Silking machine spindle assembly, silking machine and method for balancing dynamic unbalance of silking machine

A laying machine and spindle technology, applied in the field of steel rolling machinery, can solve problems such as large vibration, and achieve the effects of reduced vibration, increased spindle speed, and fast balance configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

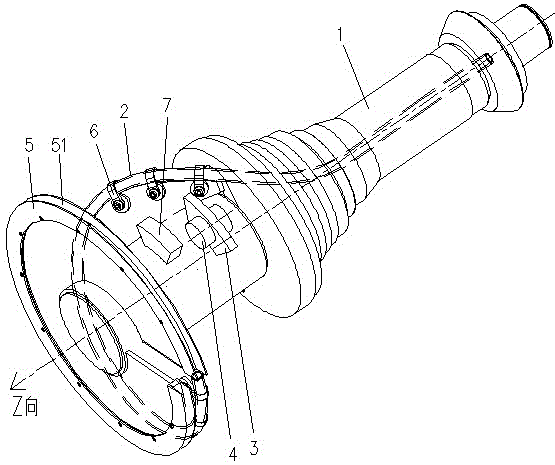

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] As shown in the figure, the method for balancing the unbalanced spinning machine in this embodiment includes the following steps:

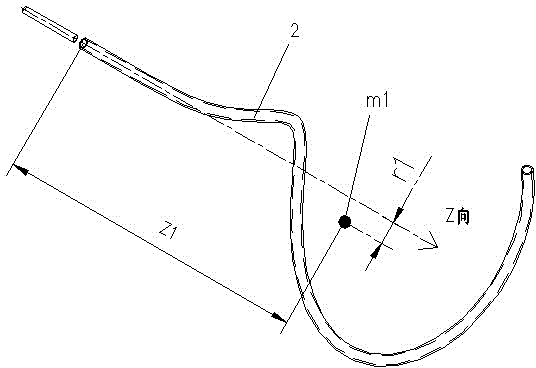

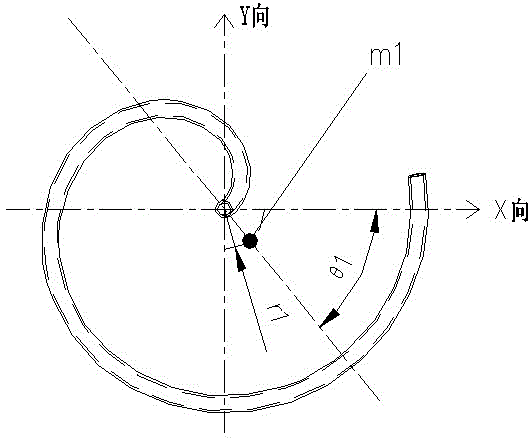

[0026] a. Establish a three-dimensional cylindrical coordinate system with the Z-axis of the three-dimensional coordinates on the axis line of the main shaft 1 of the laying machine, and use r to represent the radial distance coordinates from the midpoint of the three-dimensional cylindrical coordinate system to the Z axis, and use θ to represent the three-dimensional cylindrical coordinate system The azimuth coordinates of the midpoint, and represent the coordinates of the midpoint of the three-dimensional cylindrical coordinate system in the Z-axis direction with z, find out the coordinate position of the centroid of the spinning pipe 2 in the three-dimensional cylindrical coordinate system, and calculate the centro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com