A high-speed automatic tool-changing electric spindle using a non-contact rotary joint

A rotary joint and automatic tool change technology, which is applied in the field of electric spindles and high-speed automatic tool change electric spindles, can solve the problems of large size, unfavorable reliability, high price, etc., and achieve the goal of improving machining accuracy, reliable performance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

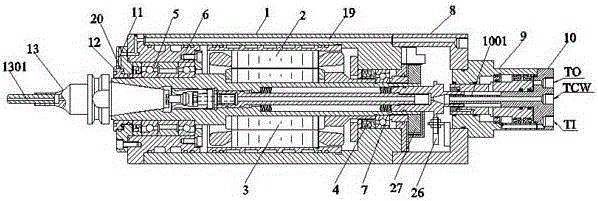

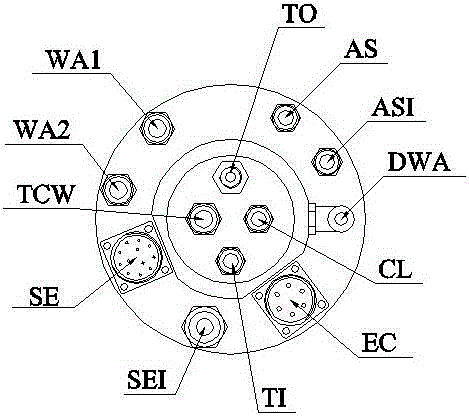

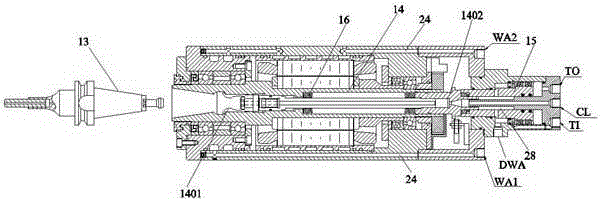

[0029] see Figure 1-Figure 4 , a high-speed automatic tool-changing electric spindle adopting a non-contact rotary joint of the present invention, the main structure includes: a body 1, a stator 2, a rotor shaft 3, a spring preload mechanism 4, a front bearing 5 and The rear bearing 7, wherein the front bearing 5 and the rear bearing 7 are respectively arranged at both ends of the rotor shaft 3 and the front bearing 5 is installed on a front bearing seat 6. The stator 2 and the rotor shaft 3 are integrated inside the machine body 1. The high-frequency three-phase power output by the external drive mechanism is supplied to the motor through the built-in motor lead EC to drive the main shaft to run at high speed. The maximum speed that can run depends on the front bearing 5 and the rear bearing. The maximum rotational speed of the shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com