Method for fabricating flange ring

A processing method and steel ring technology, applied in the direction of textiles and papermaking, etc., to achieve the effects of prolonging service life, improving output and quality, improving processing accuracy and surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

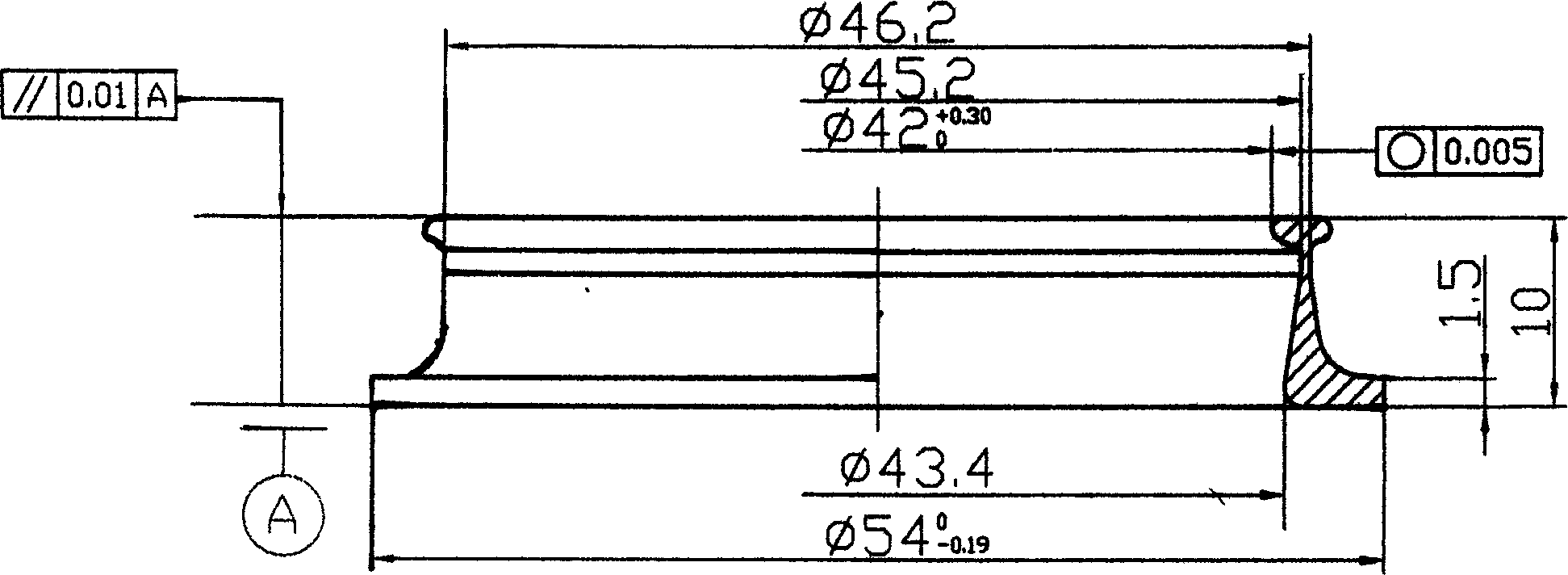

[0011] The present invention is carried out according to the processing method of decreasing tolerance, that is, as the processing steps move backward, the cumulative tolerance gradually becomes smaller until the final process eliminates the cumulative tolerance (reduces to the limit). Such as figure 1 As shown, taking the processing of PG-1 type 4251 steel ring as an example, the present invention includes the following operations (steps): 1. adopting a seamless steel pipe made of rolling bearing steel to make a blank, and this blank manufacturing method is a prior art. ② Turning, using CNC lathes to ensure the processing accuracy requirements of the next process, rough turning first, and then fine turning. ③ Heat treatment is carried out according to the conventional heat treatment method of rolling bearing steel, that is, heat treatment is carried out by spheroidizing annealing, quenching and low temperature tempering. It is a non-carburizing heat treatment, that is, the s...

Embodiment 2

[0013] The present invention is carried out according to the processing method of decreasing tolerance, that is, as the processing steps move backward, the cumulative tolerance gradually becomes smaller until the final process eliminates the cumulative tolerance (reduces to the limit). The present invention includes the following procedures (steps): ①Using a sintered powder metallurgy compact (that is, a sintered product that can be obtained by initial pressing). ② turning, with the operation in embodiment 1 ②. ③ It is heat treated according to the conventional heat treatment method of powder metallurgy, that is, it is heat treated by surface quenching. 4. Grinding and forming, eliminating (extinguishing) the accumulative tolerances of the previous processes, the same as 4. the process in Example 1. ⑤ The finished product is obtained after surface treatment. Surface treatment: Polishing, mechanical polishing or electropolishing can be used, selected according to conditions, ...

Embodiment 3

[0015] The present invention is carried out according to the processing method of decreasing tolerance, that is, as the processing steps move backward, the cumulative (product) tolerance gradually becomes smaller until the final process eliminates the cumulative tolerance (reduces to the limit). The present invention comprises the following operations (steps): 1. The seamless steel pipe made of alloy steel is used to make the blank, and the material can be made of alloy structural steel (such as ordinary low alloy steel, free cutting steel, quenched and tempered steel, rolling bearing steel) or alloy tools Steel (such as low-alloy cutting steel, high-speed steel, die steel) or special performance steel (such as wear-resistant steel, heat-resistant steel, stainless steel) seamless steel pipe. ② turning, with the operation in embodiment 1 ②. ③ Perform conventional heat treatment according to the selected material (that is, perform conventional heat treatment to improve its surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com