Steel collar for ring spinner or ring twister

A technology for a ring spinning machine and a twisting machine, which is applied to the ring field of the ring spinning machine or the ring twisting machine, can solve the problems that the comprehensive performance of the ring and the traveler cannot be fundamentally improved, and achieves the The effect of reducing yarn breakage, increasing spindle speed and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

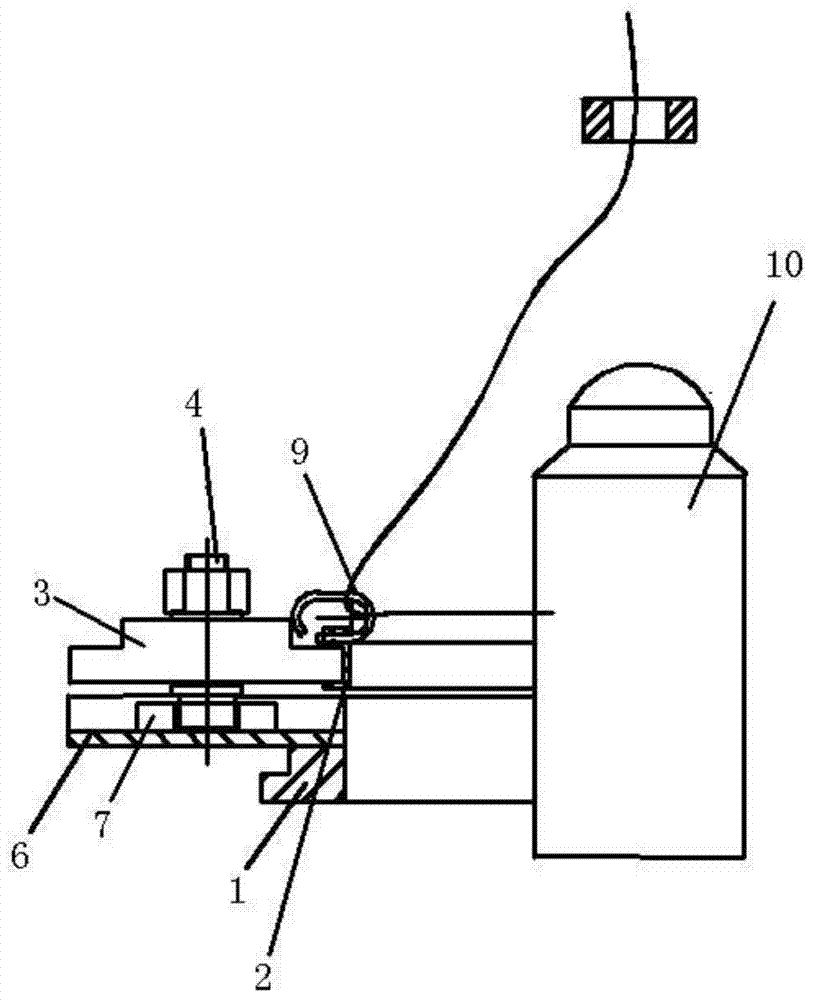

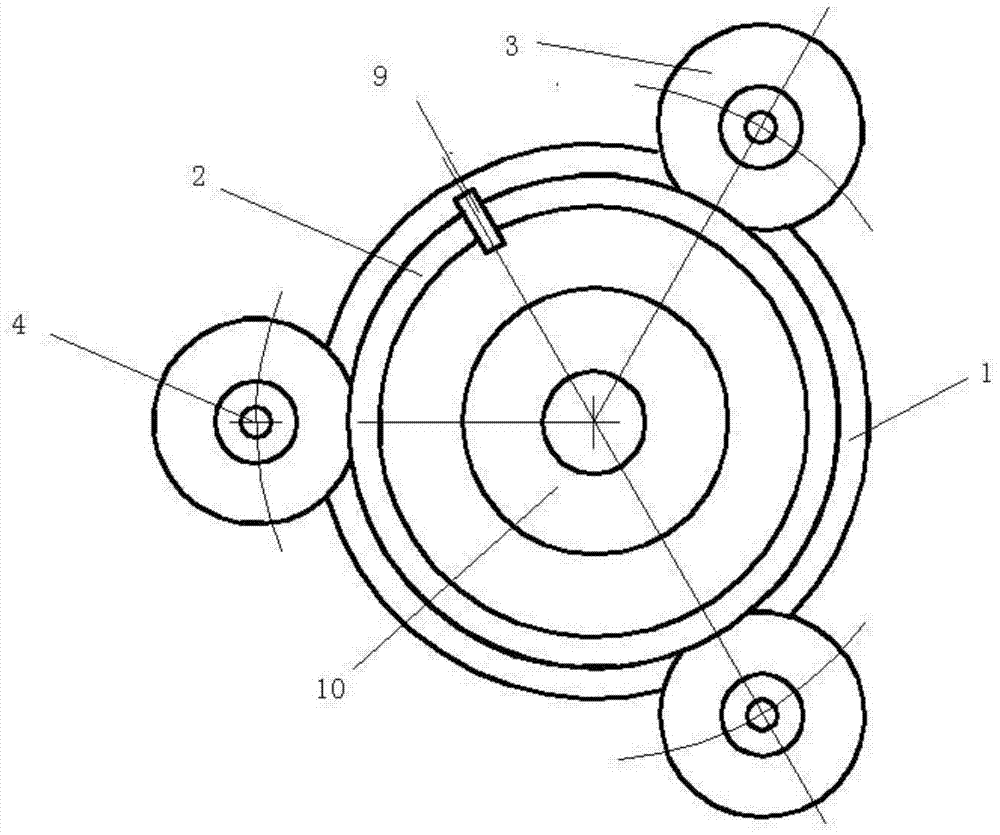

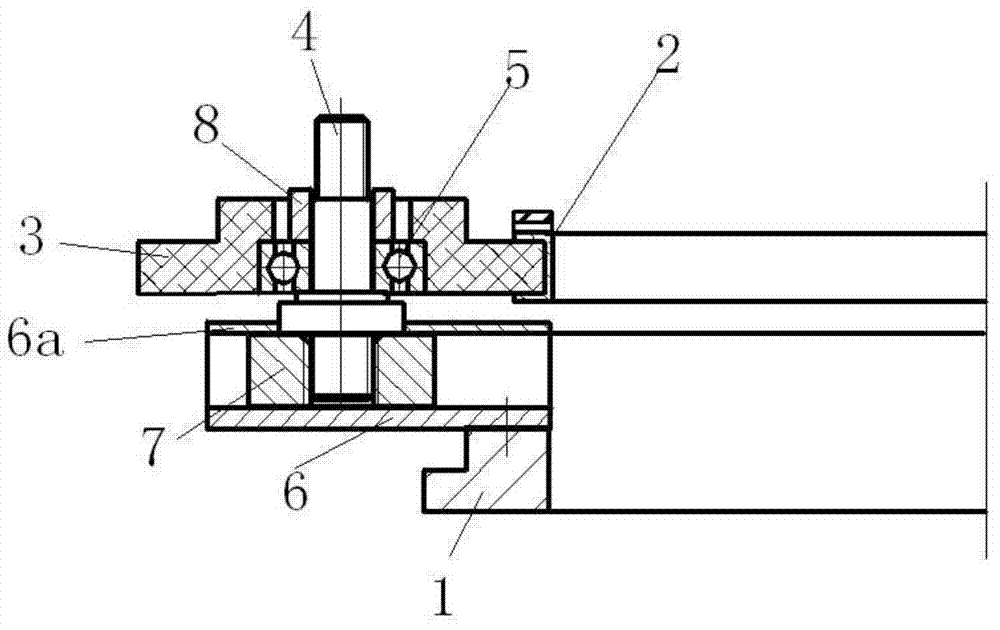

Method used

Image

Examples

Embodiment 2

[0031] Other structures are identical with embodiment 1, and difference is: as Figure 7 As shown, the outer wall of the middle section of the runner 3 has an annular groove, the outer circumference of the ring swivel 2 is inserted into the annular groove of the runner 3, and the ring swivel 2 is provided with a through hole 2b , the through hole 2b is located outside the annular groove of the runner 3. The yarn passes through the through hole 2b, driven by the spindle 10 and the yarn, the ring swivel 2 rotates accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com