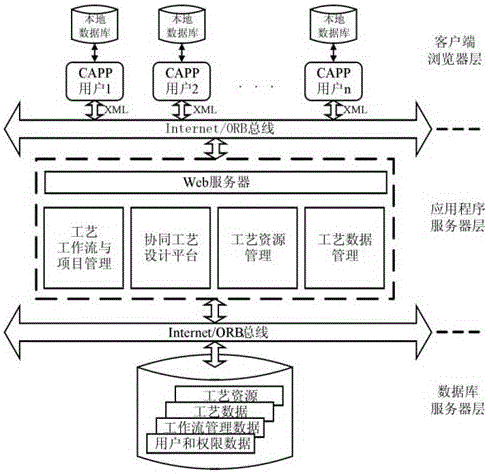

Small-sized CNC numerical control machine tool with network-based manufacturing function

A technology of networked manufacturing and CNC machine tools, which is applied in the field of machining, can solve the problems such as the low degree of compound functions of CNC machine tools, and achieve the effects of high spindle speed and feed rate, beautiful appearance, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

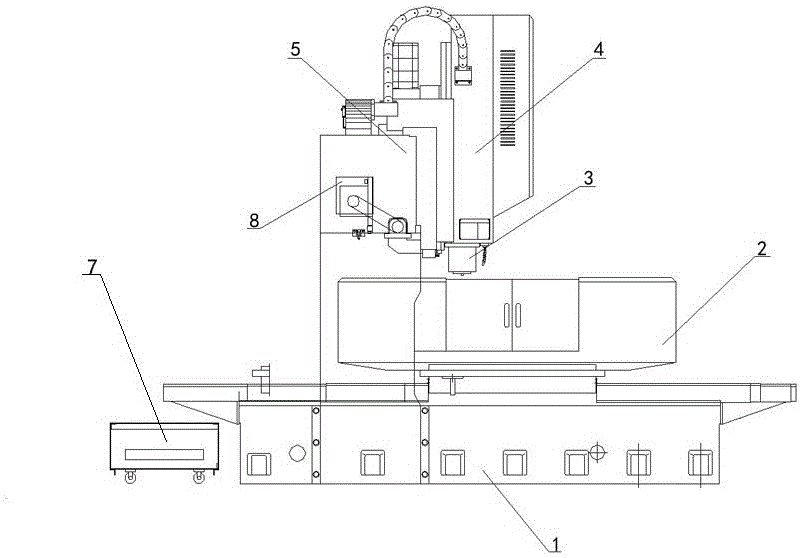

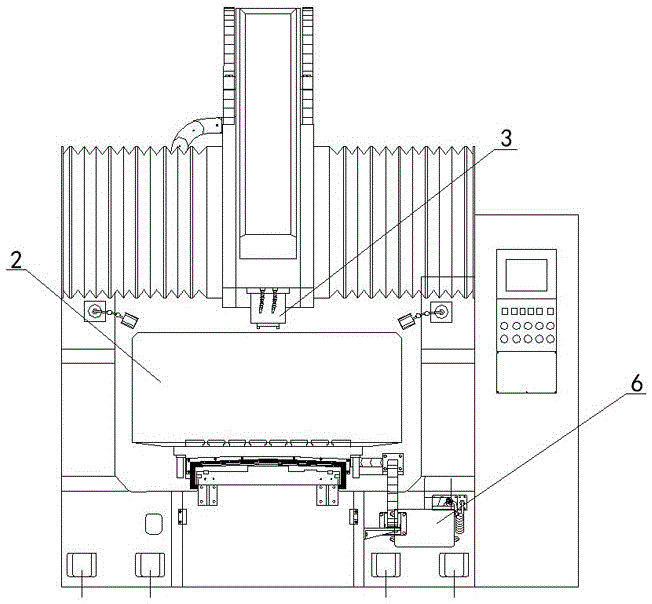

[0019] As shown in the figure: a small CNC machine tool with networked manufacturing function, including a base mechanism 1, a sliding seat mechanism, a workbench mechanism 2, a spindle mechanism 3, a headstock mechanism 4, a column mechanism 5, a main motor mechanism, Lubricating system 6, cooling system 7, pneumatic system 8 and programmable CNC control system, the table mechanism 2 performs linear motion in the X and Y directions, the spindle box mechanism 4 performs linear motion in the Z direction, and the slide mechanism passes through the X direction. The guide rail is assembled on the upper part of the base mechanism 1, and the workbench mechanism 2 is assembled on the upper part of the slide seat mechanism through the Y guide rail. The workbench mechanism 2 includes a worktable for placing workpieces to be processed, and a fixed The fixture for clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com