Numerical control gantry type multi-head linear cutting machine tool

A technology of cutting machine tools and multi-head wires, which is applied in the direction of electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of large occupied area and cost waste, reduce occupied area, improve production efficiency, improve processing accuracy and The effect of surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described further non-limitatively:

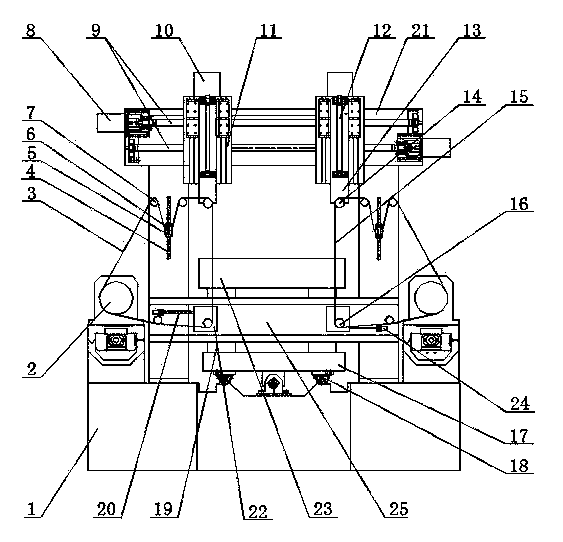

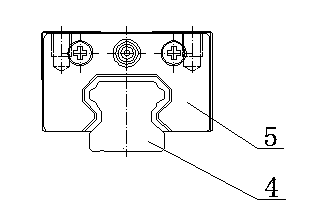

[0018] figure 1 and figure 2Among them, the CNC gantry type multi-head wire cutting machine tool includes a bed base 1, a workbench 17 is arranged on the bed base 1, and a guide rail assembly 18 is provided between the bed base 1 and the workbench 17, and the workbench 17 can be placed on the bed base 1 to move, the workbench 17 is provided with a support member 19 supporting the workpiece 23, and a crossbeam 21 and a Y lower arm 25 are arranged above the workbench. The X-axis motor that the body 1 moves, a wire transport mechanism is provided between the workbench 17 and the crossbeam 21, and the wire transport mechanism includes a mutually symmetrical left silk transport mechanism and a right silk transport mechanism, and the left and right silk transport mechanisms are respectively provided with left, The left and right electrode wires 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com