Patents

Literature

48results about How to "Humanized operation interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

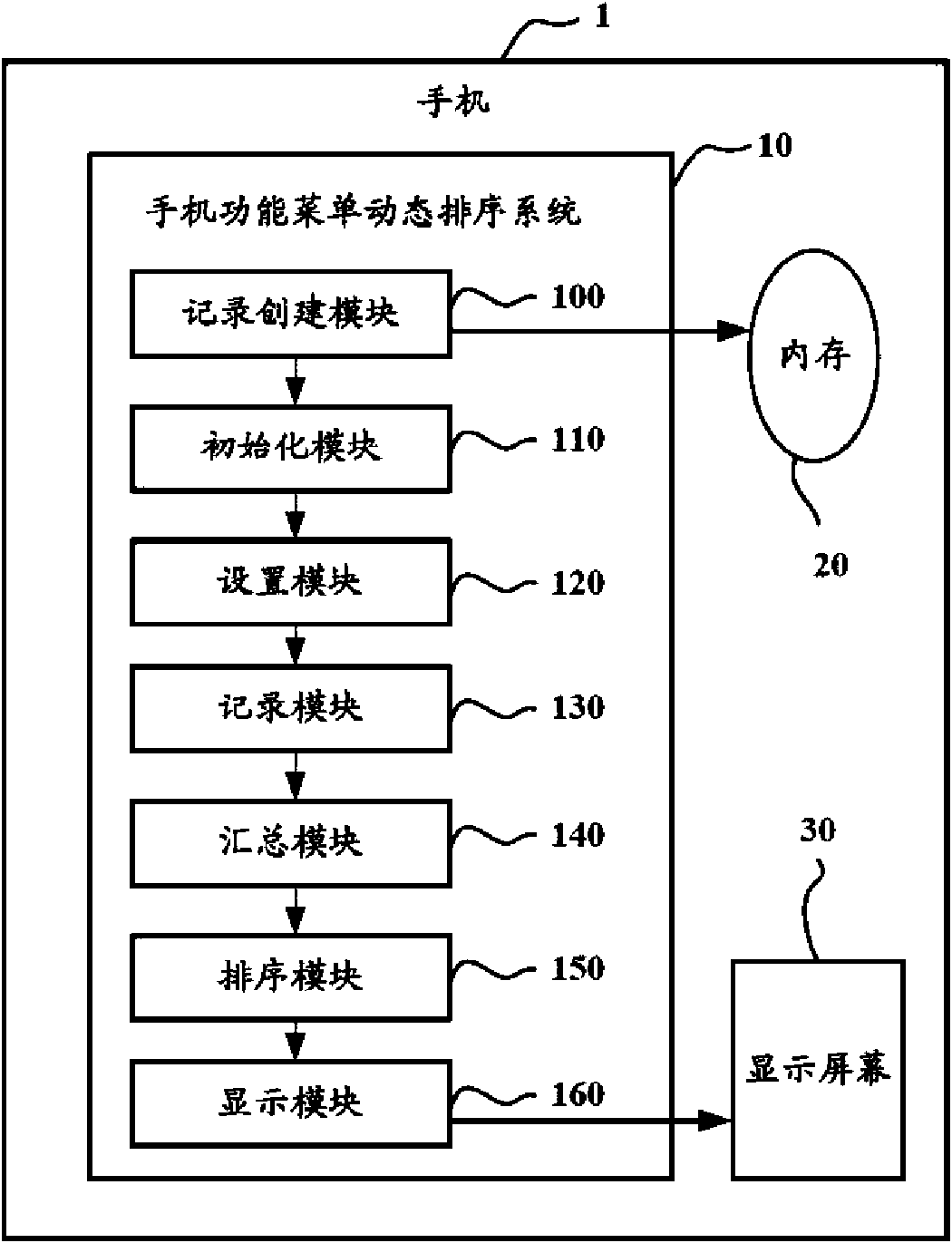

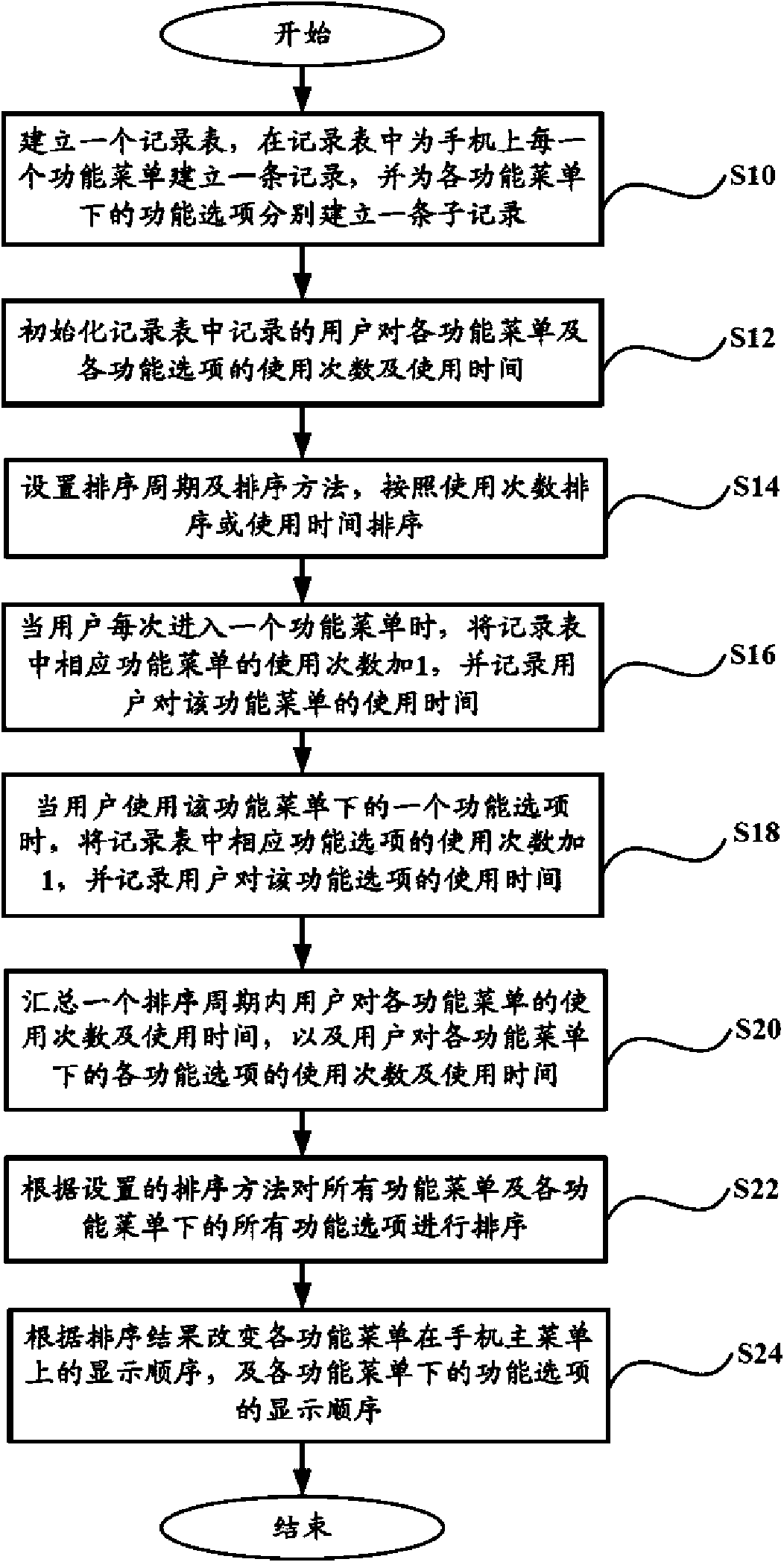

Mobile phone realizing function menu dynamic sequencing, system and method

InactiveCN101651870AHumanized operation interfaceRadio/inductive link selection arrangementsTelephone sets with user guidance/featuresMobile phoneMicroprocessor

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

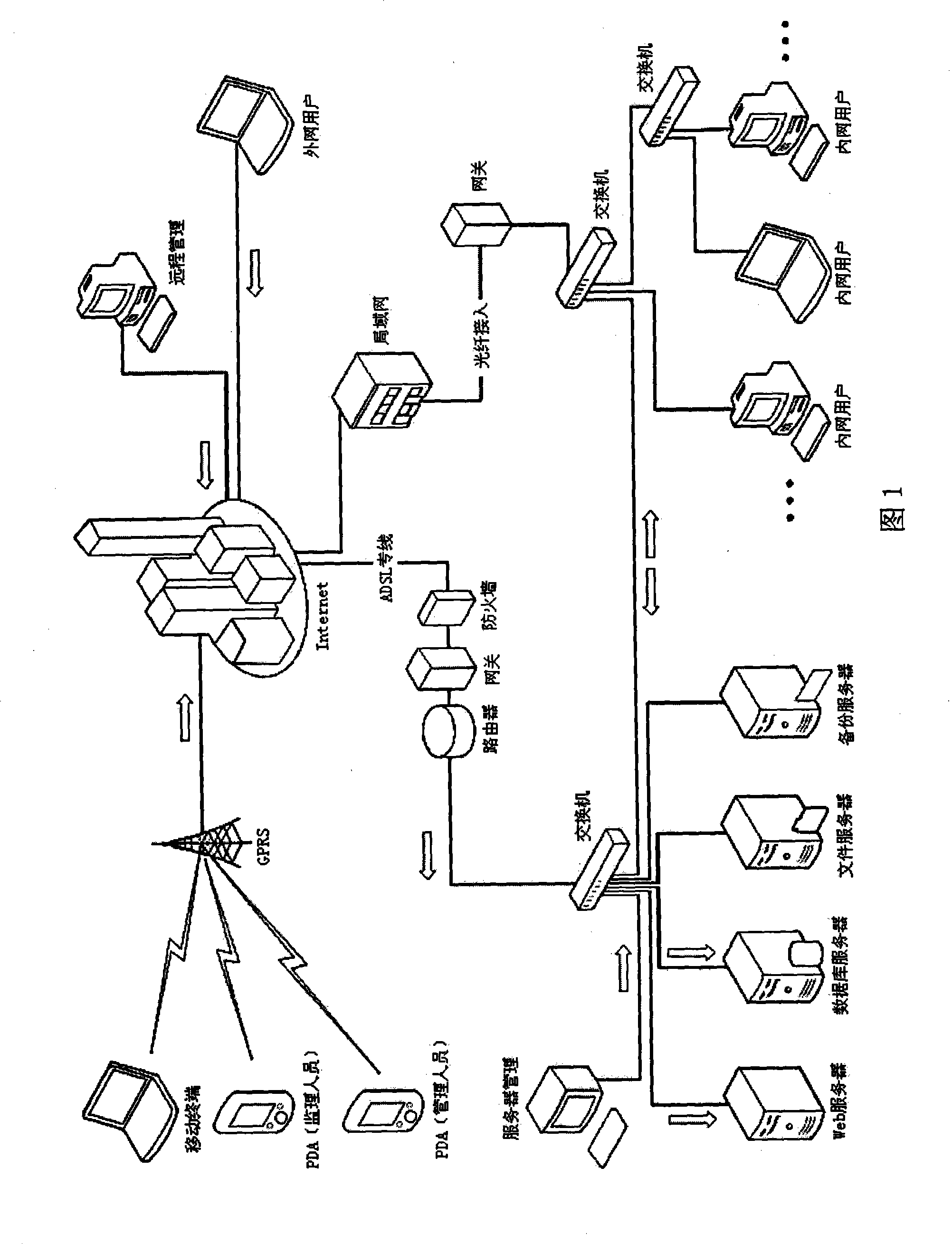

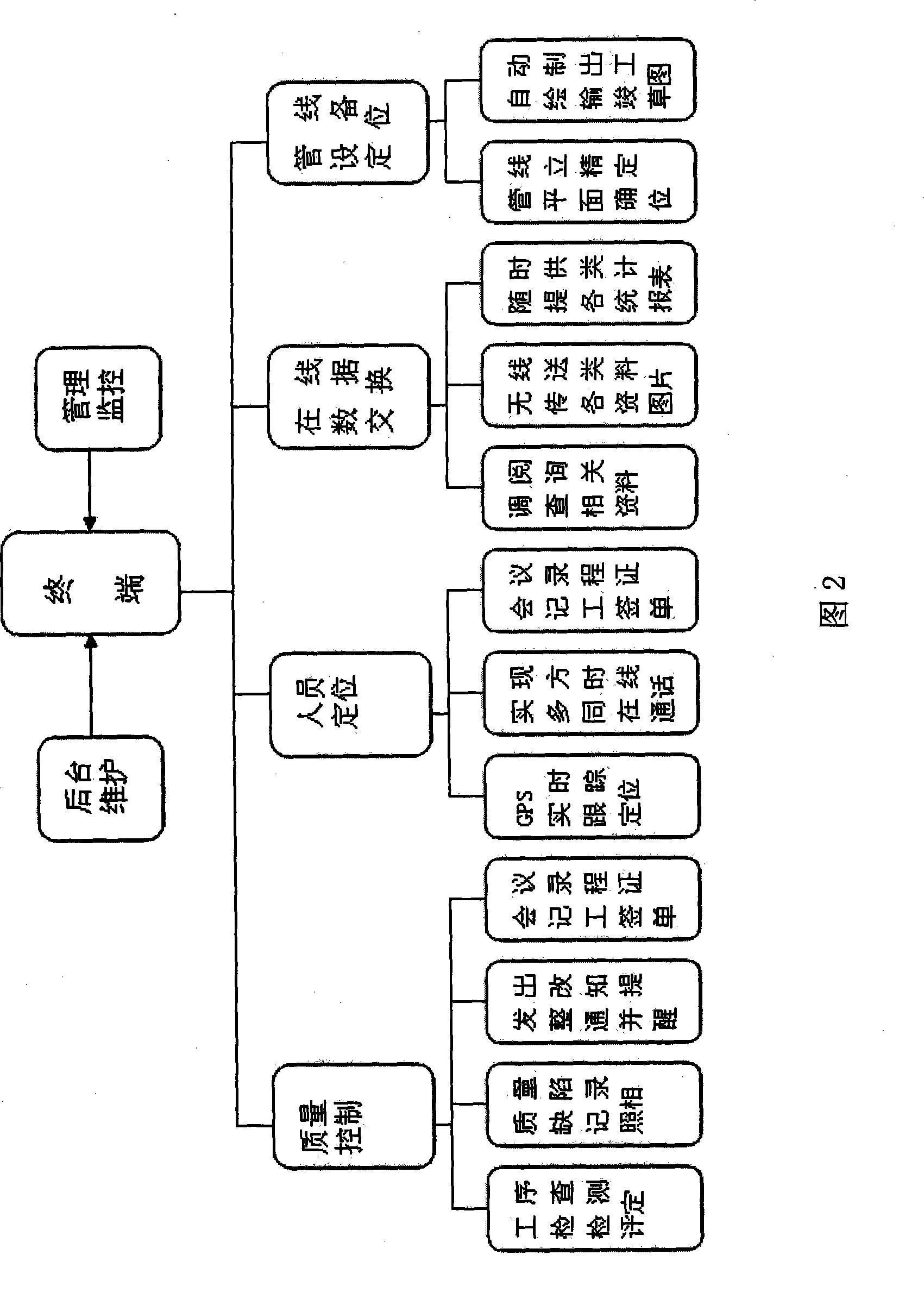

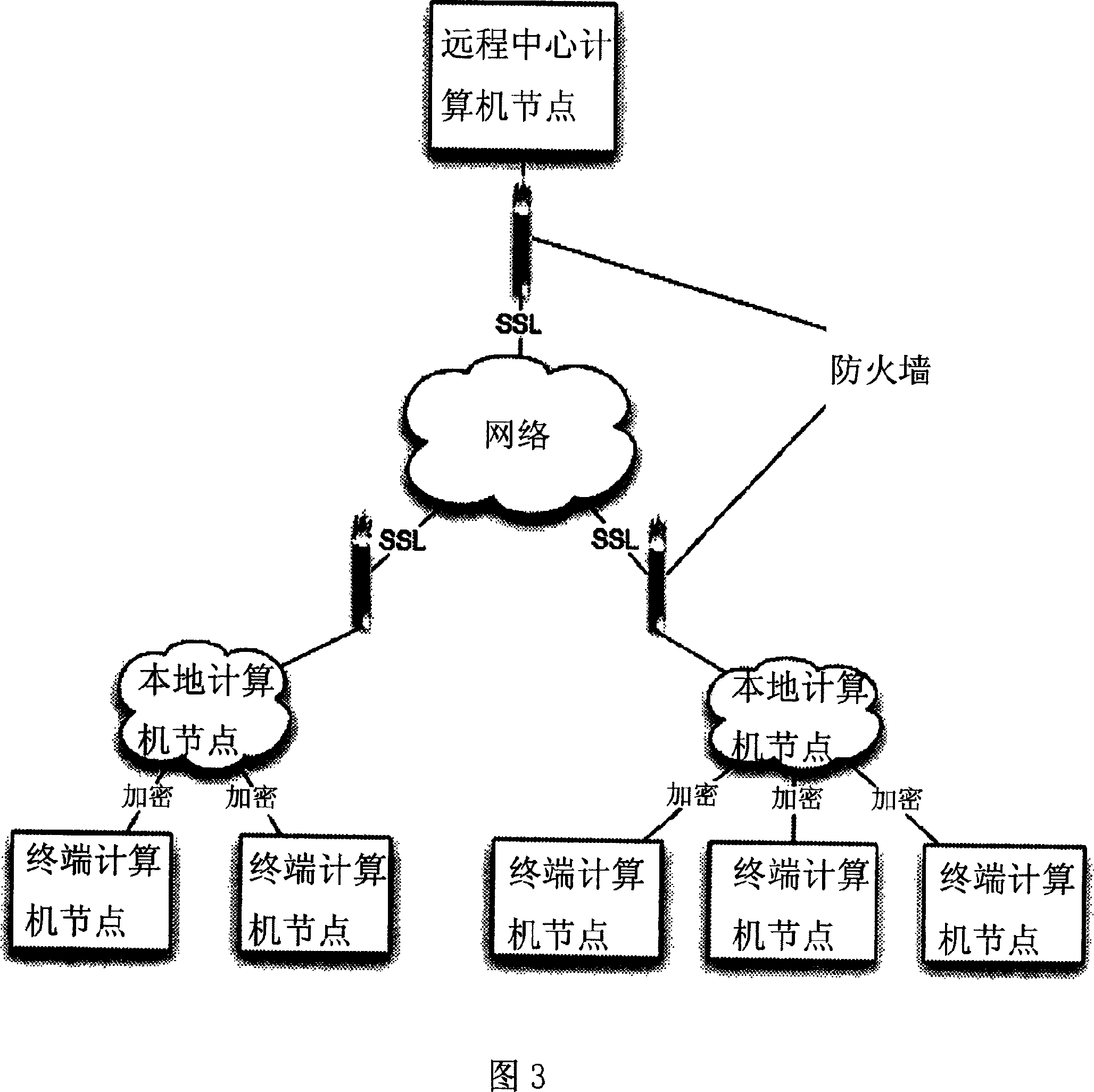

System and method for supervising gas engineering project

InactiveCN101446383ASolve on-site problemsInstantly understand the dynamicsPipeline systemsTransmissionModem deviceWeb service

The invention relates to a system and a method for supervising a gas engineering project, which is used for project quality safety of gas engineering, personnel management and exact positioning of a pipeline and mainly comprises a server of a control center, a hardware fire wall, a PDA, and a GPS locator, wherein, the server consists of a web server, a database server, a file server and a backup server; the server is connected with the hardware fire wall by a net wire or a modem; after the PDA collects field engineering data and personnel positions information and transmits the data to the server by a GPRS; the GPS locator collects the three-dimensional coordinate information of all crates, equipment and turning points of a pipe network; by adopting the invention, the field operation situations can be remotely monitored at any time and the invention has the advantages of displaying the conditions of all engineering constructions comprehensively and accurately in real time and solving the problems in time, thereby ensuring the engineering construction to be completed with good quality on schedule.

Owner:广州万安建设监理有限公司 +1

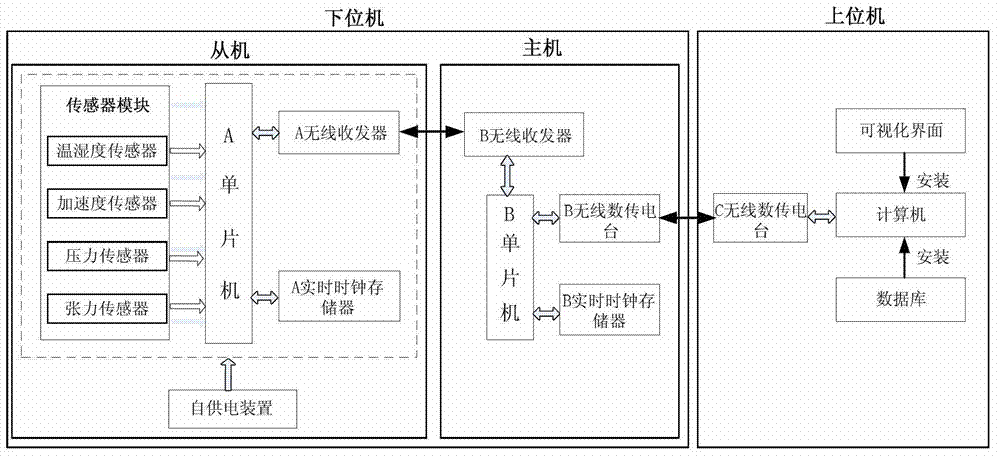

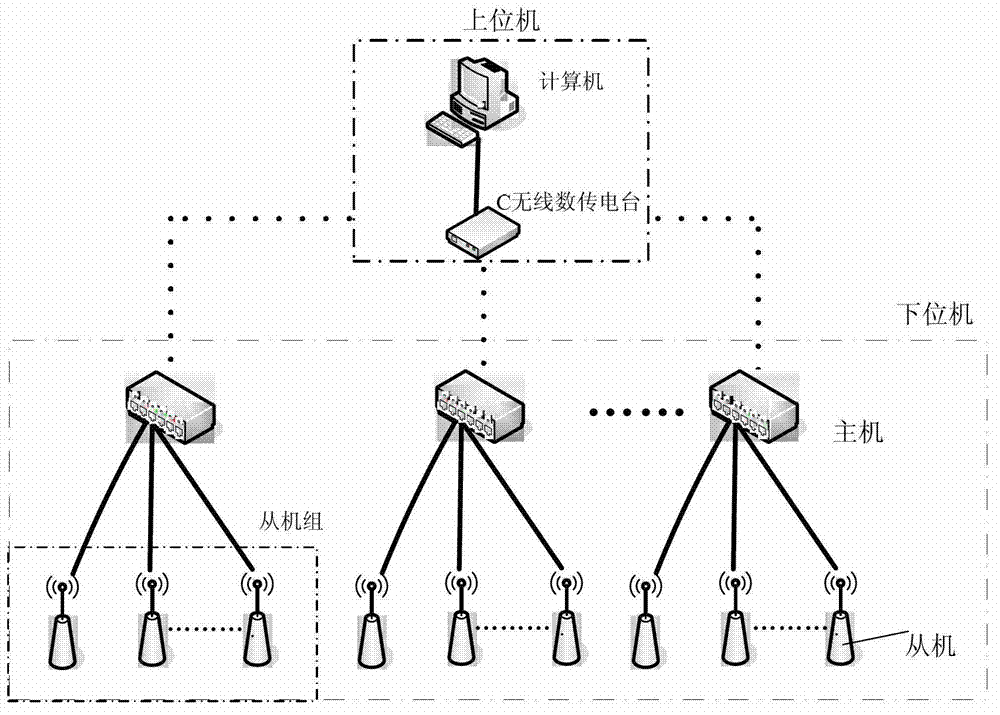

Embedded type self-powered wireless sensing system for highway health monitoring

InactiveCN103196494AImprove stabilityAdaptableMeasurement devicesTransmission systemsData informationComputer module

The invention discloses an embedded type self-powered wireless sensing system for highway health monitoring. The embedded type self-powered wireless sensing system comprises an upper computer and a lower computer, wherein the upper computer comprises a wireless data transfer radio station module, a visual interface, a computer and a data base, and the lower computer comprises a host machine and a slave machine. A control instruction sent by the upper machine is transmitted to the host machine, the host machine receives the instruction sent by the upper machine, analyzes the instruction and then sends the instruction to the slave machine, the slave machine executes a corresponding instruction and sends acquired data information to the host machine, and the host machine sends received data to the upper machine to finish transmission and execution of the instruction for one time. The embedded type self-powered wireless sensing system for the highway health monitoring has the advantages of being strong in adaptive capacity, high in reliability, strong in instantaneity, humanized in operation interface and the like.

Owner:TAIYUAN UNIV OF TECH

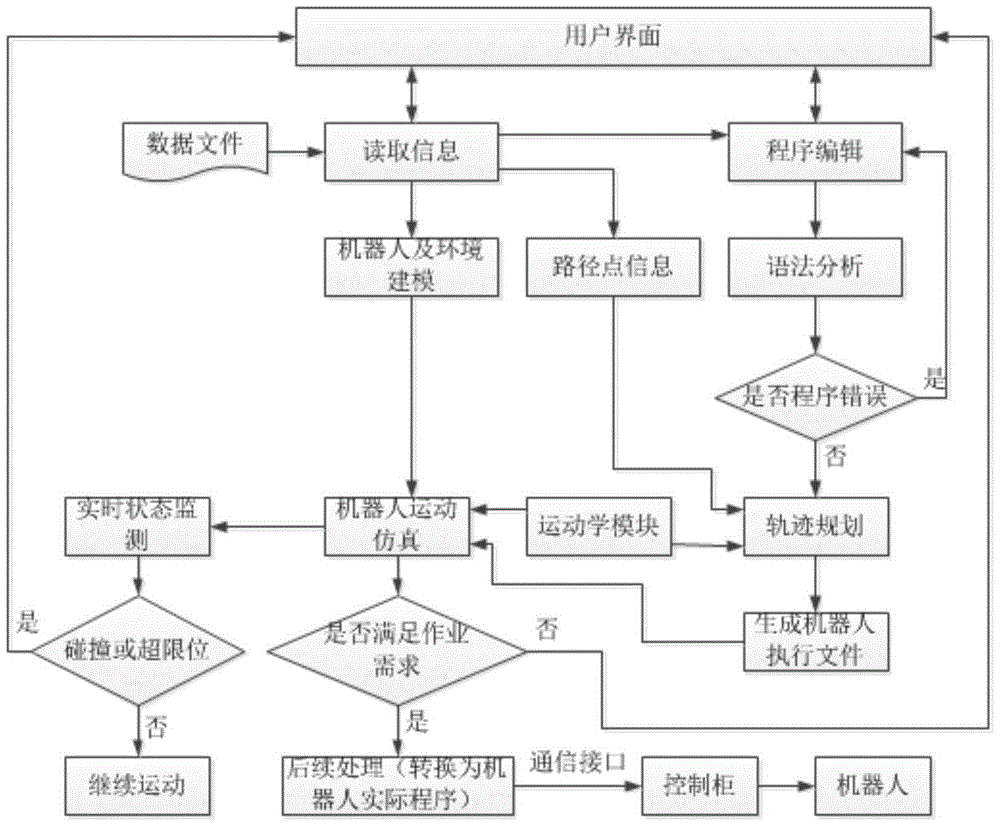

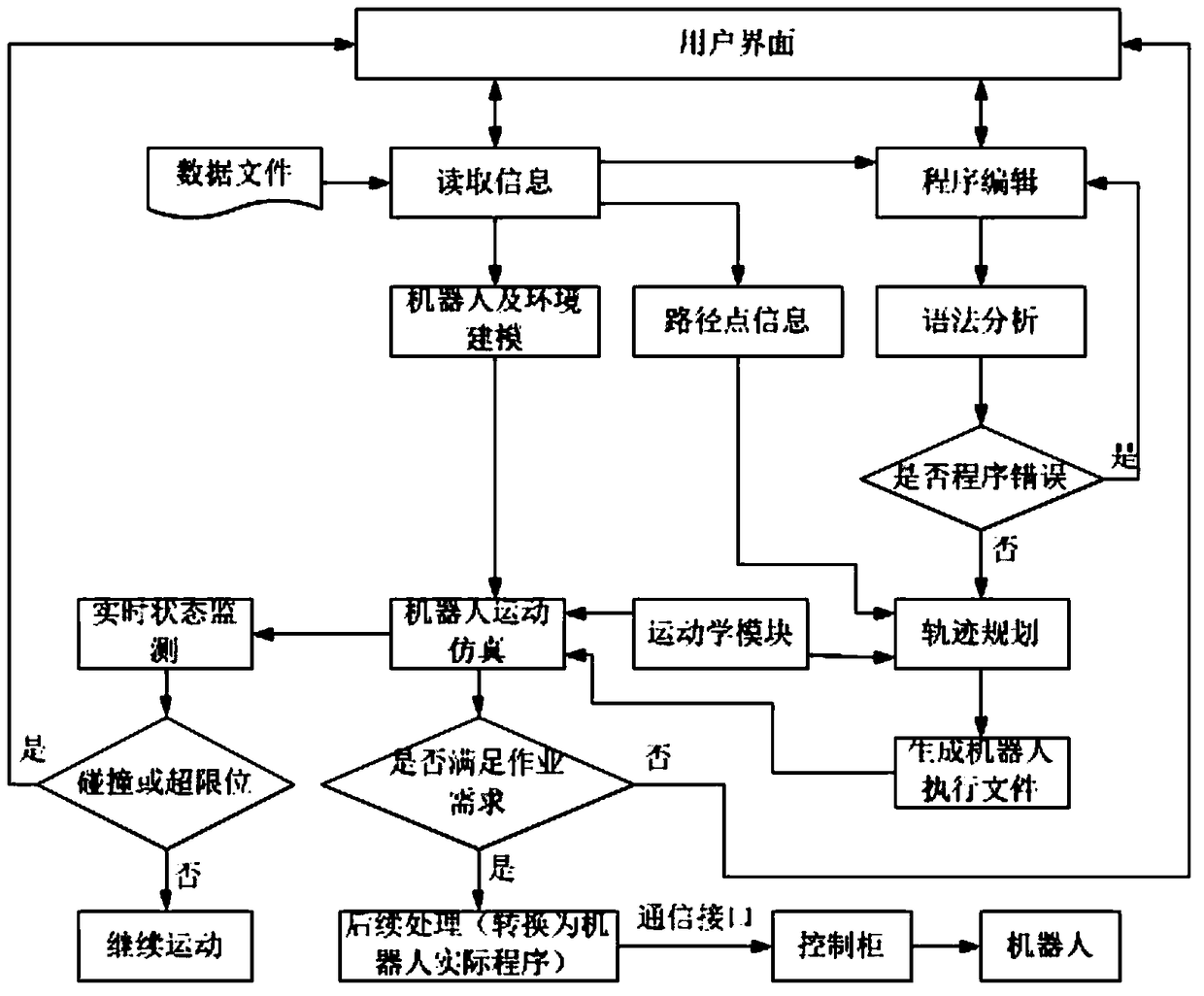

Welding robot offline programming system based on tablet computer, and offline programming method thereof

ActiveCN105786483AEasy to optimize movementEasy to acceptProgramme controlProgramme-controlled manipulatorTablet computerSimulation

The invention discloses a welding robot offline programming system based on a tablet computer, which comprises a system modeling module, a kinematics simulation module, a track planning module, an automatic programming module, a status detection module, and a communication module. The invention further discloses an offline programming method of the offline programming system. The offline programming system provided by the invention has the advantages that compared with the traditional online teaching programming system, the system adopts a human operating interface based on the Linux operating system; highly controllable edit capabilities achieve easy optimization of motions of all axes; an actual working environment is simulated, and arc welding, spot welding and other welding functions of a robot are achieved; special offline and simulation technologies facilitate program optimization, and a completed program can be directly read and adopted by the robot through a wireless network, so that the onsite verification waiting time is shortened, and errors and unnecessary risks are reduced; the cost is low, so that the system is highly acceptable by a vast number of users; the operation is simple and convenient, and the teaching effects are good.

Owner:NANJING PANDA ELECTRONICS +2

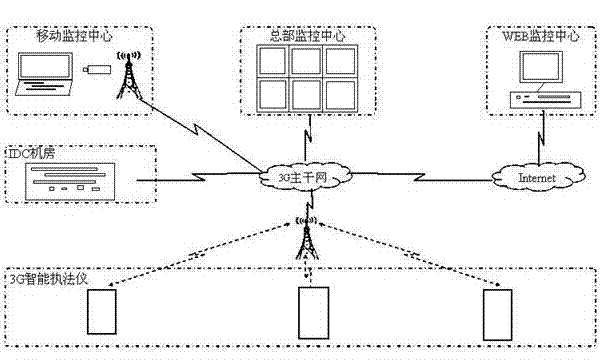

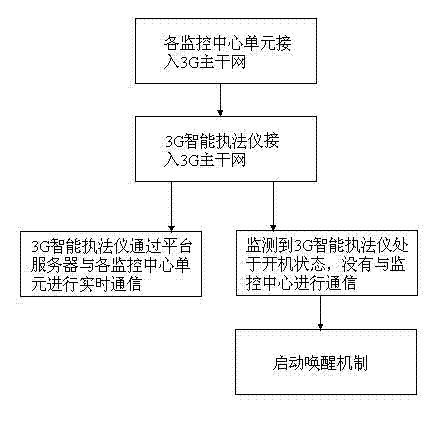

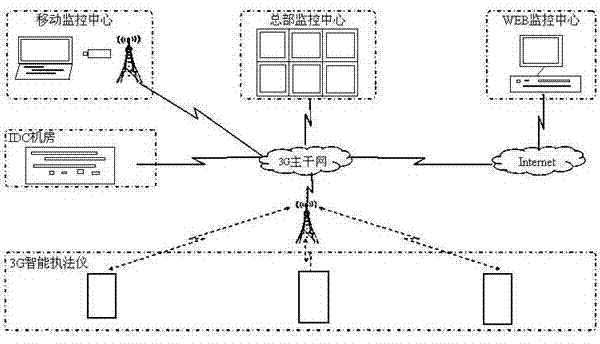

A 3G remote emergency command system

ActiveCN102263821ASolve the limitations of geographical boundariesIncrease opennessClosed circuit television systemsTransmissionCommand systemThird generation

The invention relates to the technical field of third-generation (3G) communication, and provides a 3G remote emergency direction system, which comprises a 3G intelligent recorder, an information and direction center (IDC) machine room unit, a headquarter monitoring center unit, a mobile monitoring center unit and a WEB monitoring center unit. The 3G remote emergency direction system can track and record the whole law enforcement process of a front-end police officer and timely transmit the environment and actual conditions of a law enforcement site in form of video and audio to make a direction center accurately and effectively direct the police officer and improve law enforcement efficiency.

Owner:WUHAN HUAAN SCI & TECH

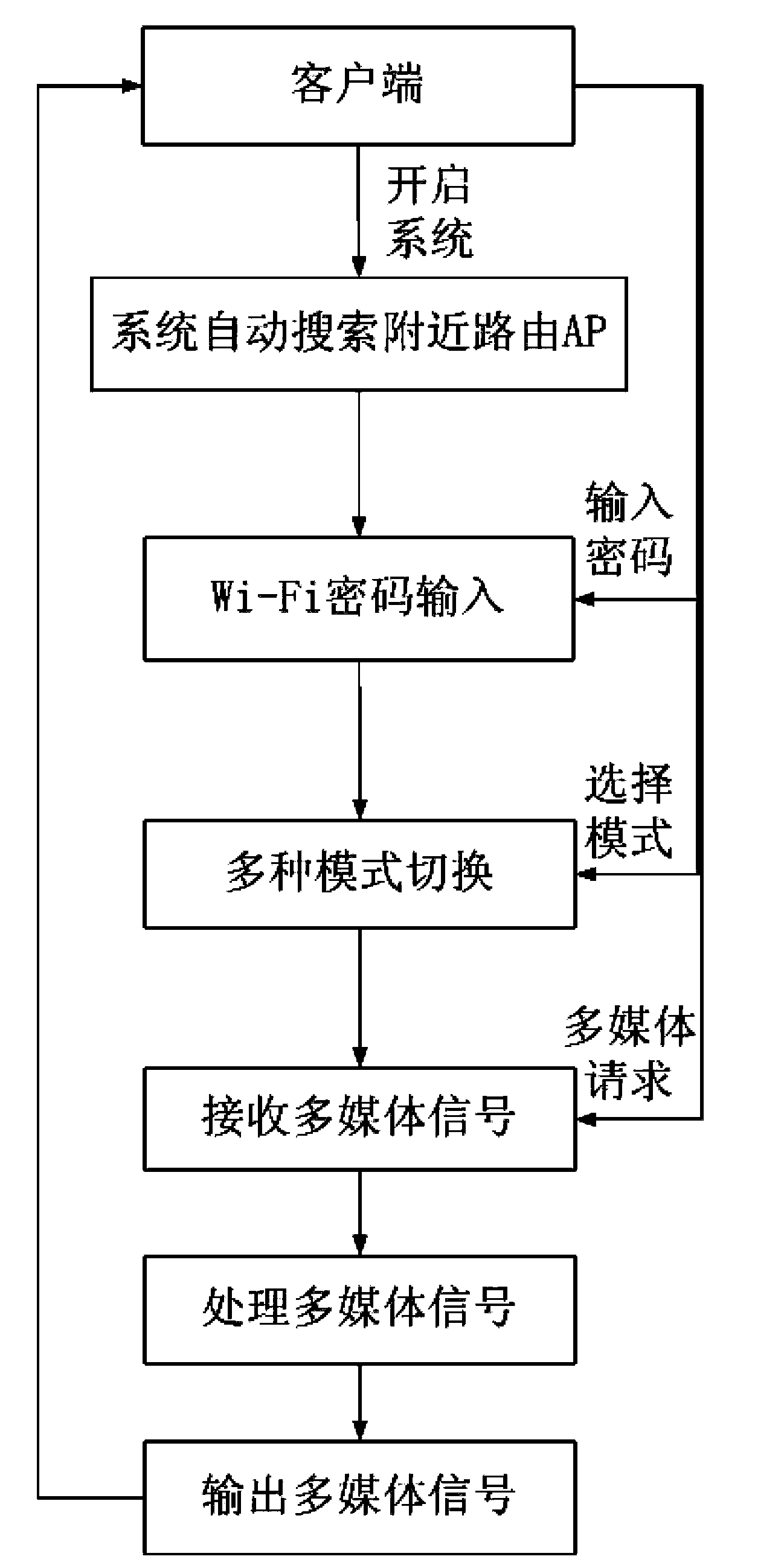

Wireless video sharing playing device and method

InactiveCN104254005AOmit inputHumanized operation interfaceSelective content distributionWireless communicationComputer hardwareRemote control

The invention relates to the technical field of players and particularly discloses a wireless video sharing playing device and method. After power is on, wireless video sharing playing software automatically searches for nearby wireless networks; a client confirms one wireless network through a wireless operating handle with physical keys or through a peripheral device with remote control software and connects to the wireless network; on a client interface, a system automatically pops out a user experience mode selection box; the client selects a user experience mode through the physical keys; the system receives a wireless multimedia signal of a media playing request of the client; a system processor decodes and processes the wireless multimedia signal; the system outputs the processed wireless multimedia signal to the client through a high-definition display. The wireless video sharing playing device and method has the advantages that integrated application of the wireless video sharing player with the physical navigation keys is achieved for the first time, plug and play is achieved, operations are simple and convenient, and a UI (user interface) is very friendly and handy.

Owner:深圳樱桃树科技有限公司

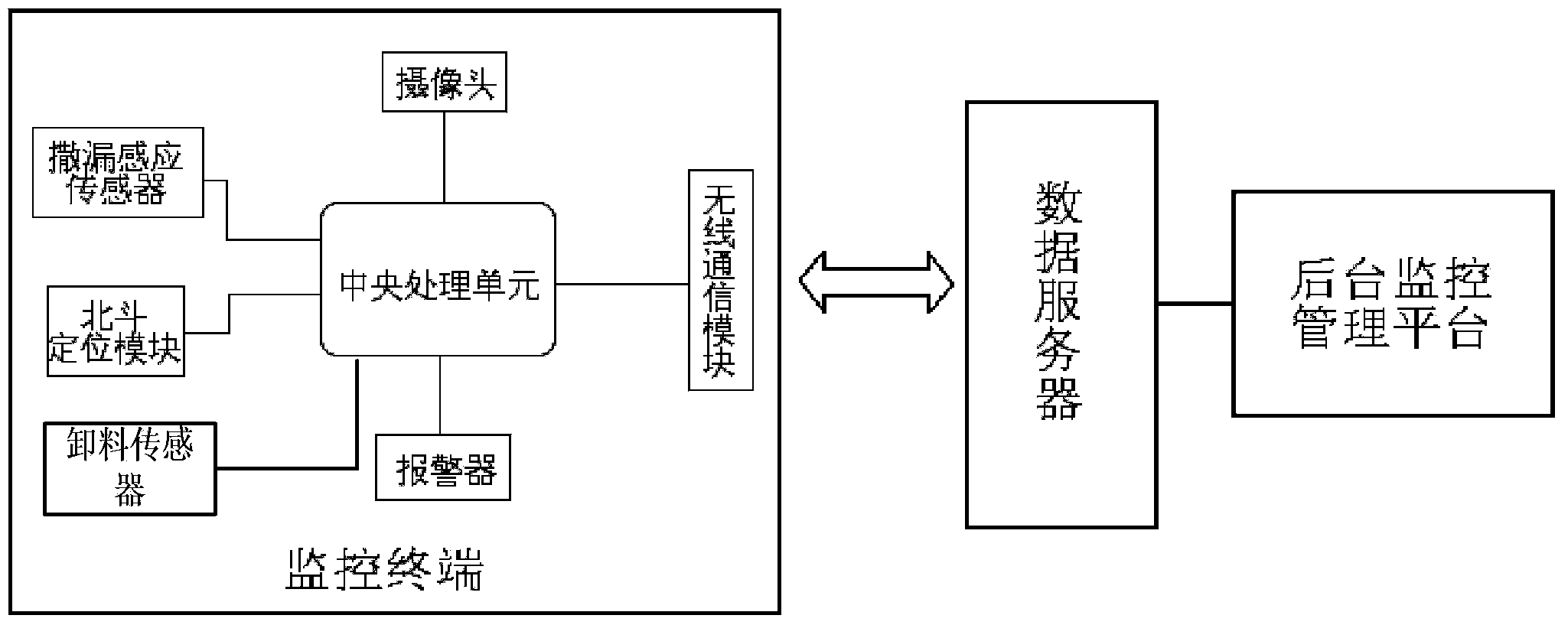

Monitoring method of vehicle leaking and sifting monitoring system

InactiveCN103473927APrecise positioningShort time to first fixDetection of traffic movementRelevant informationMonitoring system

The invention discloses a monitoring method of a vehicle leaking and sifting monitoring system. The method includes the following steps of firstly, installing a vehicle-mounted monitoring terminal on a vehicle, collecting relevant information in real time through the vehicle-mounted monitoring terminal, and then binding and sending induction information, position information and picture information to a data sever of a vehicle scheduling center to be stored through a wireless communication module; secondly, installing a monitoring and managing system on the data server, and then operating the monitoring and managing system on an operation interface of a background monitoring and managing platform; thirdly, recognizing and judging whether the induction information is the induction information indicating the occurrence of the sifting and leaking phenomenon or not or whether the induction information is discharging sensing information or not through the data server; fourthly, generating a corresponding control instruction and sending the corresponding control instruction to a central processor of the vehicle-mounted monitoring terminal through the data server according to the operation request of the monitoring and managing system so that a vehicle can be remotely monitored. The monitoring method allows real-time monitoring to be achieved, is high in work efficiency, and allows the sifting and leaking phenomenon of the muck vehicle to be effectively supervised and governed.

Owner:柳州天运寰通科技有限公司

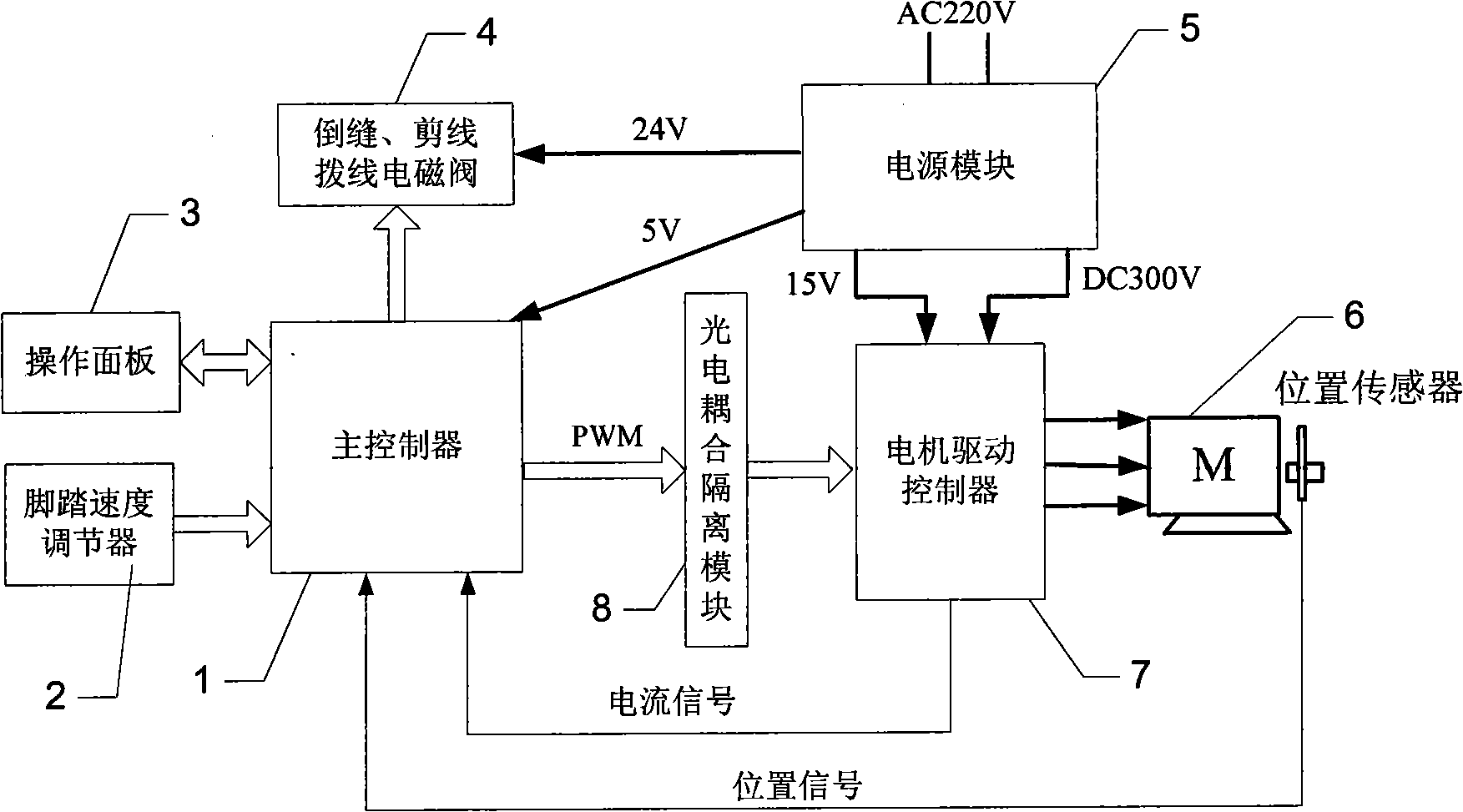

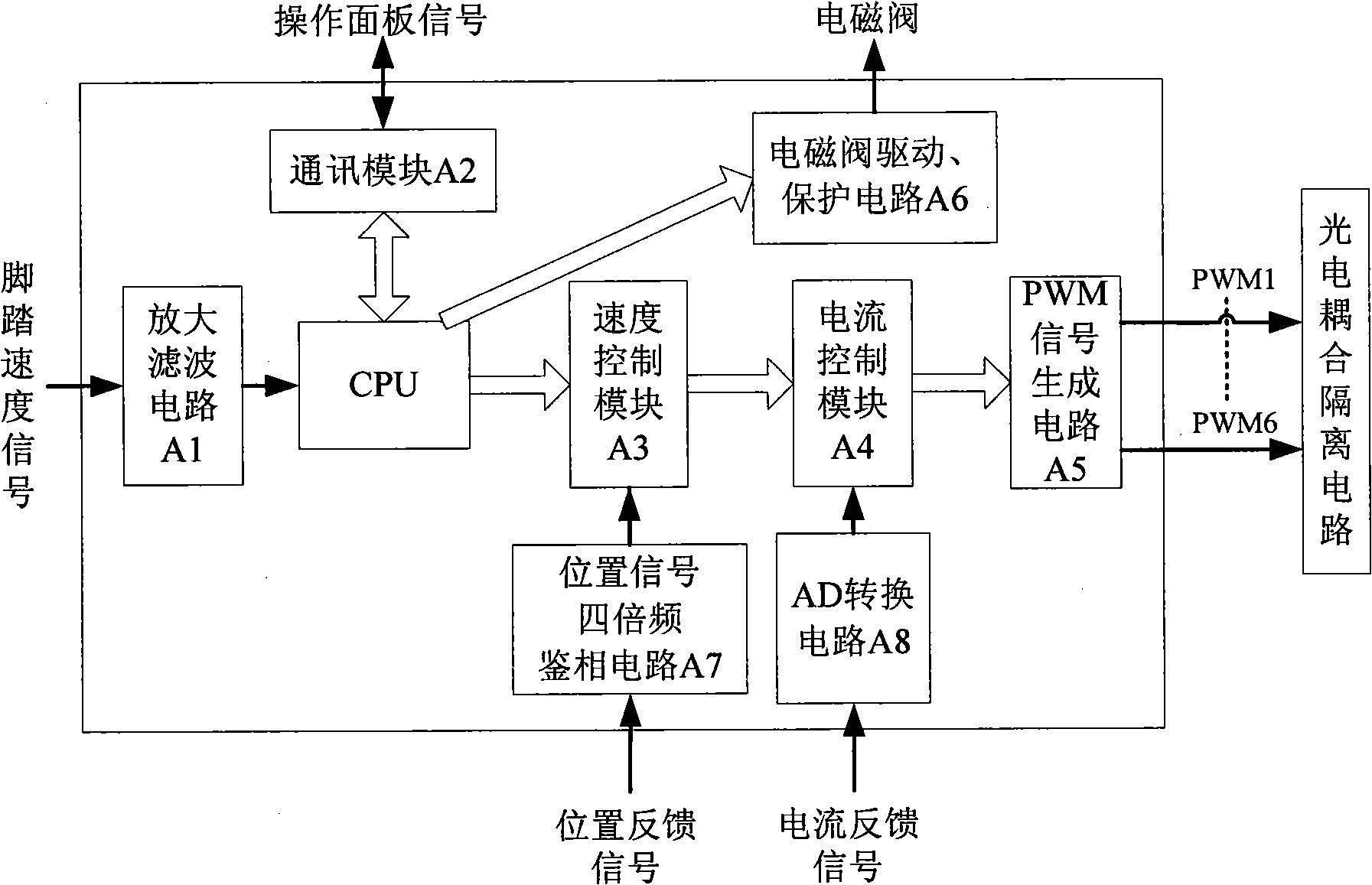

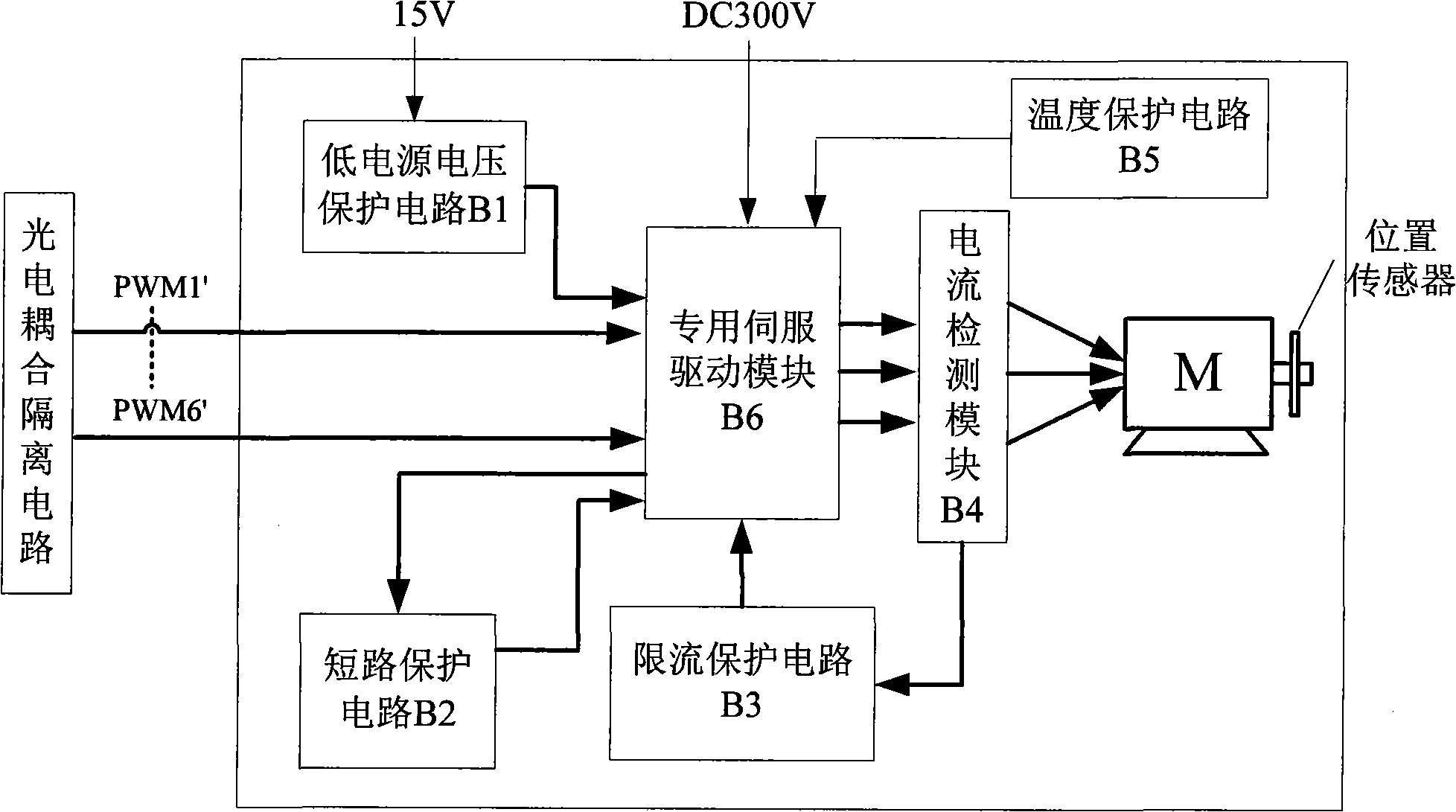

Computer control system for novel direct drive lockstitch sewing machine

InactiveCN101560720AClear structureImprove robustnessProgramme-controlled sewing machinesSolenoid valveMicroprocessor

The invention relates to a computer control system for a novel direct drive lockstitch sewing machine. The computer control system comprises a master controller, a pedal speed regulator, an operation panel, solenoid valves, a power supply module, a motor, a motor drive controller and a photocoupling isolation module. The computer control system is characterized in that the master controller consists of a microprocessor CPU, a communication module, a driving module for the solenoid valves, a speed control module and a current control module; the microprocessor CPU realizes bi-directional data communication with the operation panel by a communication module circuit, realizes control and protection over actions of the solenoid valves of the sewing machine by a solenoid valve drive circuit, and realizes variable frequency control over the motor by the speed control module and the current control module; the master controller is respectively connected with the pedal speed regulator, the operation panel, the solenoid valves and the photocoupling isolation module; and the motor drive controller consists of a special servo drive module and a current detection module.

Owner:BEIJING TIANYU TECH INNOVATION

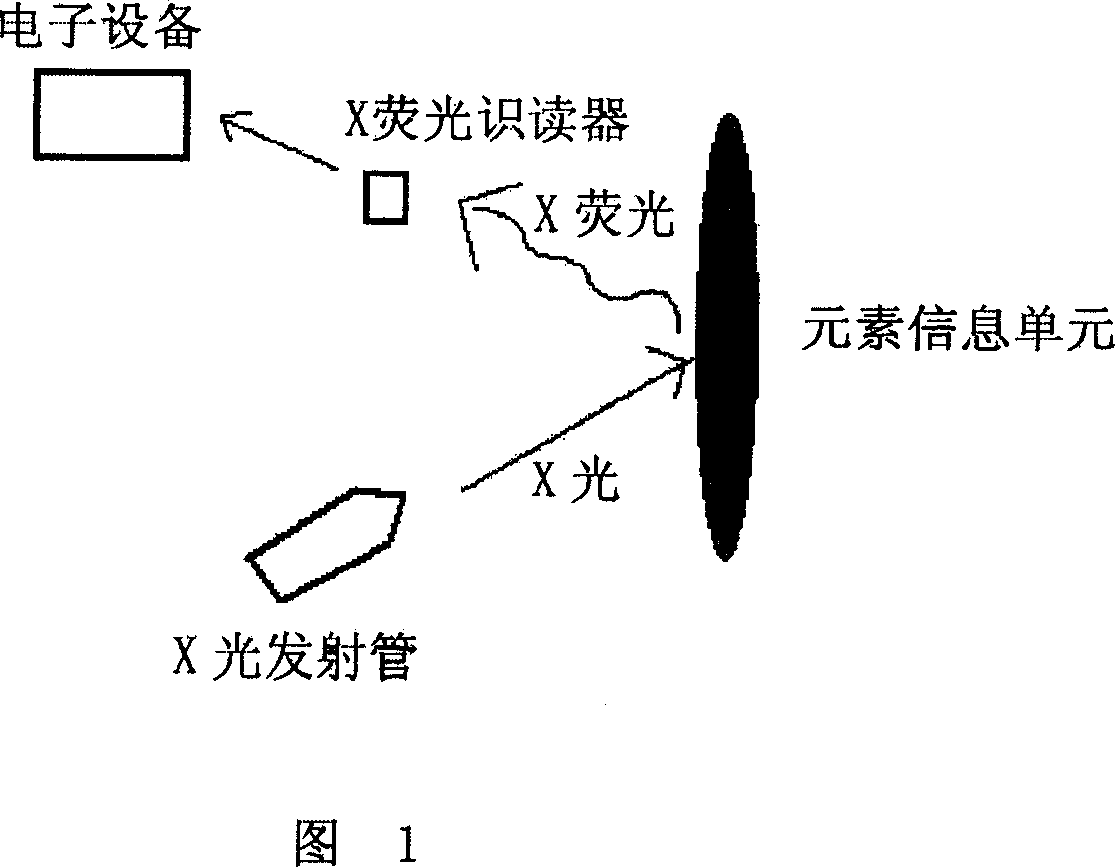

Method, apparatus and information unit for establishing, analyzing and affirming article identity information

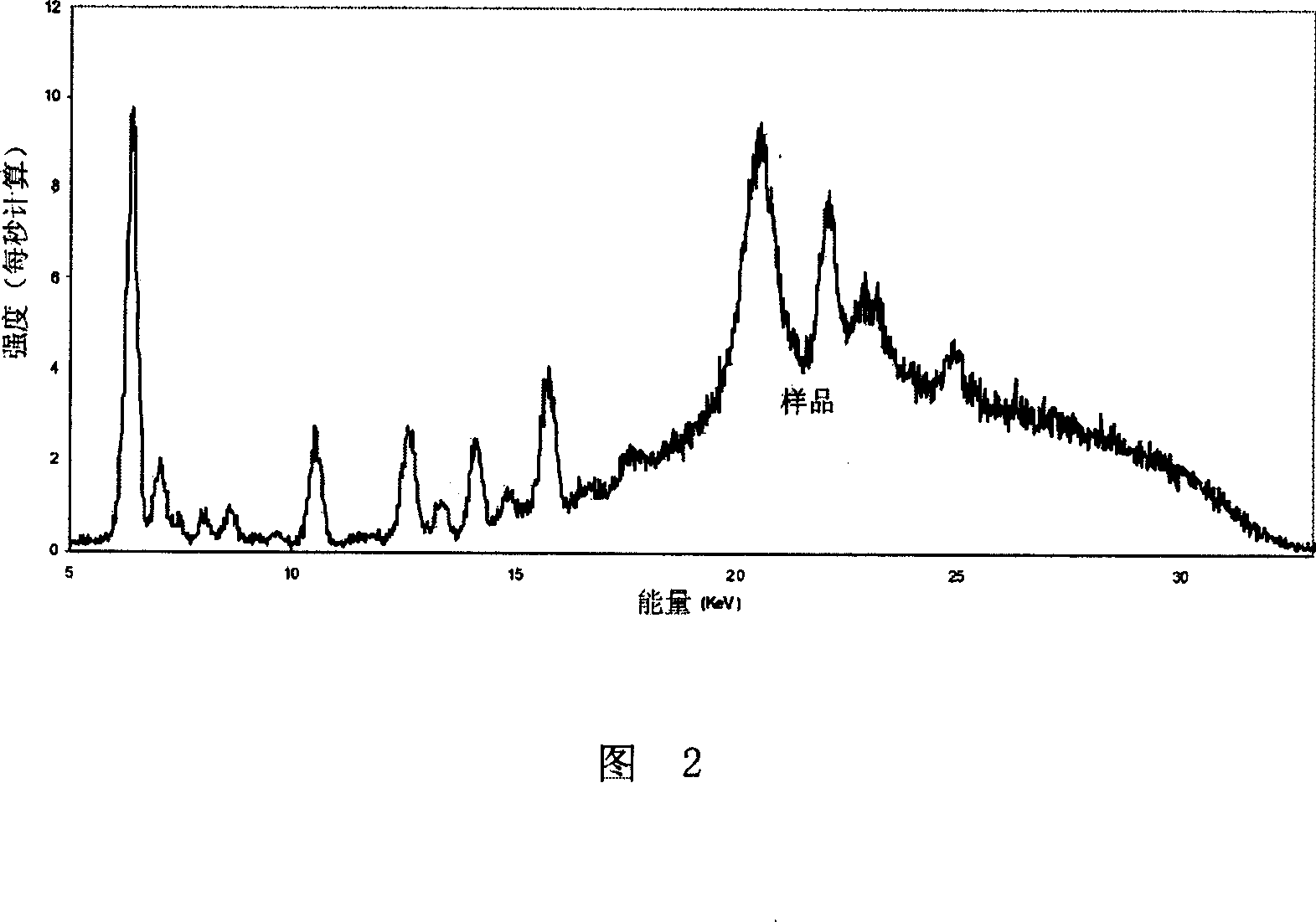

InactiveCN101078731AWon't breakAvoid breakingMaterial analysis using wave/particle radiationCharacter and pattern recognitionLogistics managementComputerized system

The invention discloses a method for building, analyzing and confirming goods identity information. Goods element in itself and setting element set on goods are sued as goods element information unit. As reading device reads the element information unit goods identity information can be built, analyzed and confirmed. The invention also provides the reading device realizing said method, the computer system connected with the reading device and said element information unit. The invention can be applied almost all materials conveniently. It can be used in goods identity authentication, safety authentication, insignia / evidence authentication, bank bill / voucher authentication, intellectual property protection, remote management, information management, duty decision, duty trace, commodities fleeing prevention, logistics monitoring, asset preservation, analysis and statistic, tort early-warning, supervision check, government procurement, door-forbidden management, file transfer and judicature basis.

Owner:TRUE PROD ID TECH BEIJING

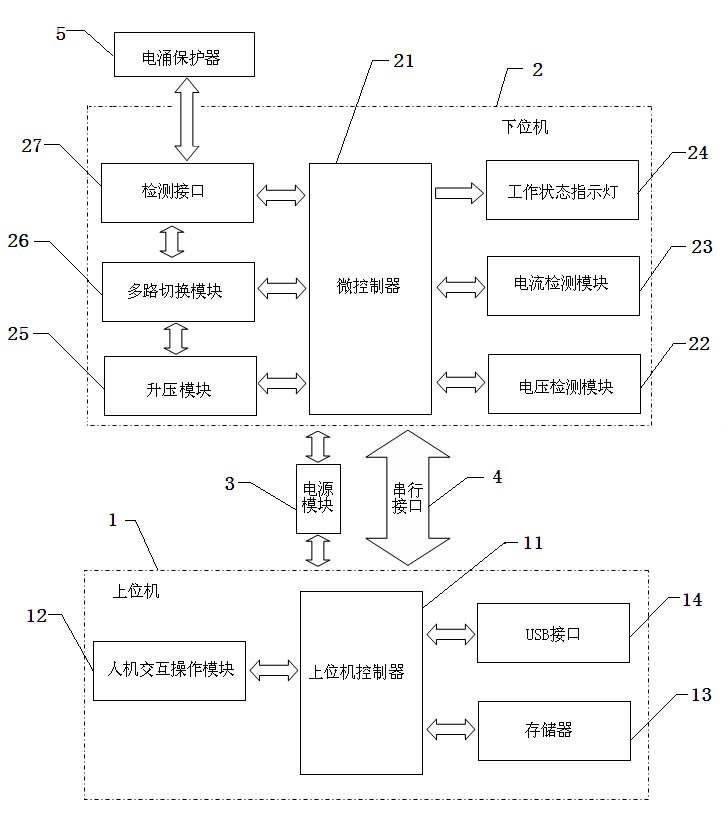

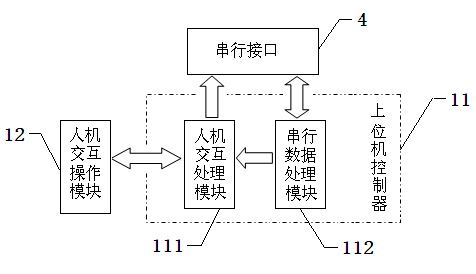

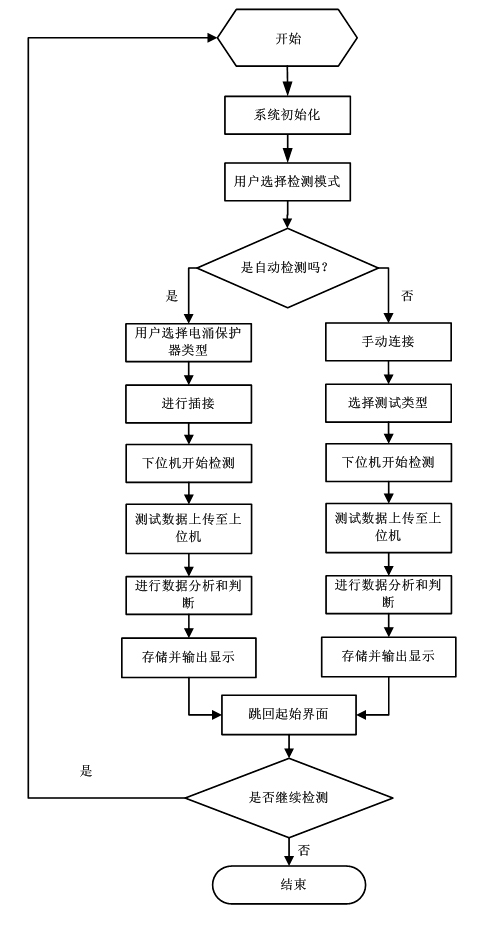

Intelligent detector for embedded system surge protection device (SPD)

ActiveCN101975902ASimple and efficient operationHumanized operation interfaceElectrical testingSurge protectorSerial port

The invention discloses an intelligent detector for an embedded system surge protection device (SPD). The intelligent detector comprises an upper computer, a lower computer, a serial interface and a power module, wherein the serial interface is connected with the upper computer and the lower computer, and the power module is respectively connected with the upper computer and the lower computer; the upper computer comprises an upper computer controller, a memory and a man-machine interactive operation module, and the memory and the man-machine interactive operation module are respectively connected with the upper computer controller; the lower computer comprises a microcontroller as well as a voltage detection module, a boosting module, a multipath switching module and a detection interface which are respectively connected with the microcontroller; and the multipath switching module is respectively connected with the boosting module and the detection interface. The intelligent detector for the embedded system SPD has the advantages of high automaticity, simple and convenient operation, humanized operation, convenient carrying and the like, and can be widely used in the field of detection on the lightning protection performance of the SPD.

Owner:北京清网华科技股份有限公司

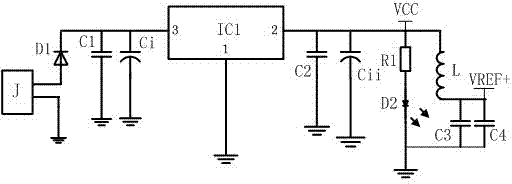

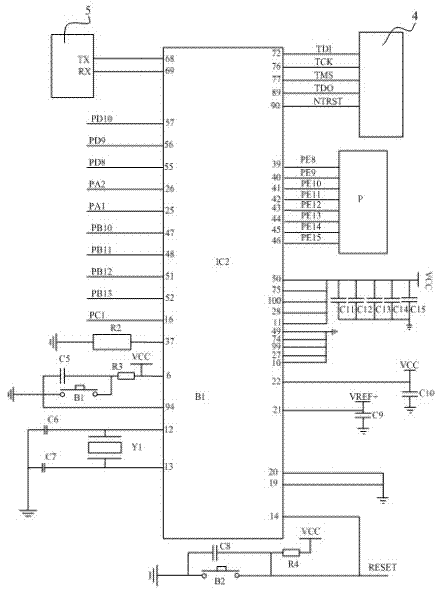

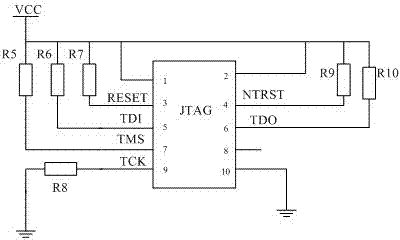

Serial port to Ethernet control device based on STM32

InactiveCN102387054AIntegrity guaranteedGuaranteed reliabilityEnergy efficient ICTData switching by path configurationCapacitanceInterconnectivity

The invention relates to a serial port to Ethernet control device based on STM32. The control device comprises: a power supply circuit, a micro-control unit circuit, a JTAG debugging interface circuit, a serial port communication interface circuit and an Ethernet physics interface transceiver control circuit. The power supply circuit comprises: a power supply voltage stabilization chip, a double pin power supply connector, a rectifier diode, a light emitting diode, an inductor, a chip resistor, two tantalum capacitors and four ceramic capacitors. The micro-control unit circuit comprises: a STM32 interconnectivity processor, an expansion pin, a crystal oscillator, two buttons, the three chip resistors and the eleven ceramic capacitors. The Ethernet physics interface transceiver control circuit comprises: an Ethernet physics interface transceiver control chip, an RJ45 interface, an active crystal oscillator, the tantalum capacitor, the sixteen chip resistors and nine ceramic capacitors. The control device has advantages of a small volume, low costs and low power consumption. And telnet can be achieved so as to perform real time operation and monitoring.

Owner:杭州先驱海洋科技开发有限公司

Vehicle leaking and sifting monitoring system

InactiveCN103472805ALow costPrecise positioningRoad vehicles traffic controlProgramme total factory controlElectronic control systemMonitoring system

The invention discloses a vehicle leaking and sifting monitoring system. The vehicle leaking and sifting monitoring system is mainly composed of a monitoring terminal, a data server and a background monitoring and managing platform. The monitoring terminal comprises a central processing unit, a leaking and sifting inductive sensor, a discharging sensor, a compass positioning module, an alarm, a camera and a wireless communication module, wherein the leaking and sifting inductive sensor, the discharging sensor, the compass positioning module, the alarm, the camera and the wireless communication module are connected with the central processing unit, and the central processing unit of the monitoring terminal is further connected with a vehicle electronic control system. The central processing unit of the monitoring terminal collects sensing information of the leaking and sifting inductive sensor, sensing information of the discharging sensor and position information of the compass positioning module in real time, transmits the sensing information and the positioning information to the data server to be stored through the wireless communication module in real time, and analyzes the sensing information and the position information according to an instruction request of a monitoring and managing system. The monitoring system is low in invested equipment cost, can conduct real-time monitoring, is high in work efficiency and can effectively supervise and govern the sifting and leaking phenomenon of a muck vehicle.

Owner:柳州天运寰通科技有限公司

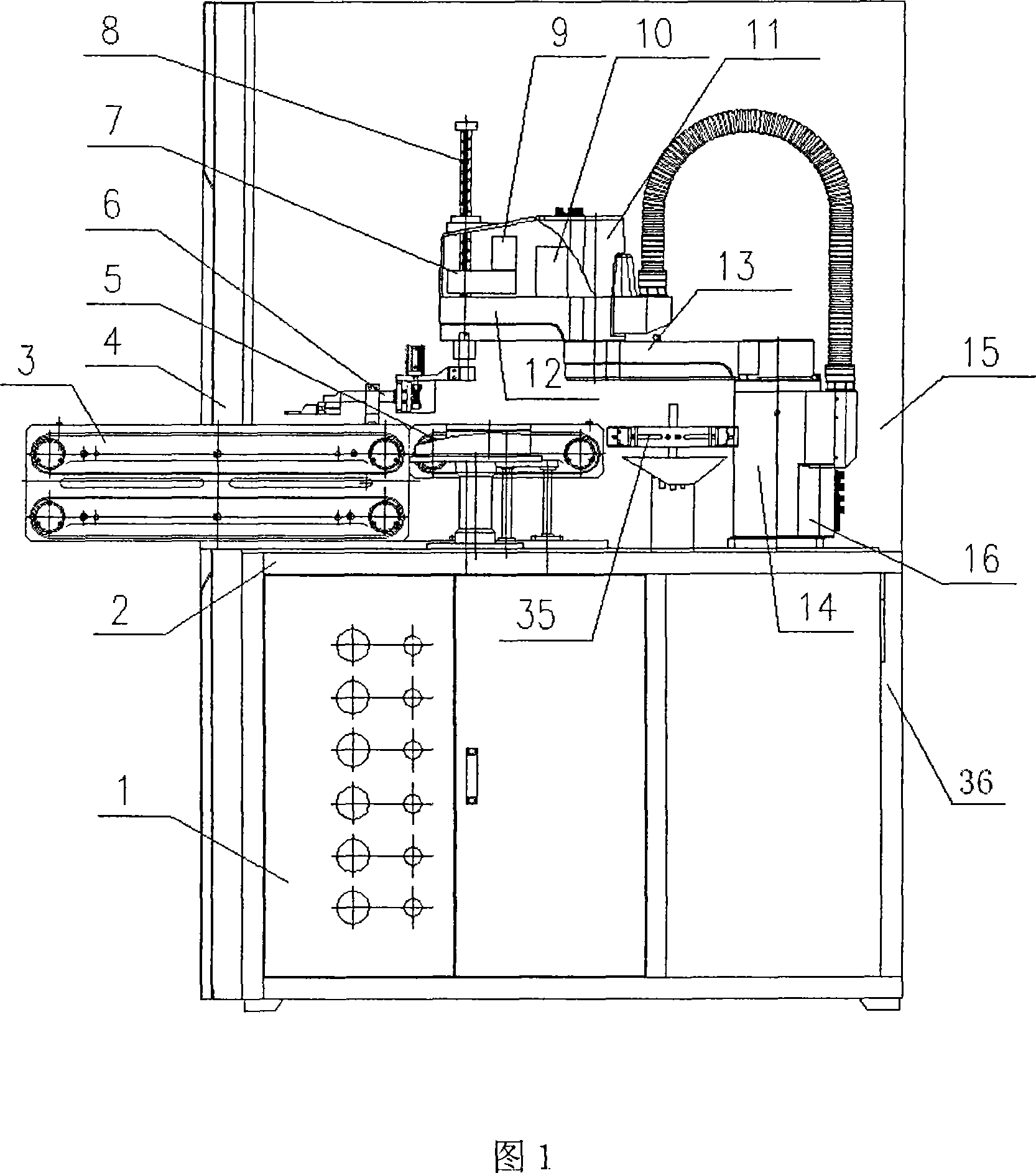

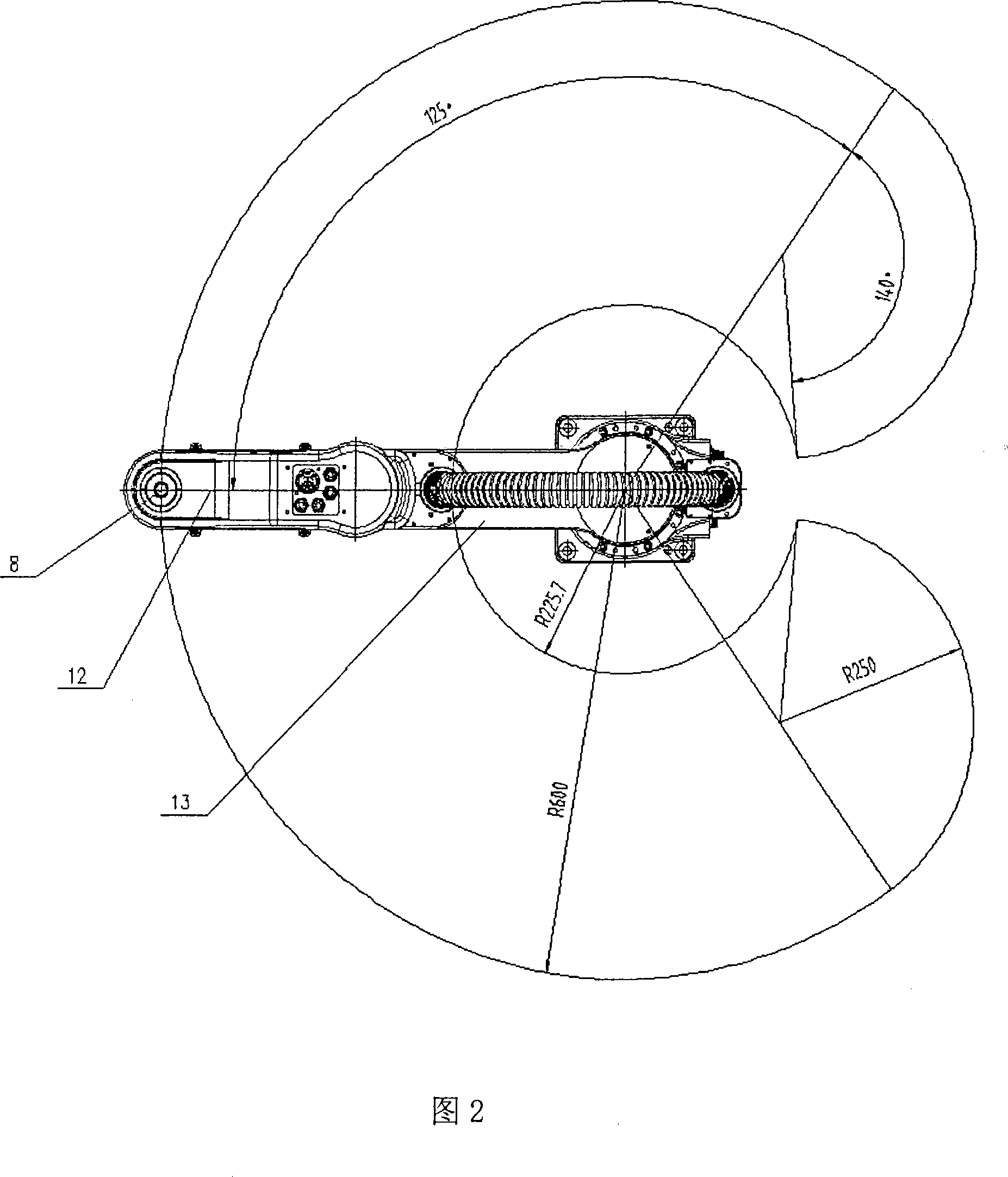

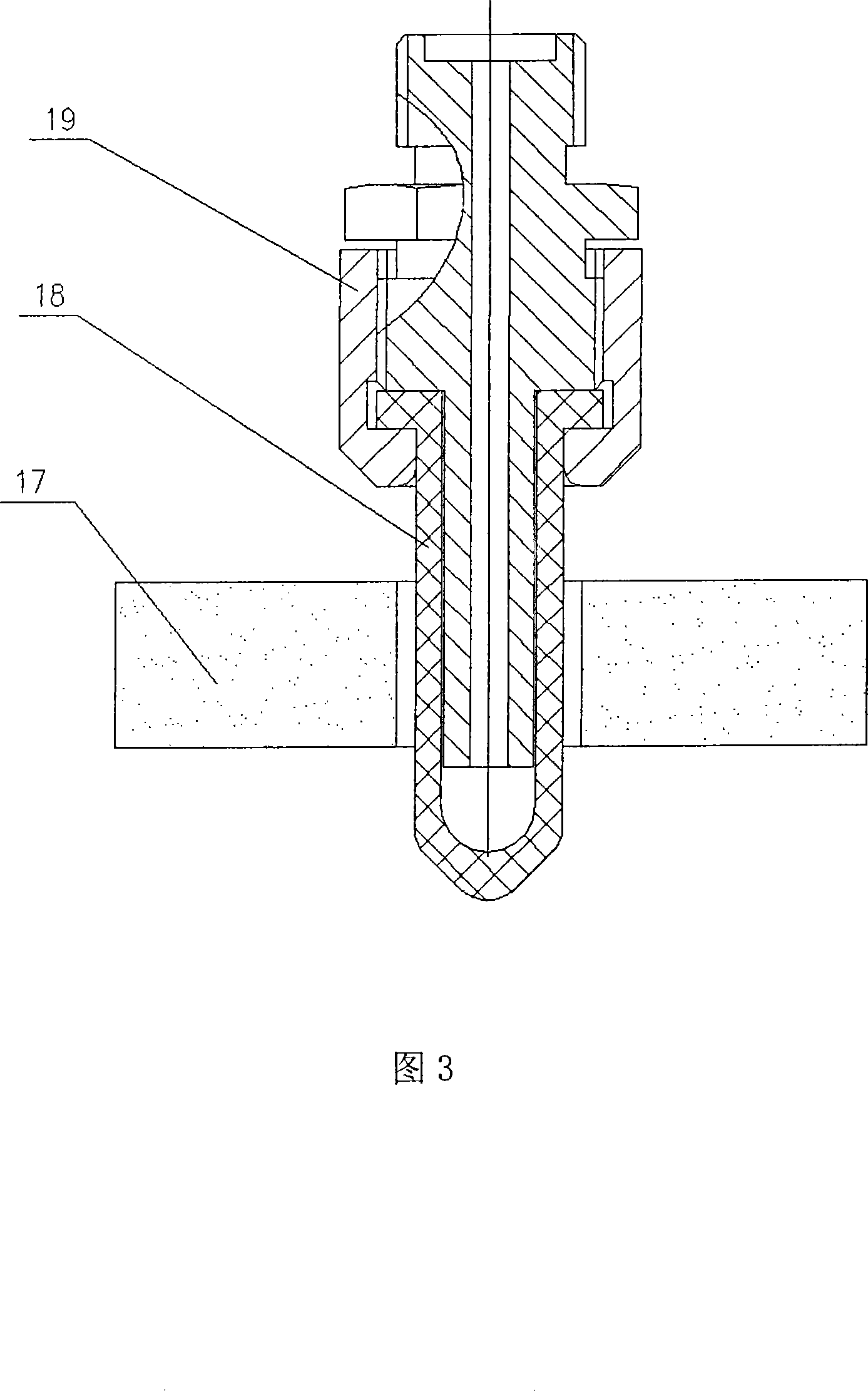

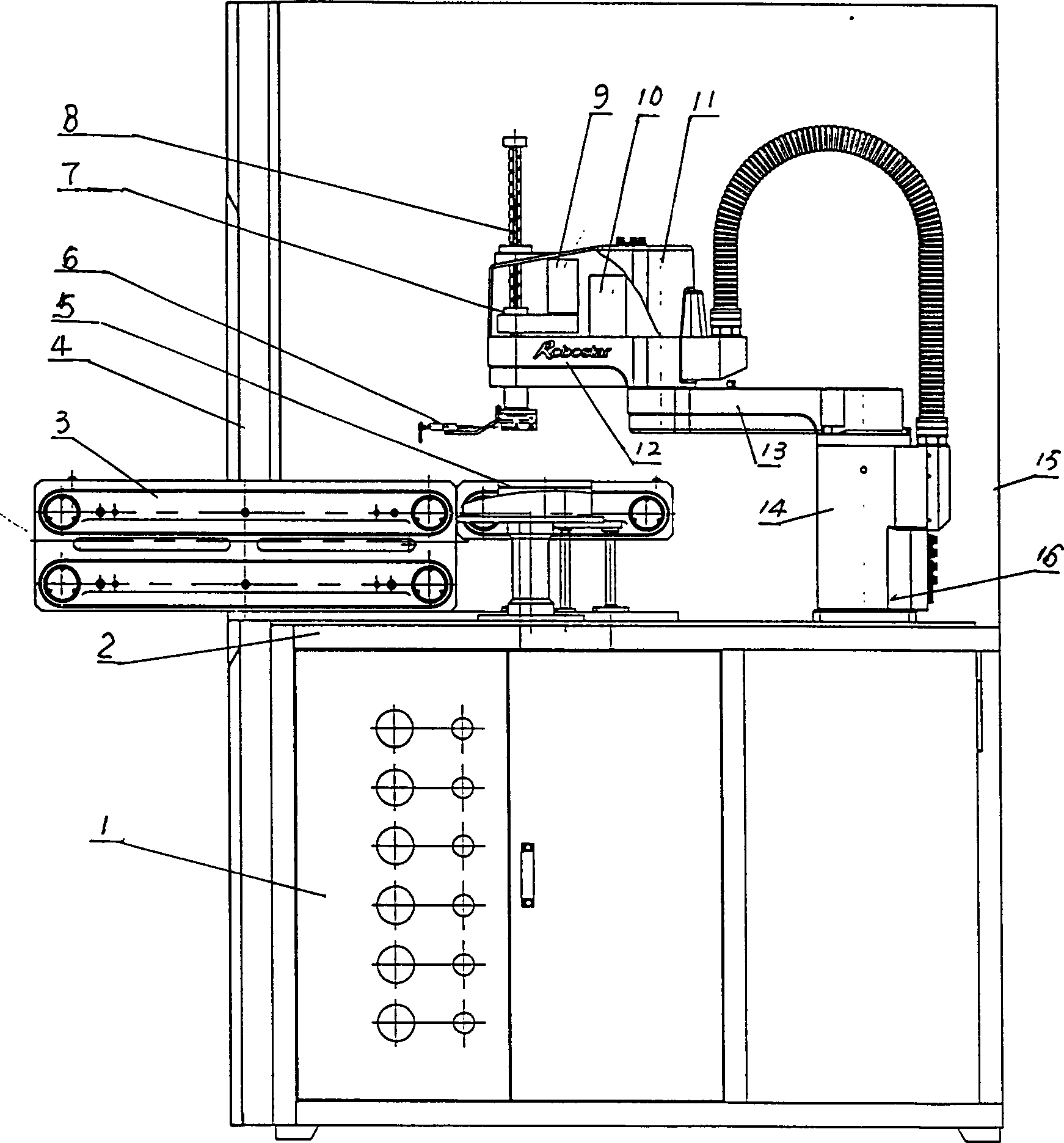

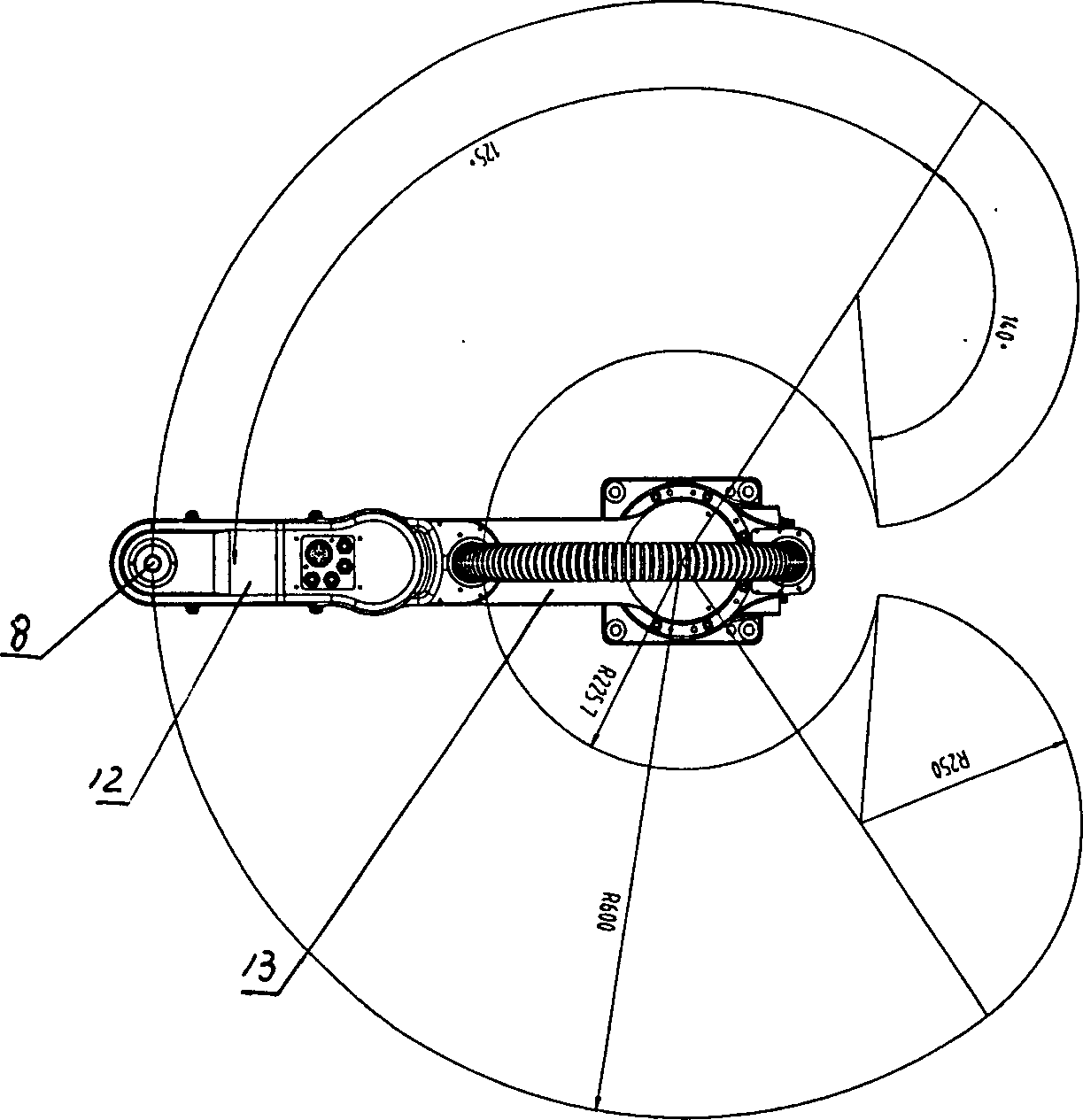

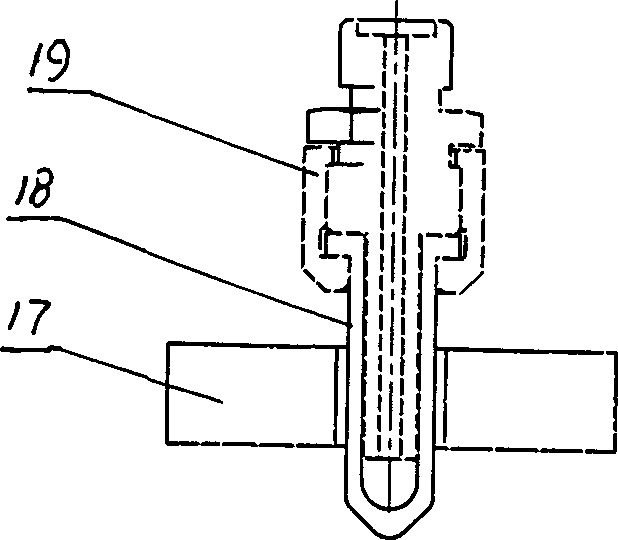

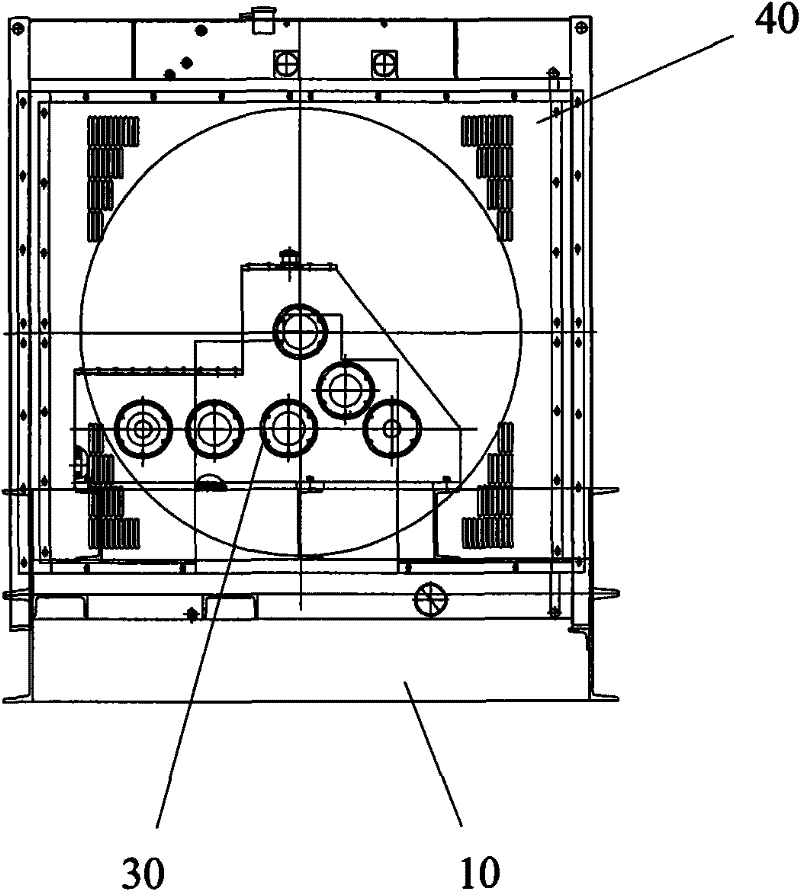

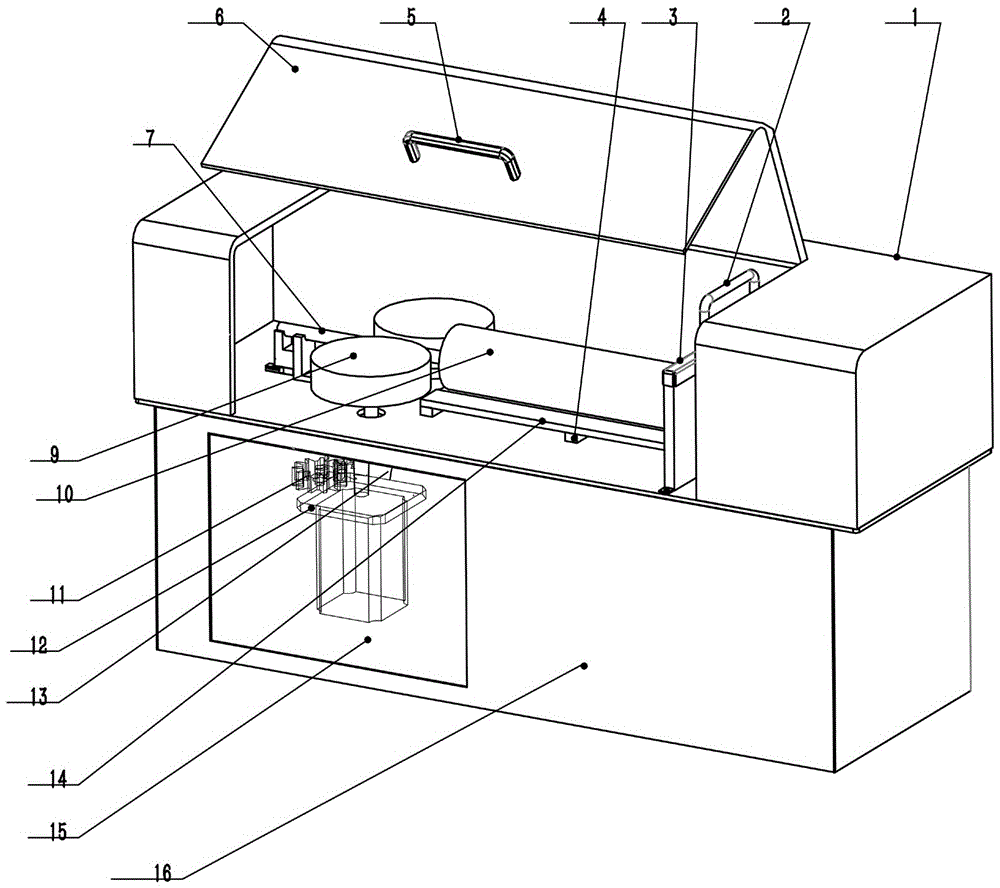

Fully-automatic hard alloy spherical-teeth robot

InactiveCN101214646AAdjust directionAdjust densityProgramme-controlled manipulatorGripping headsRotational axisDrive motor

An automatic hard alloy spheral tooth robot of the present invention is a device which is used for picking, deburring, weighing, sorting and stacking before the sintering of hard alloy spheral teeth in the field of powder metallurgy. The structure includes a stander, a deburring mechanism, an electronic scale, a multi-joint robot and an automatic plate-replacing mechanism, and wherein, the multi-joint robot, the electronic scale and the automatic plate-replacing mechanism are mounted on the panel of the stander. The multi-joint robot comprises a base seat, three horizontal joints, a Z-axis motion mechanism and grasping fingers, wherein, the three horizontal joints includes an A-axis horizontal joint, a B-axis horizontal joint and a W-axis horizontal joint, the Z-axis motion mechanism is provided with a servo motor (Z) and a ballscrew nut, and a ballscrew thread is arranged on a rotary shaft (W). The grasping fingers are arranged on the lower end of the rotary shaft (W) (also called as Z axis) on the bottom of the Z-axis motion mechanism. The automatic plate-replacing mechanism consists of driving motors (No.1, No.2, No.3), synchronous dentiform conveyer belts (No.1, No.2, No.3), setter plates and an air cylinder.

Owner:南京东部精密机械有限公司

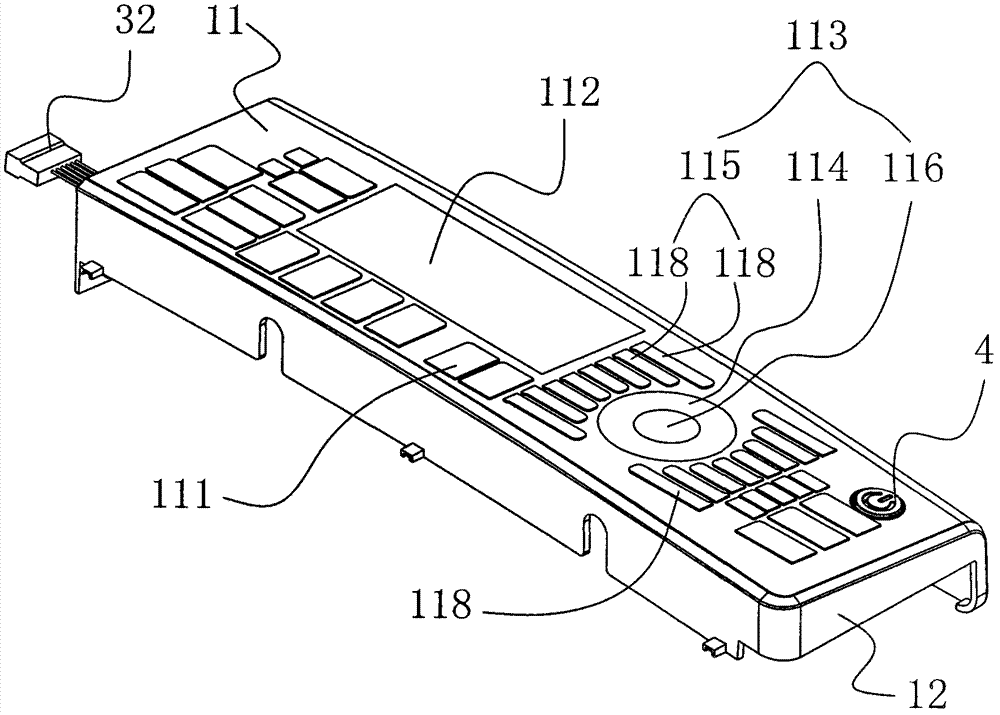

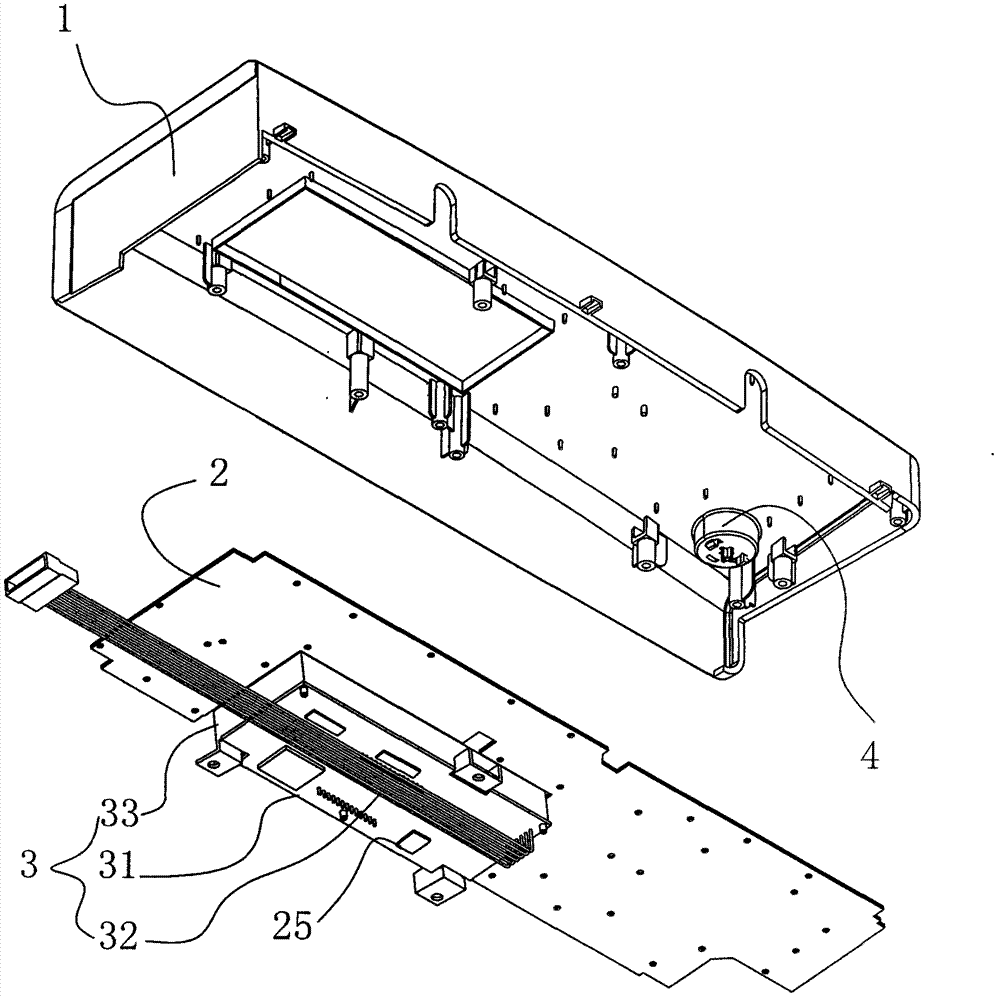

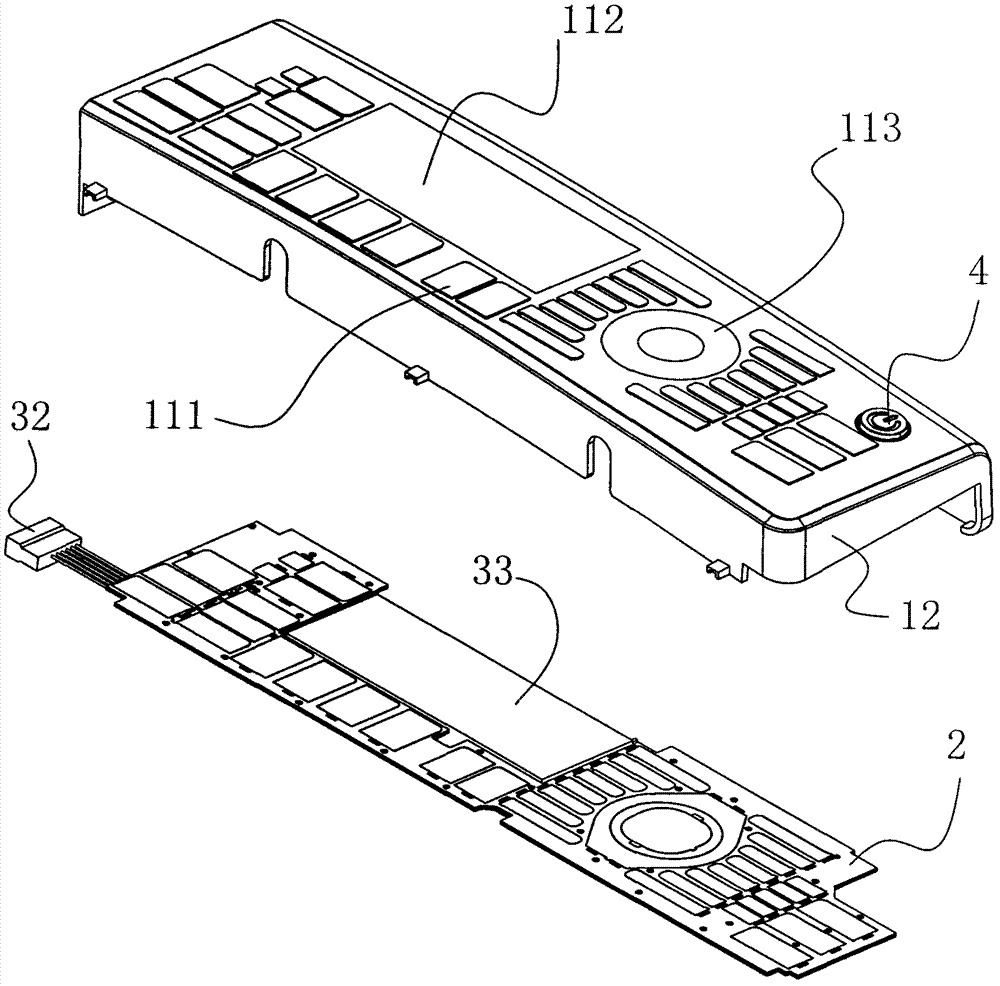

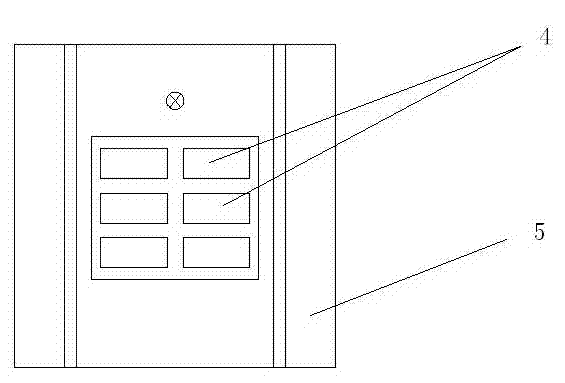

Touch panel

ActiveCN102768588AImprove experienceRaise the gradeInput/output processes for data processingControl circuitLight emitting device

A touch panel comprises a main panel and a luminous touch module installed below the same. The main panel is provided with a combined touch area and a plurality of display subunits corresponding to the same. The luminous touch module at least comprises a first circuit board and a touch control circuit. The first circuit board is provided with a plurality of continuously arranged touch sensors correspondingly below the combined touch area and light emitting devices correspondingly below the display subunits. The touch sensors can be used for sensing a proximity signal for an operator and transmitting the sensing signal to the touch control circuit to control lighting states of the light emitting devices below the display subunits. The touch panel can provide a flexible and more humanized operation interface for improving user experience so that electric products are upgraded.

Owner:DONGGUAN MOLEX INTERCONNECT +1

Full-automatic blank arranging machine

InactiveCN1788944AReduce positioning accuracyEasy to modifyProgramme-controlled manipulatorGripping headsRotational axisEngineering

The automatic stock arranging machine is used for picking up, weighing and stacking hard alloy blade stock to be sintered in powder metallurgy industry. The structure includes a frame, an electronic balance, a multi-joint robot, and an automatic plate changing mechanism. The electronic balance, the multi-joint robot and the automatic plate changing mechanism are installed on the frame panel. The multi-joint robot includes one pedestal, three horizontal joints, one Z-axis motion mechanism and picking fingers. The three horizontal joints include an A-axis one, a B-axis one and a W-axis one. The Z-axis motion mechanism includes servo motor and ball lead screw nut, and the ball lead screw in the W-axis is fitted with the ball lead screw nut, so that the rotation shaft W is driven with the Z-axis servo motor to move up and down. The automatic plate changing mechanism includes three driving motors, three toothed conveying belts, a sinter bearing plate and a cylinder.

Owner:南京东部精密机械有限公司

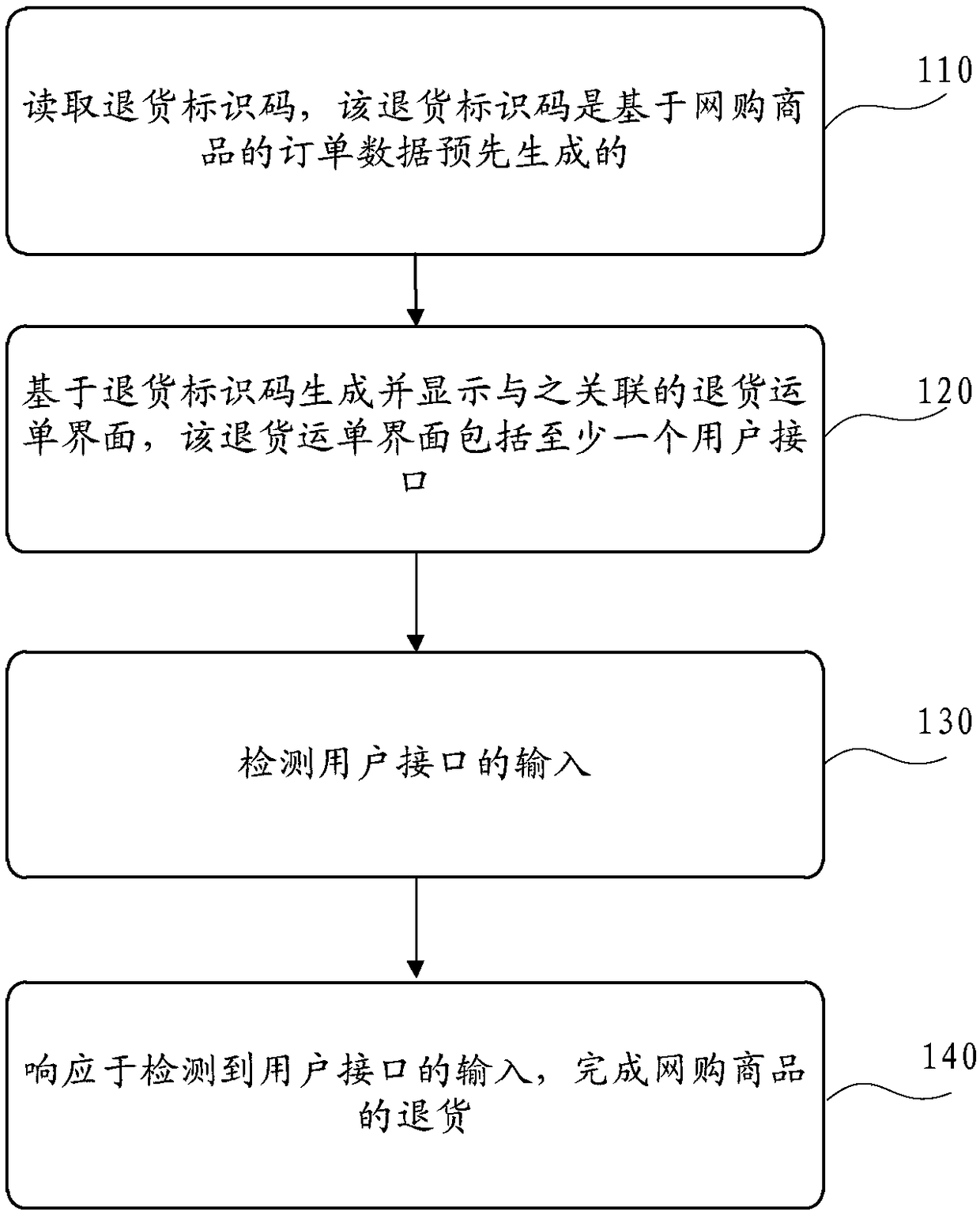

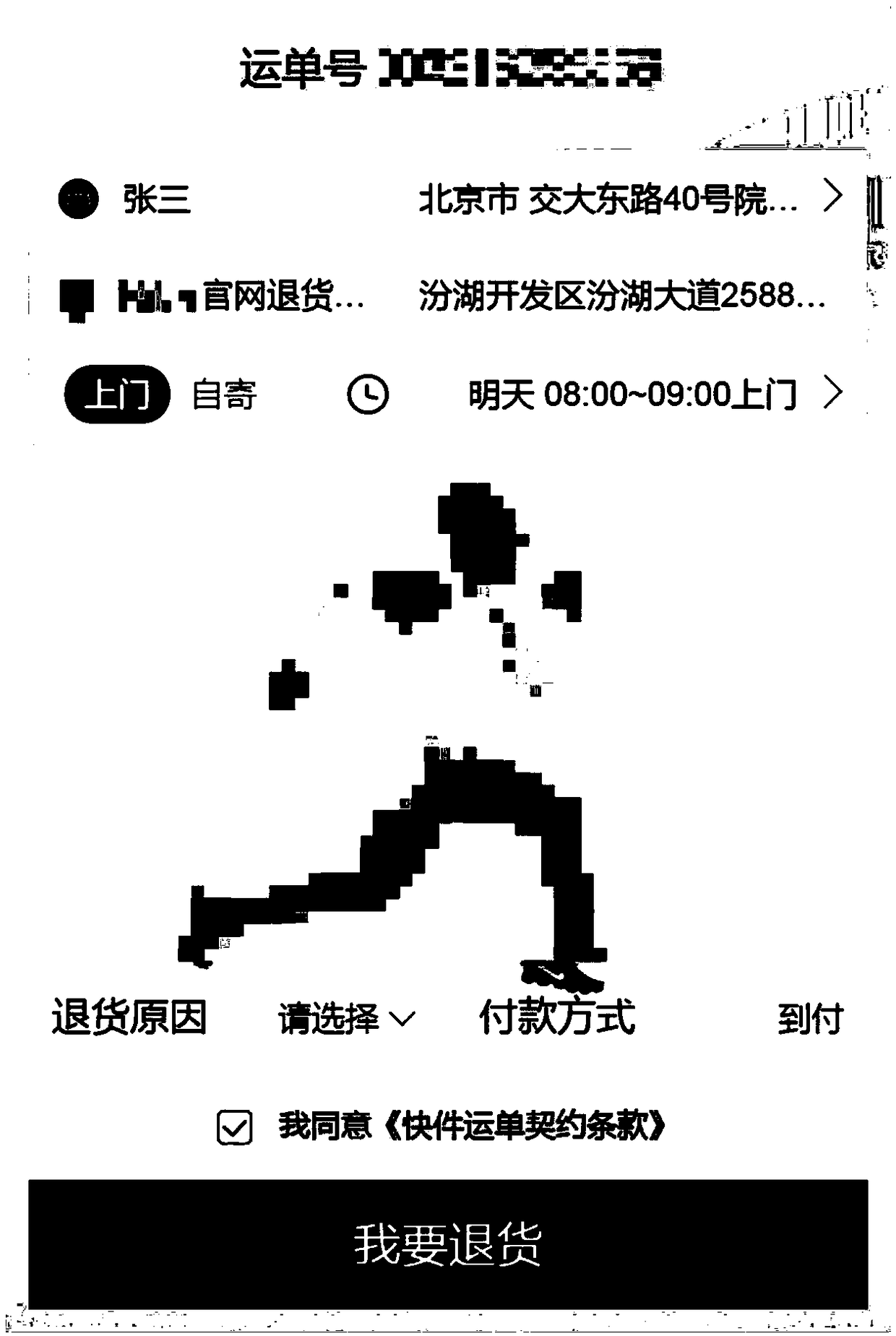

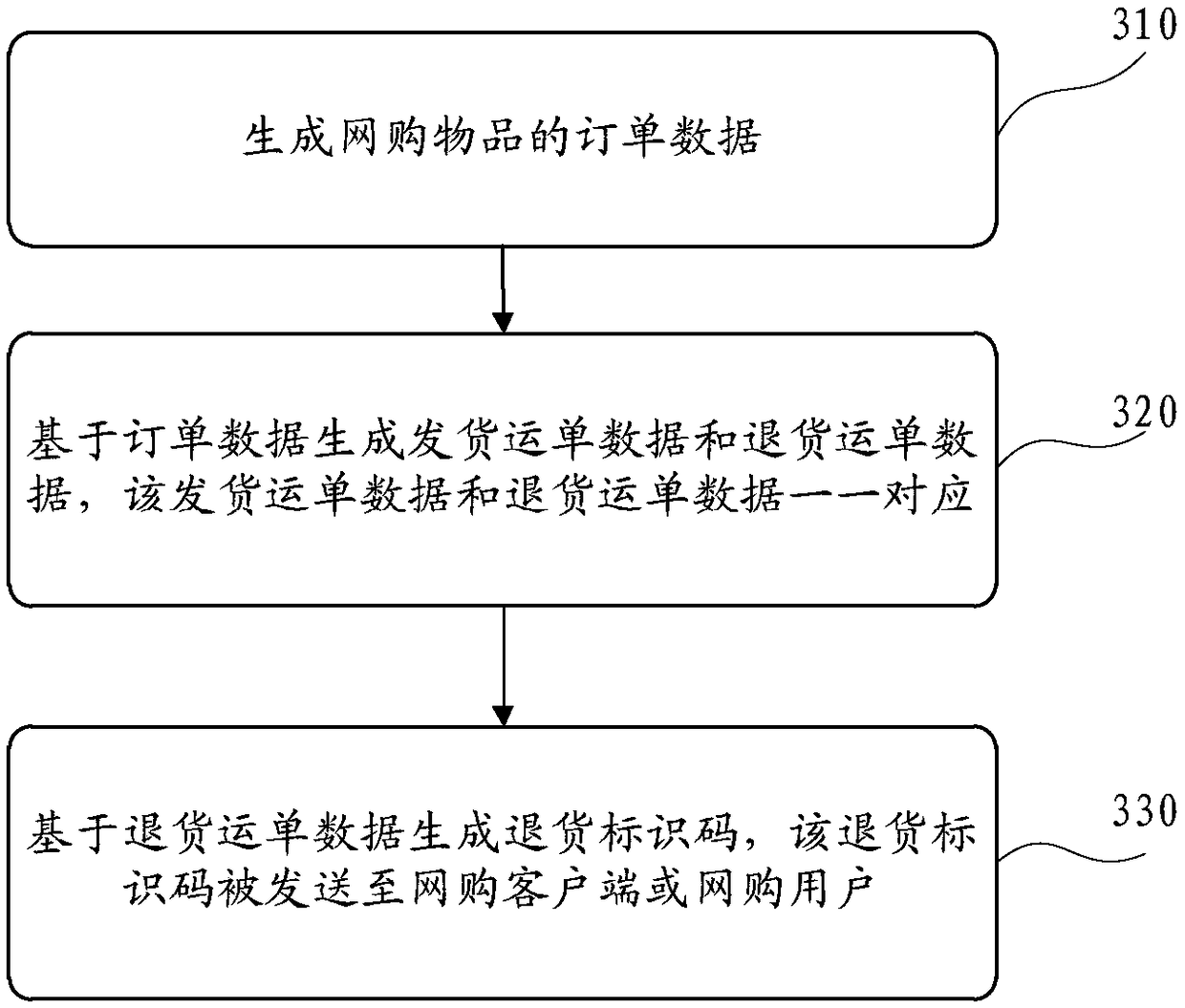

Return code generation and return method, device and apparatus, and storage medium thereof

ActiveCN109325776AAvoid repeated dictationEasy to operateBuying/selling/leasing transactionsData miningUser interface

A return code generation and return method, device and apparatus and storage medium thereof are disclosed. The method comprises the following steps of: reading a return identification code. Wherein the return identification code is generated in advance based on the order data of online shopping goods; generating and displaying an associated return waybill interface based on the return identification code, the return waybill interface including at least one user interface; detecting an input of a user interface; in response to detecting an input of a user interface, completing a return of online shopping merchandise. According to the technical proposal of the embodiment of the present application, the situation that the user or the courier worker repeatedly dictates the consignment note data generated on the merchant side is avoided, and also the tedious operations such as manually filling in the consignment note to be sent to the merchant, is avoided, thereby improving the user's experience degree.

Owner:SF TECH

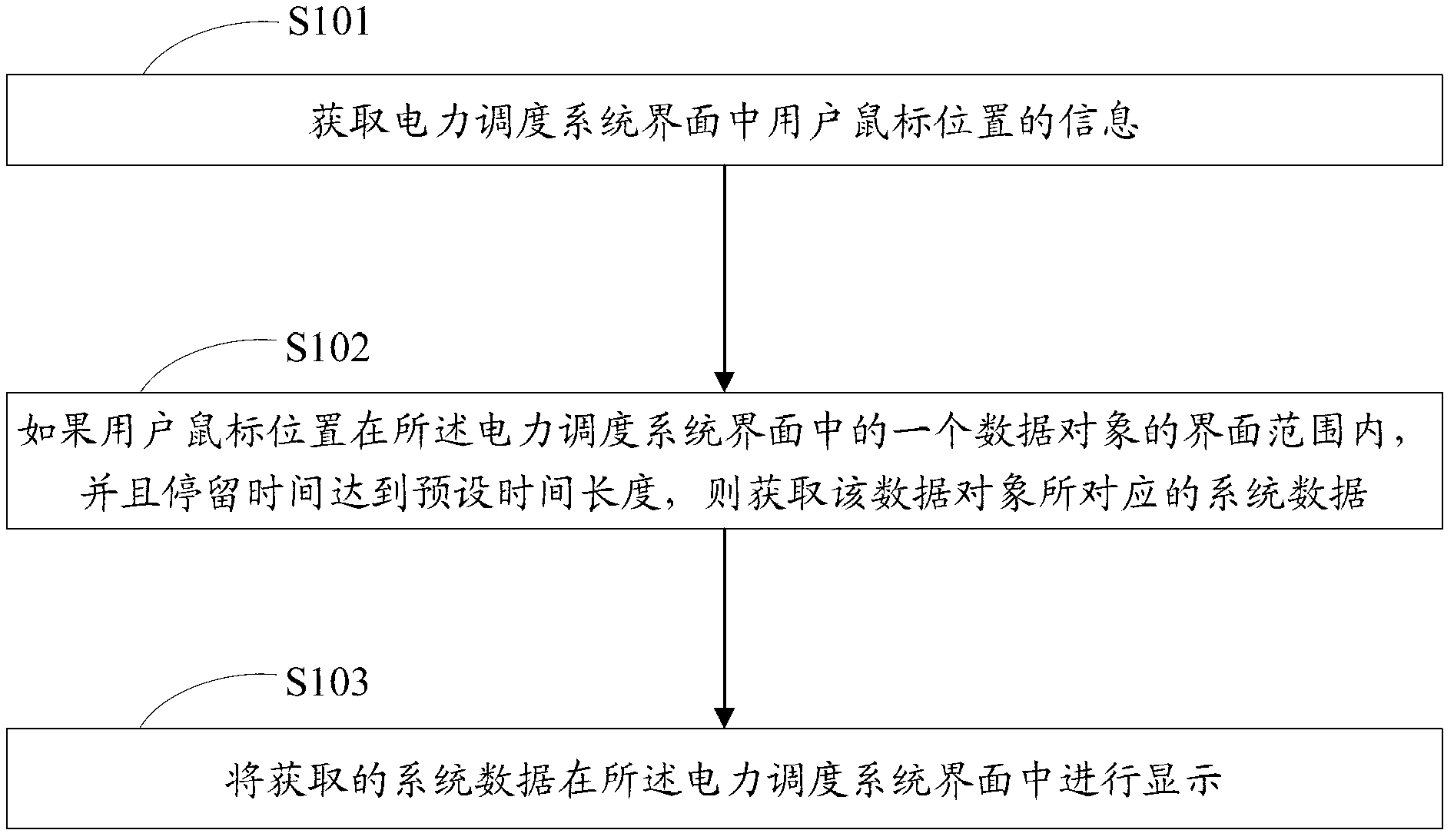

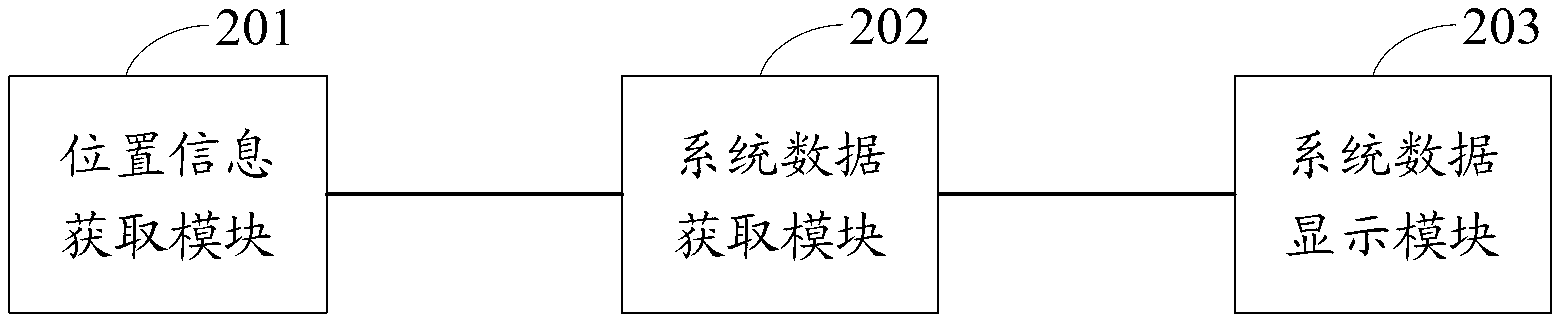

Data display method and device for power dispatching system

InactiveCN102799362AImprove efficiencyReduce stepsInput/output processes for data processingData displayRetention time

The invention discloses a data display method for a power dispatching system. The method comprises the following steps of: acquiring information of a user mouse position in a power dispatching system interface; if the user mouse position is in an interface range of a data object in the power dispatching system interface and the retention time reaches the preset time span, acquiring system data corresponding to the data object; and displaying the acquired system data in the power dispatching system interface. Moreover, the invention also discloses a data display device for the power dispatching system. The data display device comprises a position information acquisition module, a system data acquisition module and a system data display module. By the method and the device, operating steps of data display can be effectively reduced, efficiency when a user consults the data of the power dispatching system is greatly improved, the system is operated quickly by the user, and the operating interface of the system is humanized.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

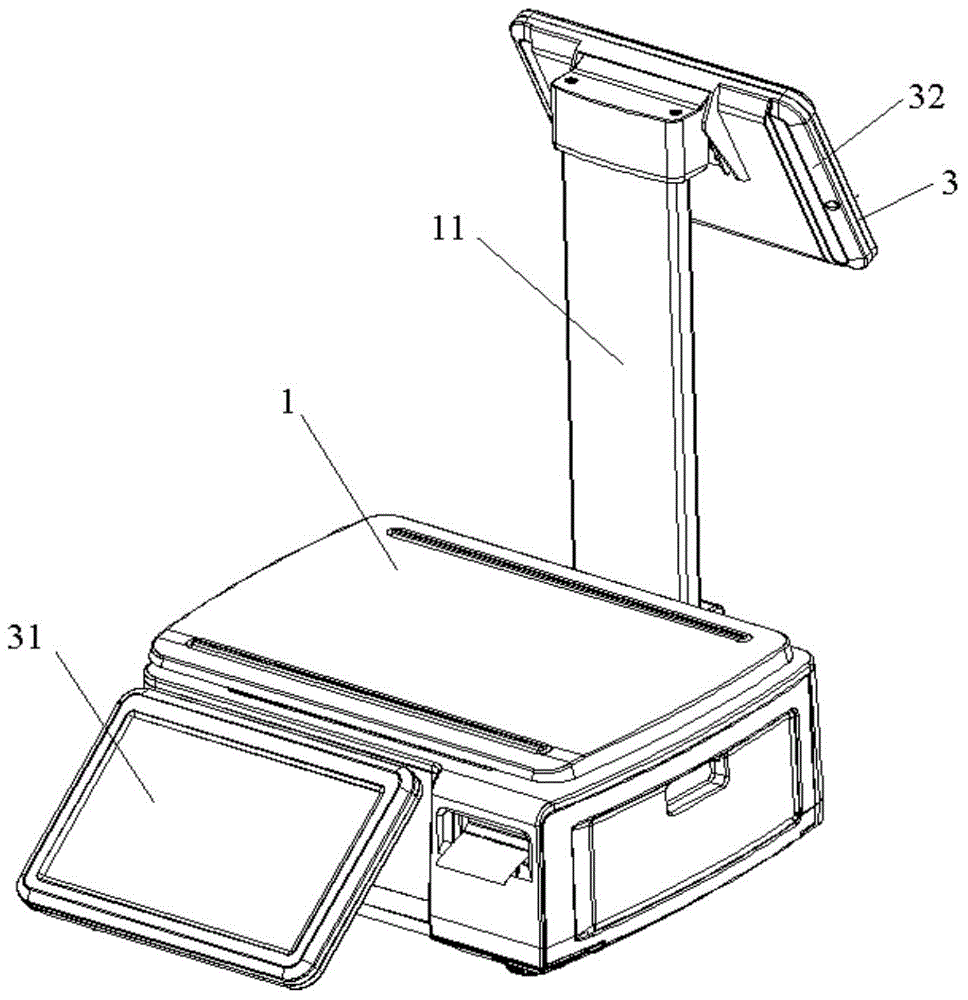

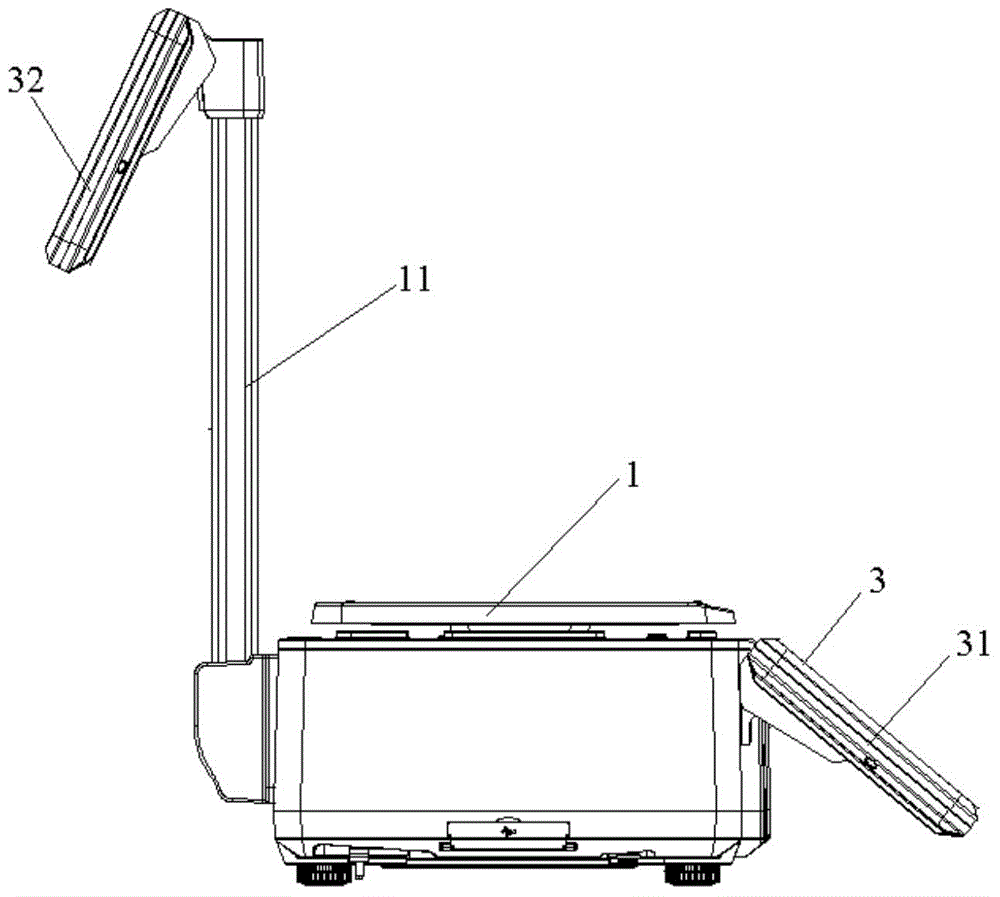

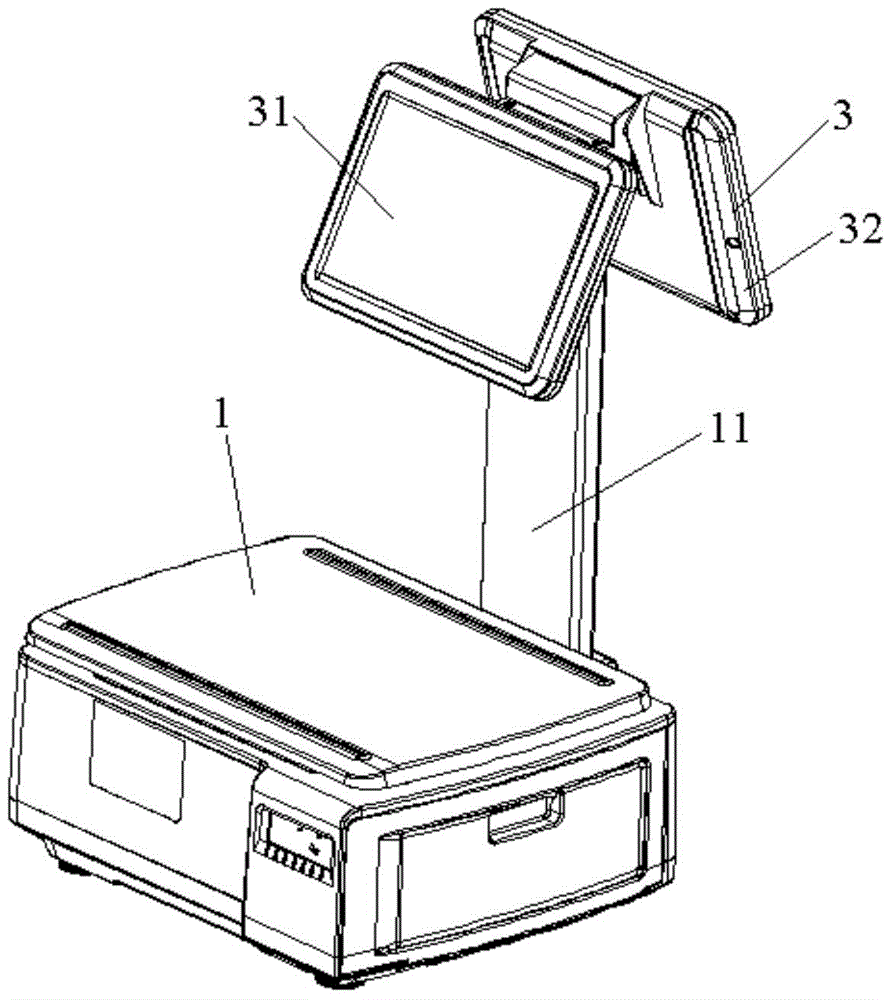

Bar code scale

InactiveCN104897263AThe operation interface is moreHumanized operation interfaceSpecial purpose weighing apparatusPush-to-type operationComputer science

Disclosed in the invention is bar code scale comprising a scale body, a sensor arranged inside the scale body, and an operation display module arranged outside the scale body. The operation display module contains an operating terminal and a client display terminal; the operating terminal uses a touch screen; and the client display terminal is connected with the scale body movably. According to the invention, the touch-screen operating terminal is used for replacing the traditional key type operating terminal, so that the operation interface is humanized; the identification capability is high, management becomes convenient, the operation is simple, and the usage convenience of the bar code scale is substantially improved. Meanwhile, because of the client display terminal movably connected with the scale body, the position and display angle of the client display terminal can be adjusted according to actual demands, so that people with different heights can observe the weighing data clearly and conveniently. Therefore, the bar code scale has advantages of reasonable and exquisite design, stable and reliable effect, and simple and convenient usage and can meet actual requirements of different users on various occasions.

Owner:台衡精密测控(昆山)股份有限公司

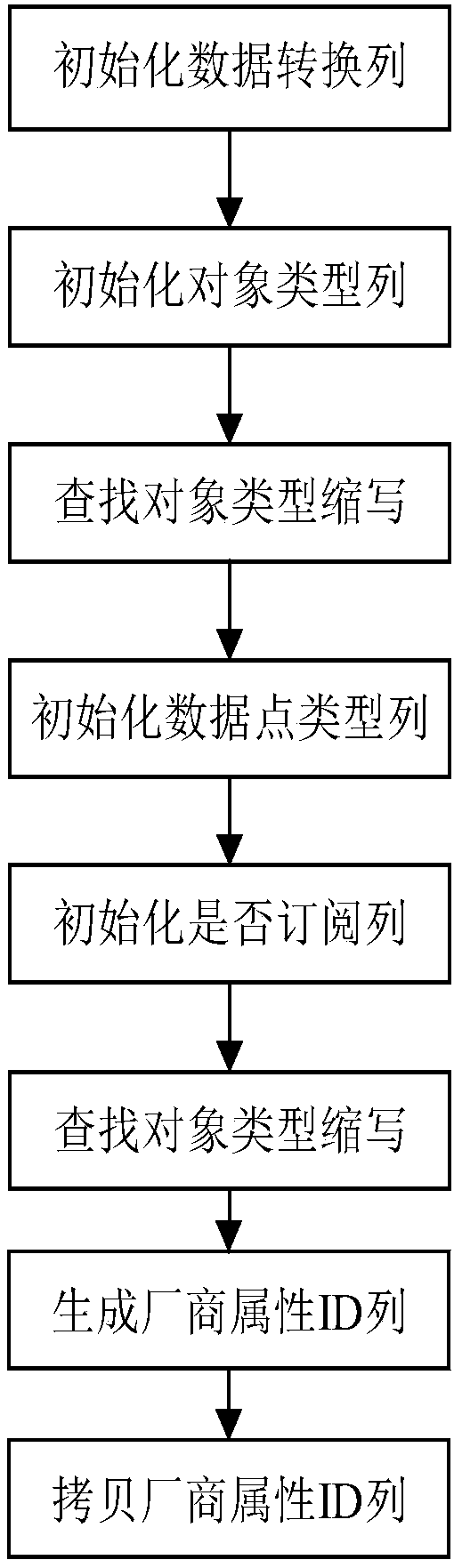

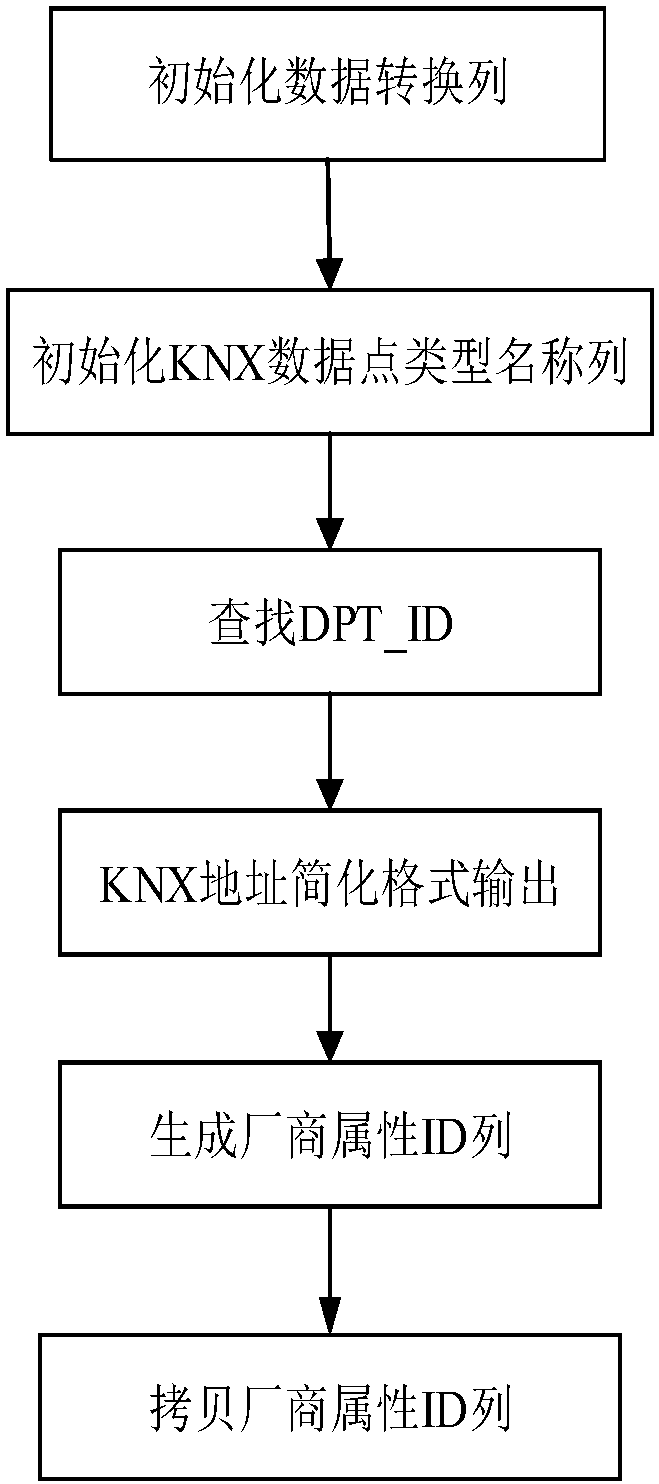

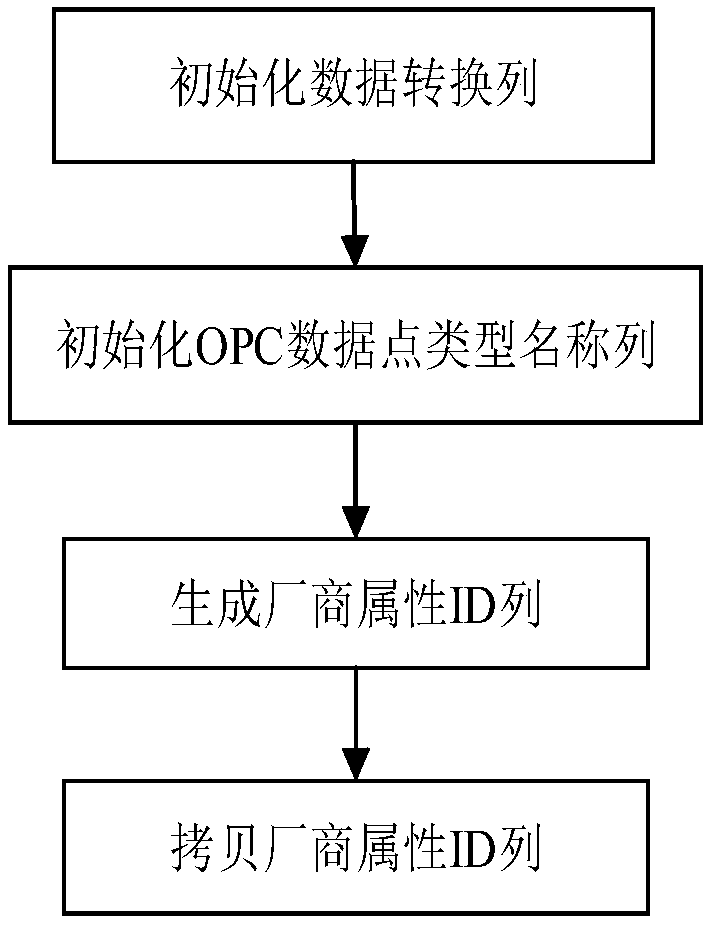

Method for rapidly completing smart building multi-protocol adaptive project template through VBA

The invention discloses a method for rapidly completing a smart building multi-protocol adaptive project template through VBA. The method comprises the following steps: S1, defining sheet pages of protocol modules, subsystems, equipment, gateway configurations and protocol working parameter tables, and carrying out initialization; S2, carrying out format unification on the sheet pages through a public function, so that standard lines and rows are established; S3, acquiring protocol types of the subsystems, and hiding and displaying sheets in forms according to the protocol types; S4, judging whether the acquired protocol types are OPC protocols or not, directly entering S5 if the acquired protocol types are the OPC protocols, and initializing equipment IPs of non-OPC protocols according torequirements if the acquired protocol types are not the OPC protocols; S5, carrying out IP address configuration and validity examination on the OPC protocols and the initialized non-OPC protocols; and S6, calling VBA scripts configured for the protocol modules to automatically generate equipment attribute IDs of the protocols. The method provided by the invention has the advantages that the attribute IDs of the protocol modules are automatically generated through VBA codes, so that the accuracy and consistency of configuration template data can be improved, and errors in complicated operation steps can be avoided.

Owner:WUHAN HONGXIN TECH SERVICE CO LTD

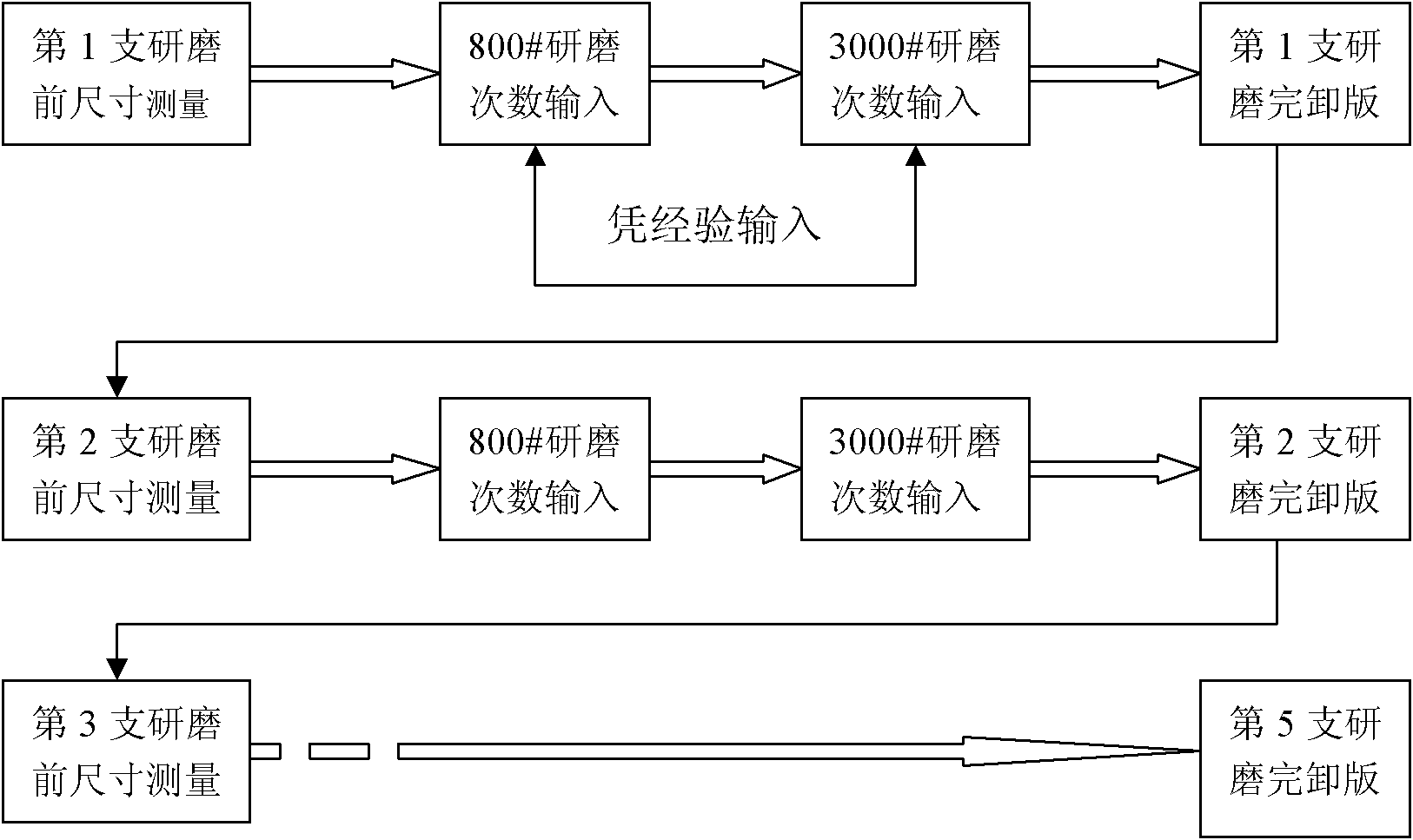

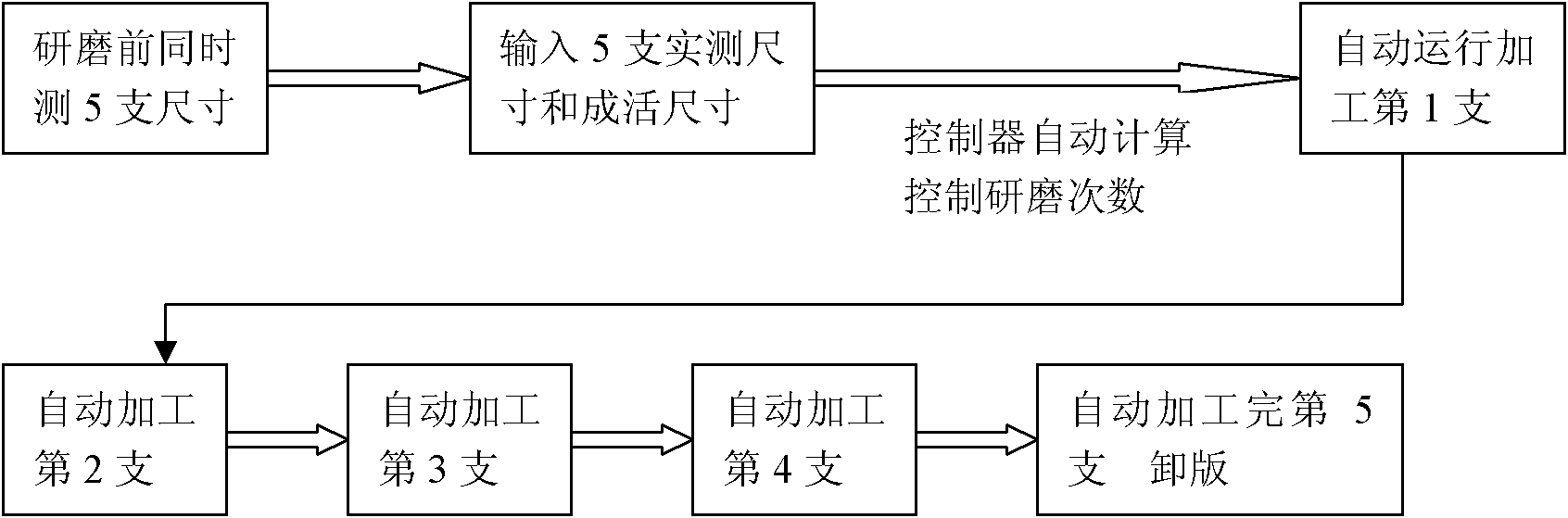

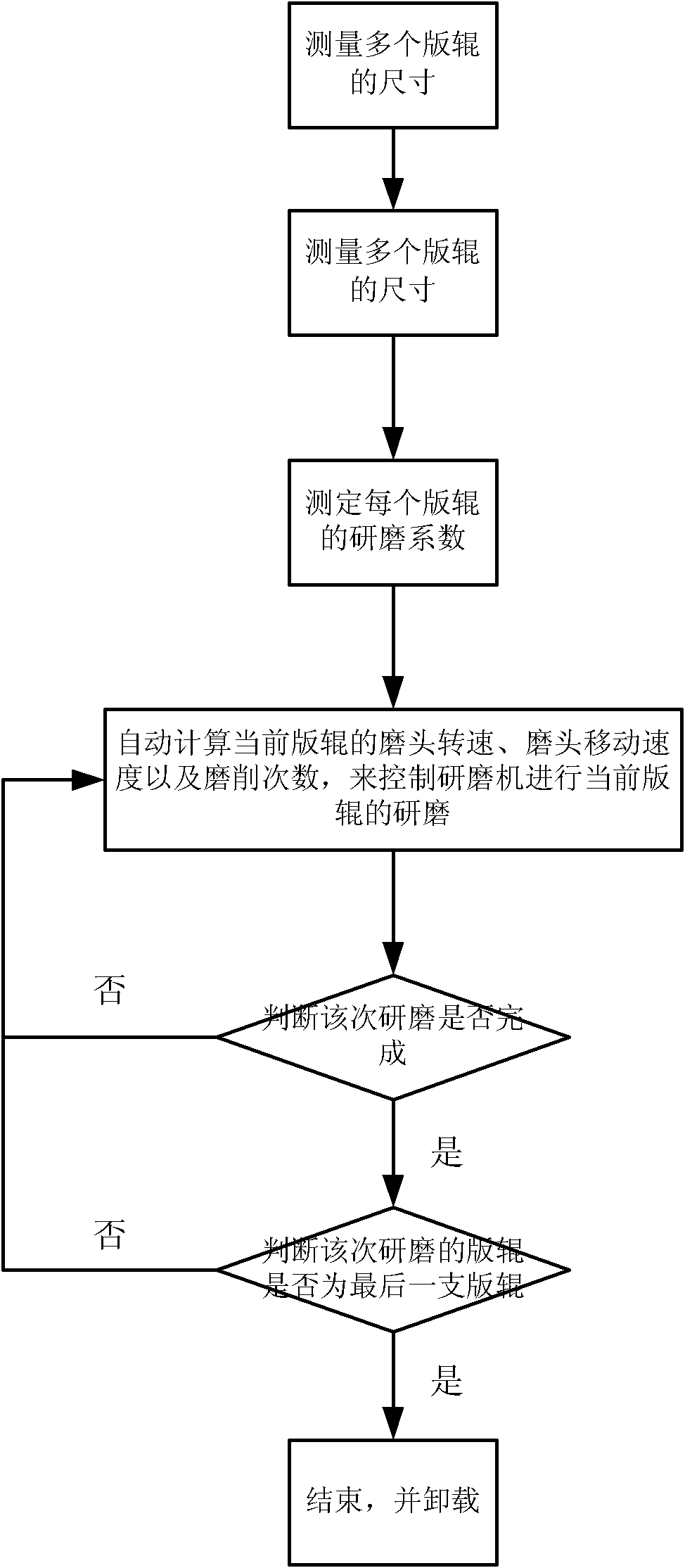

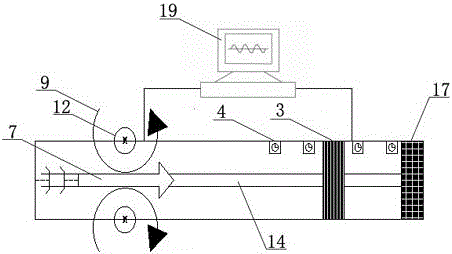

Automatic control method and automatic control device of grinding machine

InactiveCN102581744AHigh dimensional accuracyIncrease productivityLapping machinesAutomatic controlMechanical engineering

The invention relates to an automatic control method and an automatic control device of a grinding machine. The method provided by the invention comprises the following steps: (1) measuring sizes of a plurality of plate rollers at the same time; (2) inputting information about really-measured sizes and finished sizes of the plurality of plate rollers; (3) measuring grinding factor of each plate roller by a controller; (4) automatically computing the rotational speed of a grinding head, the moving speed of the grinding head and the cutting times for the current plate roller by the controller according to the grinding factor of the current plate roller; (5) performing step (6) if the grinding is judged to be finished by the controller, or keeping grinding if the grinding is judged to be not finished by the controller; (6) performing step (7) if the plate roller being subjected to grinding is judged to be the last plate roller by the controller, or invoking the grinding factor of the next plate roller and returning to step (4) if the plate roller being subjected to grinding is judged to be not the last plate roller by the controller; and (7) ending the grinding. The automatic control device provided by the invention comprises a keyboard, the controller and the grinding machine. Compared with the prior art, the automatic control method and the automatic control device provided by the invention have the advantages that the size precision of the plate roller in the plate making and grinding process is promoted, the productive efficiency is improved, etc..

Owner:SHANGHAI YUNQING PLATE MAKING

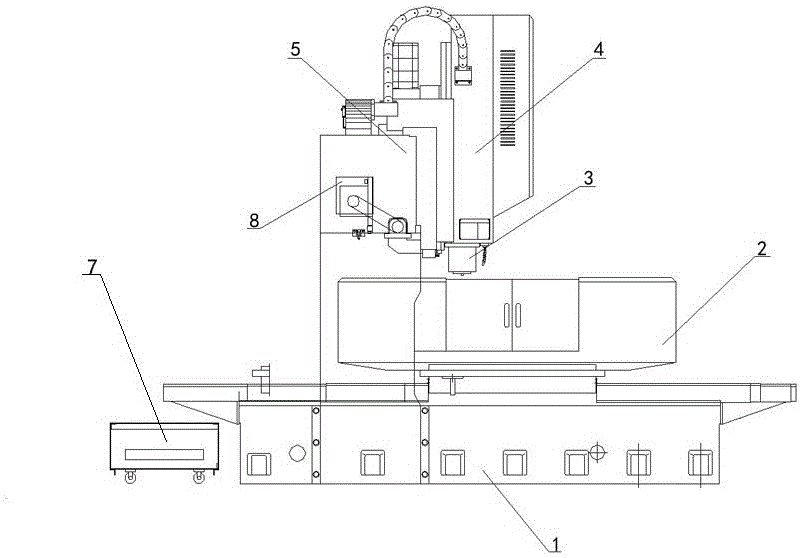

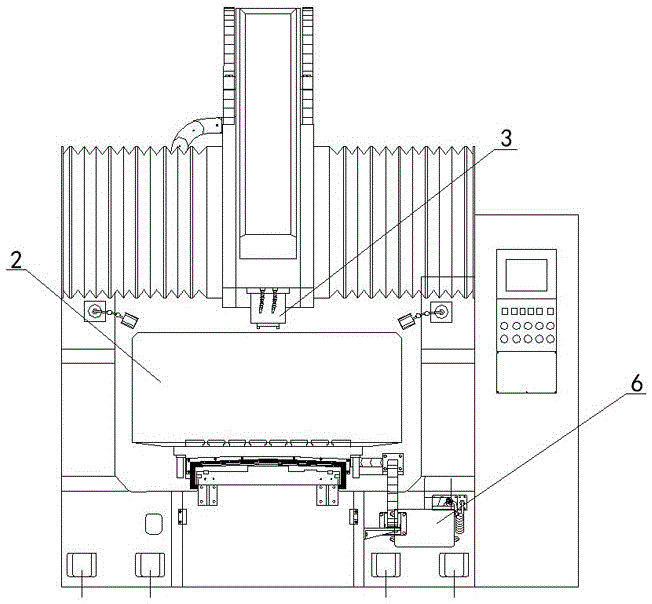

Small-sized CNC numerical control machine tool with network-based manufacturing function

InactiveCN106271685AEasy to operateLow costProgramme controlComputer controlNumerical controlControl system

The invention relates to a small-sized CNC numerical control machine tool with a network-based manufacturing function. The small-sized CNC numerical control machine tool comprises a base mechanism, a sliding seat mechanism, a working table mechanism, a main shaft mechanism, a main shaft box mechanism, a vertical column mechanism, a main motor mechanism, a lubricating system, a cooling system, a pneumatic system and a programmable CNC control system, wherein the working table mechanism comprises a working tabletop; a clamp is mounted on the working tabletop; the vertical column mechanism is perpendicularly fixed on the base mechanism; the main shaft box mechanism is assembled at the front part of the vertical column mechanism through a Z-directional guide rail; the main shaft mechanism is fixed on the assembling surface of the main shaft box mechanism through a screw; the X and Y directional motions of the working table mechanism and the Z directional motion of the main shaft box mechanism can be controlled through the programmable CNC control system. The machine tool disclosed by the invention overcomes the shortcomings that the existing numerical control machine tool is large in size, inconvenient to operate and high in cost, only has the motions in two coordinate axis directions, is complicated in operation and the like, has the advantages of high main shaft rotating speed, high feeding rate, function compounding and the like, and can complete all machining procedures of complicated parts and realize control intelligence.

Owner:LUOYANG INST OF SCI & TECH

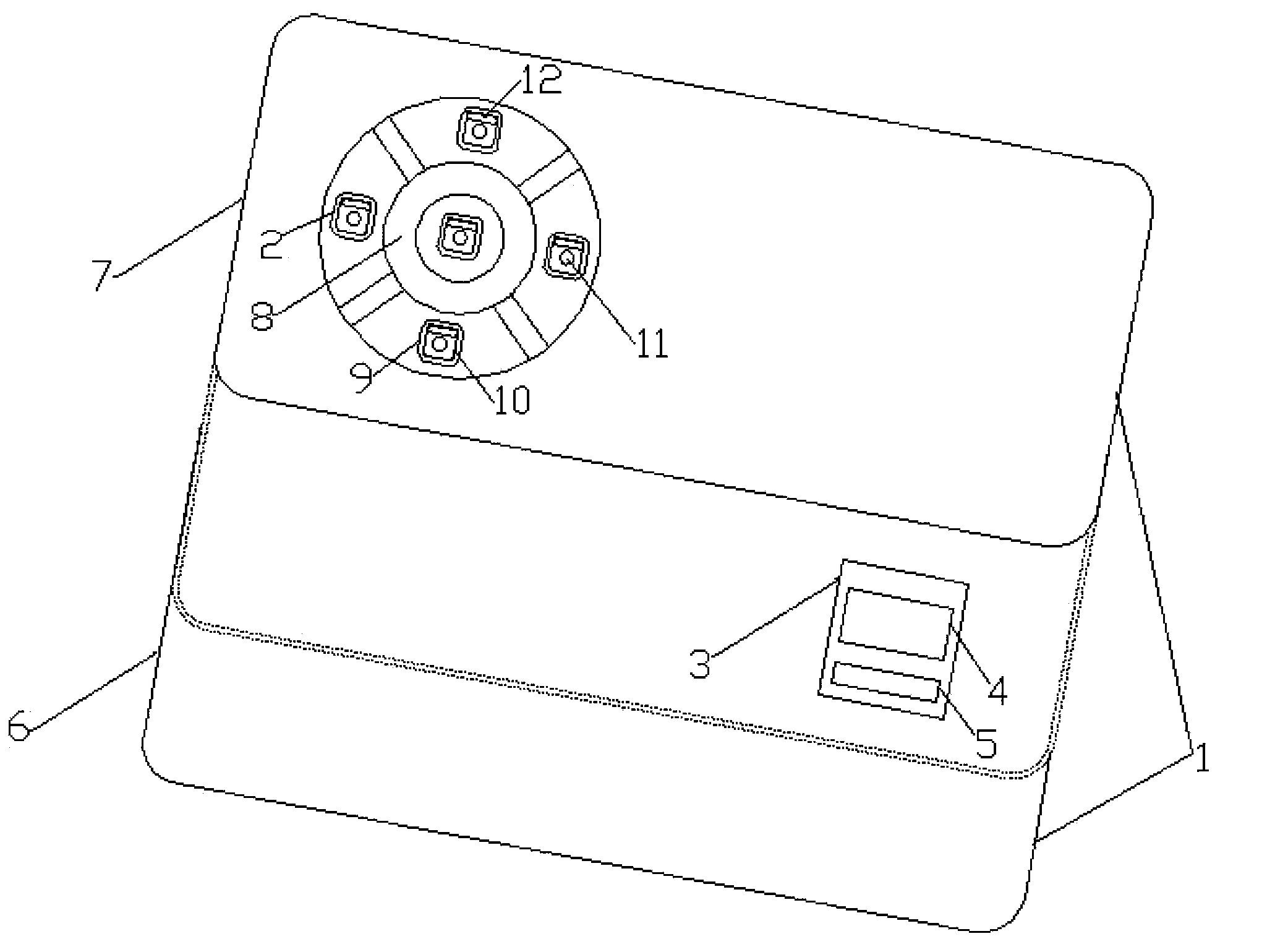

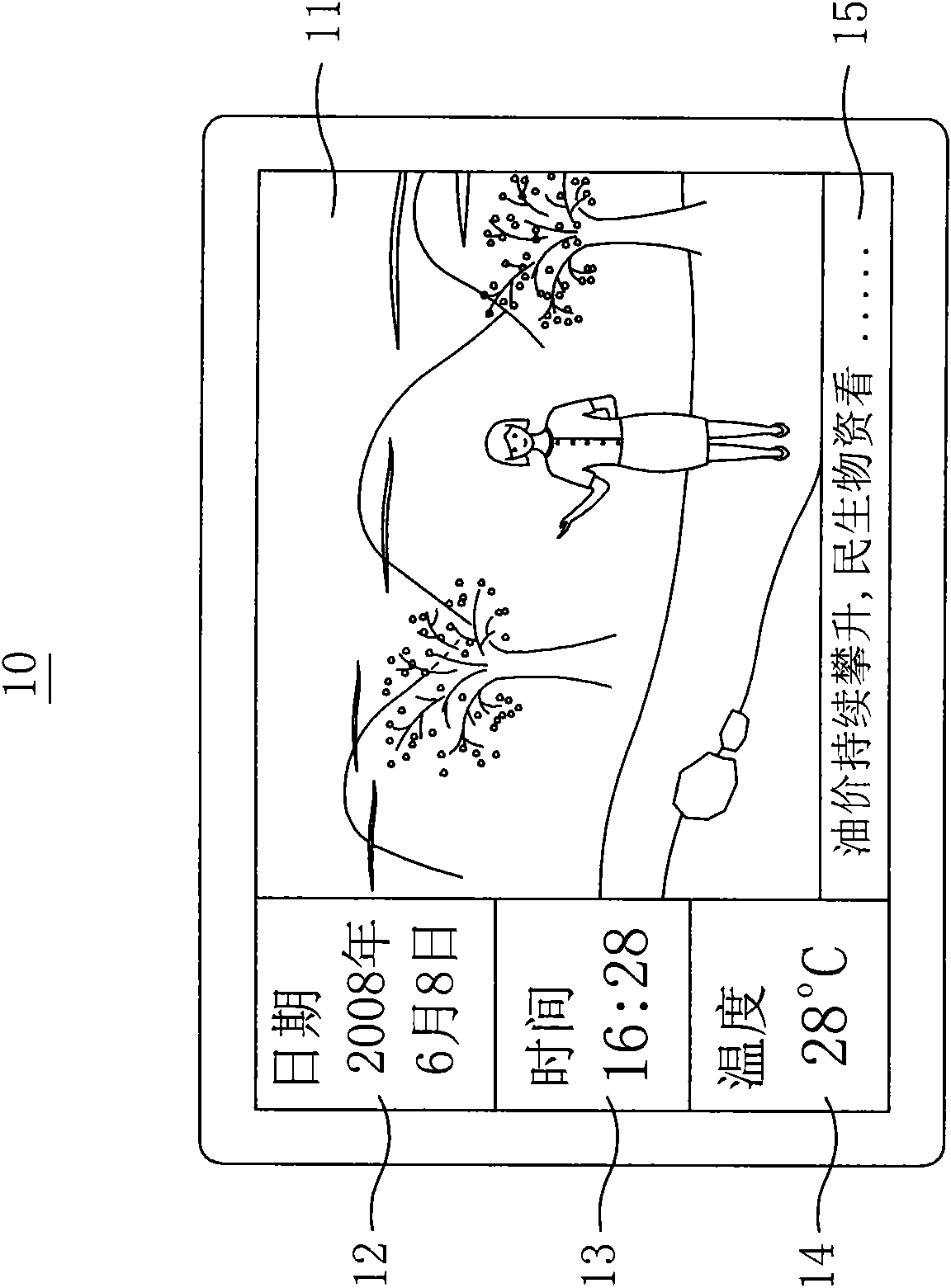

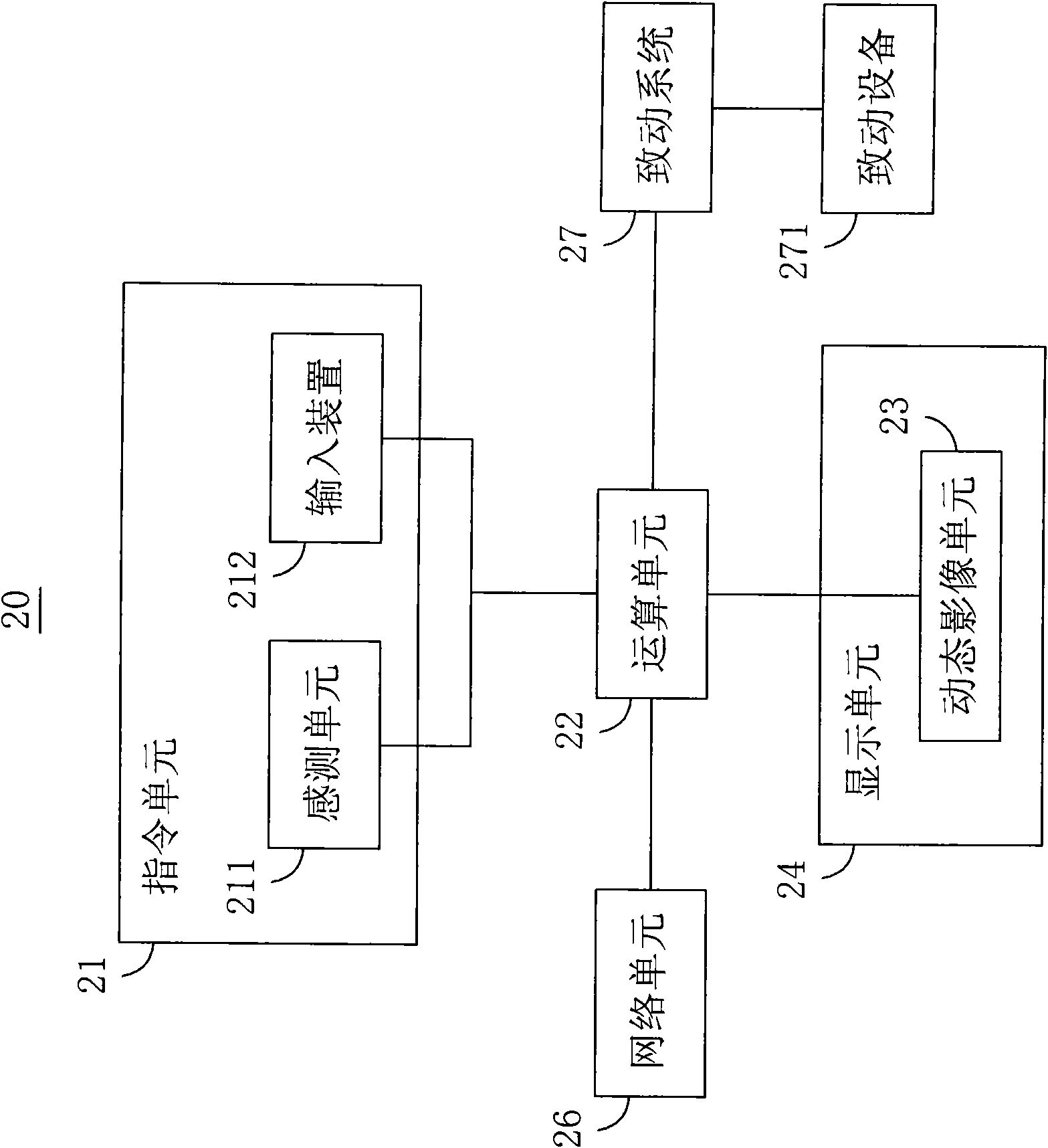

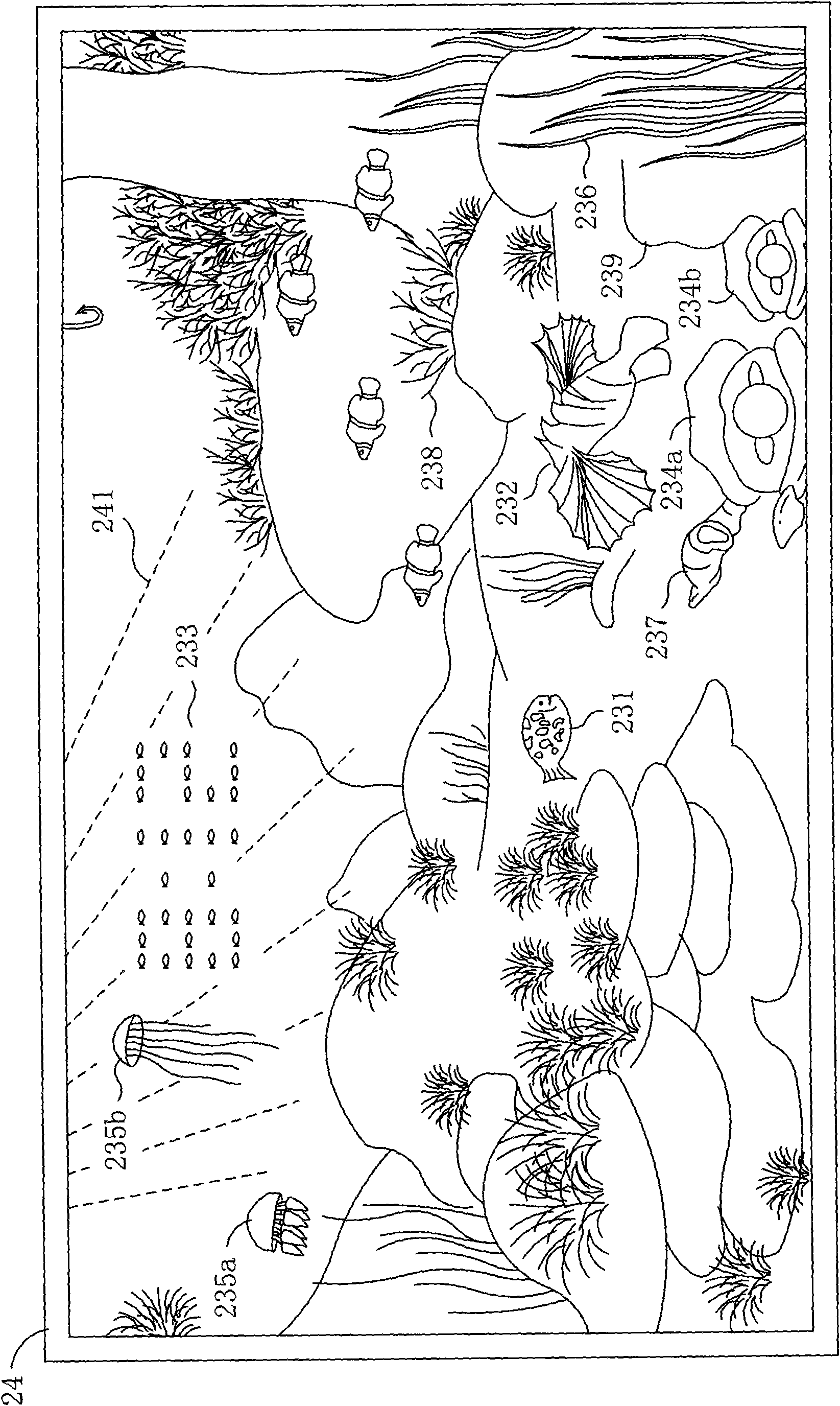

Interactive multimedia system with humanization interface and display method thereof

ActiveCN101616010AHumanized operation interfaceEntertainingSpecial service provision for substationAdvertisingInstruction unitControl signal

The invention discloses an interactive multimedia system with a humanization interface and a display method thereof. The interactive multimedia system comprises a command unit, an operational unit, at least one dynamic image unit and at least one display unit, wherein the command unit is used for receiving at least one control command and transmitting the control command to the operational unit; a control signal is generated by the operational unit according to the received control command; and after the control signal is transmitted to the display unit, the control signal is used for controlling the shape of the dynamic image unit which is displayed on the display unit to change. The interactive multimedia system has an extended function, can supply integrated information of home safety and information service and is suitable for being used at home, an operational interface has humanization and diversification, and the display has entertainment property and aesthetic property.

Owner:IND TECH RES INST

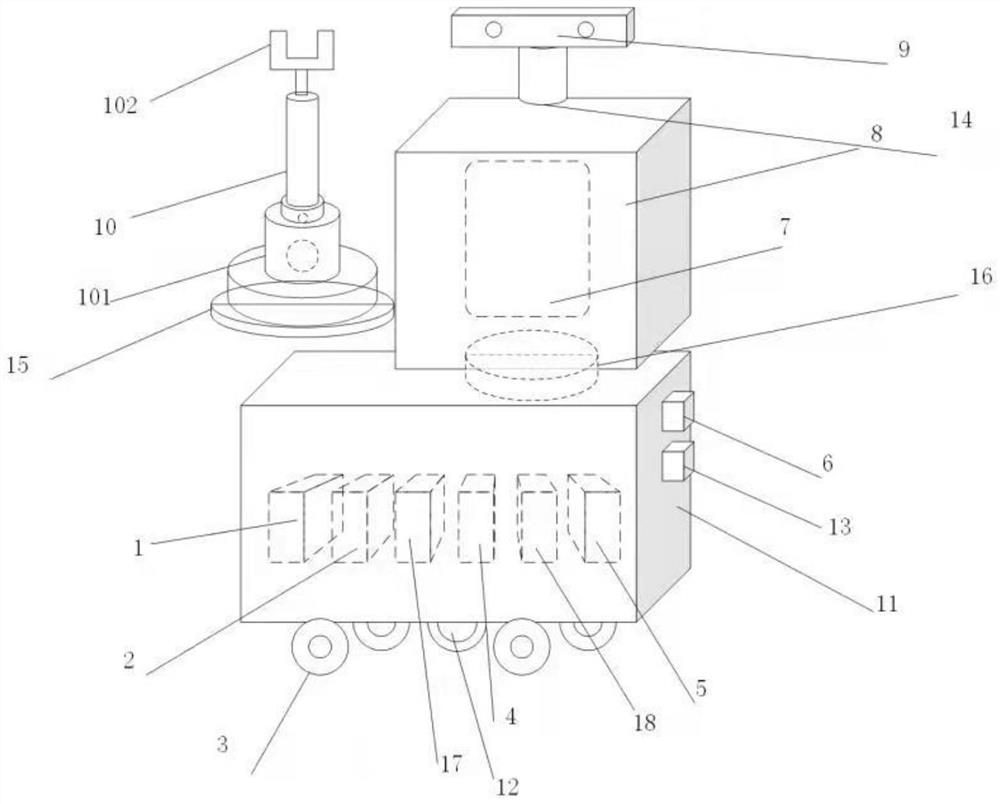

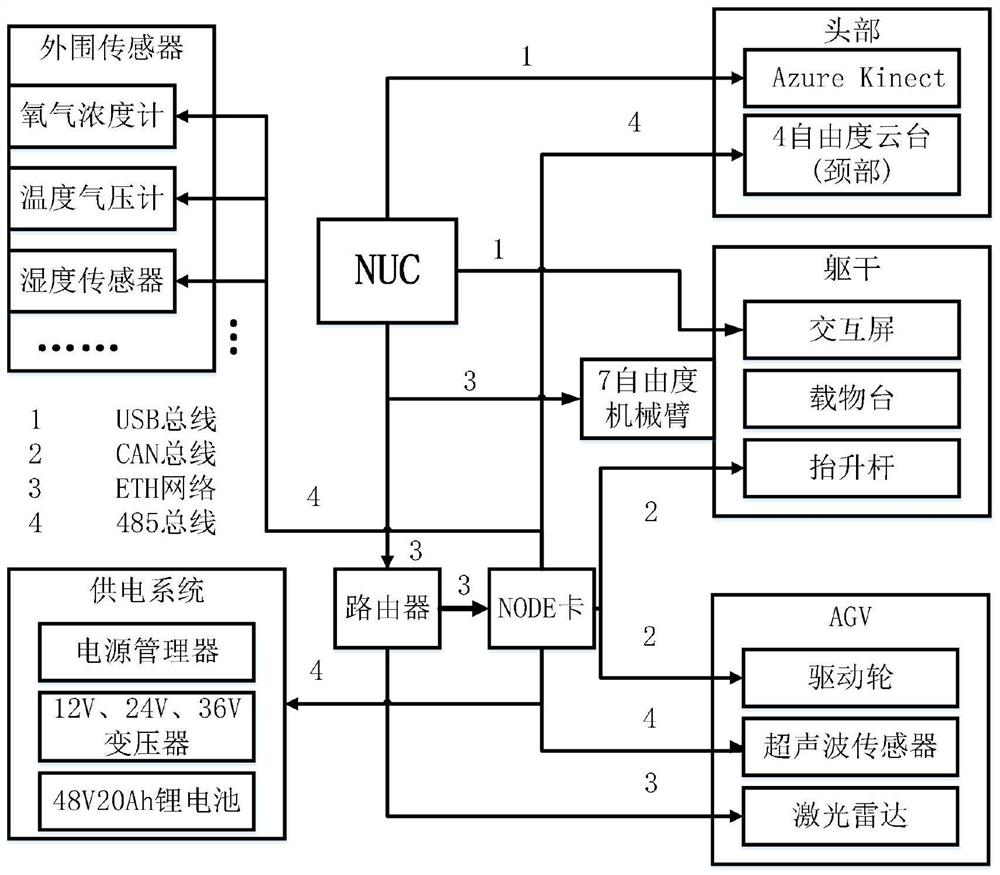

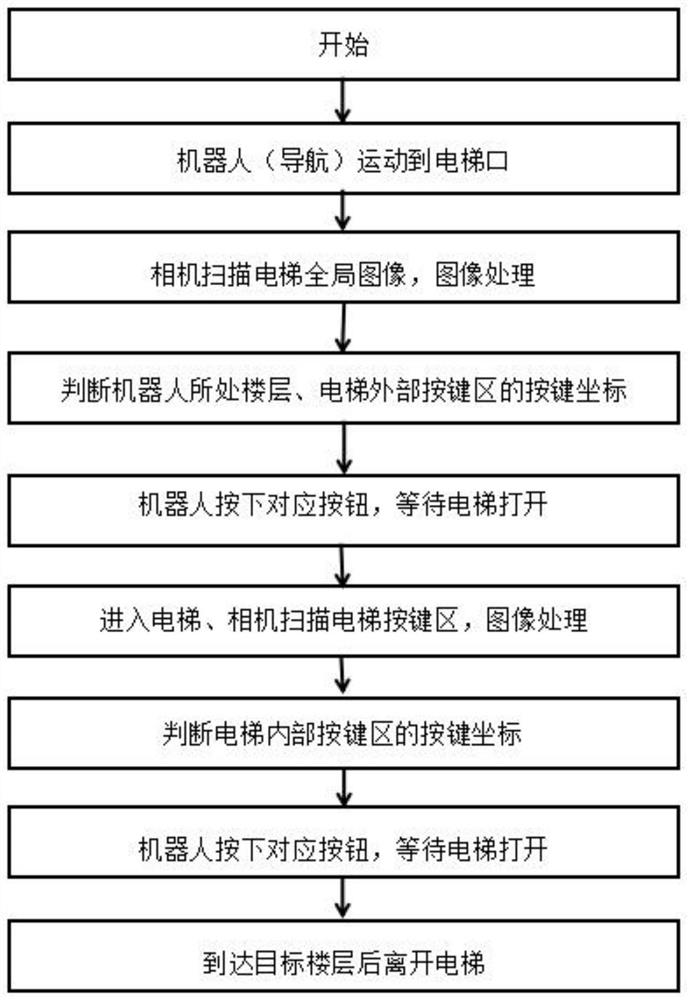

Intelligent service robot for autonomously operating box type elevator

PendingCN114505840AHumanized operation interfaceEasy to downloadProgramme-controlled manipulatorSpeed controllerRobotic systemsDrive wheel

According to the intelligent service robot system of the autonomous operation box type elevator, a laser radar sensor is connected with a PC end, a robot base is connected with the PC end, and a hardware platform comprises a robot intelligent moving platform, a mechanical arm elevator key pressing device and a computer visual recognition positioning device; the industrial personal computer is connected with the embedded controller, and the embedded controller is connected with the driving wheel and an end effector of the mechanical arm; an object recognition detection module of the industrial personal computer provides elevator position information for a movement module, the elevator moves to an elevator opening through the movement module, then elevator key pixel coordinates are provided for a coordinate system conversion module through the object recognition detection module for coordinate conversion, and then the elevator key pixel coordinates are output. The mechanical arm motion module adjusts the pose of a mechanical arm by receiving coordinate information, provided by the coordinate system conversion module, of elevator keys under a mechanical arm base coordinate system, then the key module carries out key pressing by receiving a key pressing result judged by the object detection module, and the mechanical arm compliance control module controls the key pressing force of an object.

Owner:ZHEJIANG UNIV OF TECH

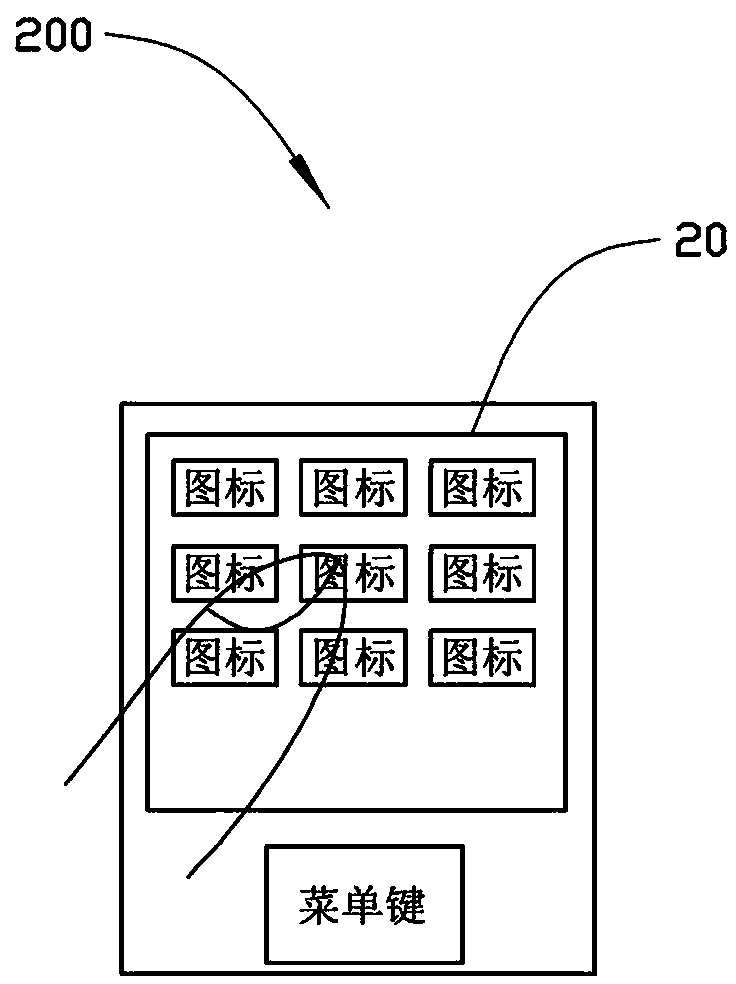

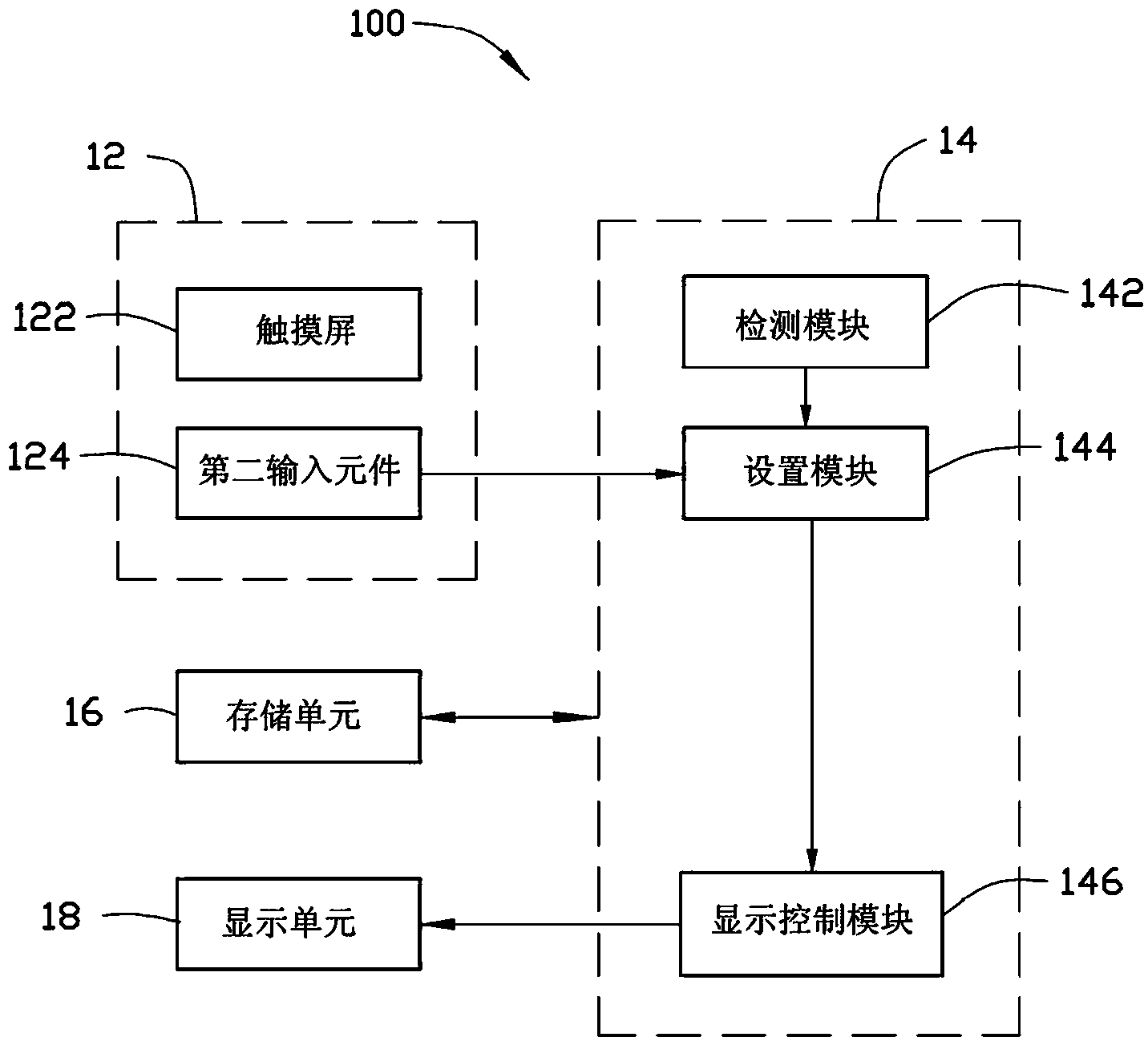

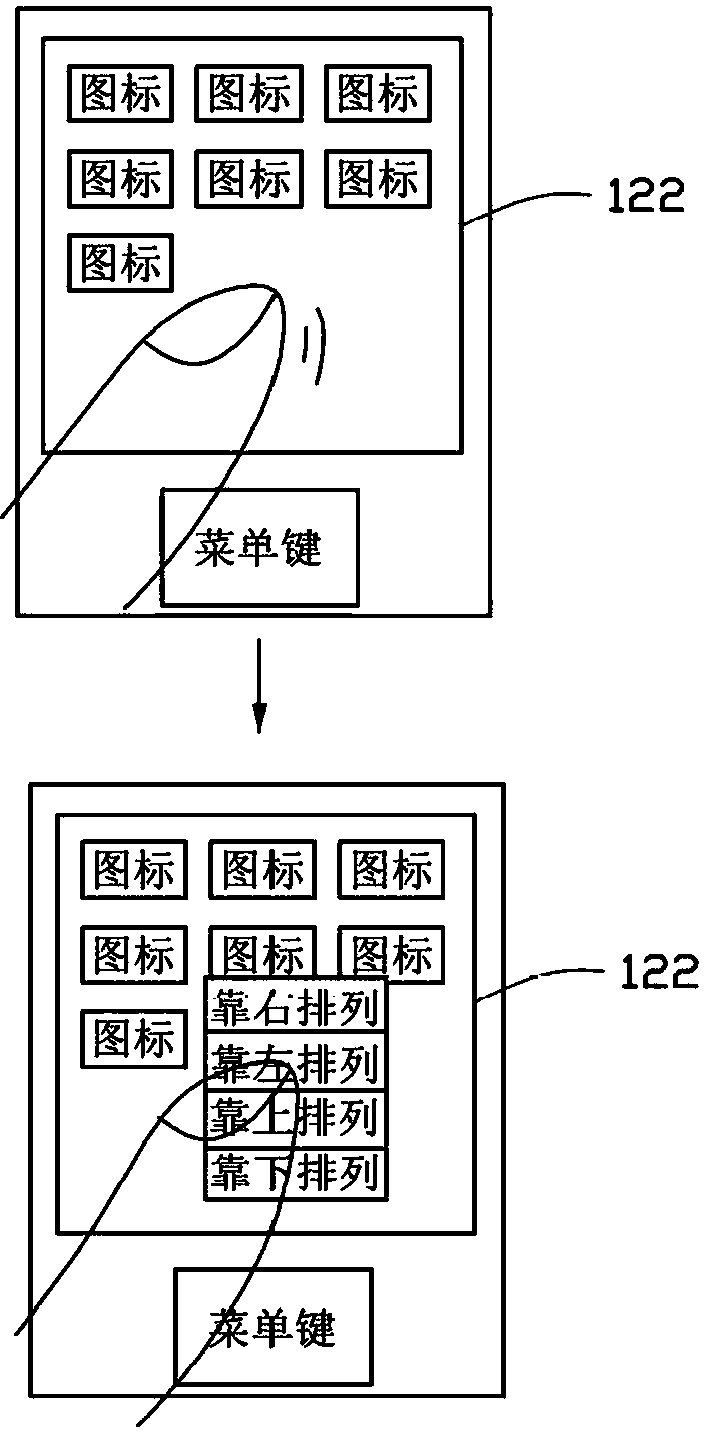

Device and method for achieving dynamic arrangement of desktop functional icons

InactiveCN103902141ASuitable for one-handed operationHumanized operation interfaceInput/output processes for data processingComputer moduleTouchscreen

A portable electronic device having two input units, a processor, a memory and a display unit, allows single handed operation for the repositioning of desktop icons and shortcuts. The input unit includes a touch panel and another sensor and movements of the device are interpreted as commands to rearrange the current display locations of desktop items, for more convenient and personalized operations on the items. A method for arranging the functional icons of the electronic device is also provided.

Owner:BEIJING FUNATE INNOVATION TECH

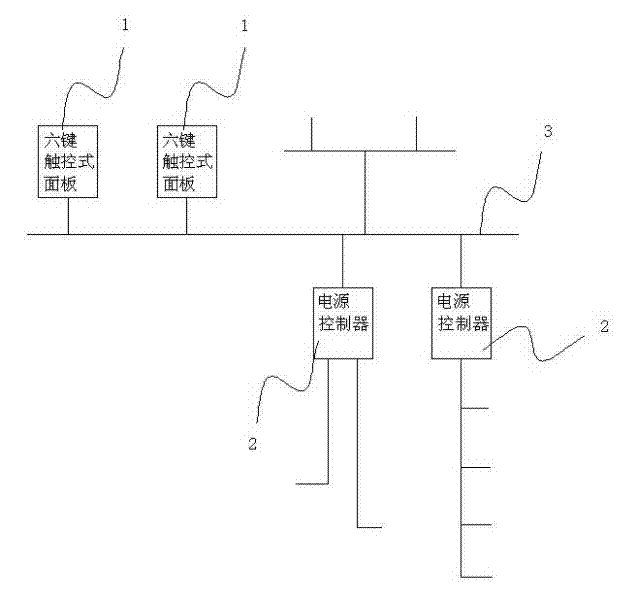

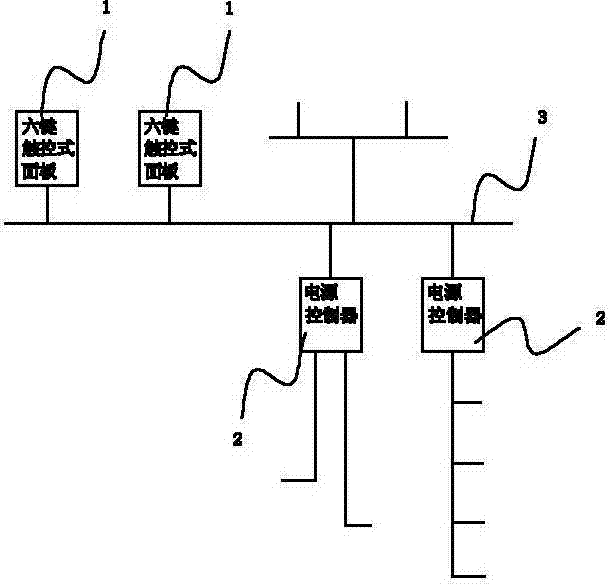

Home network automation system

InactiveCN102520692AEasy wiringFlexible controlProgramme total factory controlPower controllerResidence

The invention discloses a home network automation system. The system is composed of a multi-key touch panel, a power supply controller connected with the multi-key touch panel, and a field bus connected with the multi-key touch panel and the power supply controller. The multi-key touch panel can be connected with a home intelligent system, a security system and a central monitoring system, and is integrated with functions of air conditioner, lighting, security and audiovisual entertainment control systems; and the power controller is connected with a lighting device or / and a non-lighting device through a circuit. The home network automation is designed based on the LonWorks (field bus) technology, and is used for providing a simple, convenient and flexible operating mode for the lighting systems, the electrical appliances and the network sub-systems thereof in residence, office buildings and industry. A lighting dimming system based on the LonWorks technology has superlative stability and excellent open property.

Owner:JIANGMEN LONGWO NETWORK TECH

Off-line programming system and off-line programming method of welding robot based on tablet computer

ActiveCN105786483BEasy to optimize movementEasy to acceptProgramme controlProgramme-controlled manipulatorTablet computerOperational system

The invention discloses a welding robot offline programming system based on a tablet computer, which comprises a system modeling module, a kinematics simulation module, a track planning module, an automatic programming module, a status detection module, and a communication module. The invention further discloses an offline programming method of the offline programming system. The offline programming system provided by the invention has the advantages that compared with the traditional online teaching programming system, the system adopts a human operating interface based on the Linux operating system; highly controllable edit capabilities achieve easy optimization of motions of all axes; an actual working environment is simulated, and arc welding, spot welding and other welding functions of a robot are achieved; special offline and simulation technologies facilitate program optimization, and a completed program can be directly read and adopted by the robot through a wireless network, so that the onsite verification waiting time is shortened, and errors and unnecessary risks are reduced; the cost is low, so that the system is highly acceptable by a vast number of users; the operation is simple and convenient, and the teaching effects are good.

Owner:NANJING PANDA ELECTRONICS +2

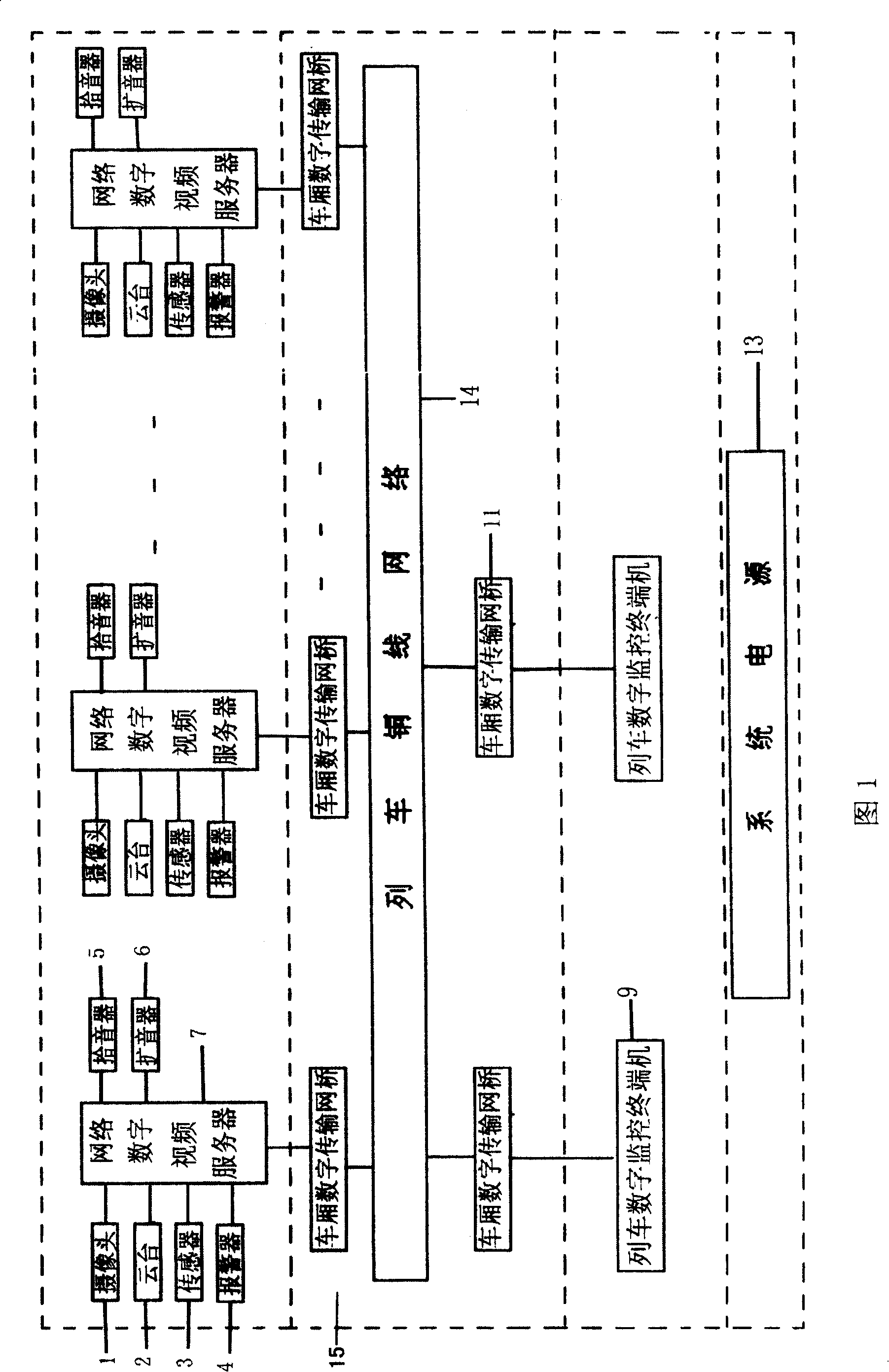

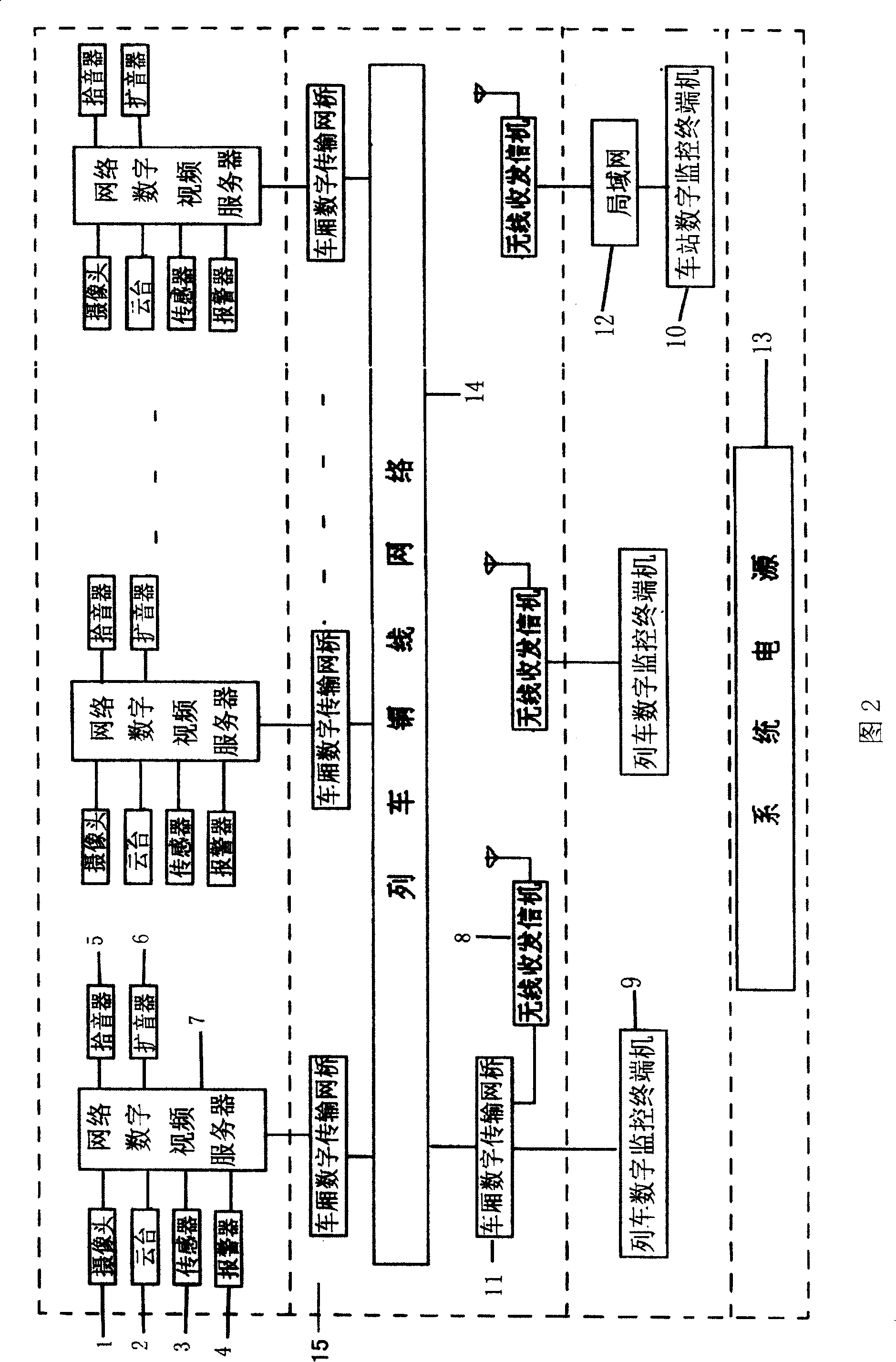

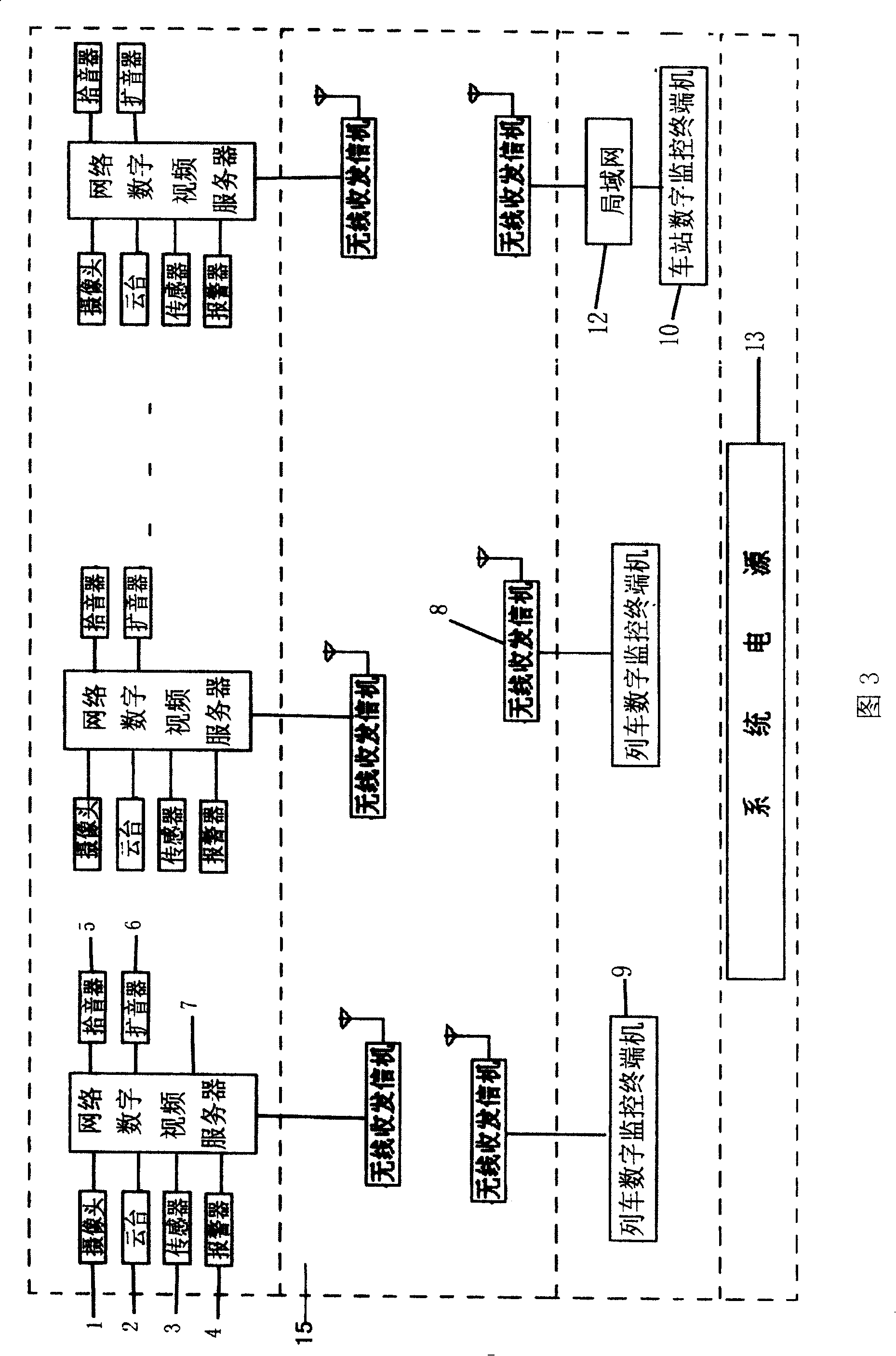

Digital safeguard video monitoring system for railway train

InactiveCN100391184CRealize digital security monitoringSolving problems with different network connectionsData switching by path configurationRailway signalling and safetyDigital videoVideo monitoring

The disclosed system is composed of following parts: (1) camera device in use for taking image information on train, and transferring signal of image to networked digital video server; (2) the networked digital video server in use for receiving each signal, encoding and compressing the received signal to digital signal; sending the digital signal to train digital monitoring terminal, converting signal from the train digital monitoring terminal to analog signal and control signal, which are sent to front end devices; (3) train digital monitoring terminal processes and displays signal from the networked digital video server, and sends control signal to the networked digital video server based on operational commands; (4) transmission part in use for transferring data between the networked digital video server and the train digital monitoring terminal. Monitoring special environment of train, the invention convenient for train staff to solve sudden events in time.

Owner:沈阳泽通数码有限公司

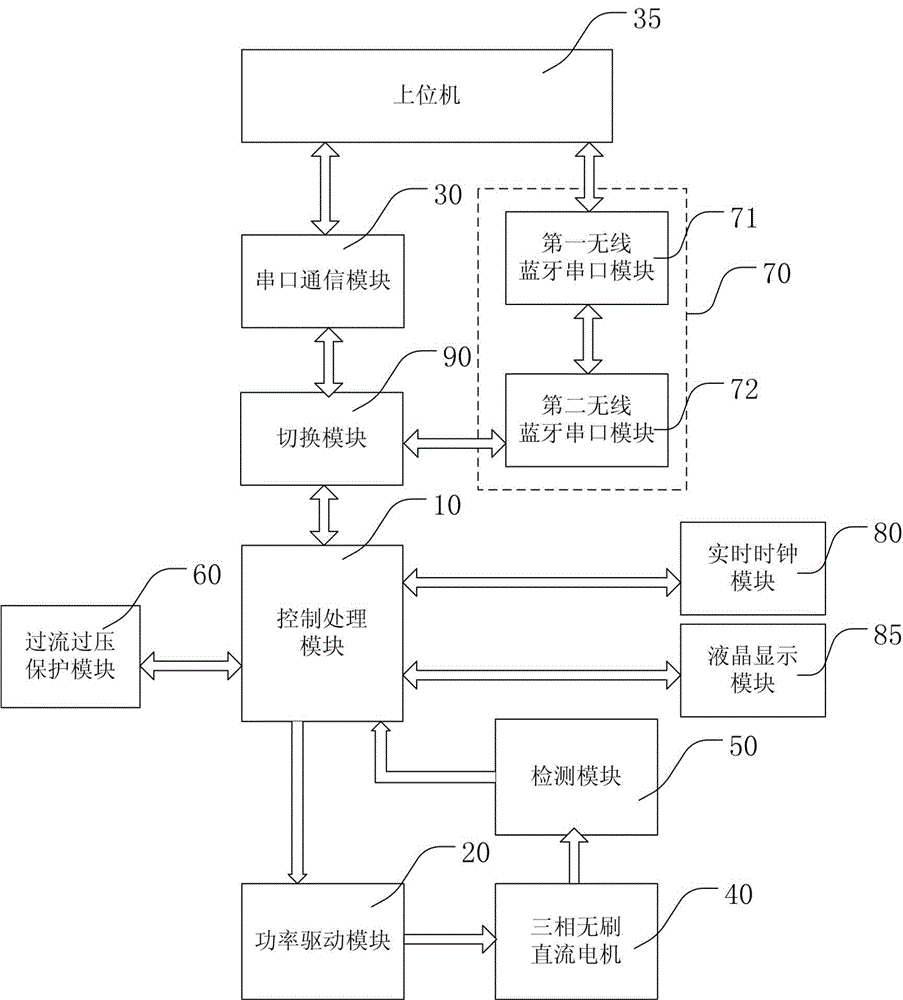

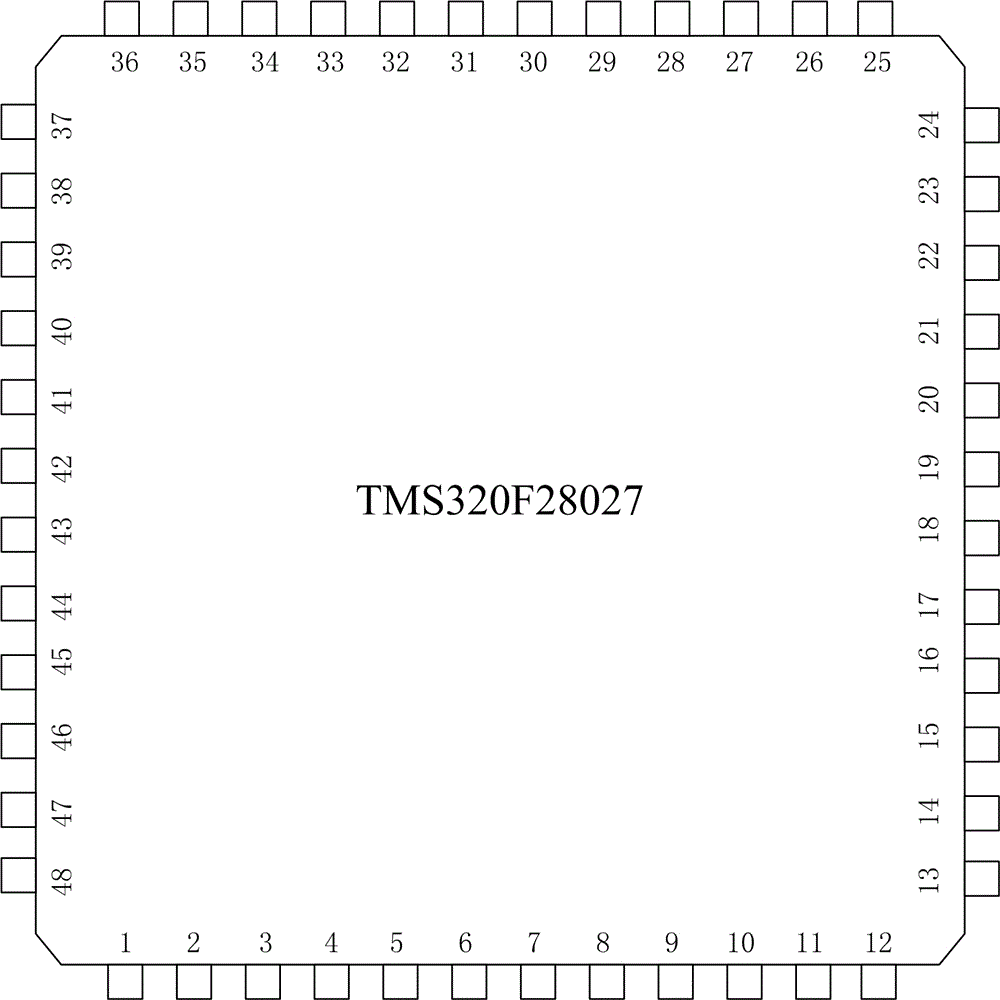

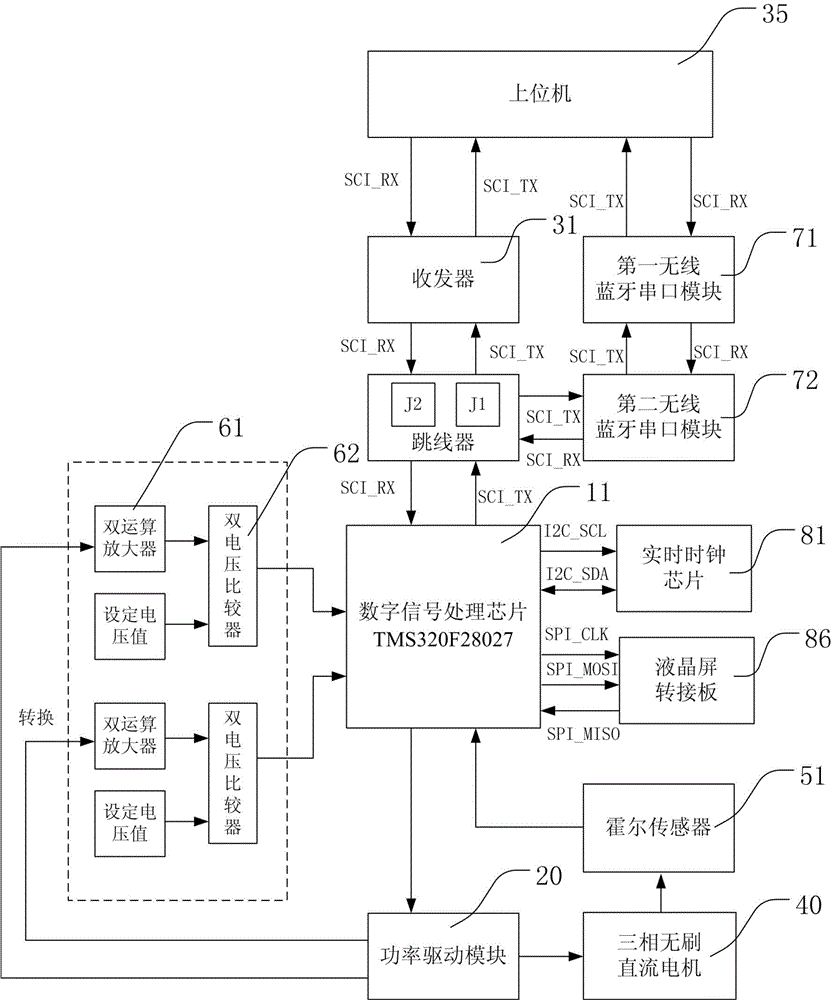

Three-phase brushless DC motor control device for electric vehicles

ActiveCN103208955BEliminate power lossImprove transmission efficiencySingle motor speed/torque controlElectronic commutatorsRemote controlComputer module

The invention discloses a three-phase brushless direct-current motor control device for an electric vehicle. The device comprises an upper computer, a serial port communication module, a wireless Bluetooth module, a switching module, a control processing module and a power driving module; the serial port communication module is used for receiving a control instruction sent by the upper computer and forwarding the control instruction to the control processing module; the wireless Bluetooth module comprises a first wireless Bluetooth module and a second wireless Bluetooth module, wherein the first wireless Bluetooth module communicates with the upper computer; the second wireless Bluetooth module communicates with the control processing module; the control processing module is connected with the power driving module and used for sending pulse width modulation signals to the power driving module after the control instruction is received; and the power driving module is connected with a three-phase brushless direct-current motor and used for reading the pulse width modulation signals and driving the three-phase brushless direct-current motor, so that the electric vehicle assembled with the three-phase brushless direct-current motor executes the operations of starting, advancing, retreating, braking, cruising, steering, whistling, vehicle lamp control and remote control.

Owner:SHANGHAI DIANJI UNIV

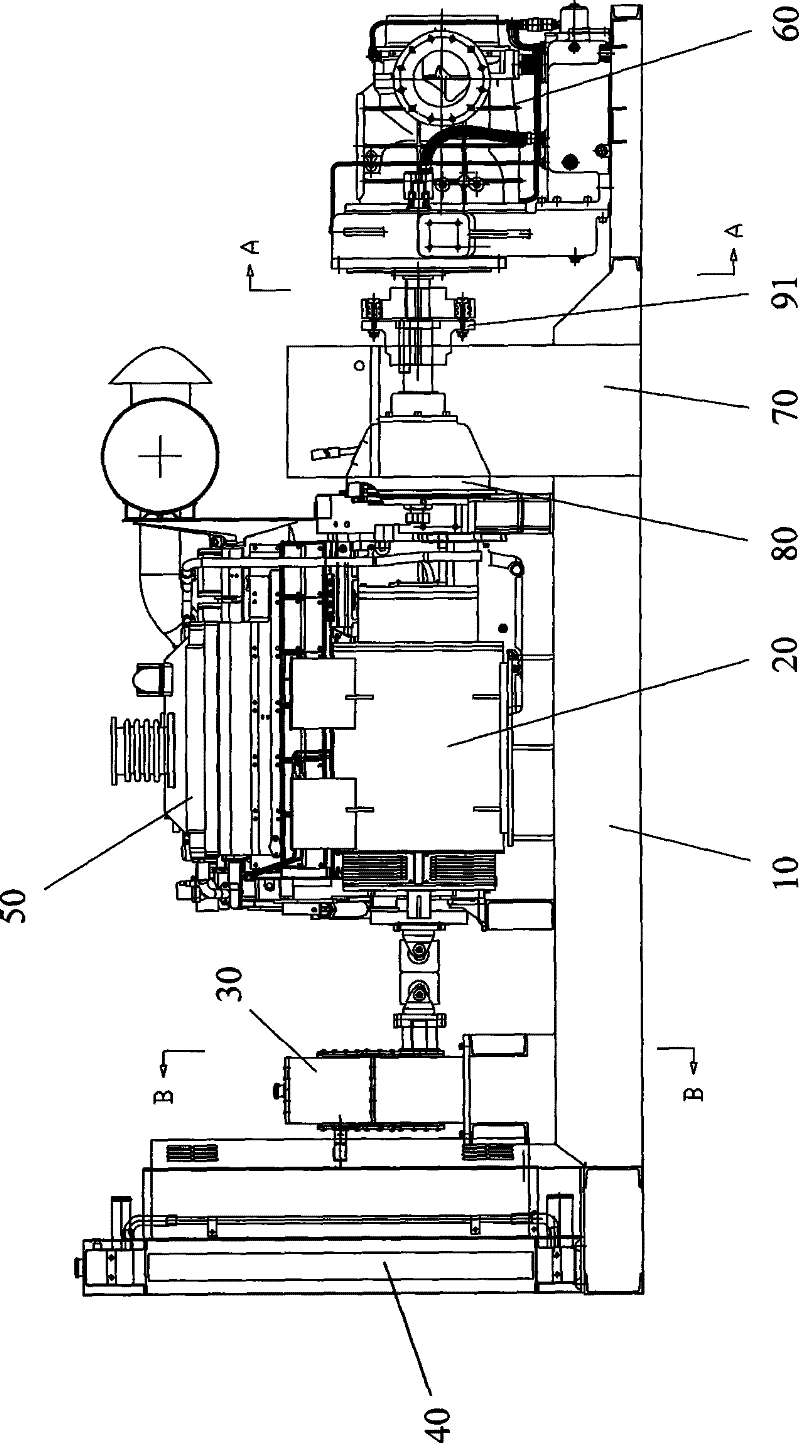

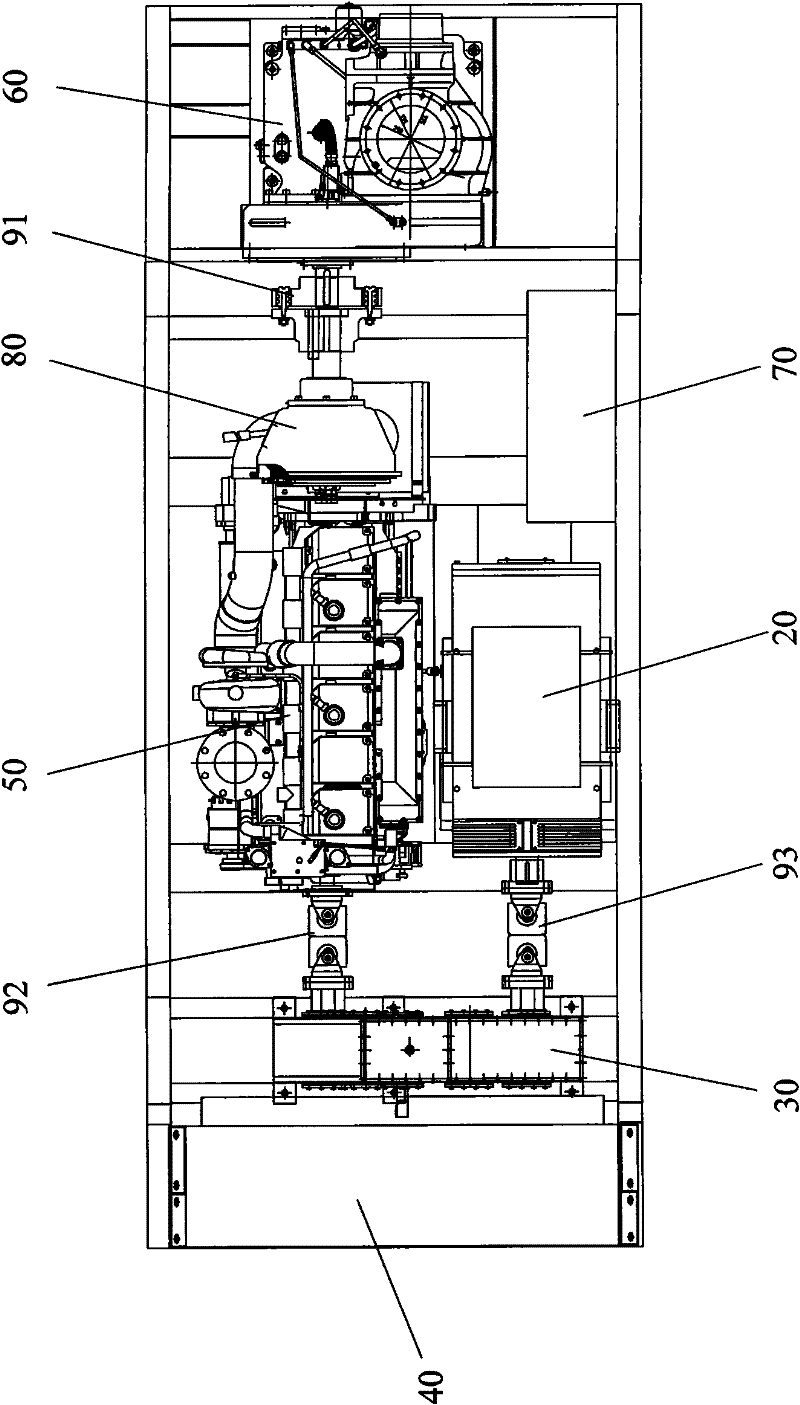

On-vehicle machine set integrated with electricity generation and air compression

InactiveCN101581251BGuaranteed cooling effectEasy to install and debugMachines/enginesGas compressorAir compressor

The invention discloses an on-vehicle machine set integrated with electricity generation and air compression, which comprises a generator, a speed reduction gear box, a radiator, an internal-combustion engine and an air compressor, wherein the generator, the speed reduction gear box, the radiator, the internal-combustion engine and the air compressor are fixedly arranged on a support base; the first output end of the internal-combustion engine is connected with the air compressor through a clutch and a first shaft joint; the second output end of the internal-combustion engine is connected withthe input end of the speed reduction gear box through a second shaft joint; and the speed reduction gear box is provided with two output units, a first output unit is connected with the radiator, anda second output unit is connected with the generator through a third shaft joint. The machine set adopts the air compressor to increase the function of outputting compressed air of an electric generating set, and makes the electric generating set multifunctional and achieve wider application range. The proper redistribution of the relative position of the generator, the internal-combustion engineand the air compressor makes the structure of a product more compact. Moreover, the shaft joint and the speed reduction gear box adopted further improve the connection reliability and operation stability.

Owner:广东康菱动力科技有限公司

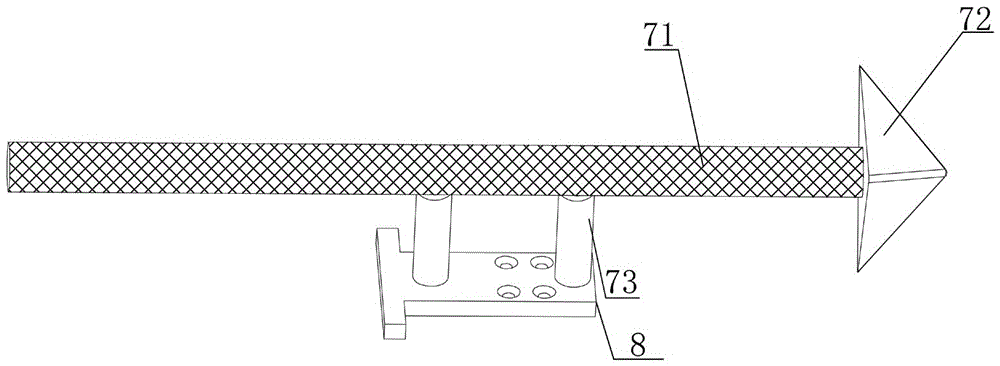

A corrugated box puncture tester

ActiveCN104483212BReduce lossReduce kinetic energy lossMaterial strength using single impulsive forceDetonationTest sample

The invention belongs to the field of instruments for testing strength characteristics of solid materials, particularly relates to a corrugated carton puncture tester, and overcomes defects that traditional testers are low in detection accuracy, poor in stability, low in automation degree, poor in safety protection and the like. The tester structurally comprises a base, wherein a pyramid and a guide rail for the pyramid to slide are arranged on the base, an acceleration mechanism for providing power for the pyramid is arranged at the left end of the guide rail, two speed measuring devices are arranged at the right end of the guide rail at an interval, and a fixing clamp for fixing a test sample is arranged between the two speed measuring devices. The tester is good in accuracy and stability and can accurately test the puncture performance of corrugated cartons, the operation interface is more humanized, protection of detection workers is strengthened, and the safety during detection is improved.

Owner:THE INSPECTION & QUARANTINE TECH CENT ZHEJIANG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com