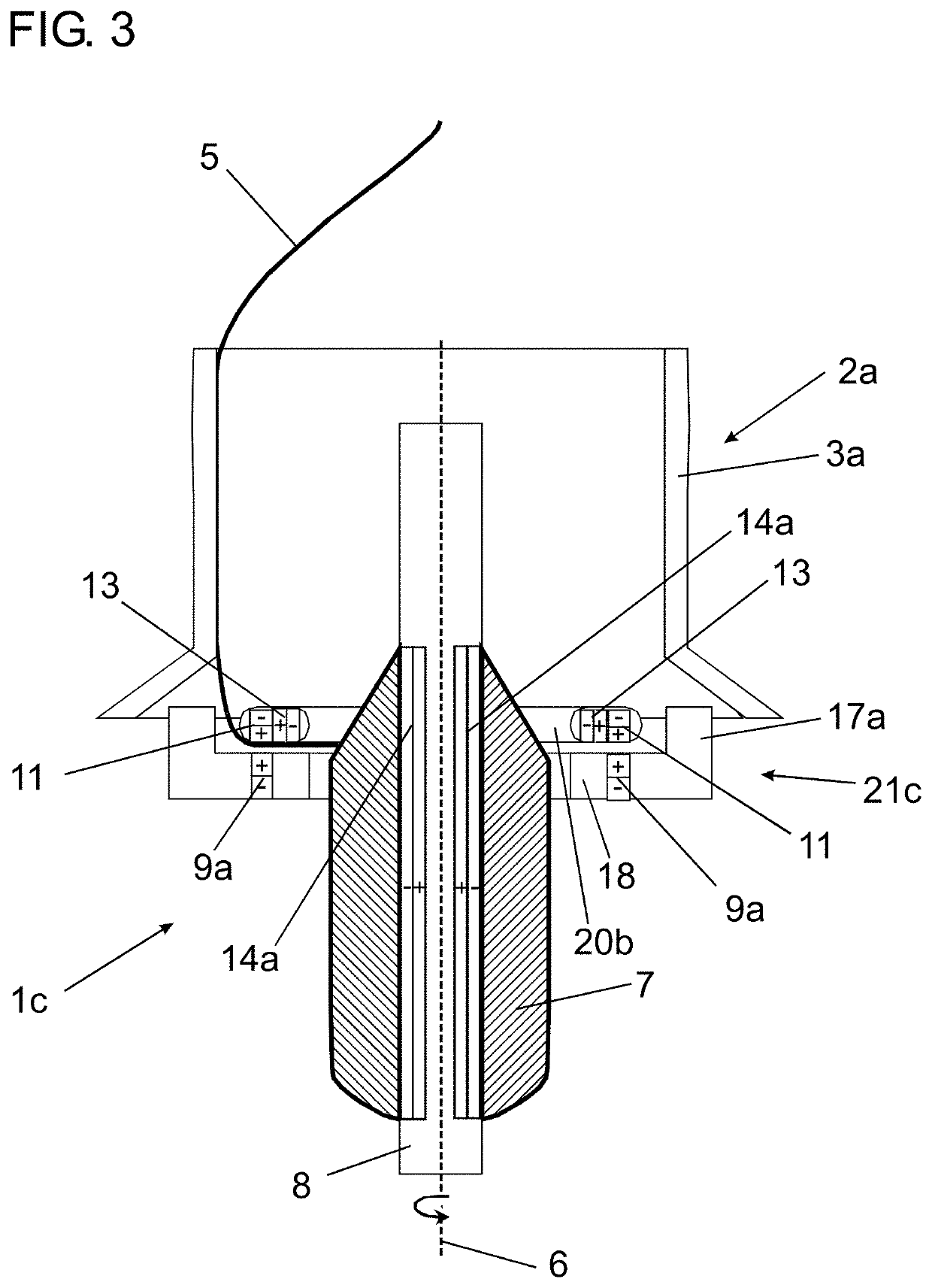

Recoil impulse generator for a weapon simulator

InactiveUS20110318715A1Solve the lack of spaceRealistic recoil forceTraining adaptationCouplingEngineering

The invention relates to a recoil impulse generator for a weapon simulator comprising a force storage element and an impulse mass that can be moved and that is moved from a stressed to an unstressed position with a triggering element is actuated in order to simulate a recoil impulse. The recoil impulse generator comprises a drive that drives a spindle uniterruptedly during a shot sequence simulating several shots; a coupling that is connected to the impulse mass and to the force storage element and that engages in the spindle in an engaged state and that is moved along the spindle by means of rotation of the spindle in order to bring the impulse mass into the stressed position again the force applied by the force storage element; a disengaging means that switches the coupling to a disengaged state when the impulse mass has reached the stressed position; and an engaging means that switches the coupling to the engaged state when the impulse mass has reached the unstressed position.

Owner:E SIGMA TECH

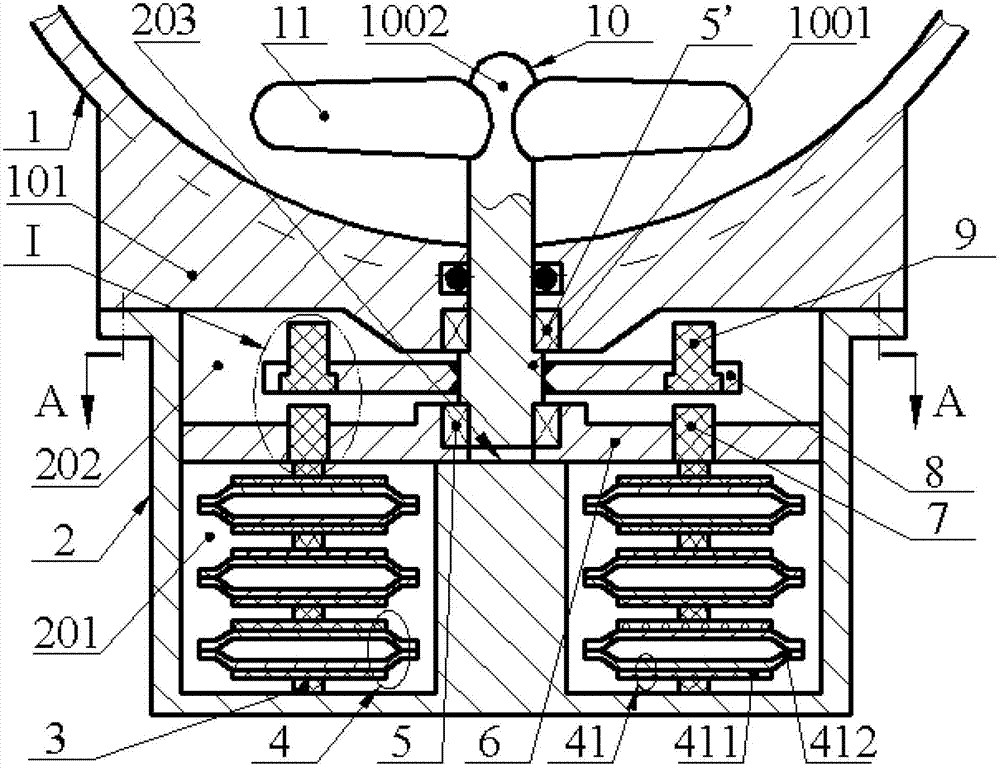

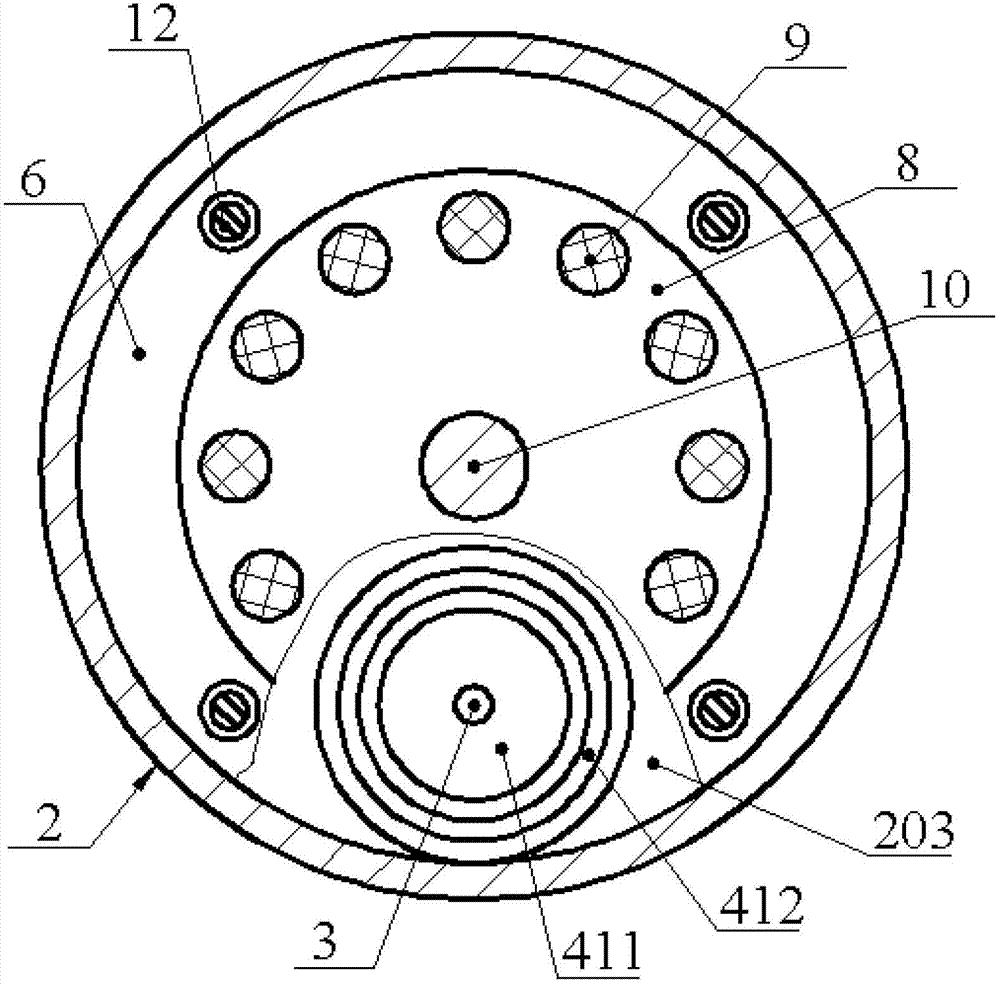

Self-powered device for monitoring oil and gas transmission pipelines

InactiveCN102790551AReliable energy supplySufficient energy supplyPiezoelectric/electrostriction/magnetostriction machinesLow speedTransducer

The invention relates to a self-powered device for monitoring oil and gas transmission pipelines and belongs to the field of oil and gas pipeline monitoring and power generation. A body is fixed on a boss inlaid with a bearing and arranged on the outer side of a pipeline, a press plate inlaid with a bearing is mounted in the body, the upper ends of columnar magnets enter large round holes at the upper end of the body through guide holes on the press plate, the lower ends of the columnar magnets are adhered with a group of bowl-shaped piezoelectric transducers arranged in small round holes, a spindle is mounted on inner rings of the bearings, blades are mounted at one end of the spindle, T-shaped magnets are inlaid on a flange plate which is welded at the other end of the spindle, and the T-shaped magnets and the columnar magnets are mounted with like poles close to one another. The self-powered device for monitoring the oil and gas transmission pipelines has the advantages that the piezoelectric transducers are used for converting oil and gas kinetic energy into electric energy, and reliable and sufficient energy can be obtained without laying cables or batteries; the self-powered device is high in power generation capacity, free of contact impact and noise and high in reliability; and power generation is determined by magnetic field intensity, and the self-powered device has high power generation capacity when the spindle rotates at a high speed, at a low speed and at a uniform speed.

Owner:ZHEJIANG NORMAL UNIVERSITY

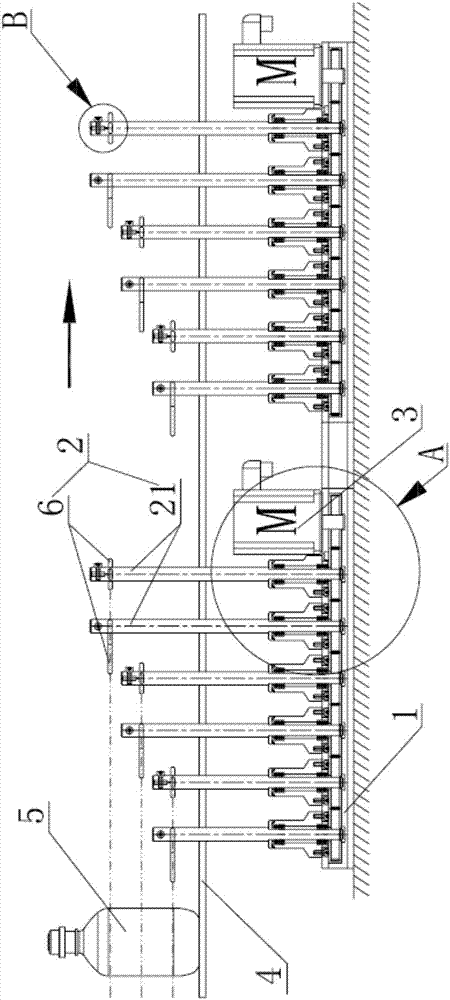

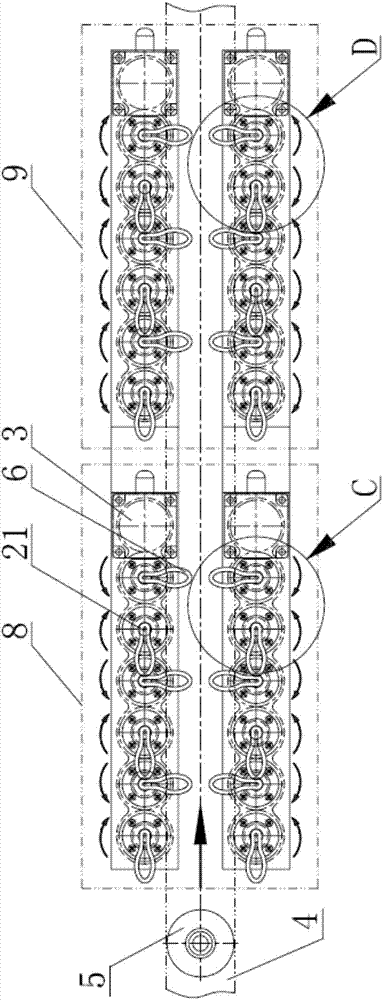

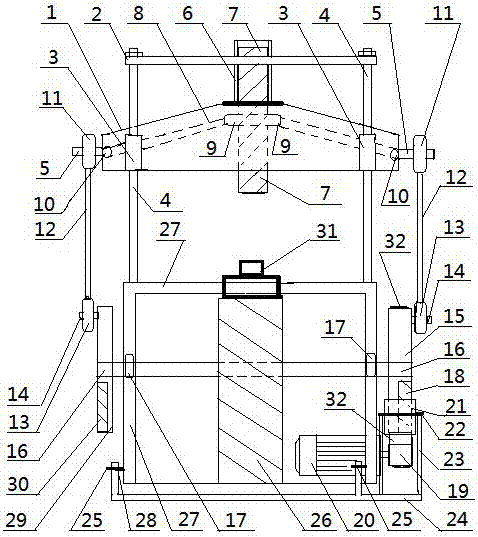

Conveying joint device for cops and bobbins for spinning and doffing connection and conveying method thereof

ActiveCN108560088AAchieve automatic round-trip transportationReasonable structureTextiles and paperWinding machineBobbin

The invention relates to a conveying joint device for cops and bobbins for spinning and doffing connection. The device comprises a stirring plate arranged at the joint between first pallet conveying track and a second pallet conveying track, a pallet output mechanism, a pallet input mechanism, multiple pallets and multiple pallet support assemblies. The multiple pallets and the multiple pallet support assemblies are used for placing cops and bobbins. The stirring plate is used for stirring pallets which are conveyed to the joint and. Clamping positioning of the above pallets is released. The stirring plate is coaxially installed onto a guide wheel. The pallet output mechanism is used for automatically conveying all pallets separated from the pallet support assemblies to the second pallet conveying track. The pallet input mechanism is used for automatically conveying all the pallets outputted by the second pallet conveying track to the pallet support assemblies of the first pallet conveying track. Therefore, the purpose of automatically conveying pallets in a reciprocating manner between an automatic winding machine and an automatic doffing and spinning machine is fulfilled. As a result, connection between the automatic doffing and spinning machine and the automatic winding machine is realized. The device is reasonable and compact in structure and helps reduce the conveying process. Spindle speed and production efficiency of the spinning machine can be greatly increased.

Owner:常州市同和纺织机械制造有限公司

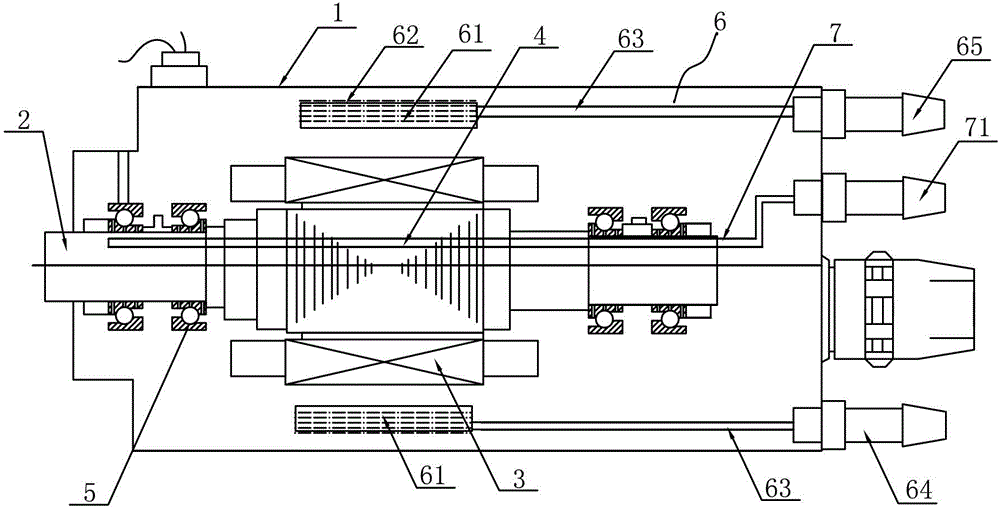

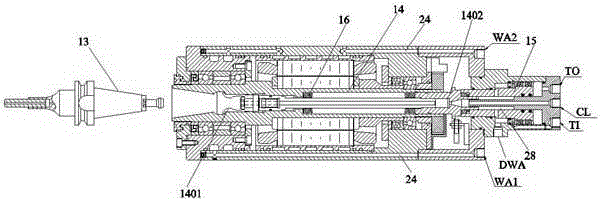

High-speed motor spindle adopting lubrication under loop

InactiveCN102794467AIncrease speedIncrease the spindle speedMaintainance and safety accessoriesGas lubricationEngineering

The invention discloses a high-speed motor spindle adopting lubrication under a loop, which belongs to the technical field of motor spindles. The high-speed motor spindle comprises a spindle casing and a spindle arranged in the spindle casing, wherein bearings are sleeved at the two ends of the spindle respectively; the middle of the spindle is sleeved by a rotor; a stator corresponding to the rotor is arranged in the spindle casing; an oil mist pipe is arranged in spindle and provided with a plurality of nozzles corresponding to lubricating holes of the bearings; through holes are formed in the connecting parts of the spindle and the nozzles of the oil mist pipe; an oil mist inlet connected with the oil mist pipe is formed in the spindle casing; a cooling system is further arranged in the spindle casing of the high-speed motor spindle; and the oil lubrication under the loop or oil gas lubrication under the loop is adopted for the bearings. With the adoption of the lubrication under the loop for the high-speed motor spindle, lubricating oil or oil gas arrives at bearing lubrication areas more easily under the action of a centrifugal force, so that the lubrication effect is better than the effects of ordinary jet lubrication and oil gas lubrication.

Owner:SHAOXING UNIVERSITY

Recoil impulse generator for a weapon simulator

InactiveUS8608474B2Solve the lack of spaceFrequent replacementTraining adaptationCouplingImpulse generator

The invention relates to a recoil impulse generator for a weapon simulator comprising a force storage element and an impulse mass that can be moved and that is moved from a stressed to an unstressed position with a triggering element is actuated in order to simulate a recoil impulse. The recoil impulse generator comprises a drive that drives a spindle uninterruptedly during a shot sequence simulating several shots; a coupling that is connected to the impulse mass and to the force storage element and that engages in the spindle in an engaged state and that is moved along the spindle by means of rotation of the spindle in order to bring the impulse mass into the stressed position again the force applied by the force storage element; a disengaging means that switches the coupling to a disengaged state when the impulse mass has reached the stressed position; and an engaging means that switches the coupling to the engaged state when the impulse mass has reached the unstressed position.

Owner:E SIGMA TECH

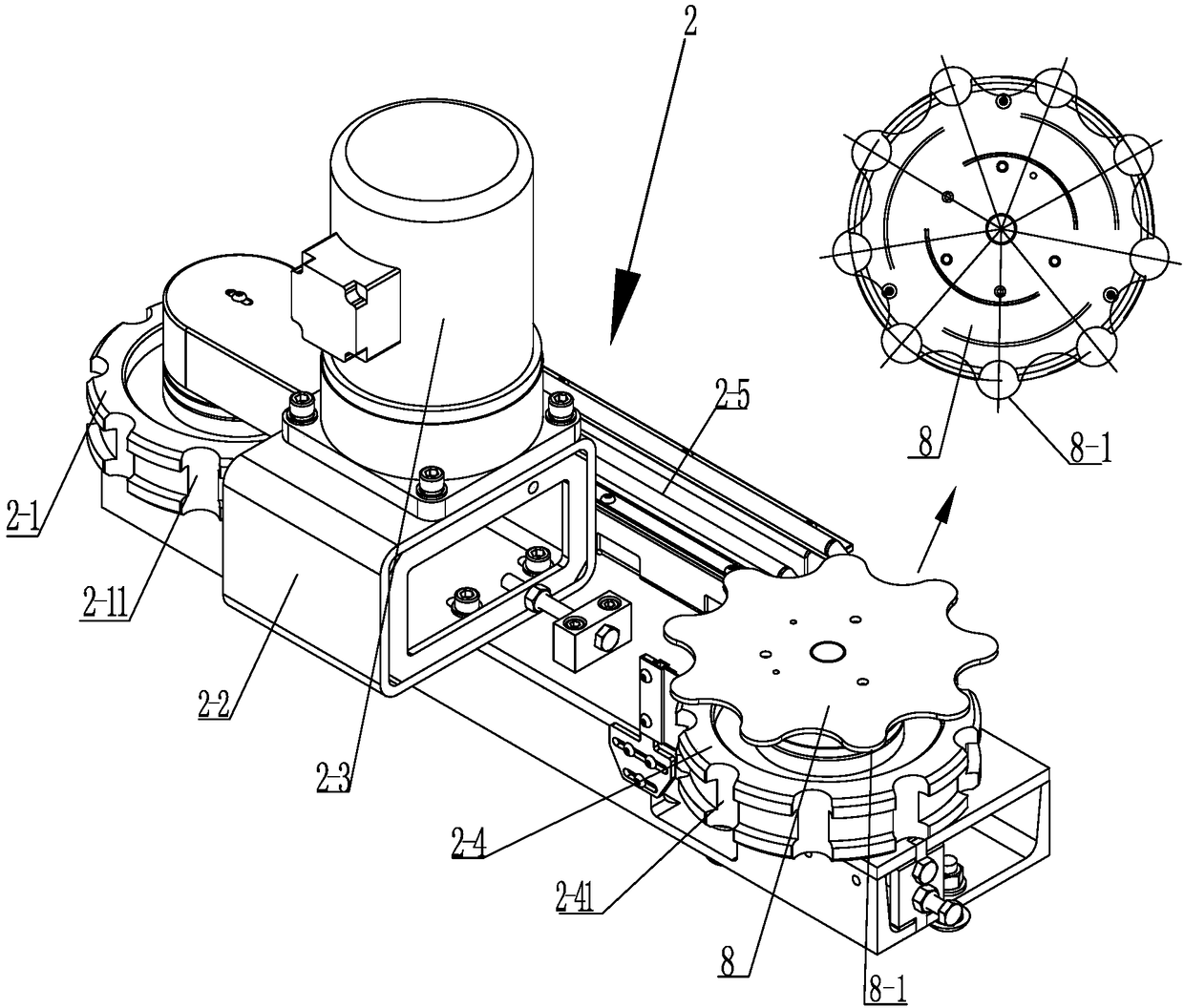

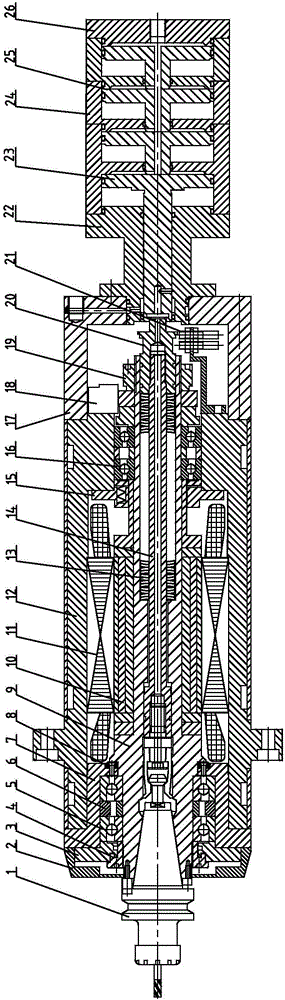

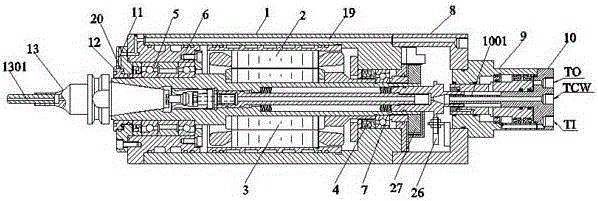

Low-speed high-torque and permanent-magnet synchronous high-speed automatic tool-changing electric spindle

ActiveCN106041130ARealize automatic replacementEasy tool changePositioning apparatusMaintainance and safety accessoriesElectricityLow speed

The invention discloses a low-speed high-torque and permanent-magnet synchronous high-speed automatic tool-changing electric spindle. The electric spindle comprises a motor body, and a stator, a rotor, a rotor shaft, a spring pre-tightening mechanism, a front bearing and a rear bearing are arranged inside the motor body. The electric spindle further comprises a connection base fixed to the rear end of the motor body, a connector fixedly connected to the connection base, a steam cylinder assembly fixedly connected to the connector, a rear cover arranged at the end of the steam cylinder assembly and a front end cover connected to the front end of the motor body. A tool loosening and pulling mechanism is arranged in the center of the rotor shaft, a pulling claw is arranged at the front end of the tool loosening and pulling mechanism, a disc spring assembly is installed in the middle of the tool loosening and pulling mechanism, a high-performance sensor is adopted together, and therefore automatic tool changing is more convenient and accurate and rapider. A magneto-electric coder is adopted at the rear end, so that low-speed torque output is more balanced. Compressed air is adopted for non-contact air sealing so that higher rotation speed can be obtained. The electric spindle is simple and compact in structure and powerful in function, is smaller than common electric spindles with the same power in size, has the advantages that the speed is low and the torque is high and can be widely applied to high-speed and low-speed precision machining of various materials.

Owner:江苏华雕机械有限公司

Door check and method for blocking a door check

ActiveUS20170350175A1Prevents unintentional pivotingStop the movement of the vehicle door quickly and reliablyWing accessoriesWing fastenersElectrical and Electronics engineeringCar door

The door check includes a retaining bar (20) which can be connected to one of the two door assembly parts, i.e. the door (8) or the door frame (6), and a retaining housing (13) which can be connected to the other door assembly part. In order to design a door check that allows a vehicle door to be reliably and safely blocked in an automated manner, a threaded bar (50) can be accommodated in an axially movable fashion in a cavity of the retaining bar (20).

Owner:EDSCHA ENG GMBH

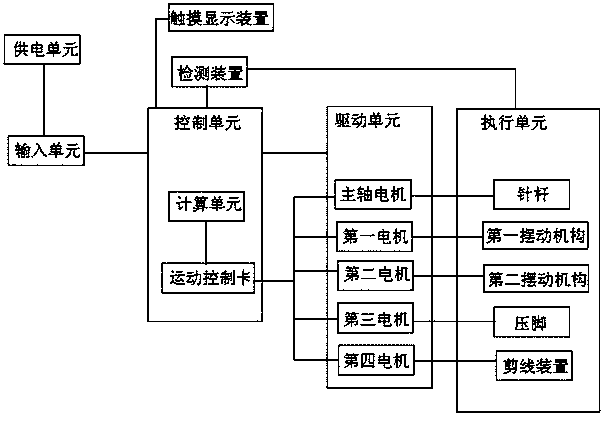

Industrial sewing machine and sewing method

InactiveCN104372530AImprove sewing efficiencyFlexible configurationProgramme-controlled sewing machinesSewing-machine control devicesControl signalDisplay device

The invention relates to an industrial textile processing machine, in particular to an industrial sewing machine and a sewing method. The industrial sewing machine comprises an industrial sewing machine body which is provided with a handpiece. The handpiece is connected with a frame needle through a needle rod. A presser foot matched with the frame needle is arranged at the lower end of the handpiece. The industrial sewing machine further comprises an input unit, a control unit and a drive unit. The drive unit is connected with the control unit and an execution unit and used for receiving and amplifying a control signal and outputting the control signal to the execution unit matched with the drive unit for execution. Compared with the prior art, the industrial sewing machine has the advantages that the modular unitization structure is adopted, all units are internally independent and respectively systematic, the degree of integration is high, the structure is simple, errors are not likely to occur in the sewing process by adoption of the automatic sewing method, sewing is attractive, the sewing efficiency of the industrial textile processing machine is improved due to the high rotation speed of a spindle, and by adoption of a touch screen display device, operation is convenient.

Owner:SHANGHAI POWERMAX TECH INC

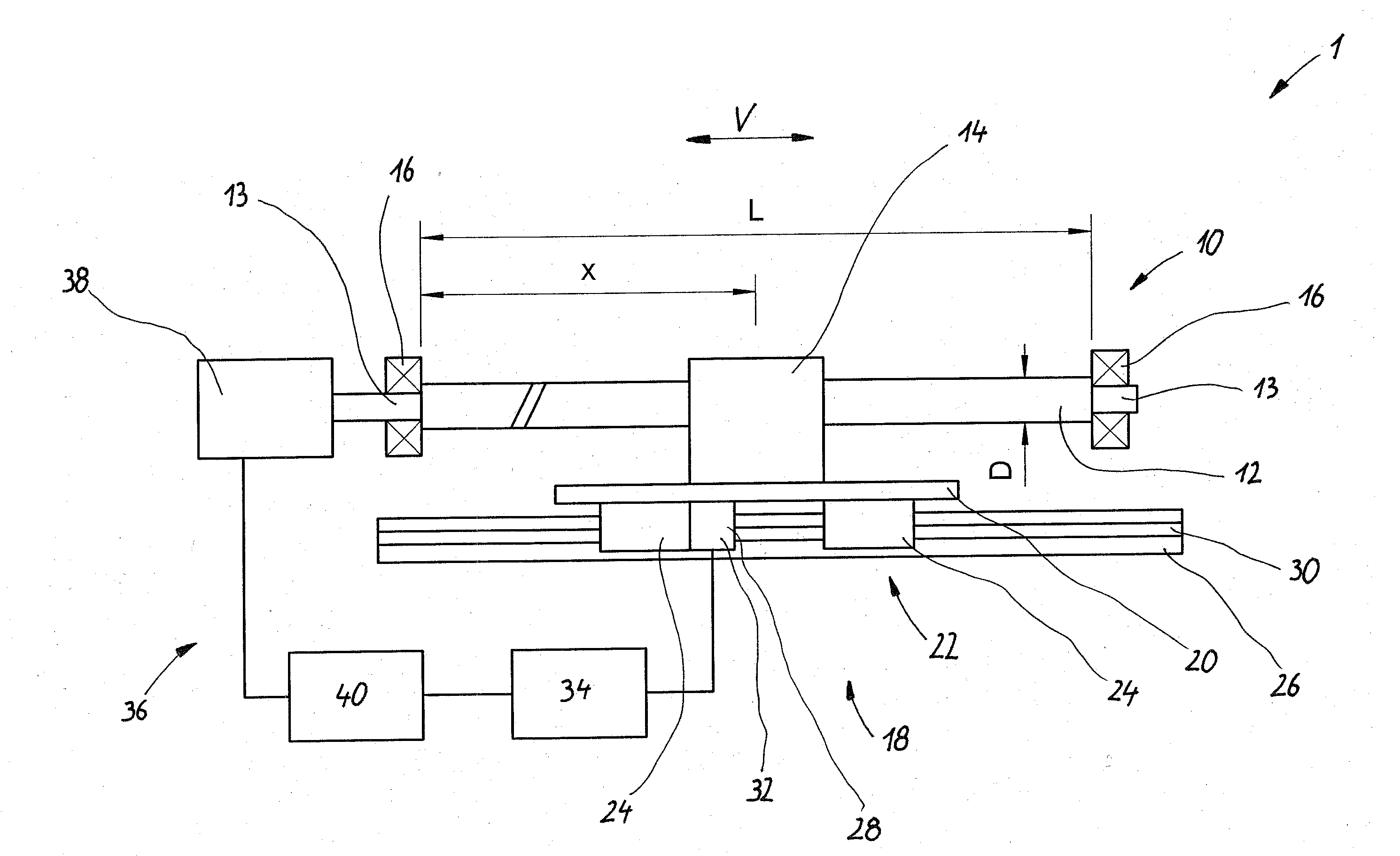

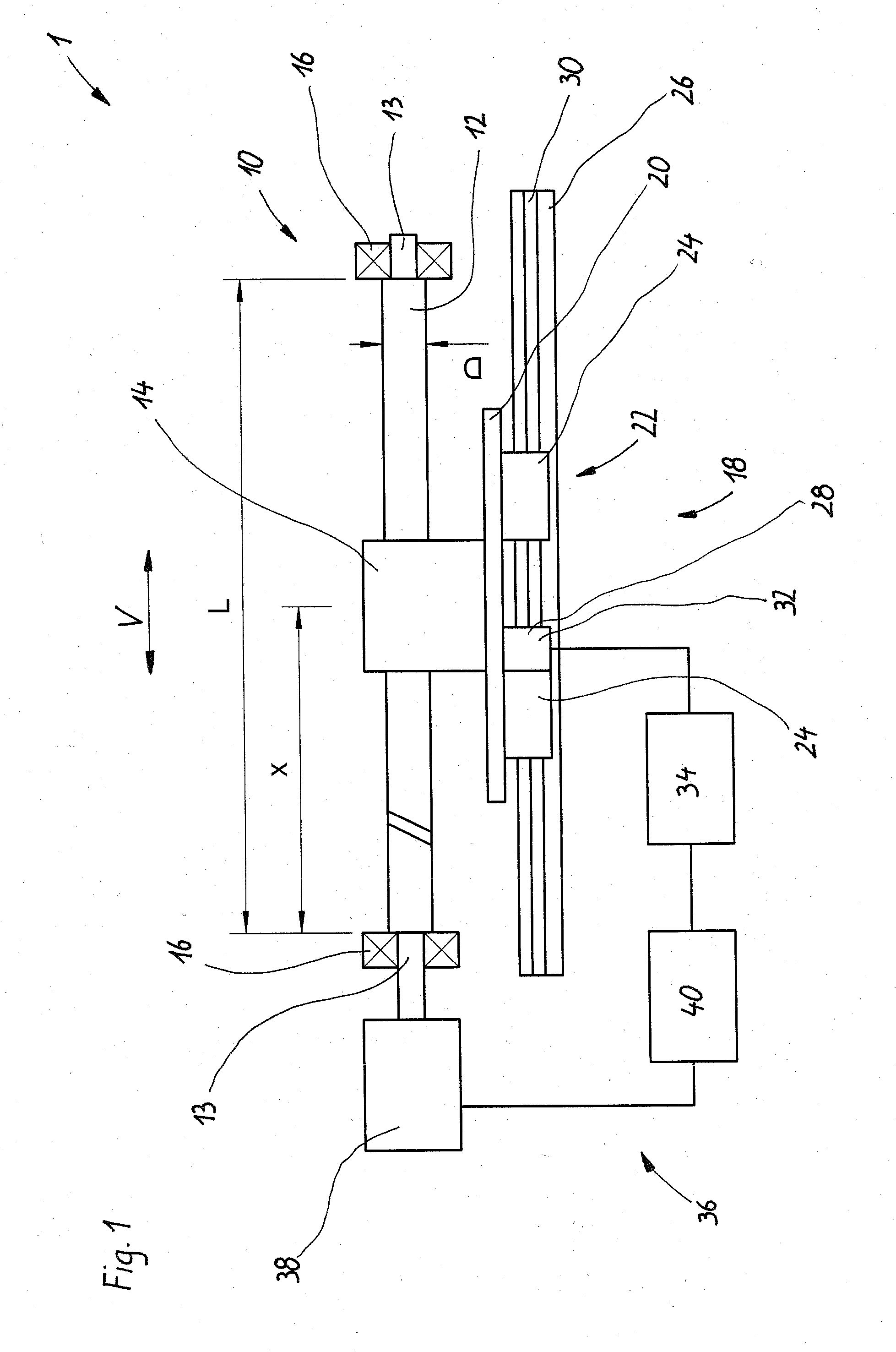

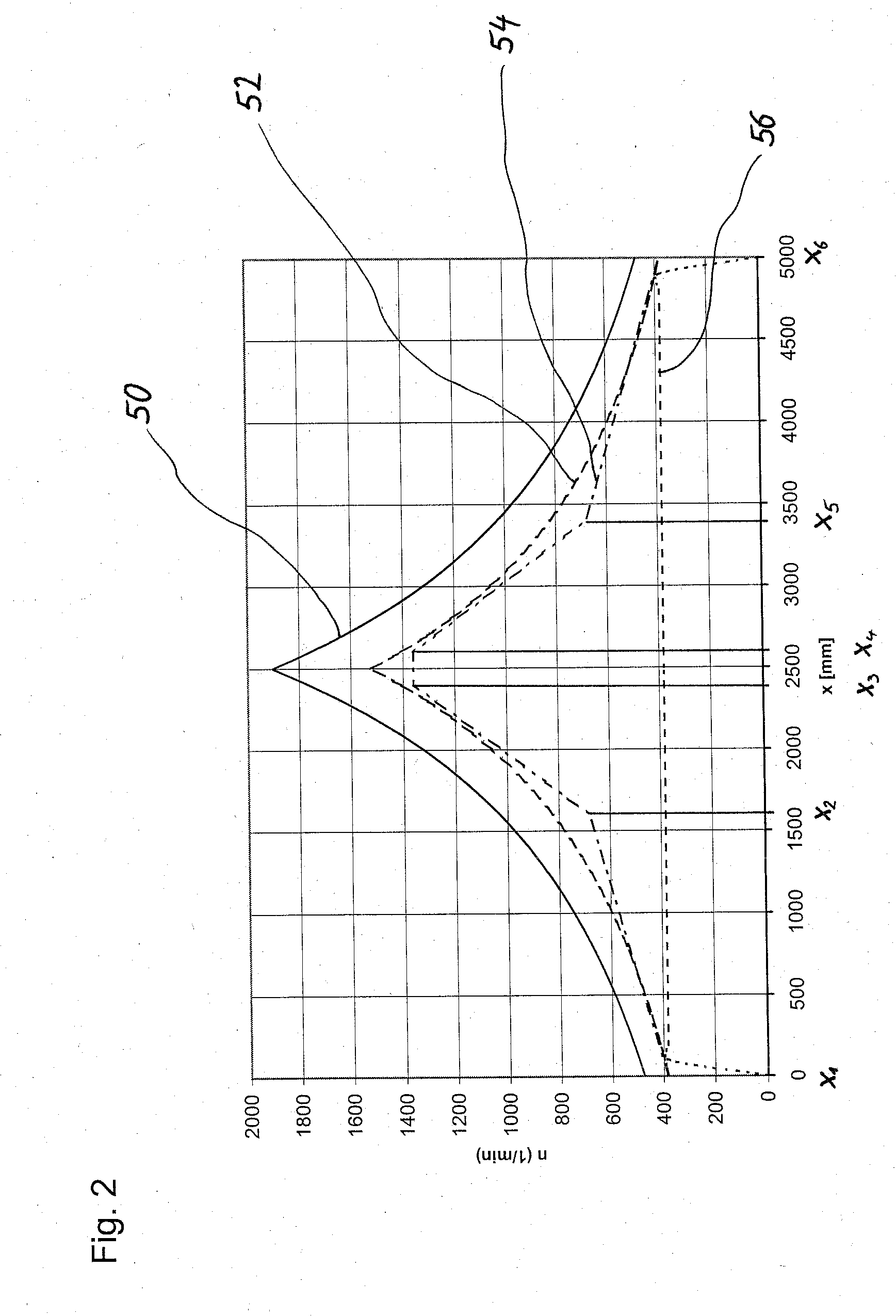

Fast-moving screw assembly

In a method for operating a screw assembly, having a spindle, which is rotatably supported on at least one end, and a nut, which is drivable by the spindle in a forward-feed direction, the nut being braced transversely to the forward-feed direction on a primary subassembly, and the spindle rpm is selected as a function of the position of the nut such that this rpm is just below a position-dependent limit rpm, in order to attain the shortest possible travel time.

Owner:BOSCH REXROTH MECHATRONICS

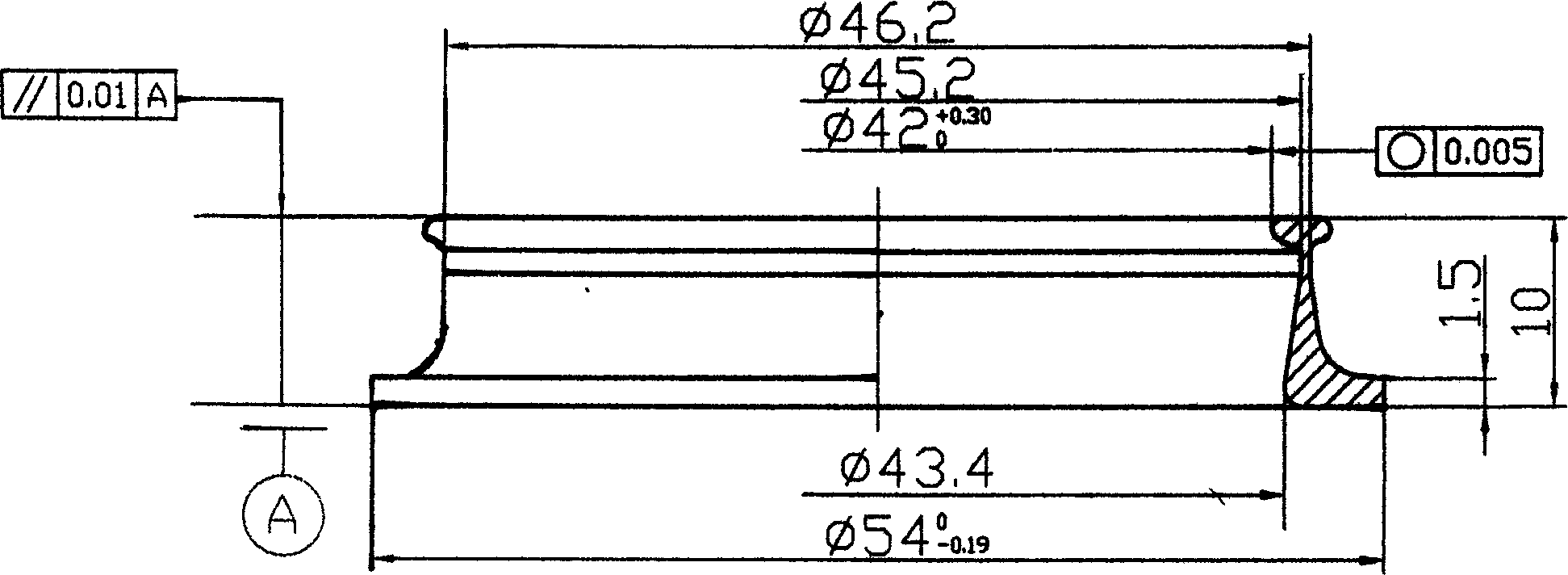

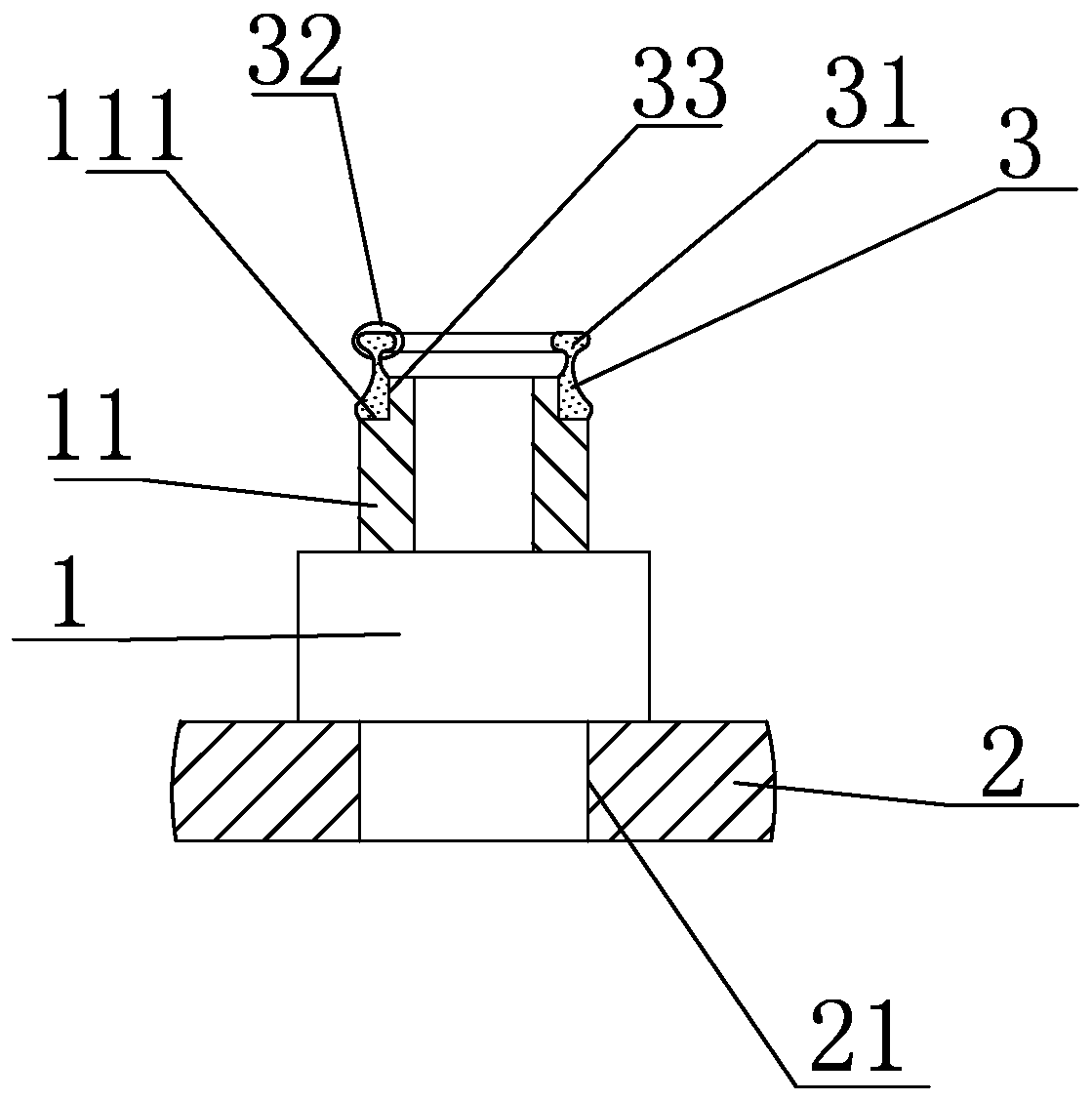

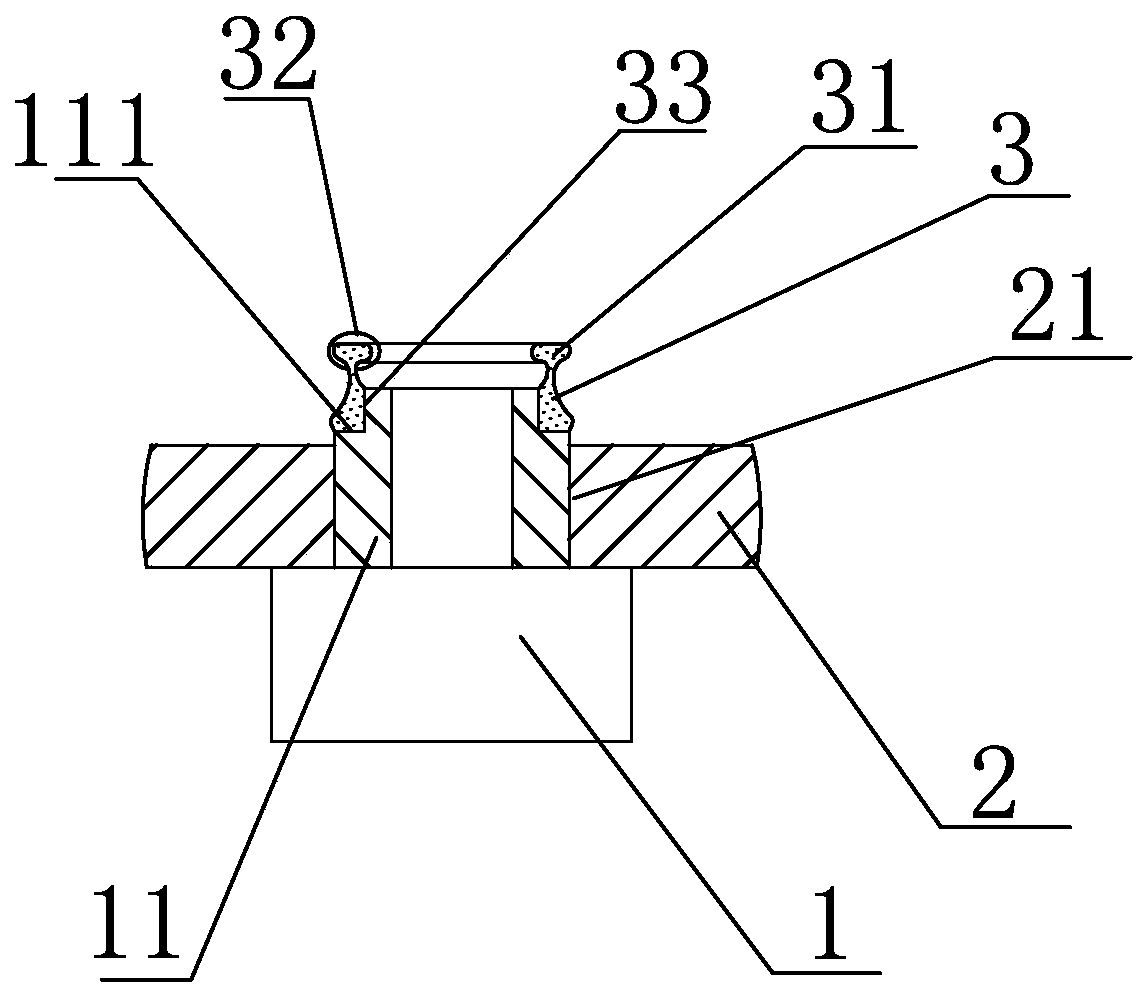

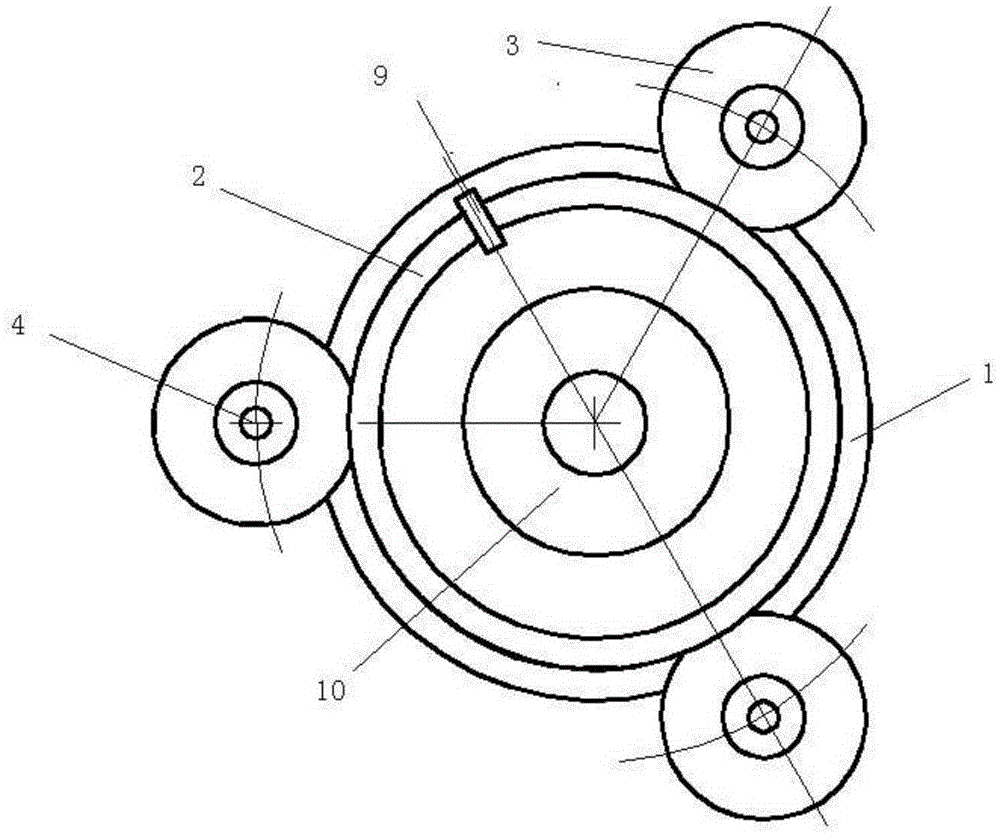

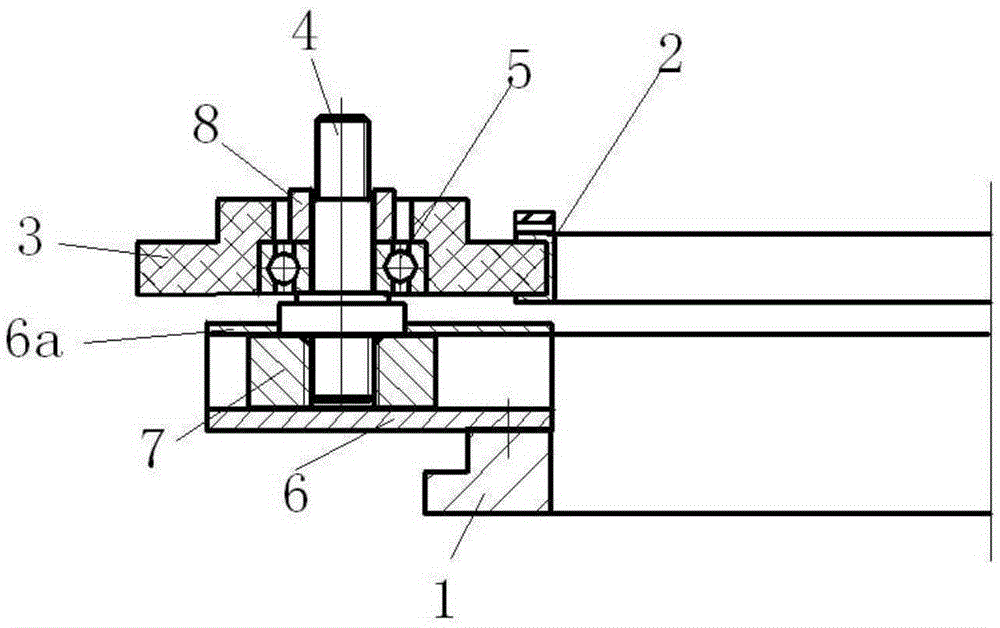

Steel collar for ring spinner or ring twister

ActiveCN103484997AExtended service lifeReduce labor costsTextiles and paperMetallurgyMaterials science

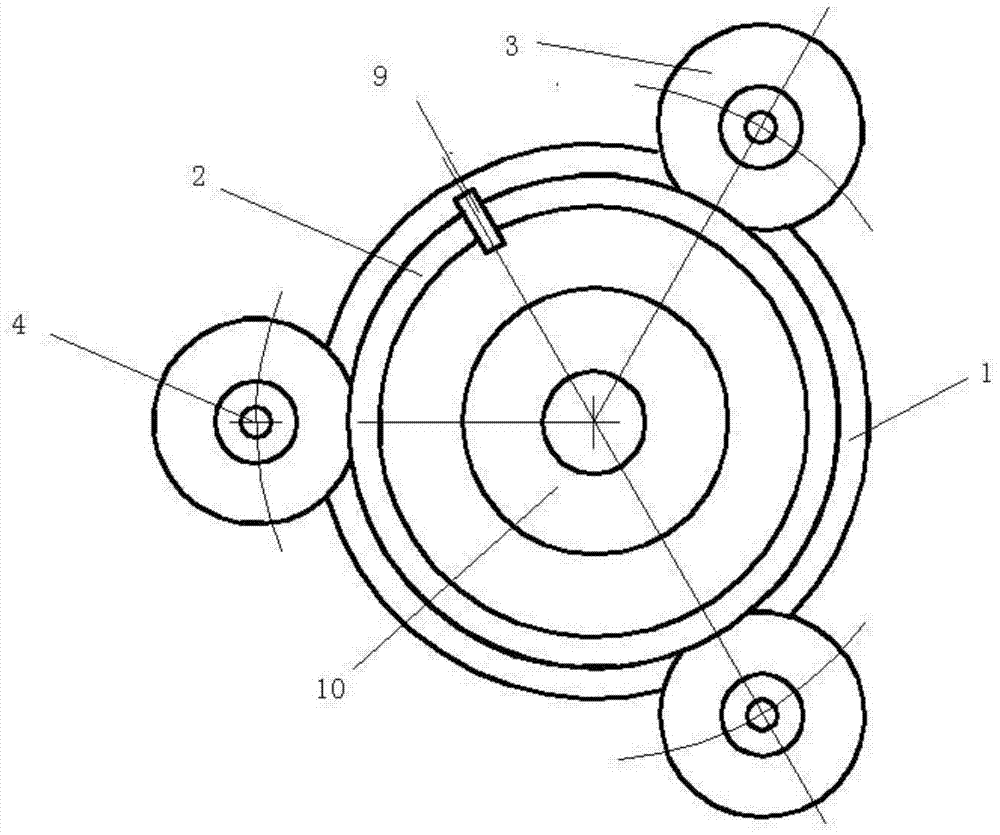

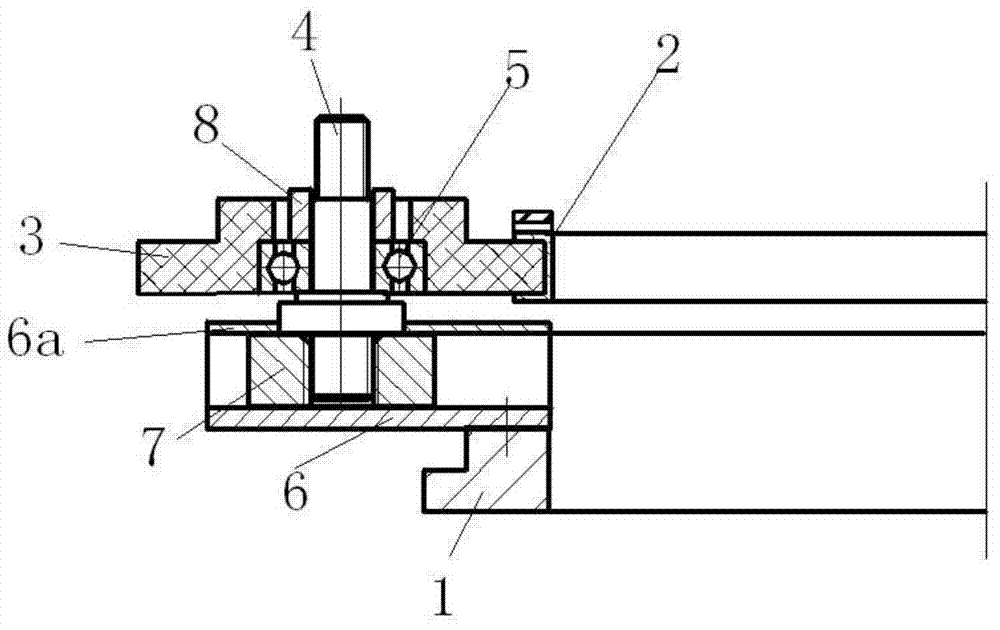

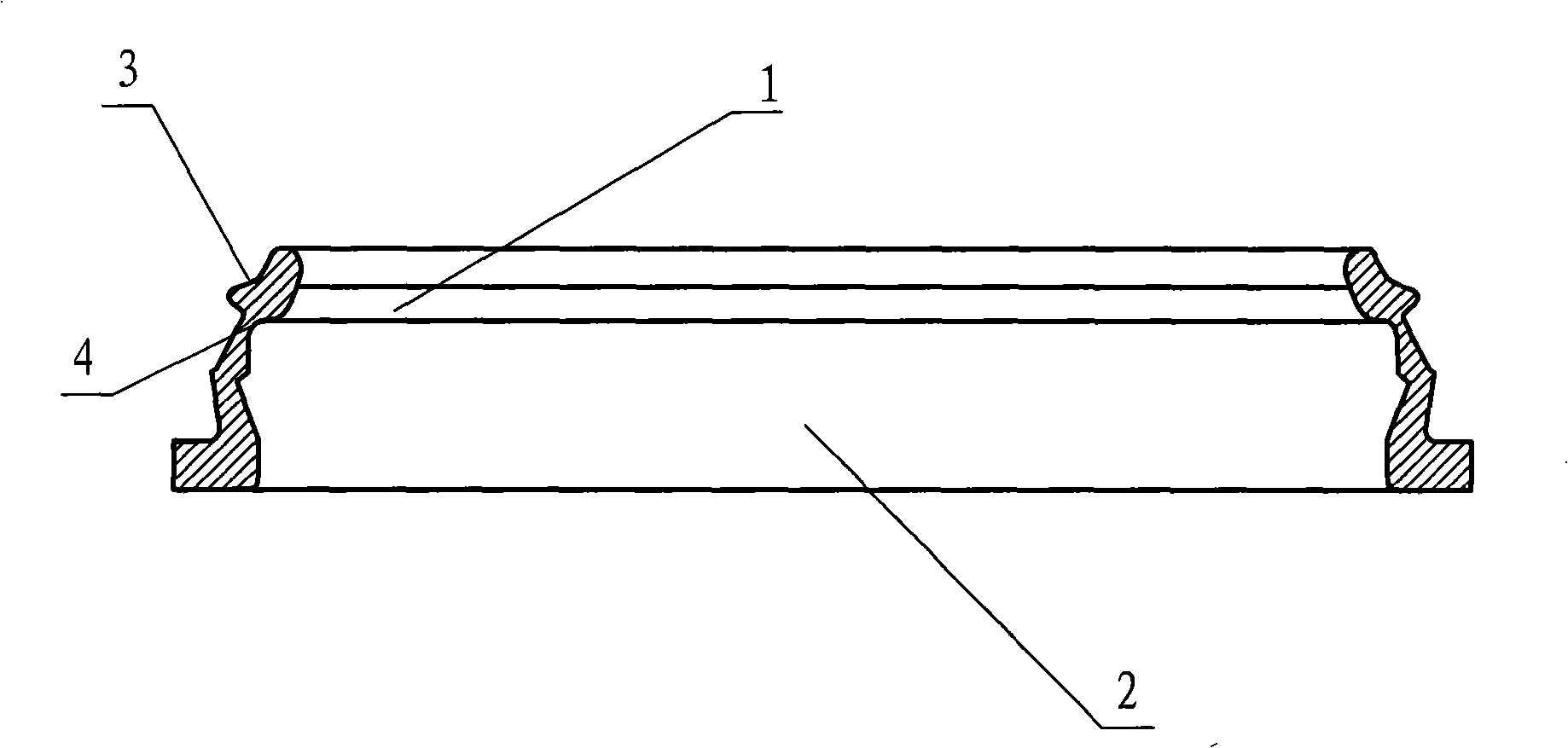

The invention discloses a steel collar for a ring spinner or a ring twister. The steel collar is characterized by comprising a steel collar fixing base (1), steel collar rotating rings (2), rotating wheels (3) and rotating wheel shafts (4). The steel collar fixing base (1) and the steel collar rotating rings (2) are ring-shaped. The outer diameter of the steel collar fixing base (1) is larger than that of the steel collar rotating rings (2). The steel collar fixing base (1) is evenly provided with at least three rotating wheel bases. The rotating wheel shafts (4) are installed on the rotating wheel bases. Each rotating wheel shaft (4) is movably sleeved with one rotating wheel (3). Center lines of the rotating wheels (3) are located on the same ring. The steel collar rotating rings (2) are installed on the rotating wheels (3) in an inserting mode after being connected in a butting mode, and can rotate relative to the rotating wheels (3). The rotating wheels (3) limit the steel collar rotating rings (2) in the radial direction. The service life of a bead ring and the steel collar is greatly prolonged.

Owner:CHONGQING JINMAO TEXTILE ACCESSORIES

High-precision double-hardness cotton spinning ring and preparing method and device thereof

InactiveCN101514504AShort processing timeImprove efficiencyIncreasing energy efficiencyTextiles and paperQuenchingLubrication

The present invention provides a high-precision double-hardness cotton spinning ring and a manufacturing method and a device thereof. The high-carbon alloy steel is sequentially processed to ring blanks through baiting processing. The ring blanks are processed to ring substrates through rough turning and finish turning. Then heating, quenching and tempering are executed. Finally polishing is executed for obtaining the ring of which the hardness of upper part of ring is different from the hardness of lower part of ring. A heating induction furnace is adopted for executing rotation heating to the upper part of ring substrate requiring heating. A home-made quenching machine which comprises a heating device, a quenching device, a pushing mechanism and a control circuit is adopted for quenching the ring substrate, and the quenching time is not shorter than 1 second. Not only can the precision of cotton spinning ring be remarkably increased, but also the high-hardness wearing resistant lubrication requirement on the surface of cotton spinning ring is satisfied. The manufacturing method has the advantages of simple technique, easy operation, remarkably reduced manufacturing cost and prolonged service lifetime of cotton spinning ring.

Owner:李小平

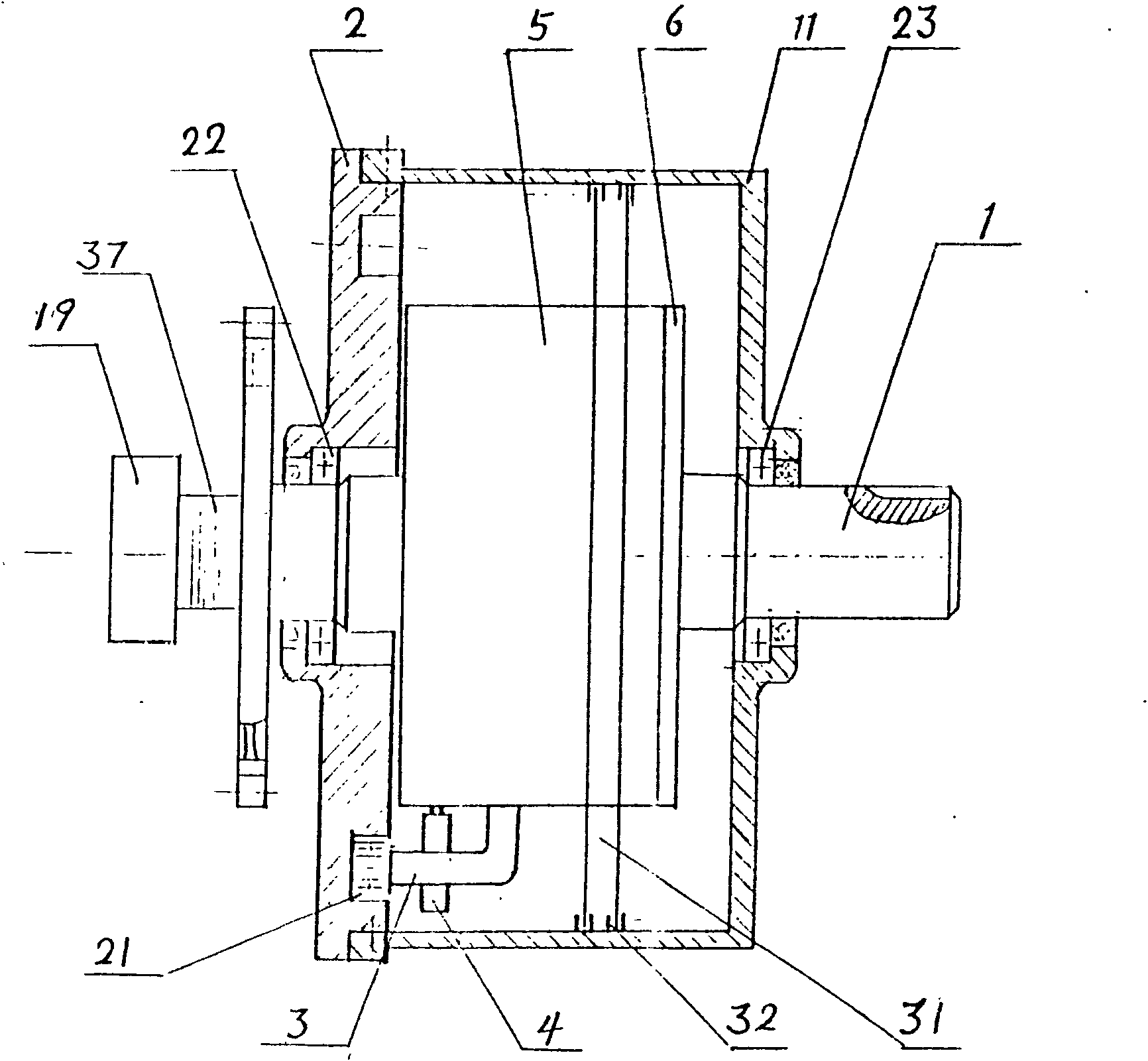

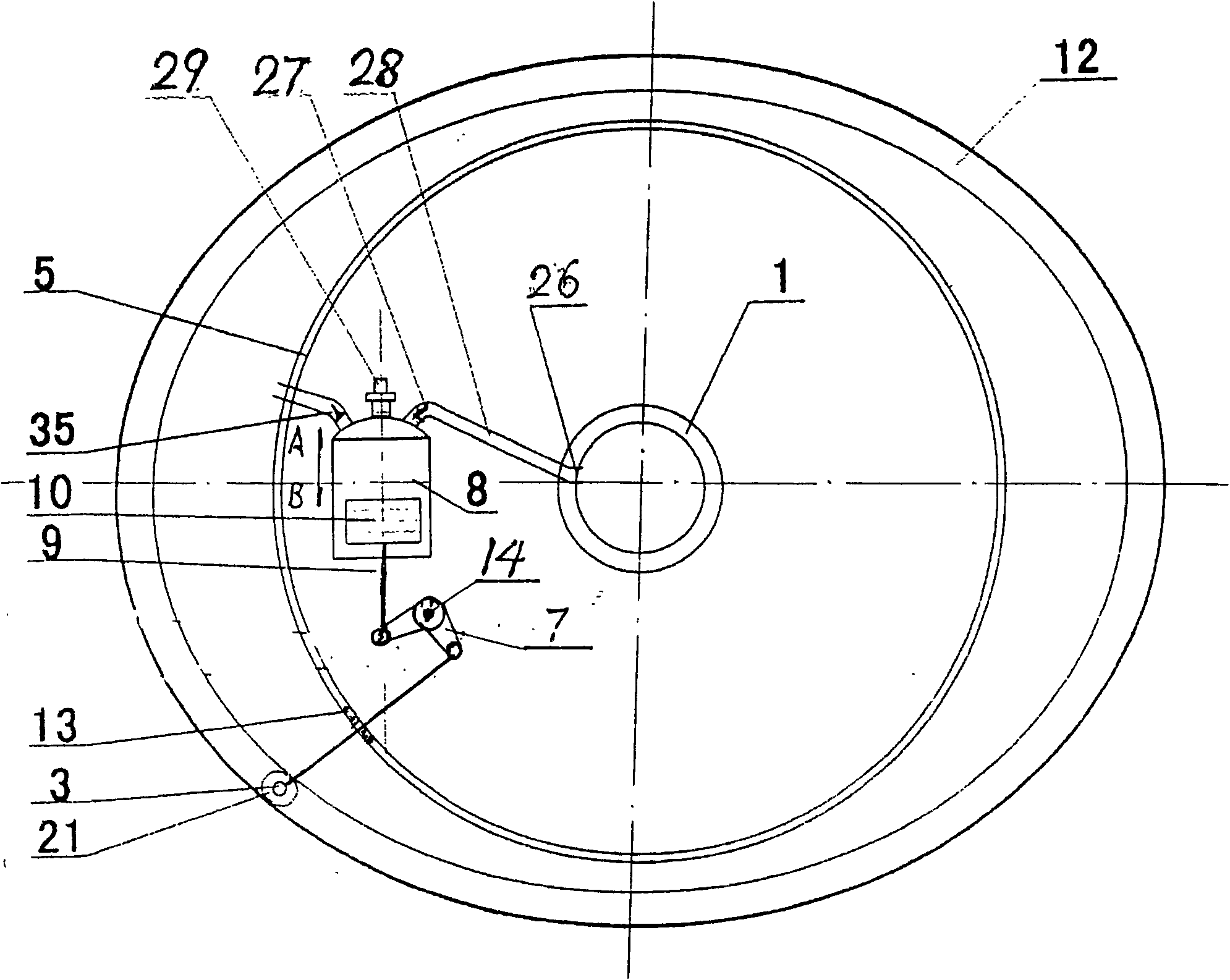

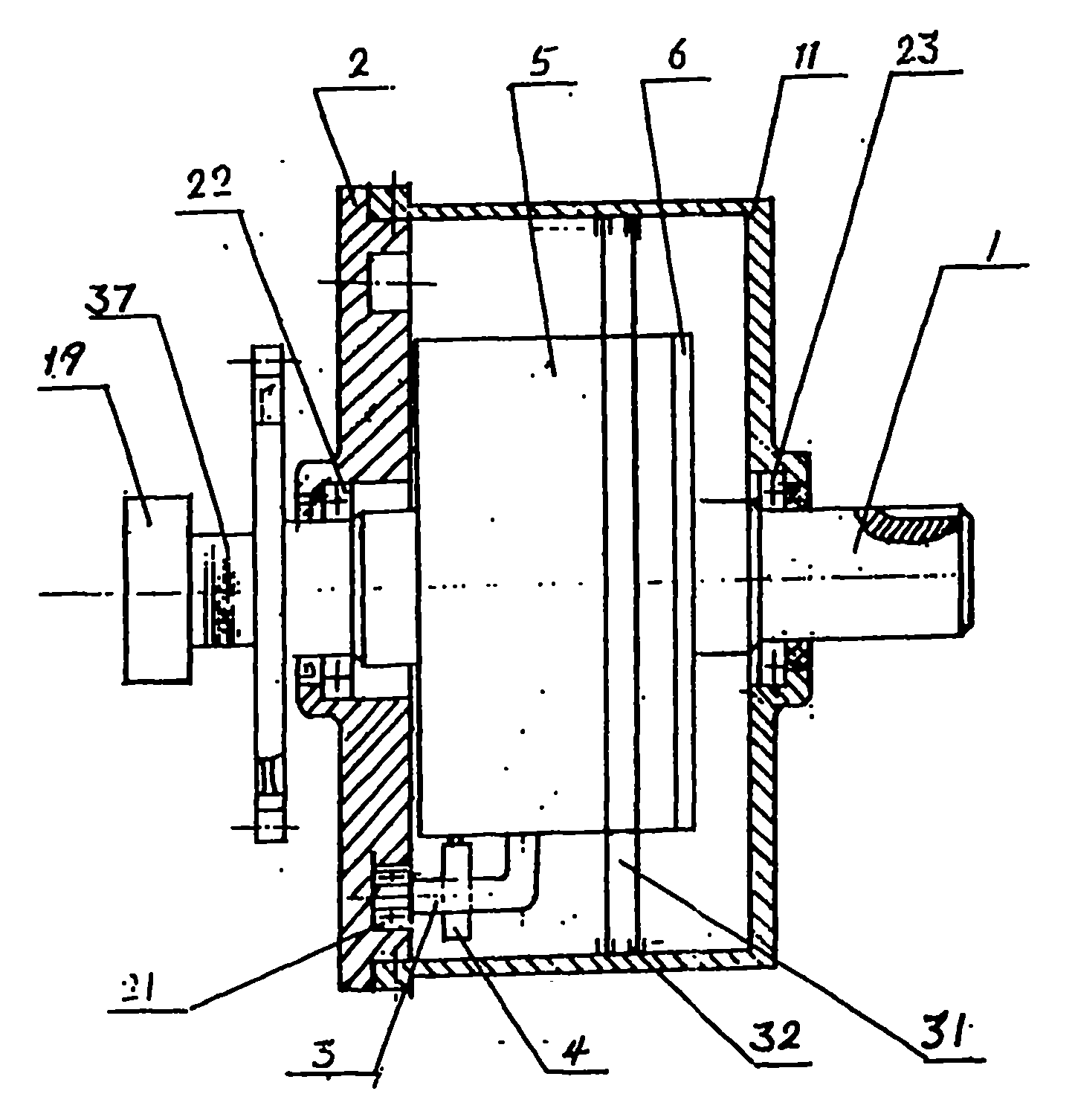

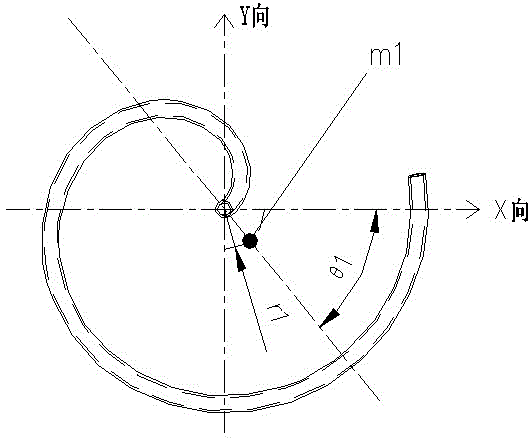

Transmission mechanism and rotary engine thereof

InactiveCN102032043AGet rid of bulkyRemove complexityInternal combustion piston enginesCylinder headsRotary engineGasoline

The invention relates to a single-row reciprocating piston type rotor engine, belonging to the field of power generating machines. The engine comprises a main shaft (1), an elliptic orbit groove disc body (2), a transmission connecting rod (3), a positioning U-shaped fork (4), a cylindrical rotary cylinder body (5), a rotary cylinder body end cover (6), a turning lever (7), a turning lever shaft (14), a traditional single cylinder engine nose (8), a piston connecting rod (9), a piston (10), a cylindrical enclosure (11) and the like, wherein the lower end of the transmission connecting rod (3) is provided with a bearing (21) inserted into an elliptic orbit groove (12); a horizontal elbow of the transmission connecting rod (3) passes through the tube wall of the cylindrical rotary cylinder body (5); a perforation is sealed by using a shaft seal (13); the horizontal elbow is connected with one end of the turning lever (7) by using the bearing; the piston connecting rod (9) is connected with the other end of the turning lever (7) also by using the bearing; the turning lever shaft (14) is fixed on the bottom of the rotary cylinder body (5) and is in positioning connection with the turning lever (7) by using the bearing. The invention has the advantages of simple and compact structure, few components, light weight, small volume, high efficiency, energy saving, convenience of maintenance and long service life and not only can be made into a gasoline engine but also can be made into a diesel engine.

Owner:SHANGHAI MOSES MARINE ENG

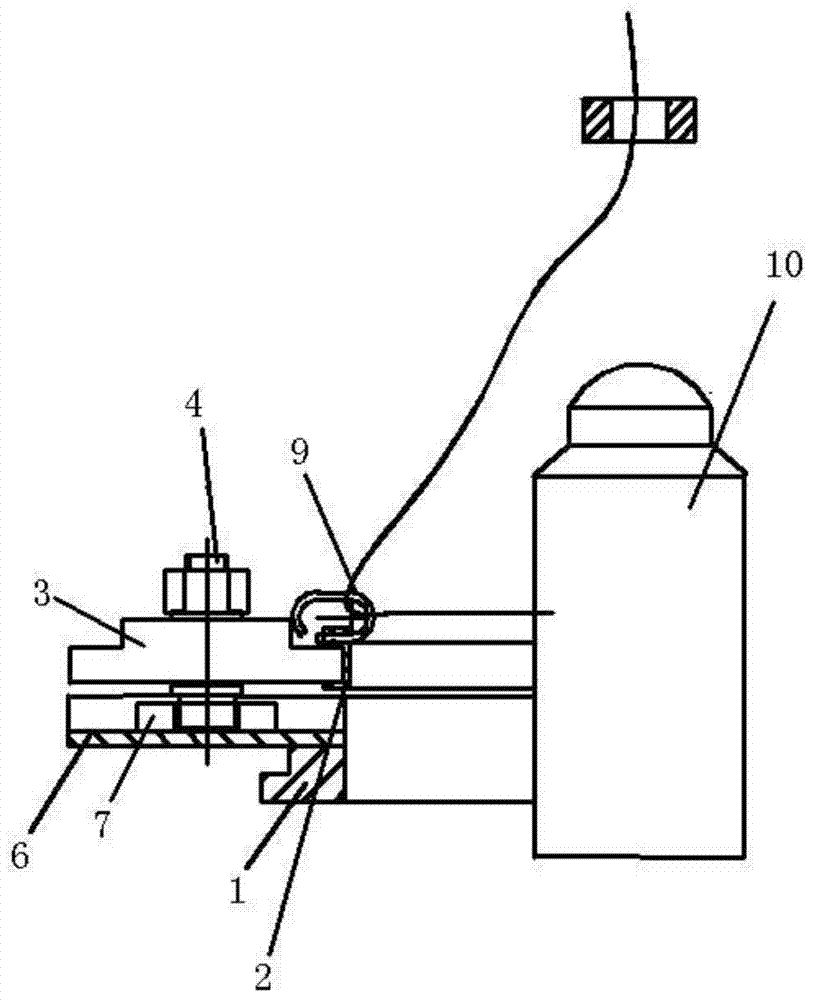

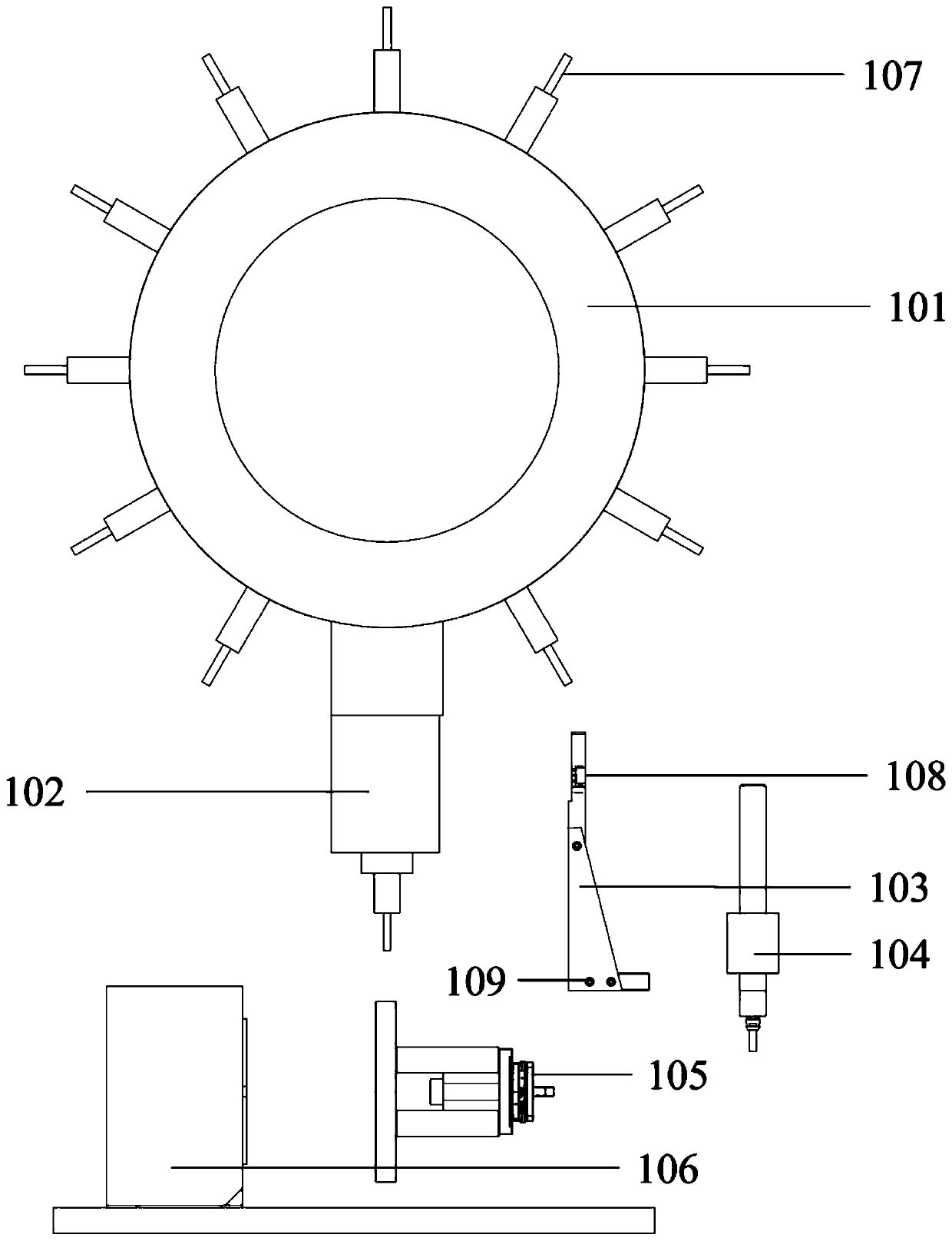

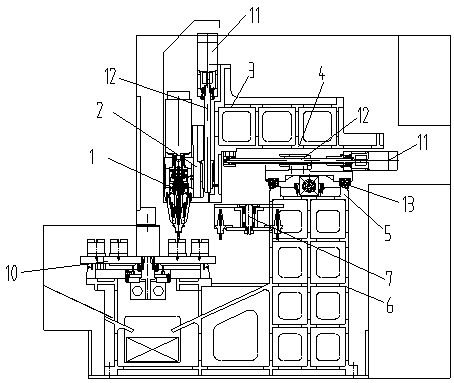

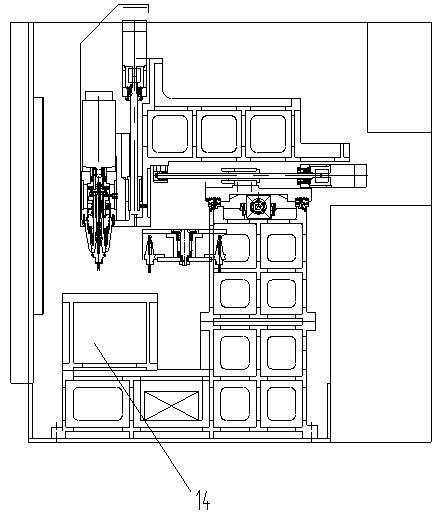

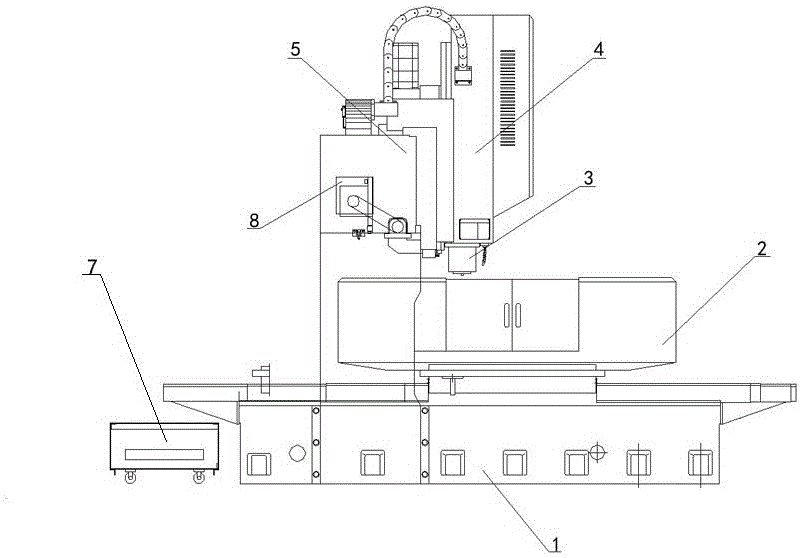

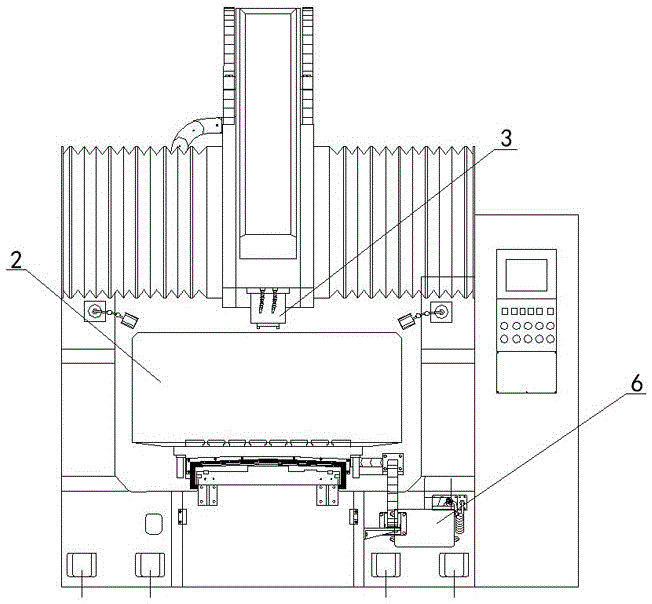

Common metal CNC machine additionally provided with high-speed spindle and application method thereof

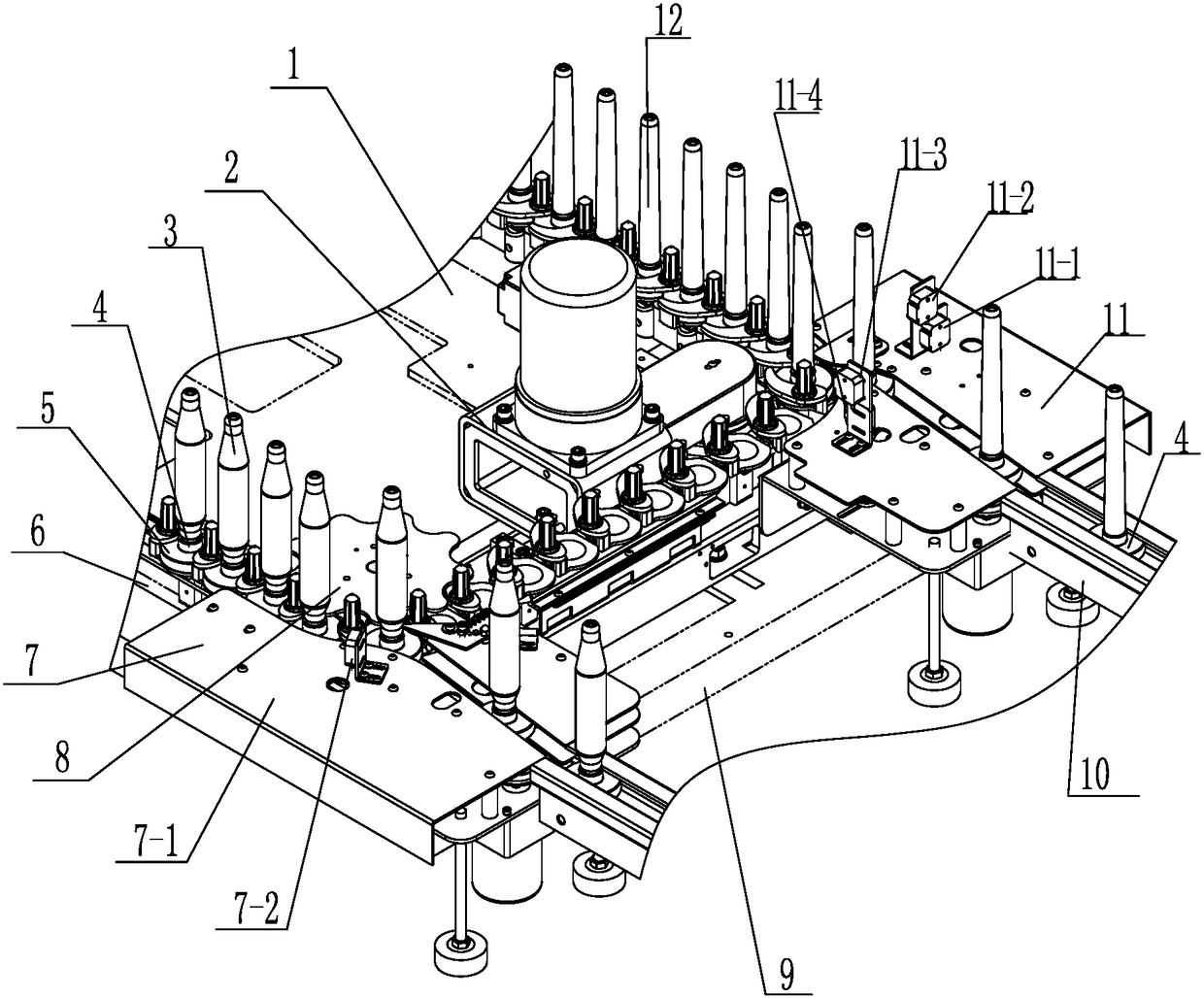

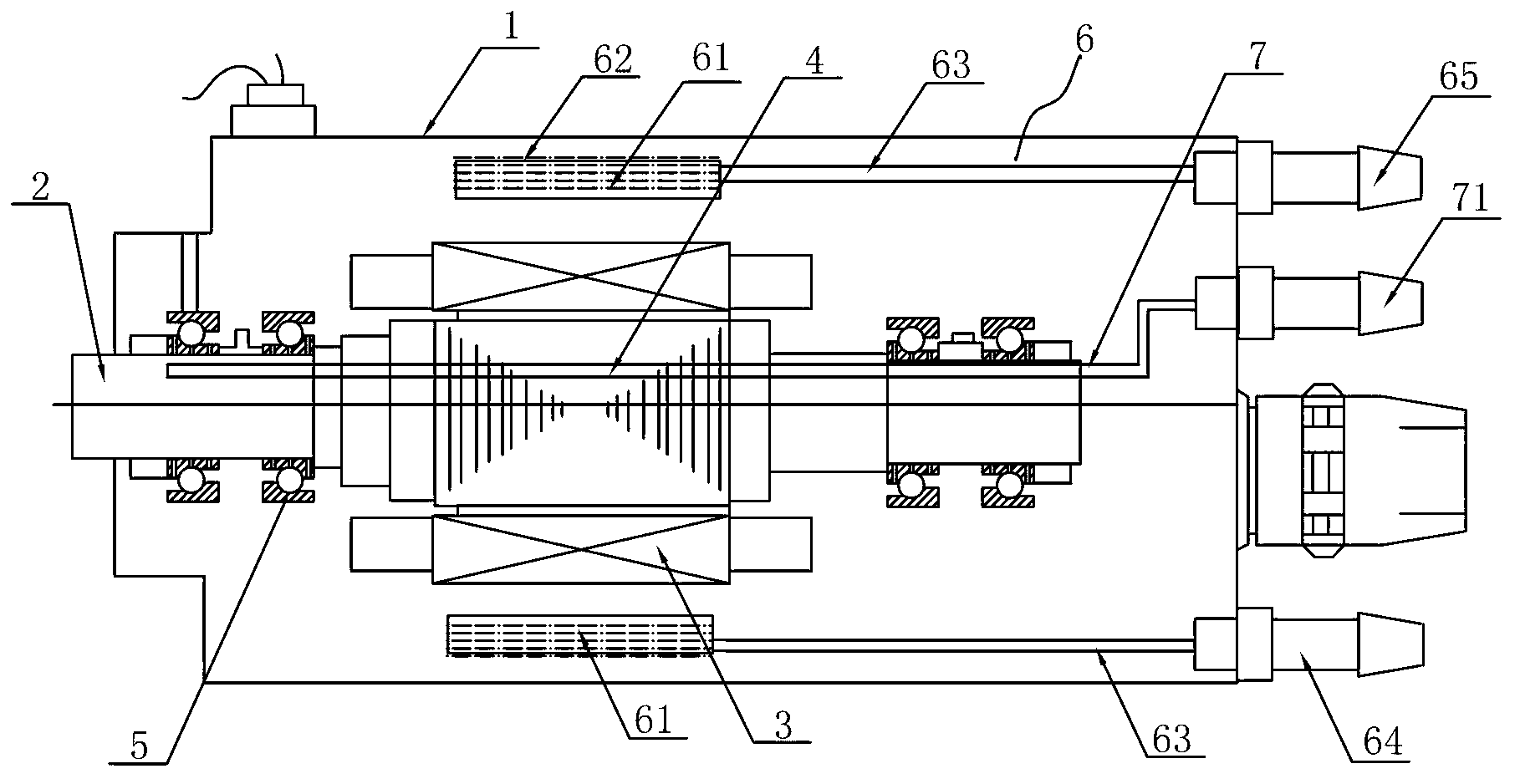

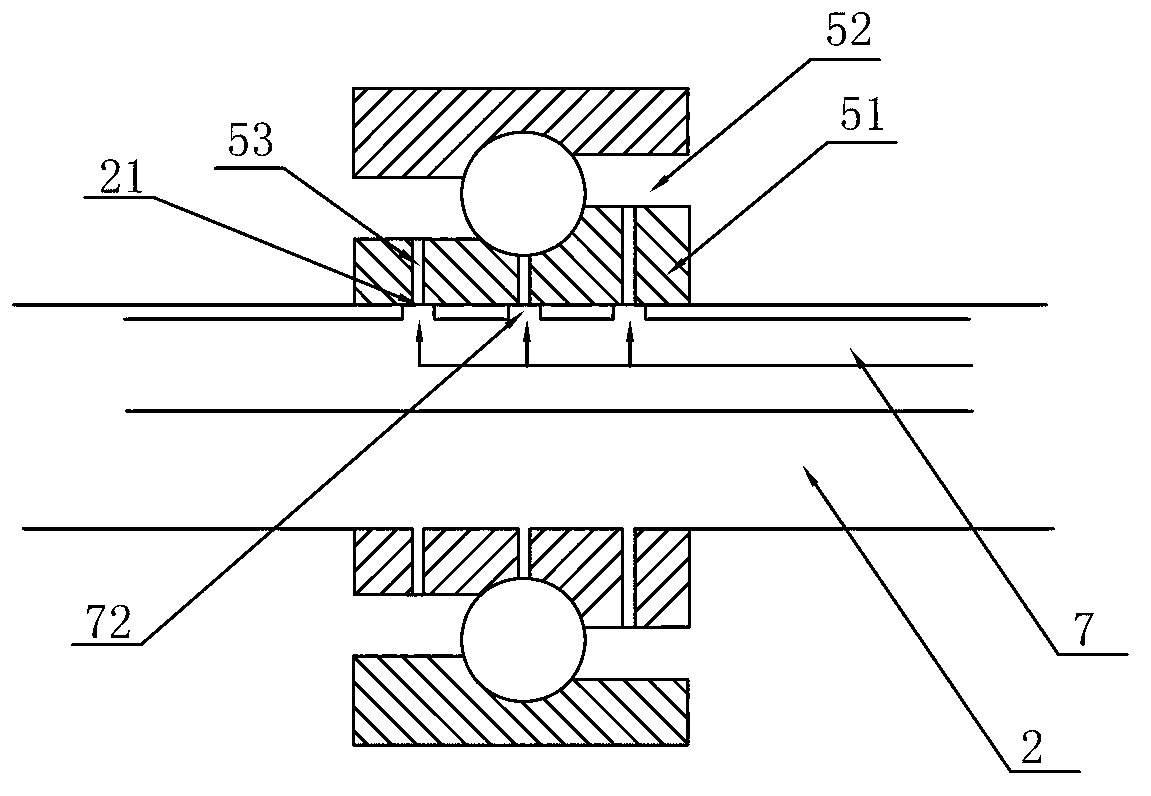

PendingCN109732106AIncrease the spindle speedImprove processing efficiencyLarge fixed membersPositioning apparatusEngineeringMechanical engineering

The invention relates to the technical field of CNC processing and discloses a common metal CNC machine additionally provided with a high-speed spindle and an application method thereof. The common metal CNC machine additionally provided with the high-speed spindle comprises a four-shaft workbench, a fixture, an original spindle and a tool magazine which are arranged on a machine base. The four-shaft workbench is located below the original spindle. The fixture is mounted on the four-shaft workbench. The tool magazine is located above the original spindle. The tool magazine is used for clampingand carrying a plurality of different sizes of cutting tools. The original spindle is provided with a high-speed spindle fixing bracket. The high-speed spindle fixing bracket is provided with the high-speed spindle. The fixture is used for clamping and fixing a workpiece to be processed. The high-speed spindle grabs and clamps the corresponding cutting tool from the tool magazine to implement processing on the workpiece. The four-shaft workbench drives the fixture clamping the workpiece to do four-shaft motion relative to the high-speed spindle. The effects that an existing common metal CNC machine is used for processing plastic outer parts or plastic-metal combined parts and improves the processing yield are achieved. The common metal CNC machine additionally provided with the high-speedspindle has the advantages of high processing efficiency and low invested cost.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

Spindle condition detection device for machine tool

ActiveUS10286514B2Reduced service lifeImprove accuracyProgramme controlPlug gaugesPresent momentMachine tool

A spindle condition detection device for a machine tool includes: bearing load detecting means for detecting a load on a bearing that rotatably supports a spindle of a machine tool; and present usage ratio calculating means for calculating, based on the load detected by the bearing load detecting means, a present usage ratio that is a ratio of usage of the bearing with respect to a prescribed operating life of the bearing, which is achieved over a period until a present moment.

Owner:JTEKT CORP

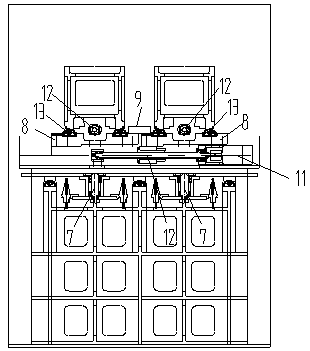

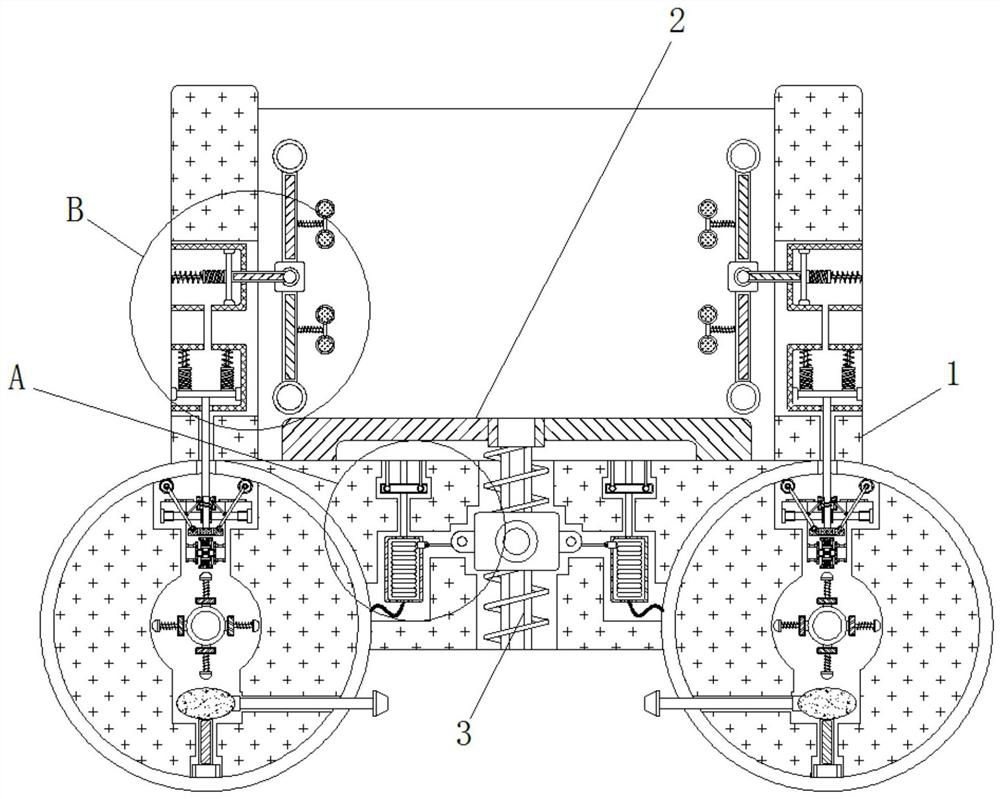

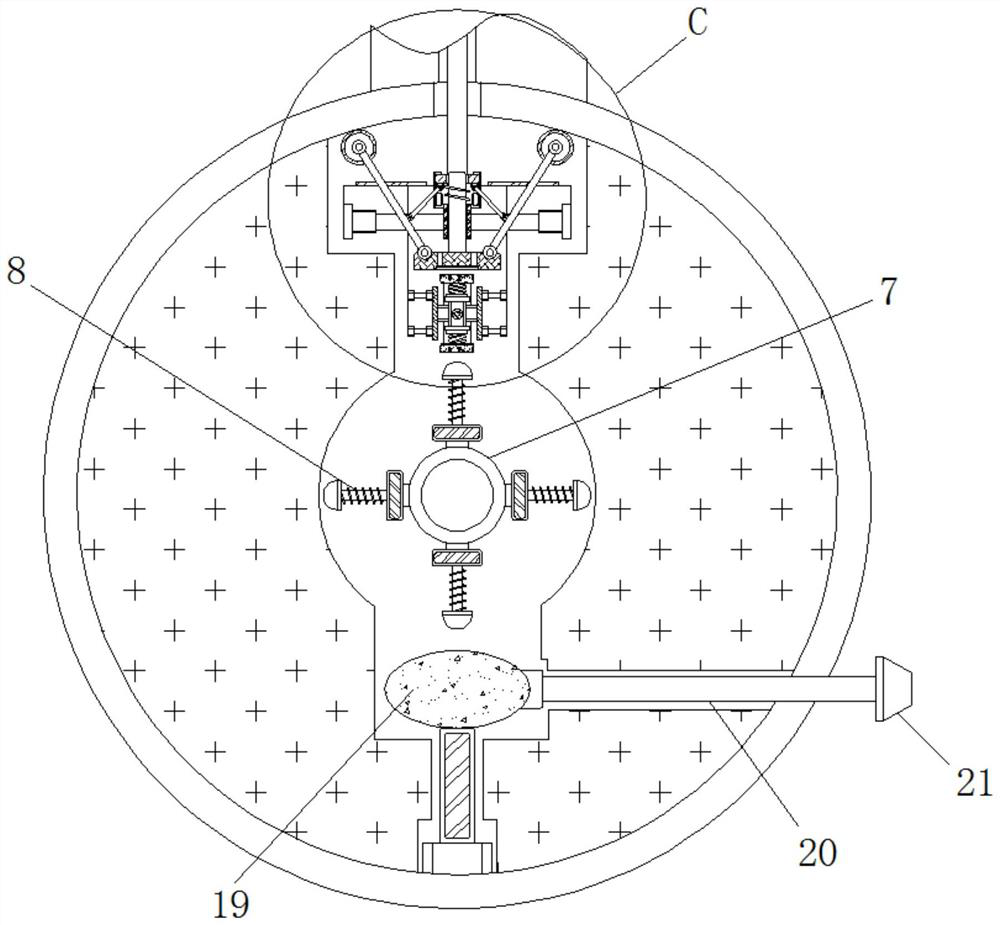

Multi-main-shaft vertical machining center

PendingCN108620958AConducive to the narrowing of the parallel spacingReduce vibration mutual interferenceMetal working apparatusNumerical controlEngineering

The invention discloses a multi-main-shaft vertical machining center. The center is mainly composed of a plurality of sets of main shaft units, X-direction numerical control sliding tables, Y-direction numerical control sliding tables, Z-direction numerical control sliding tables, rotary tool changers and a set of machine body. According to the machining center, multi-main-shaft synchronous tool changing can be carried out at the same time, and independent compensation can be independently carried out on the length of the tool on each main shaft; and the multi-main-shaft vertical machining center is simple in structure and convenient to maintain, and is ideal drilling and milling comprehensive machining equipment.

Owner:林志贺

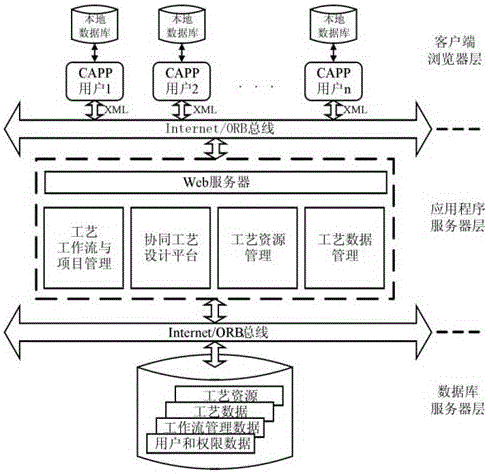

Small-sized CNC numerical control machine tool with network-based manufacturing function

InactiveCN106271685AEasy to operateLow costProgramme controlComputer controlNumerical controlControl system

The invention relates to a small-sized CNC numerical control machine tool with a network-based manufacturing function. The small-sized CNC numerical control machine tool comprises a base mechanism, a sliding seat mechanism, a working table mechanism, a main shaft mechanism, a main shaft box mechanism, a vertical column mechanism, a main motor mechanism, a lubricating system, a cooling system, a pneumatic system and a programmable CNC control system, wherein the working table mechanism comprises a working tabletop; a clamp is mounted on the working tabletop; the vertical column mechanism is perpendicularly fixed on the base mechanism; the main shaft box mechanism is assembled at the front part of the vertical column mechanism through a Z-directional guide rail; the main shaft mechanism is fixed on the assembling surface of the main shaft box mechanism through a screw; the X and Y directional motions of the working table mechanism and the Z directional motion of the main shaft box mechanism can be controlled through the programmable CNC control system. The machine tool disclosed by the invention overcomes the shortcomings that the existing numerical control machine tool is large in size, inconvenient to operate and high in cost, only has the motions in two coordinate axis directions, is complicated in operation and the like, has the advantages of high main shaft rotating speed, high feeding rate, function compounding and the like, and can complete all machining procedures of complicated parts and realize control intelligence.

Owner:LUOYANG INST OF SCI & TECH

Intelligently manufactured sofa capable of automatically massaging based on self pressure

InactiveCN112806765AIncrease the spindle speedLower resistanceChiropractic devicesSofasMassageCushion

The invention provides an intelligently manufactured sofa capable of automatically massaging based on self pressure, and relates to the technical field of sofas. The intelligently manufactured sofa capable of automatically massaging based on self pressure comprises a machine body shell, a cushion is fixedly installed at the top of the machine body shell, a spring rod is fixedly connected to the interior of the machine body shell, a poker rod is rotatably connected to the periphery of the spring rod, a rheostat is slidably connected to the end, away from the spring rod, of the poker rod, and the bottom of the rheostat is fixedly connected with a wire. The spring rod is extruded, the poker rod changes the resistance value of the rheostat, a rotating shaft rotates, a U-shaped cover is driven to move through a telescopic rod, so that an air pressure plate changes the air pressure in a first air cylinder, an automatic massage effect is achieved through cooperative use of a push plate and massage balls, and through cooperative use of the telescopic rod and an air bag, the dust at the bottom of the sofa is cleaned, and the effect of automatically cleaning the dust is achieved.

Owner:兰道富

Method for fabricating flange ring

InactiveCN1563531AImprove machining accuracy and surface finishIncrease spindle speedTextiles and paperSteel tubePowder metallurgy

A processing method for a plane steel collar is carried out according to a tolerance decrement method including the following steps : applying seamless steel tube made of alloy steel to process blanks or applying powder smelt to press blanks, turning : processing in conventional hot process to the selected materials, no carbon penetration heat treatment formed by grinding eliminating the front several procedure accumulation tolerance to get the product after surface process which eliminates the accumulation tolerances of the last several procedures since applying formation procedure by grinding, the smoothness is not greater than 0.01mm roundness is less than 5 mum.

Owner:SHANYUAN PASHMINA GARMENT SHIJIAZHUANG

High precision cotton spinning ring using low hardness steel material as base body and its manufacture method

InactiveCN101187095ASimple processReduce manufacturing costTextiles and paperManufacturing cost reductionWear resistant

The invention relates to a high precision cotton spinning ring which uses low hardness steels as a base and process for preparation, wherein the steels whose rockwell hardness is equal or lesser than 65 is minutely processed into the ring base according to a needed shape of a ring, a high hardness wear resistant layer is coated on the ring base, the thickness D of the high hardness wear resistant layer is equal or greater than 1micron and is equal or lesser than 30 micron. The process for preparation is that the steels are orderly processed into ring blank through blanking, then the ring blank is processed into the ring base whose spherical degree is lower than 40 micron and smoothness is lower than 10 micron through rough turning and finish turning, and then a product is obtained through the surface hardening wear-resistant treatment of the ring base. The invention overcomes technology bias, both is capable of observably improving the precision of the cotton spinning ring, and meets the requirements of high hardness wear resistance lubrication of the surface of the cotton spinning ring. The process for preparation not only has simple process and very easiest operation, but also observably reduces the manufacturing cost, and prolongs the service life of the cotton spinning ring.

Owner:李祥德

Active rotating steel collar

PendingCN109763220AIncrease the diameterReduce the relative angular velocityTextiles and paperYarnAngular velocity

The invention relates to an active rotating steel collar. The steel collar is structurally characterized in that a hollow shaft motor is fixedly connected with a steel collar plate, a through hole isformed in the steel collar plate, a central shaft of a hollow rotating shaft of the hollow shaft motor penetrates the center of the through hole, the steel collar body is fixedly connected with the outer end of the hollow rotating shaft, a runway is arranged on the steel collar body, and a traveler is arranged on the runway. The steel collar has the advantages that the relative angular velocity ofthe traveler and the steel collar is reduced, the breakage rate is reduced by about 45%, and production efficiency is improved; the spindle speed can be increased by 50%, the front roller speed withthe same twist is also increased by 50%, and the single spindle output of a spinning frame is increased by 50% or higher; the diameter of the steel collar is increased, the cop capacity is increased,the doffing frequency is reduced, and the number of doffing workers is reduced; the service life of the traveler is greatly prolonged by 1-2 months, and labor intensity of the workers is reduced; when the variety of products is changed, all that is required is to change the rotating speed of the steel collar, the traveler is not needed to be changed, and the workload of knitters is reduced; yarndamage caused by heating of the traveler is reduced, and yarn quality is ensured.

Owner:江苏格罗瑞节能科技有限公司

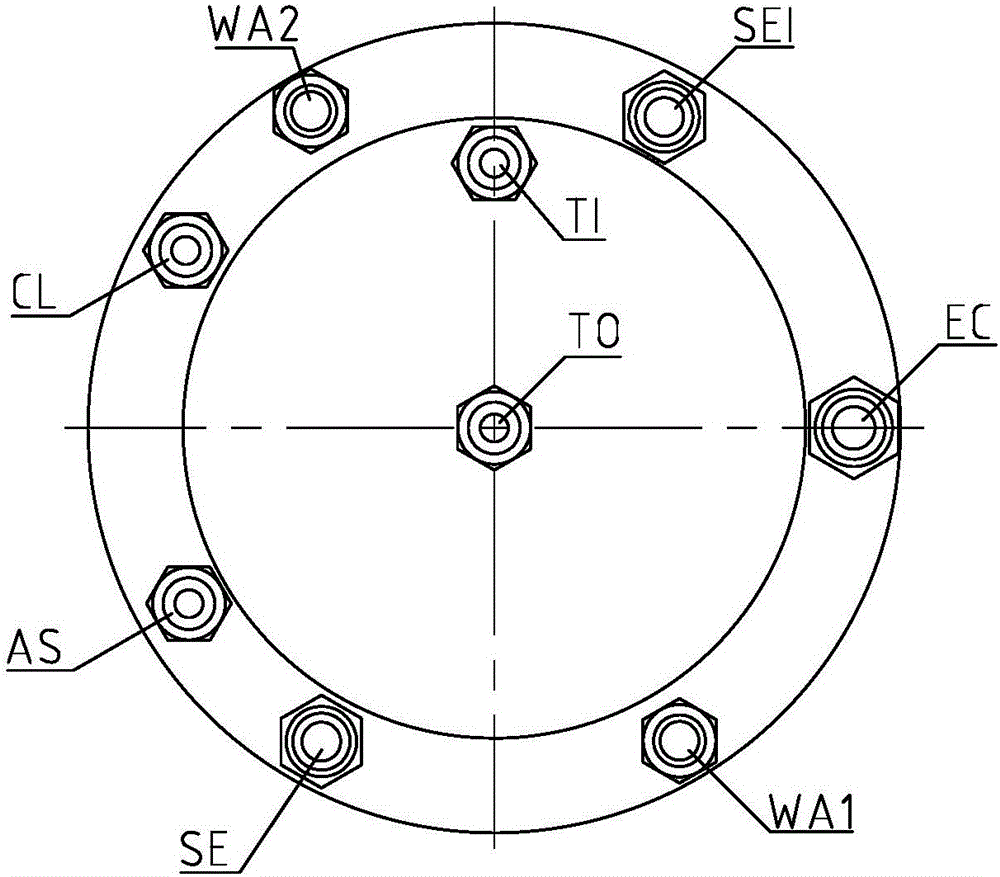

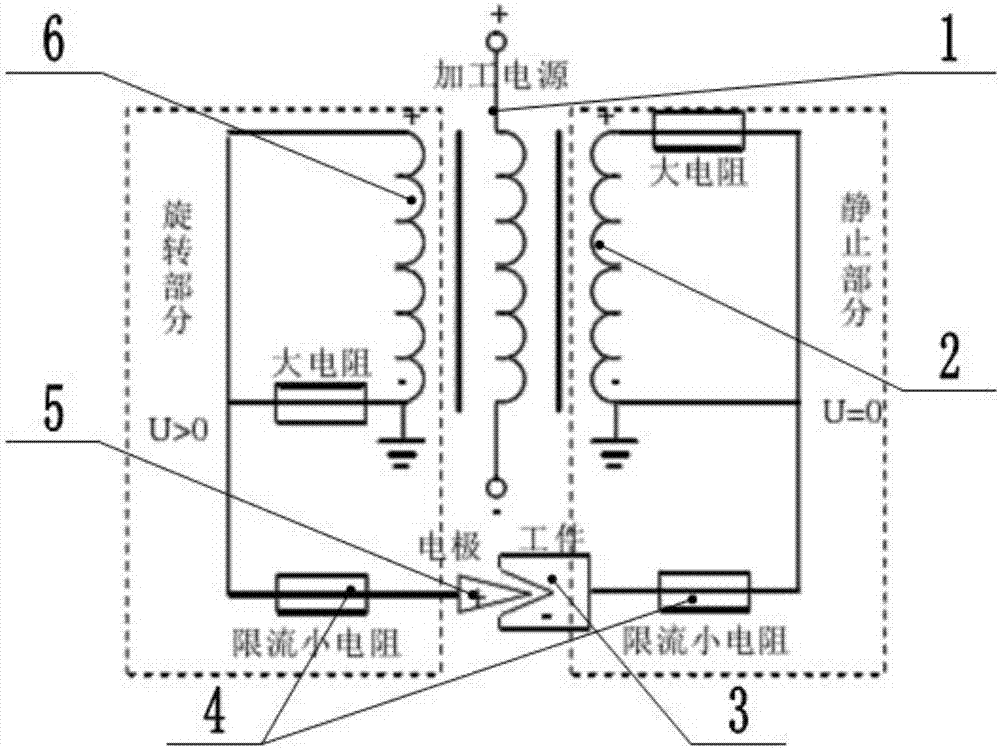

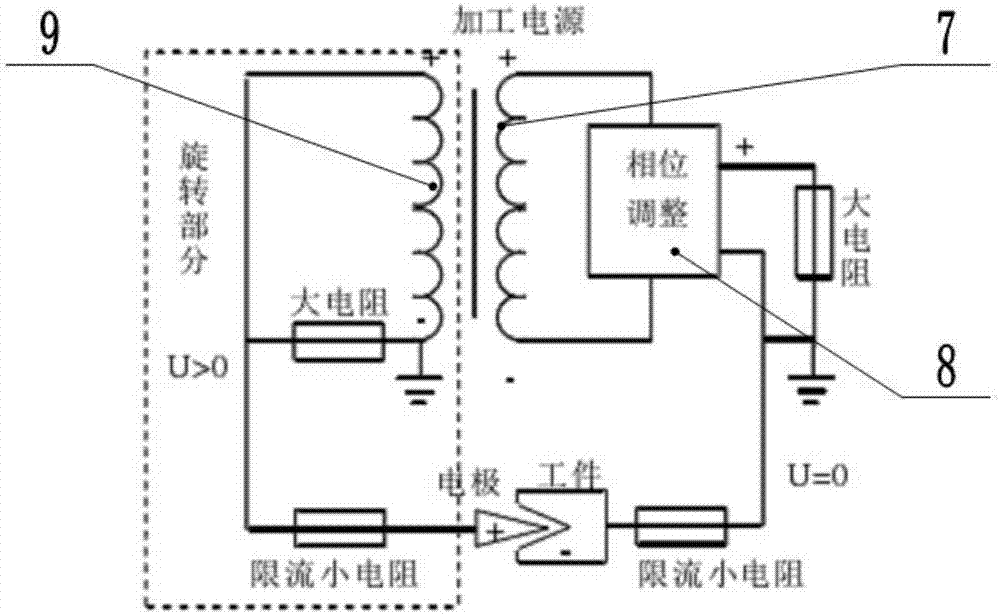

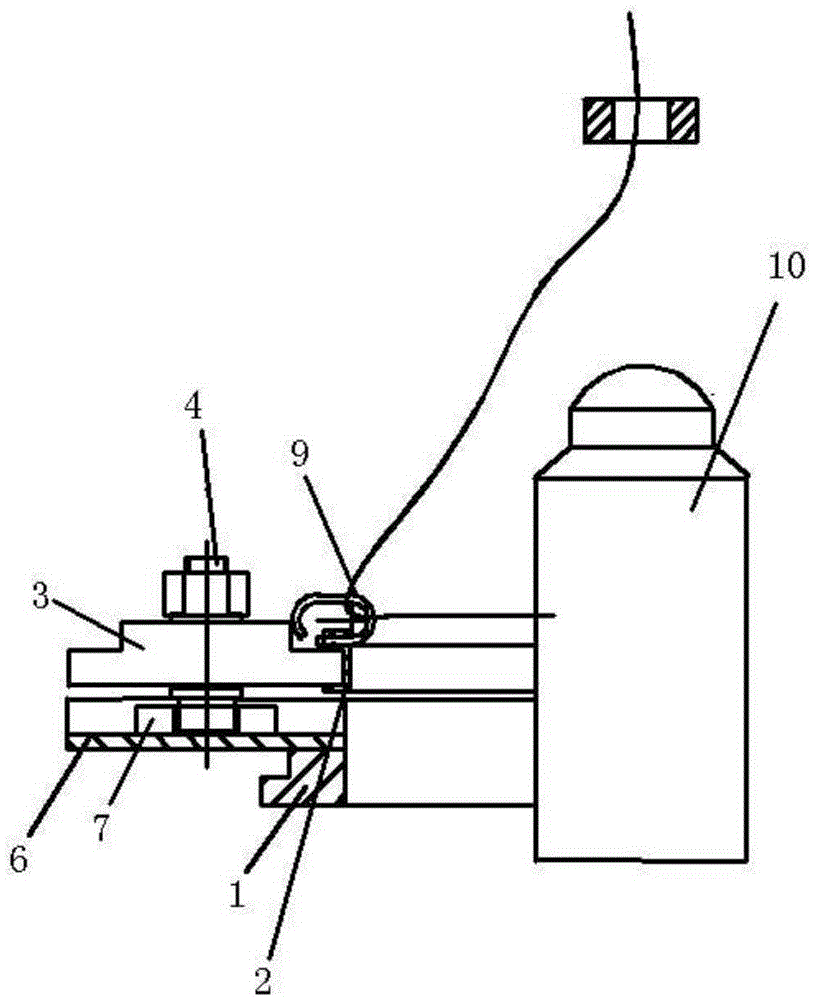

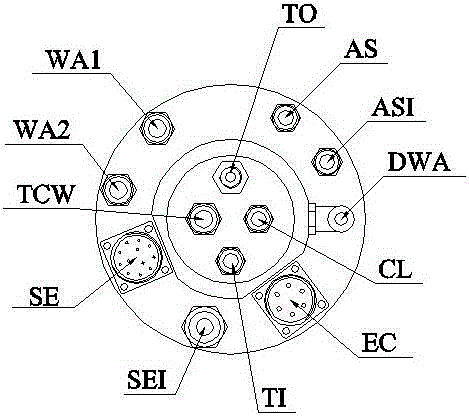

Non-contact electrical discharge machining system

ActiveCN107363350AImprove balanceSpeed up the flowElectric circuitsElectrical-based auxillary apparatusWireless transmissionMachining system

The invention relates to a non-contact electrical discharge machining system, comprising a non-contact electrical discharge machining electricity introduction system that is of inside-outside separate structure. Electricity is transferred to a tool electrode in wireless transmission manner; in this way, the structure can be compacted, good dynamic balance can be provided for a hilt, and high spindle speed can be achieved. In addition, high-speed rotation of a spindle can further accelerate flowing of an inter-electrode working fluid, discharge chips can be removed quickly, and fine electrical discharge machining efficiency is further improved. By increasing the spindle speed, it is possible to inhibit discharge concentration and abnormal arc discharge, pulse utilization rate can be increased, and machining speed is further increased.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Striking defoaming device for online conveying bottle bodies, and defoaming method thereof

ActiveCN107398097AAvoid damageImprove the effect of knocking and defoamingPlastic recyclingLiquid degasification by vibrationRubber ringStructural engineering

The invention discloses a striking defoaming device for online conveying bottle bodies, and a defoaming method thereof, belongs to the field of defoaming devices, and concretely provides a striking defoaming device for online conveying bottle bodies, capable of eliminating bubbles adhered to bottle walls and effectively improving the striking defoaming effect, and a defoaming method thereof. The striking defoaming device comprises a mounting seat, a striking mechanism and a driving mechanism; and the striking mechanism comprises a rotating shaft and a striking body, one end of the rotating shaft is mounted on the mounting seat, the striking body is mounted at the other end of the rotating shaft, the driving mechanism drives the rotating shaft to rotate, the locus of the striking body rotating with the rotating shaft interferes the bottle bodies conveyed by a conveying line, the striking body is an O-shaped rubber ring, and the plane of the O-shaped rubber ring is perpendicular to the axis of the rotating shaft. The O-shaped rubber ring adopted as the striking body can avoid damages to the bottle bodies, and also can effectively improve the striking defoaming effect of the striking on the bottle bodies.

Owner:CHENGDU HONGRUI TECH

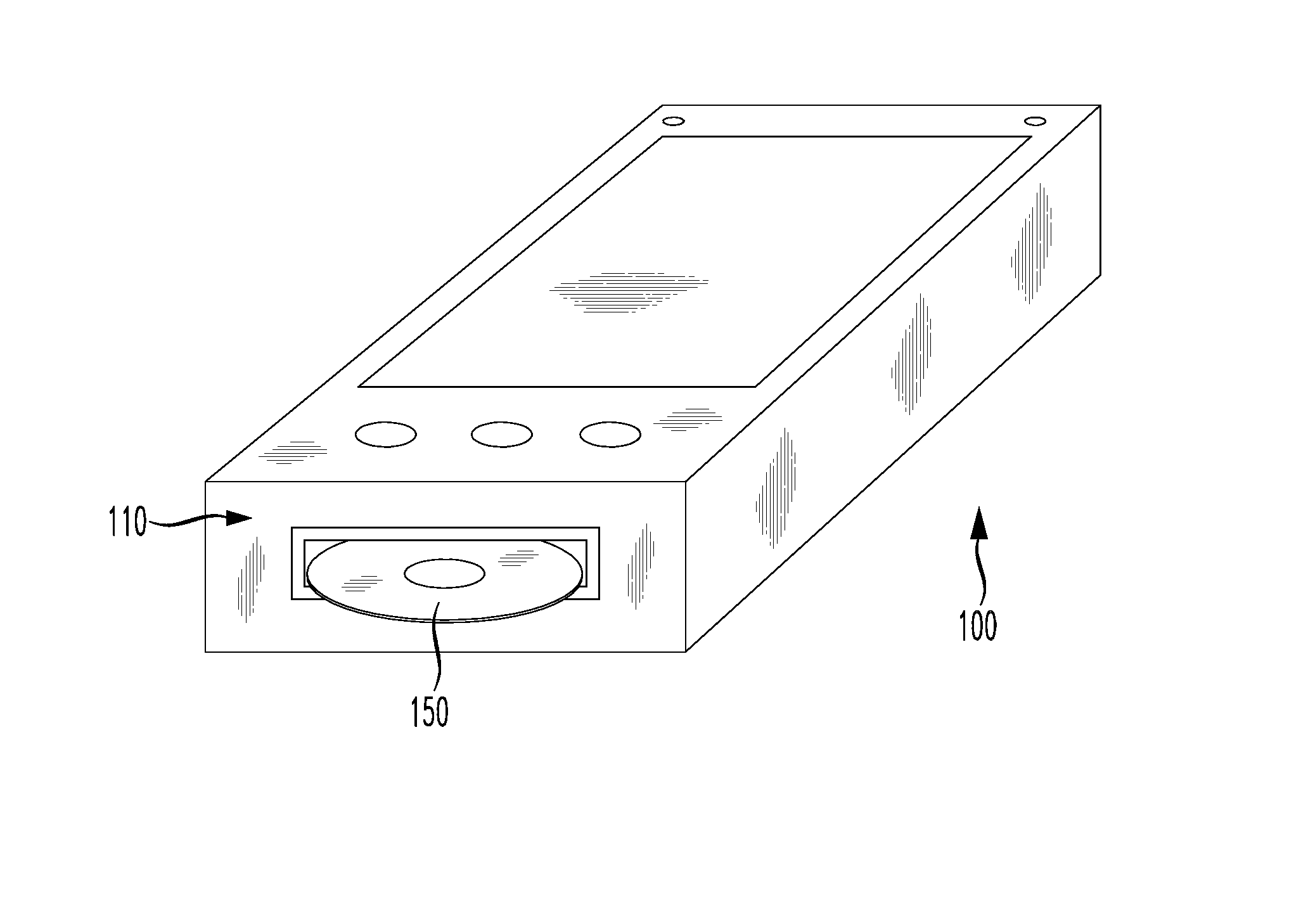

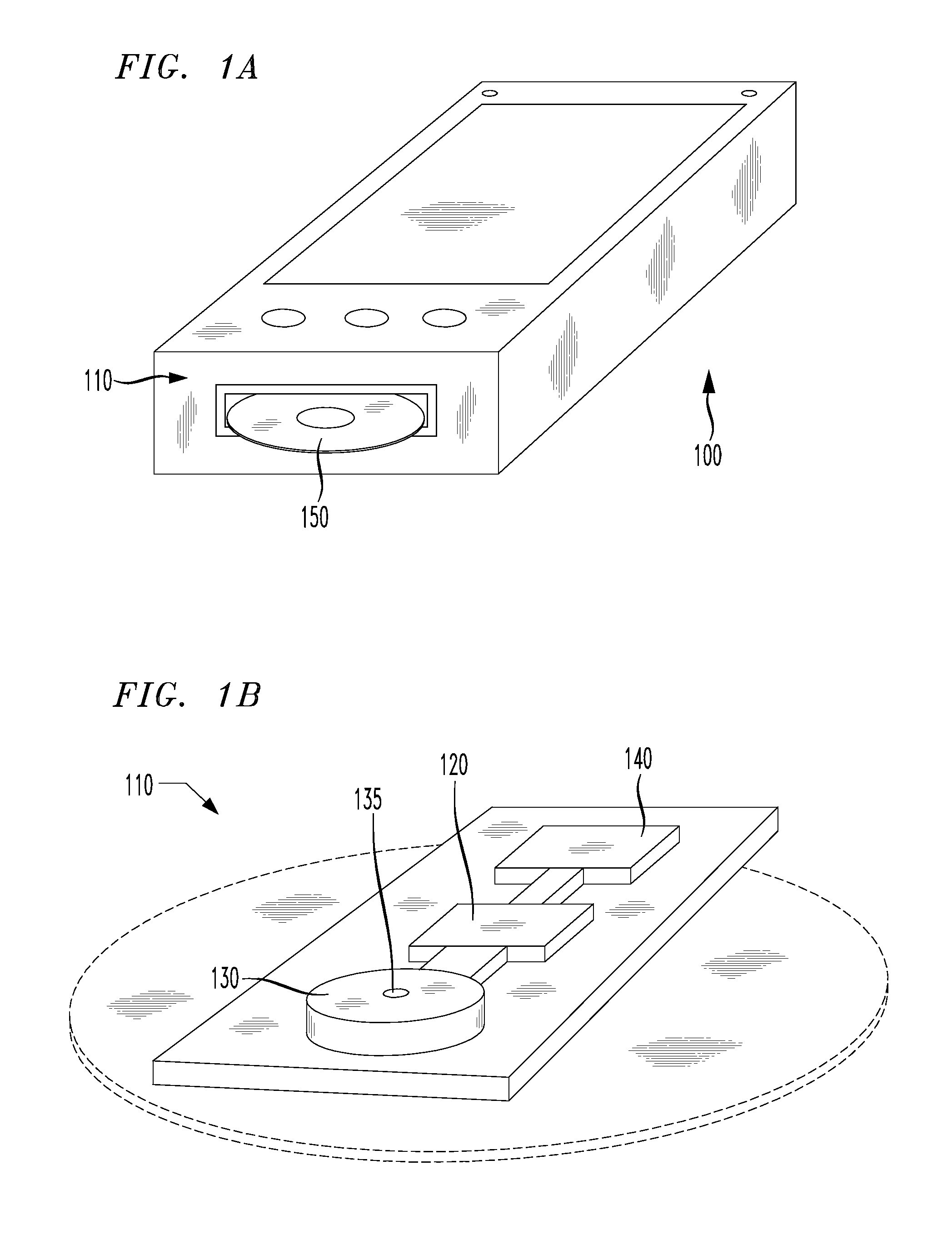

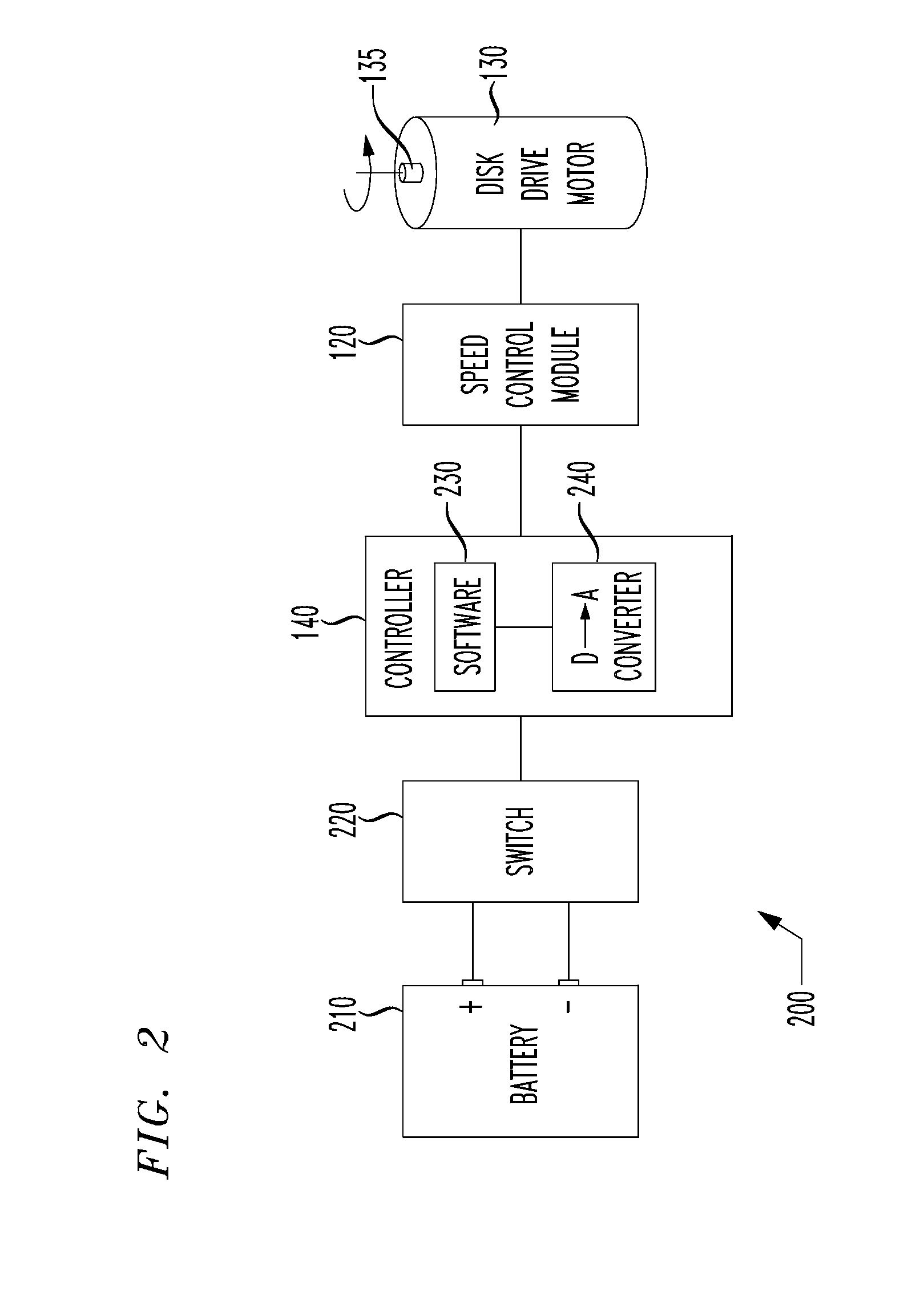

A device and method for reducing disk drive power consumption

InactiveUS20070285036A1Reduce drive power consumptionIncrease the spindle speedDC motor speed/torque controlDynamo-electric converter controlDrive motorControl theory

Introduced is a device to reduce disk drive power consumption during start-up. In one embodiment the device provides for (1) a speed control module associated with a disk drive motor; and (2) a controller coupled to the speed control module that incrementally increases the spindle rotational speed of the disk drive motor during start-up.

Owner:AGERE SYST INC

Small forging belt hammer

A small forging belt hammer comprises an impact hammer shell, guide rods, slide sleeves, an impact hammer, tire belts, U-shaped screws, connecting rods, a belt pulley, a spindle, counterweight iron, a motor, a tightening-loosening pinch roller, a foot-controlled device, a die pile, a frame, an eccentric wheel, a die, a flat plate belt, semicircular seat washers and adjusting nuts. The small forging belt hammer is characterized in that the slide sleeves are mounted on the shell, the guide rods are arranged in middles of the slide sleeves, upper ends of the guide rods are fixed through an upper frame while lower ends of the guide rods are mounted on the frame, and two sides of a waste tire are cut off while the middle portion contacting with the ground is reserved; each tire belt is mounted between each impact hammer belt lug and the corresponding U-shaped screw and locked by the corresponding screw, semicircular seats are welded to ends of the screws, the semicircular seat washers are arranged in middles of the semicircular seats, the adjusting nuts are mounted outside the semicircular seat washers, and the connecting rods are mounted on supporting pins; a spindle and spindle bearing seats are mounted on the frame, the belt pulley and the eccentric wheel are arranged on right and left of the spindle respectively and provided with counterweight iron, the flat plate belt is mounted on the belt pulley, and the die is mounted on the die pile. The small forging belt hammer is suitable for small hardware processing enterprises and worthy of wide popularization.

Owner:杨朴

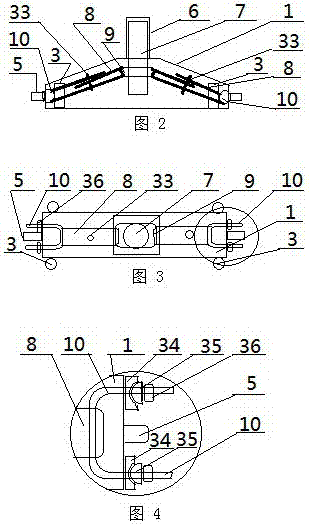

Spinning device having a floating spinning ring and balloon limiter tube

ActiveUS20220235494A1Increase the spindle speedSolve the lack of tensionContinuous wound-up machinesYarnSpinning

A spinning device, for a ring spinning or ring twisting machine, having a spinning spindle for holding a yarn tube such that the yarn tube is oriented coaxial with a spindle axis, a spinning ring for guiding, on the outside thereof, a yarn to be wound on the yarn tube, the spinning ring being arranged coaxial with the spindle axis, and a spinning-ring guiding unit arranged coaxial with the spindle axis, wherein the spinning ring is floatingly fixed at the spinning-ring guiding unit in the spindle-axis direction. In order to provide a spinning device and a spinning machine having a spinning device which allow a spinning process to be reliably performed without limitation of the spindle speed and without use of a ring traveller, a balloon limiter tube is arranged coaxial with the spindle axis such that the yarn is guided on an inner face of the balloon limiter tube.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

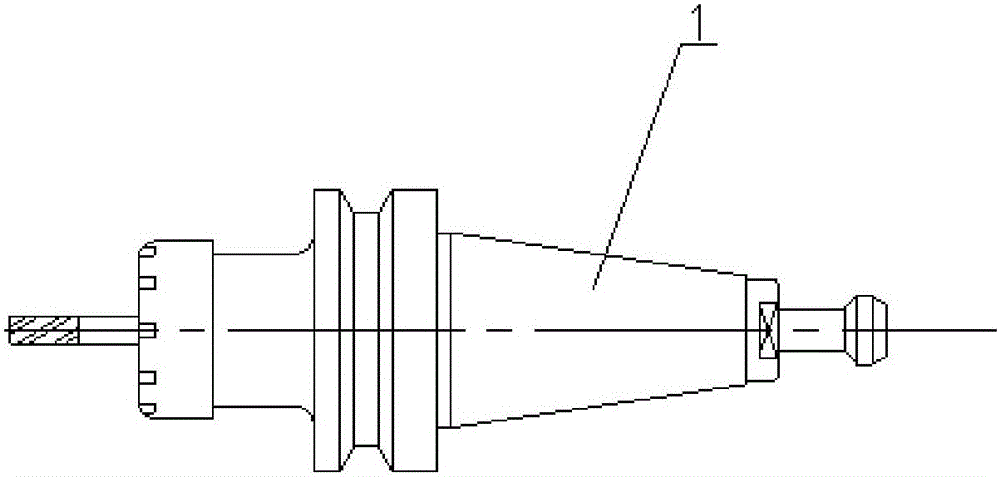

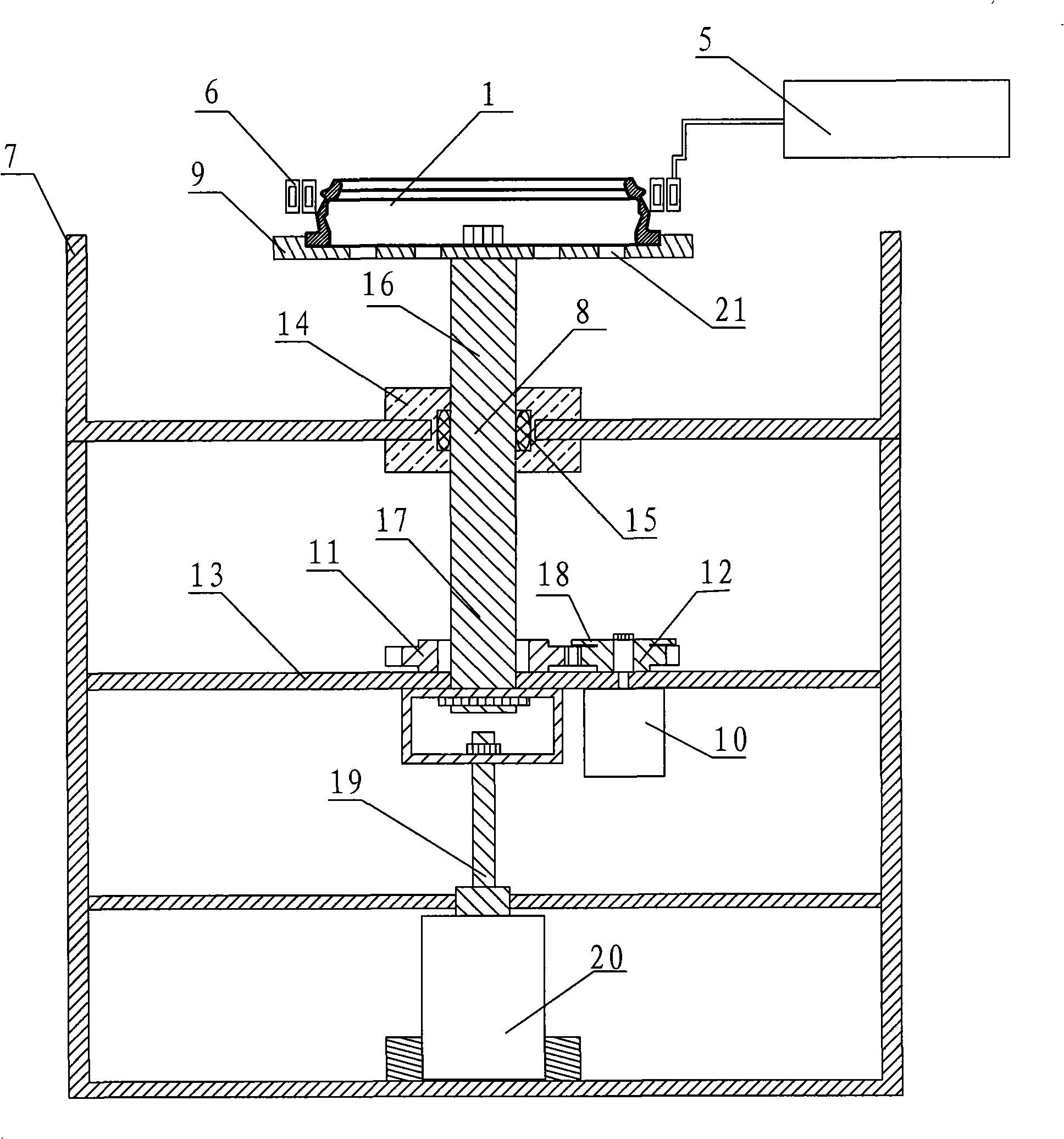

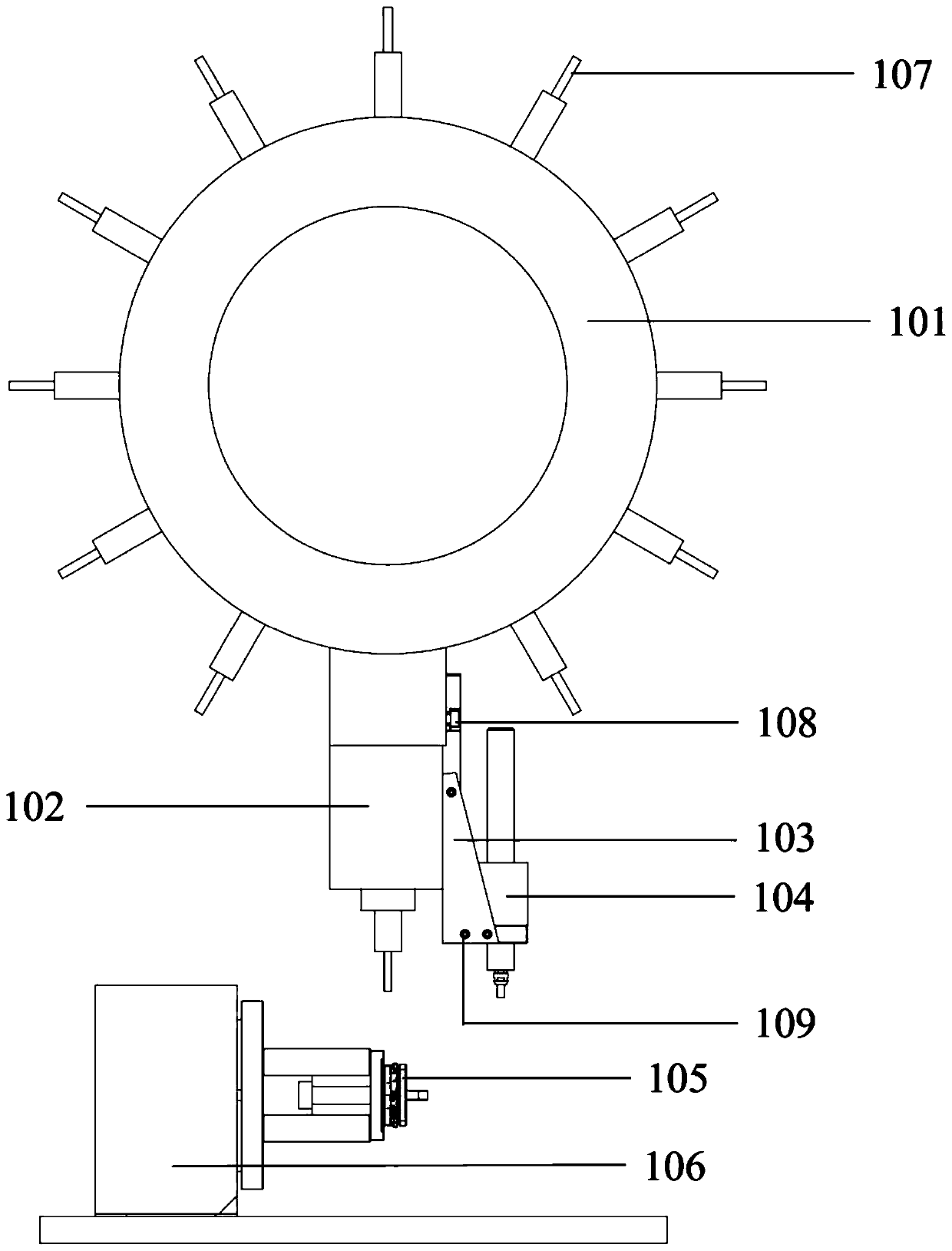

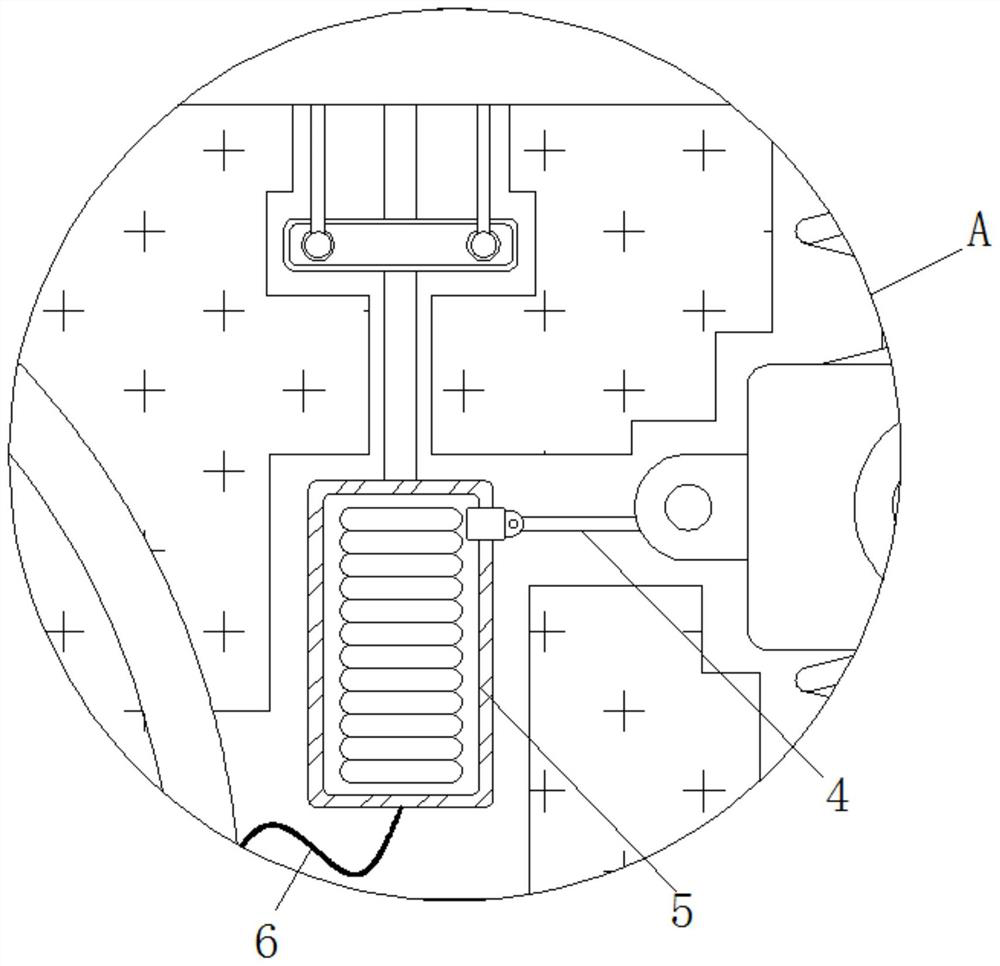

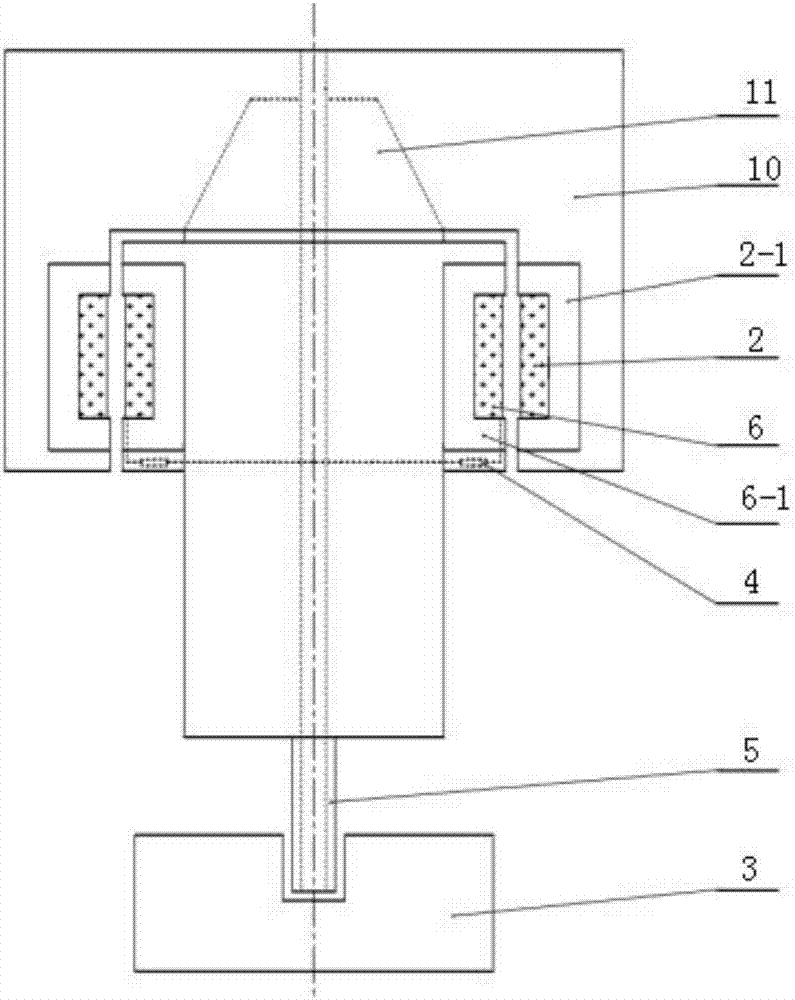

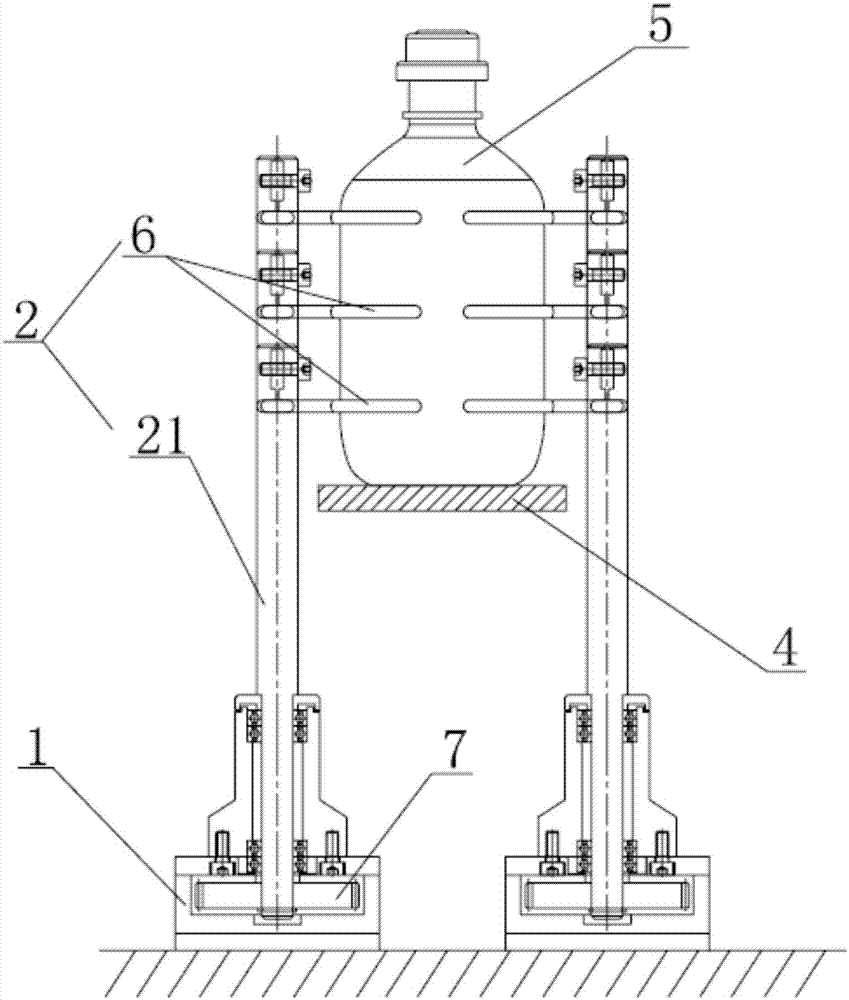

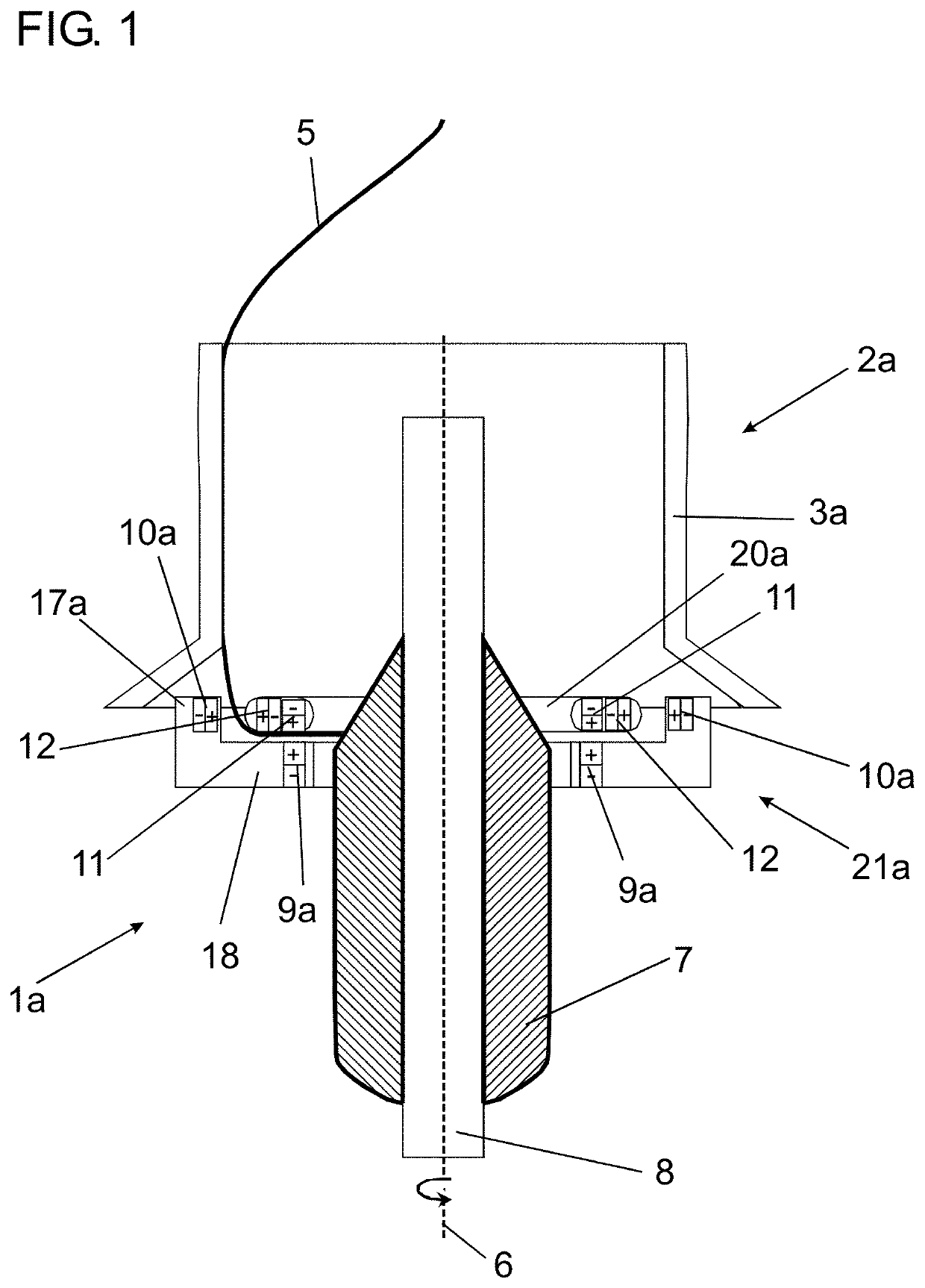

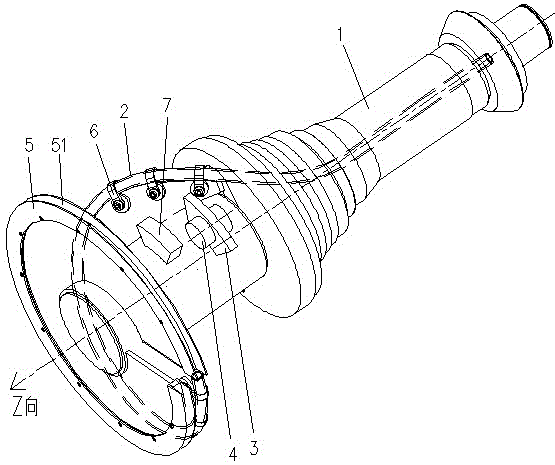

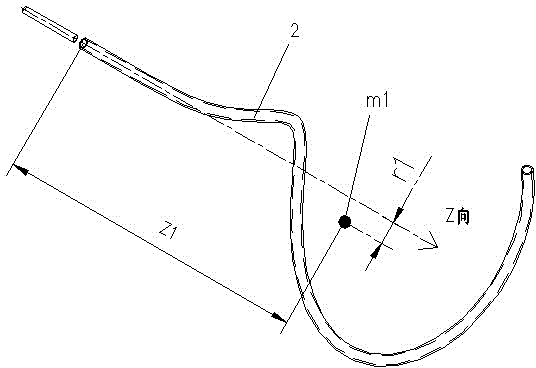

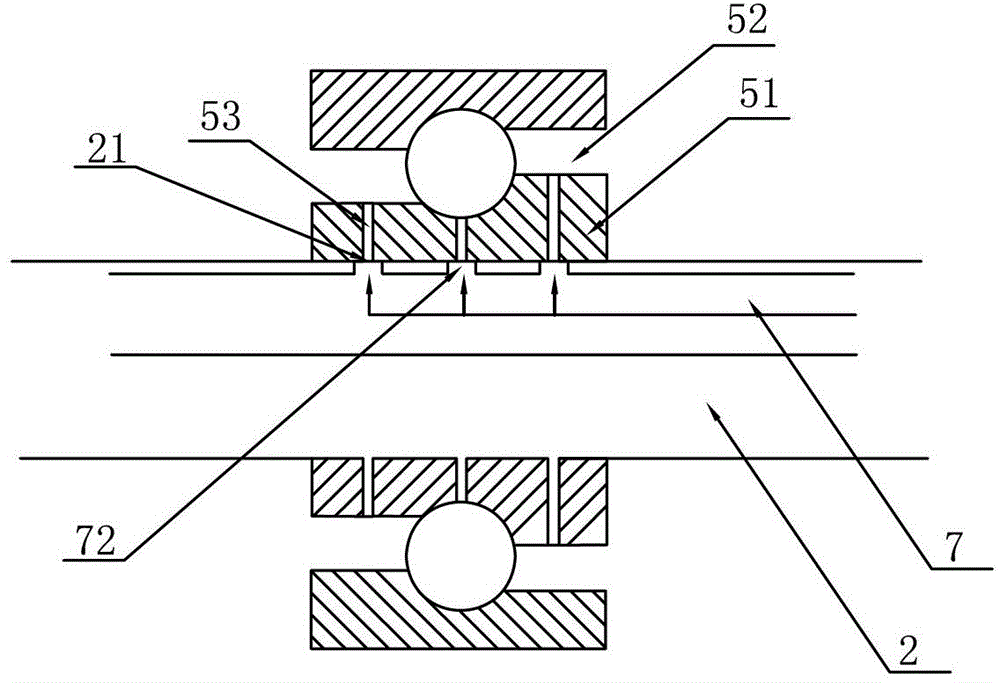

Silking machine spindle assembly, silking machine and method for balancing dynamic unbalance of silking machine

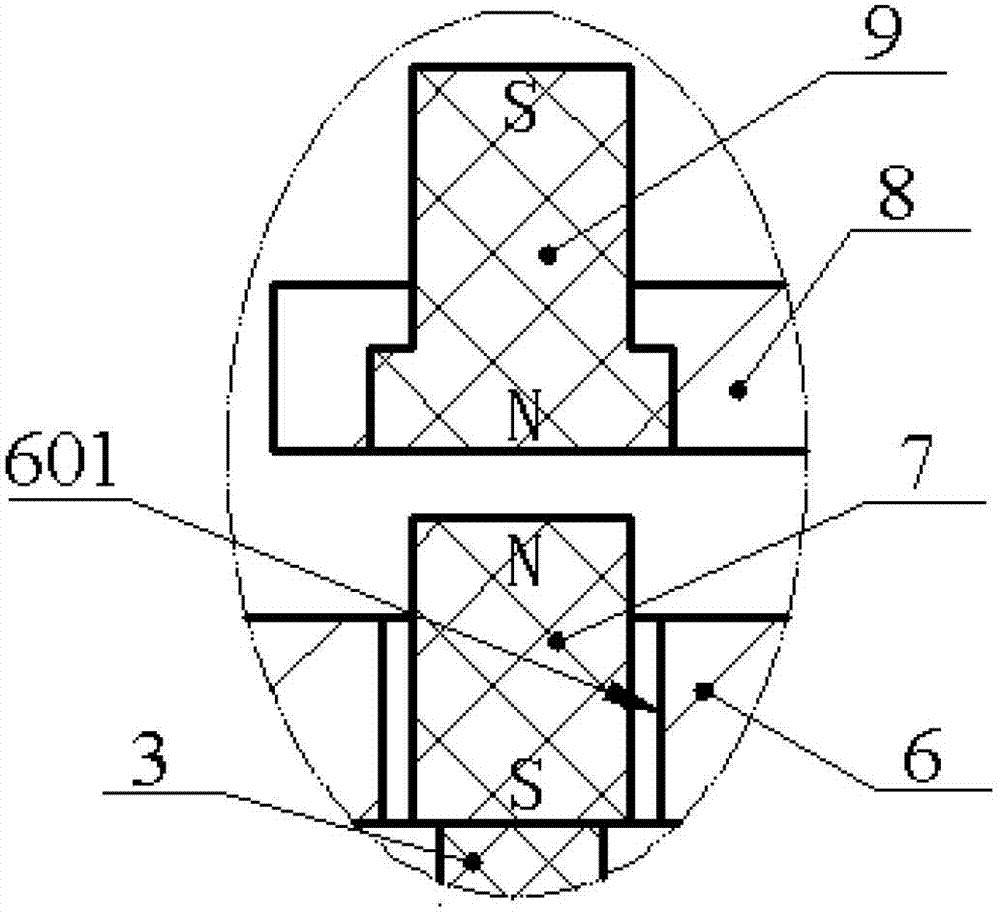

ActiveCN103230939BReduce vibrationIncrease the spindle speedRotating bodies balancingFlexible work arrangmentsFailure rateCoupling

A method for balancing a dynamic imbalance in a strand laying head, a strand laying head main shaft component, and a strand laying head. The strand laying head main shaft component comprises a main shaft (1) and a strand laying tube (2) fixed on the main shaft. A strand laying tube balancing block (3) for balancing eccentric quality of the strand laying tube is disposed on the strand laying head main shaft. The strand laying head comprises a case body (8), a motor (9), a driving bevel gear (11) connected to a motor rotor through a coupling, and a driven bevel gear (12) fixed on the main shaft. The driven bevel gear meshes with the driving bevel gear, and the main shaft is installed on the case body through a bearing. The strand laying head has small vibrations during work, can increase the rotating speed of a main shaft of the strand laying head, lower a failure rate of the strand laying head, and increase a service life of the strand laying head.

Owner:CISDI ENG CO LTD

High-speed motor spindle adopting lubrication under loop

InactiveCN102794467BIncrease speedIncrease the spindle speedMaintainance and safety accessoriesGas lubricationEngineering

Owner:SHAOXING UNIVERSITY

Rings for ring spinning machines or ring twisting machines

ActiveCN103484997BExtended service lifeReduce labor costsTextiles and paperArchitectural engineering

The invention discloses a steel collar for a ring spinner or a ring twister. The steel collar is characterized by comprising a steel collar fixing base (1), steel collar rotating rings (2), rotating wheels (3) and rotating wheel shafts (4). The steel collar fixing base (1) and the steel collar rotating rings (2) are ring-shaped. The outer diameter of the steel collar fixing base (1) is larger than that of the steel collar rotating rings (2). The steel collar fixing base (1) is evenly provided with at least three rotating wheel bases. The rotating wheel shafts (4) are installed on the rotating wheel bases. Each rotating wheel shaft (4) is movably sleeved with one rotating wheel (3). Center lines of the rotating wheels (3) are located on the same ring. The steel collar rotating rings (2) are installed on the rotating wheels (3) in an inserting mode after being connected in a butting mode, and can rotate relative to the rotating wheels (3). The rotating wheels (3) limit the steel collar rotating rings (2) in the radial direction. The service life of a bead ring and the steel collar is greatly prolonged.

Owner:CHONGQING JINMAO TEXTILE ACCESSORIES

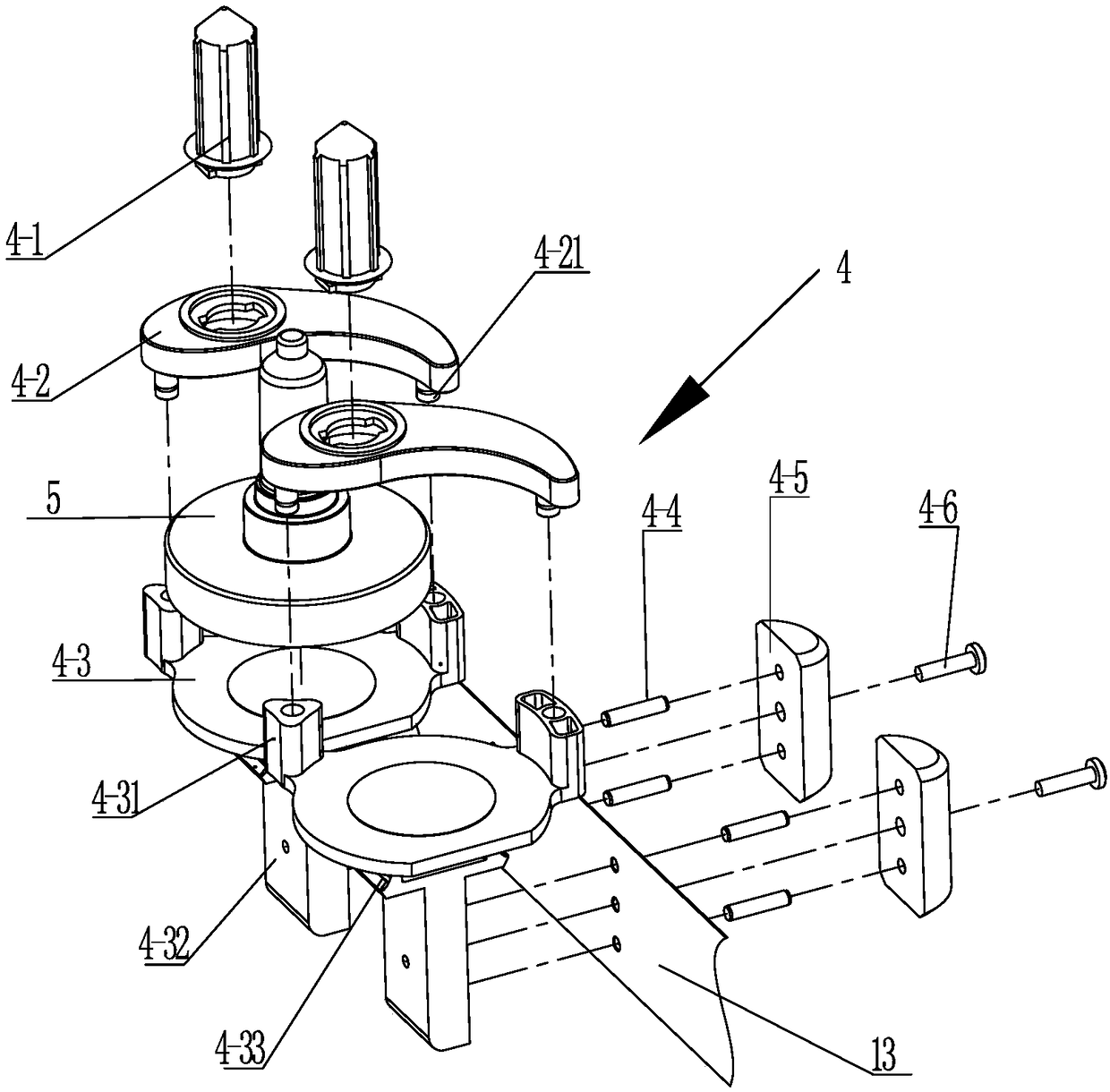

A high-speed automatic tool-changing electric spindle using a non-contact rotary joint

ActiveCN103934481BIncrease speedGuaranteed thermal stabilityLarge fixed membersPositioning apparatusElectricityContact high

The invention discloses an automatic high-speed tool replacing electric spindle with a non-contact rotating joint used. The automatic high-speed tool replacing electric spindle comprises a machine body, and a stator, a rotor shaft, a spring pre-tensioning mechanism, a front bearing and a rear bearing are arranged in the machine body. The automatic high-speed tool replacing electric spindle further comprises a connecting base fixed to one end of the machine body, an oil cylinder assembly in rotating connection with the connecting base, a rear end cover arranged at the end of the oil cylinder assembly and a front end cover connected to the other end of the machine body. A tool group with a central water outlet is arranged at the front end of the rotor shaft. The automatic high-speed tool replacing electric spindle abandons a complicated contact sealing structure, conducts non-contact sealing by using compressed air, can obtain higher spindle rotating speed, and meanwhile obtains a better sealing effect by adopting labyrinth seal. The spindle is simple and compact in structure and powerful in function, integrates various functions such as center water outgoing, automatic tool replacing, spindle cooling and motor cooling while rotating at high speed, can be widely applied to high-speed machining of various materials, and is particularly suitable for machining of parts such as cavities with deep holes.

Owner:江苏华雕机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com